Transmission system of alternating-current storage-battery electric forklift truck

A technology for electric forklifts and transmission systems, applied in the field of transmission systems, can solve the problems of poor versatility and interchangeability of axle housings, large requirements for processing and operation space, and small space for motor detachable operations, so as to facilitate cost control, Reduced space requirements for machining operations and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

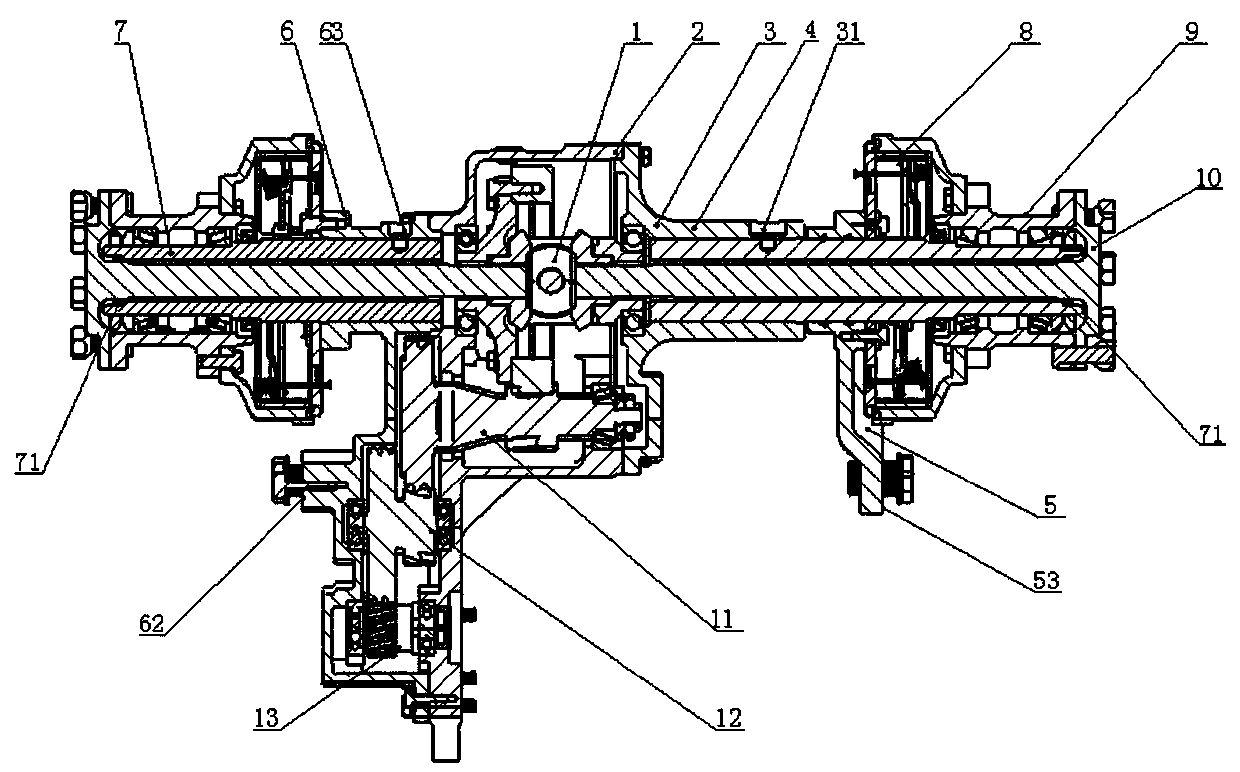

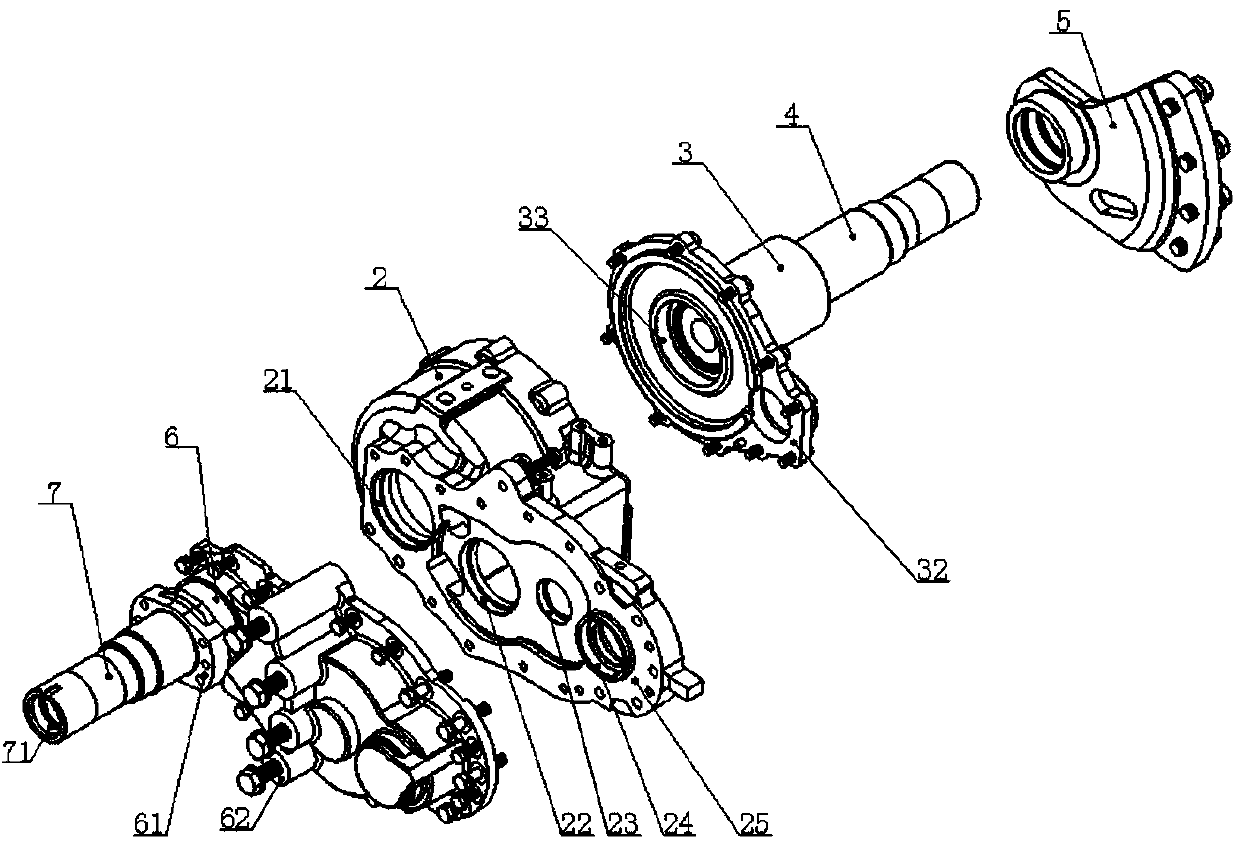

[0023] see figure 1 The transmission system of an AC battery electric forklift includes a differential assembly 1, a reducer, a drive axle housing, a left brake, a right brake 8, two brake drums and a wheel hub 9, a left half shaft and a right half shaft 10; The speed reducer includes a double gear 11 , a small double gear 12 and a pinion 13 .

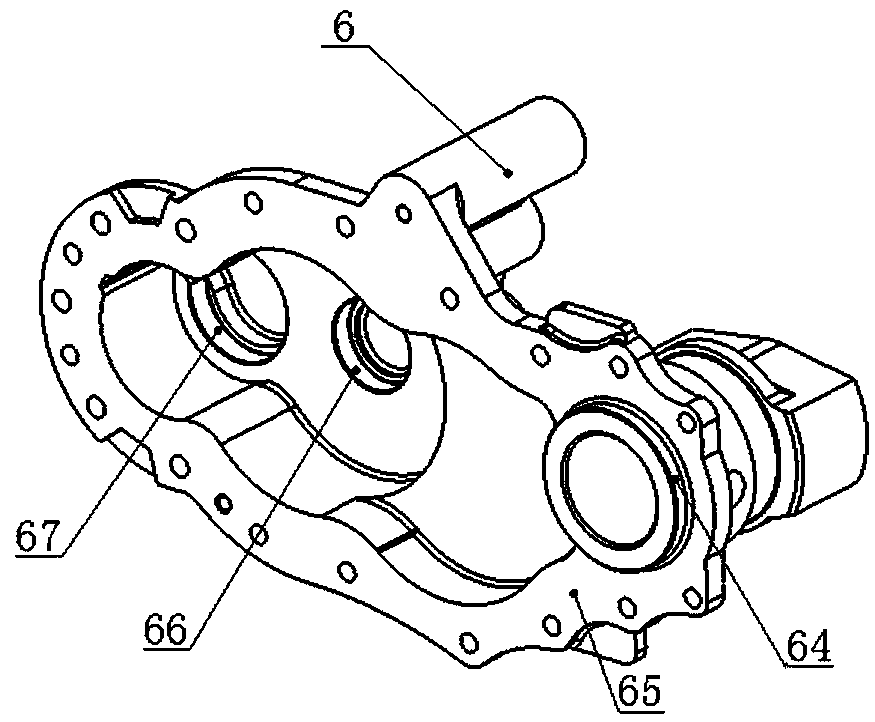

[0024] see figure 2 , The drive axle housing includes three parts: the left axle housing, the reducer main housing 2 and the right axle housing. The reducer main housing 2 includes a horizontal barrel-shaped housing. The upper part of the cylindrical housing is a differential chamber, and the lower part protrudes downwards as an axle chamber. The differential assembly 1 is located in the differential In the gearbox chamber; the end face of the open end of the barrel-shaped housing is the right join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com