High-speed airflow multi-stage ultra-thin powder mill

A technology of ultra-fine powder and high-speed airflow, which is applied in the direction of grain processing, etc., can solve the problems of low processing output, low hardness of feed material, small effective crushing work, etc., achieve high energy utilization rate, increase service life, and low energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

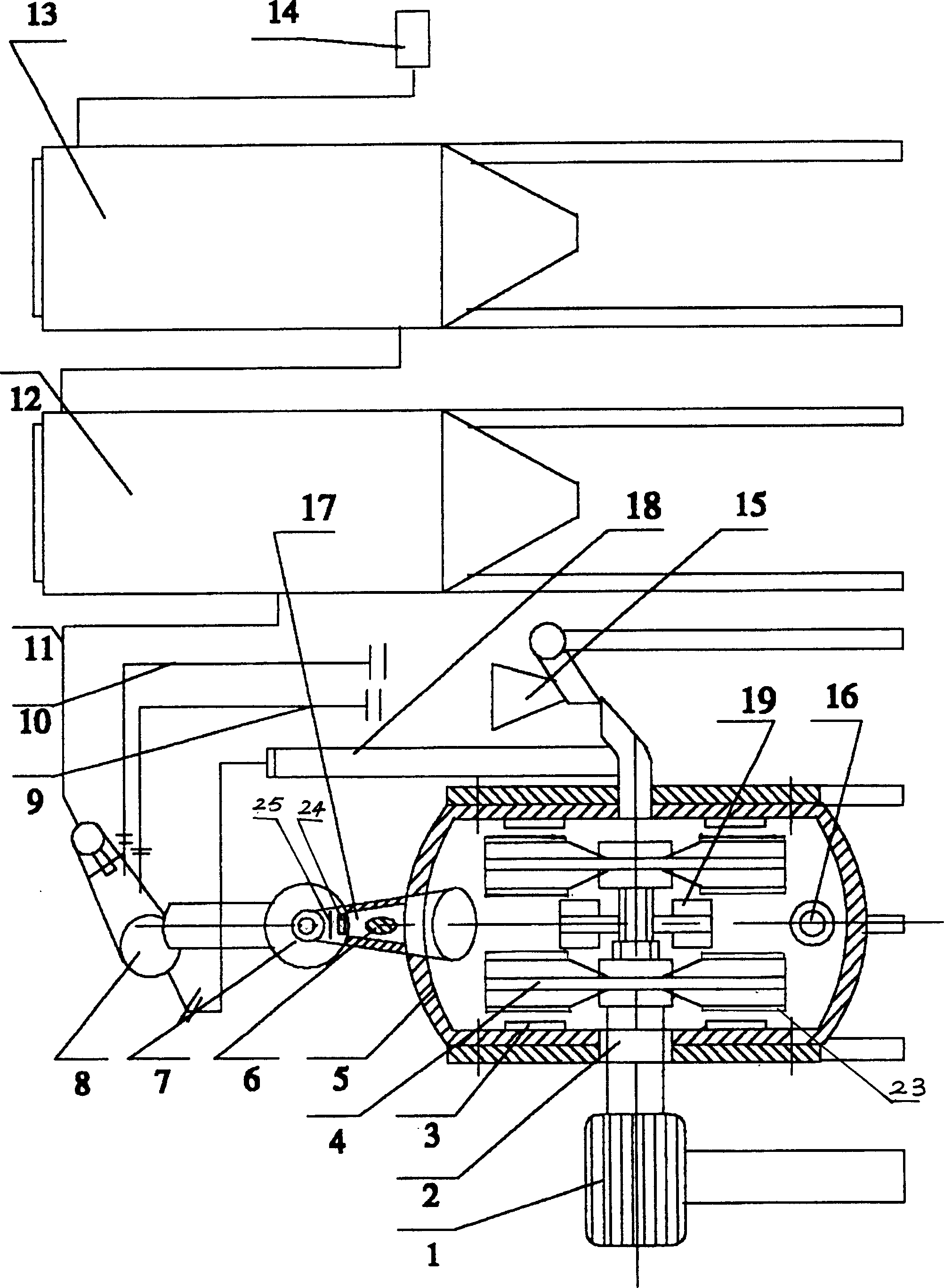

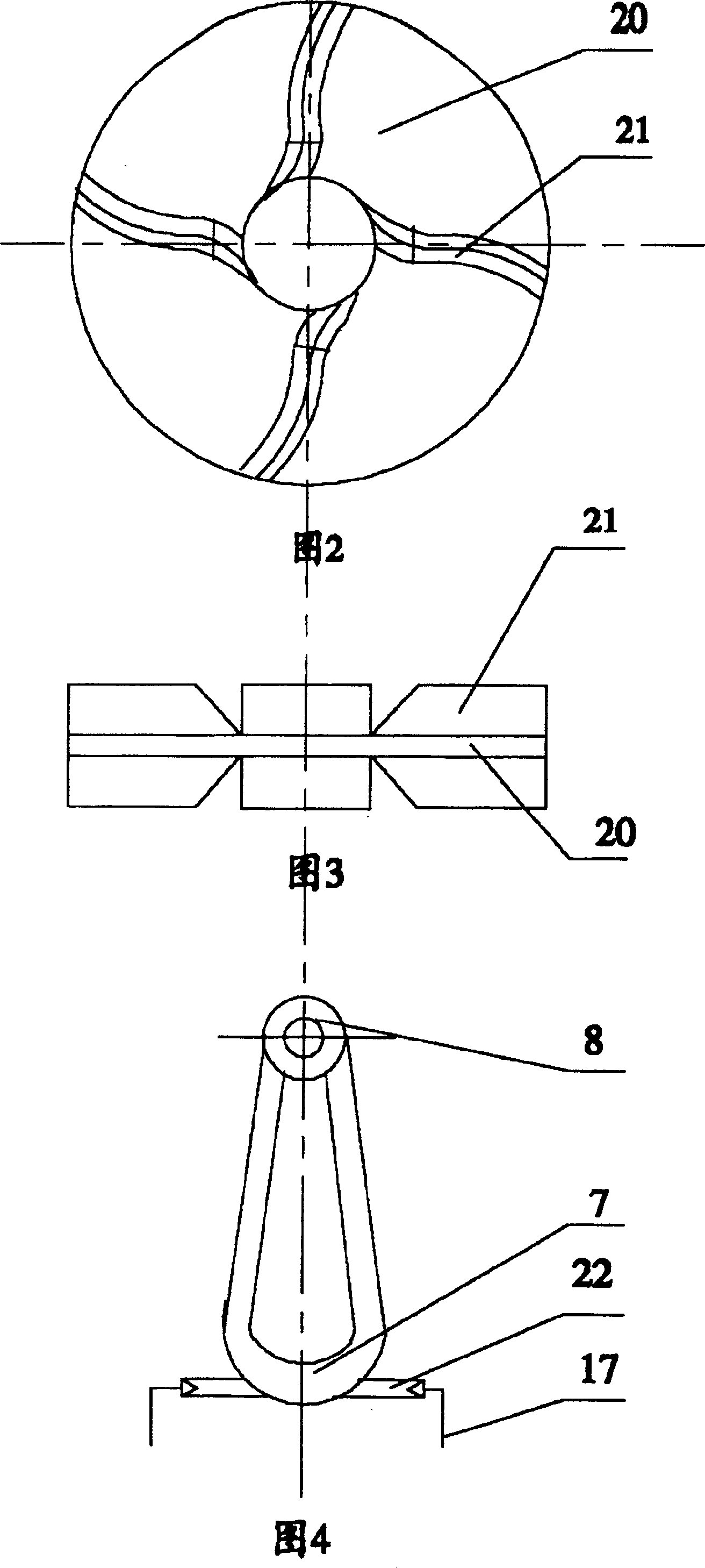

[0036] A high-speed airflow multi-stage ultra-fine powder mill, which is composed of a power drive device 1, a grinding chamber 5, a fine powder recovery device, and a feeding device 15; Feeding device, and the vertical turbulent disk 4 is connected with the grinding chamber 5; two turbulent flows 4 are coaxially installed on the main shaft 2 of the grinding chamber 5, and an inert wind wheel 19 is coaxially installed between the two turbulent disks 4 The discharge port of the grinding chamber 5 is connected with the airflow crushing chamber 7 through the discharge pipe 17, and the place where the airflow crushing chamber 7 is connected with the grinding chamber 5 discharge pipe 17 is provided with a high-speed airflow nozzle 22 (referring to Fig. 4); The upper part of the chamber 7 is connected with the separation chamber 8, and the separation chamber 8 is connected with the first-stage cyclone recovery hopper 12 and the dust removal powder collection hopper 13 connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com