Ultrafine Turbine Classifier

A turbine classifier and turbine technology, applied in solid separation, separating solids from solids with airflow, grain processing, etc., can solve problems such as high cost, short-circuit leakage of coarse-grained powder, complex structure, etc., and achieve strong wind power , High grading accuracy and high linear speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

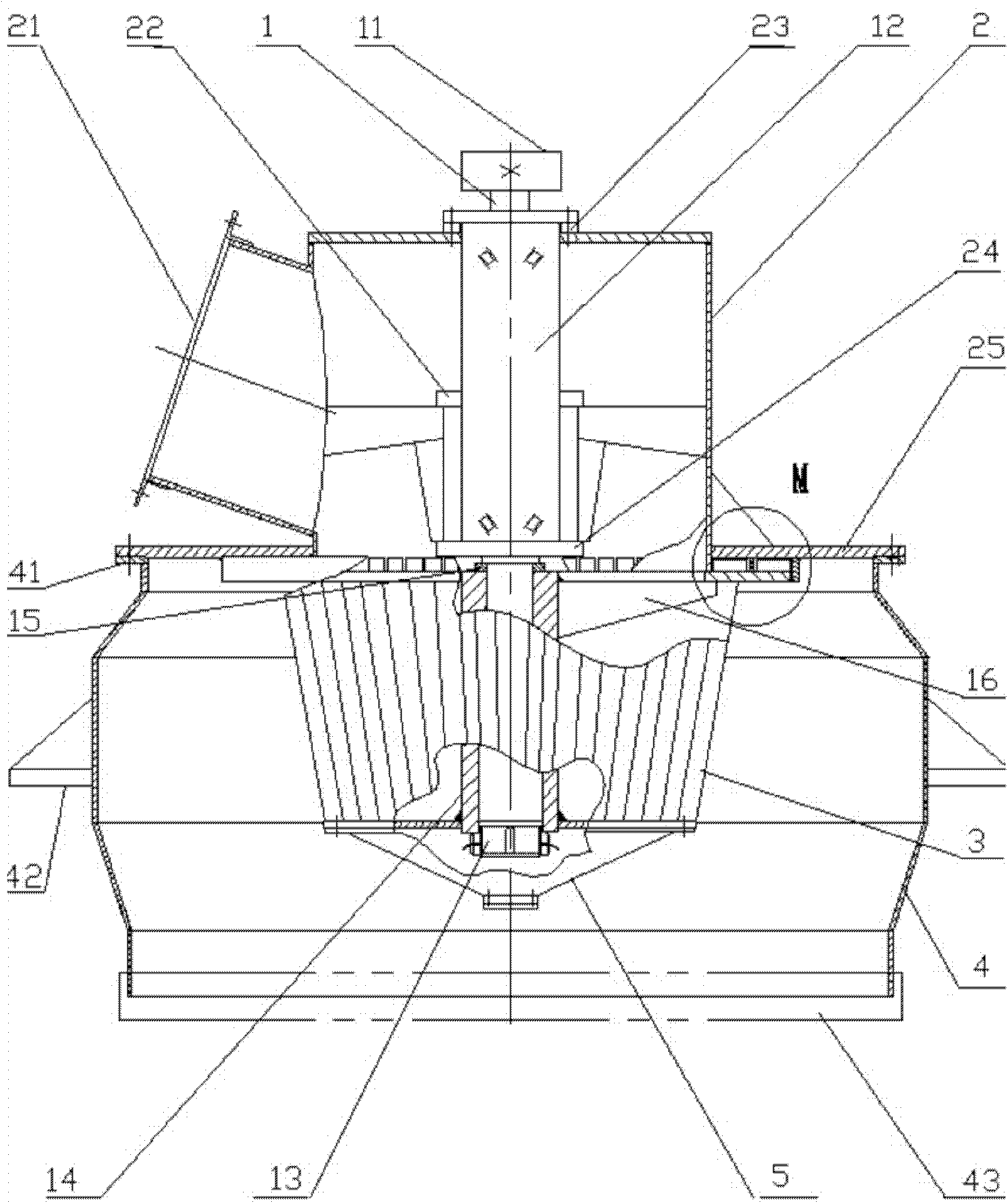

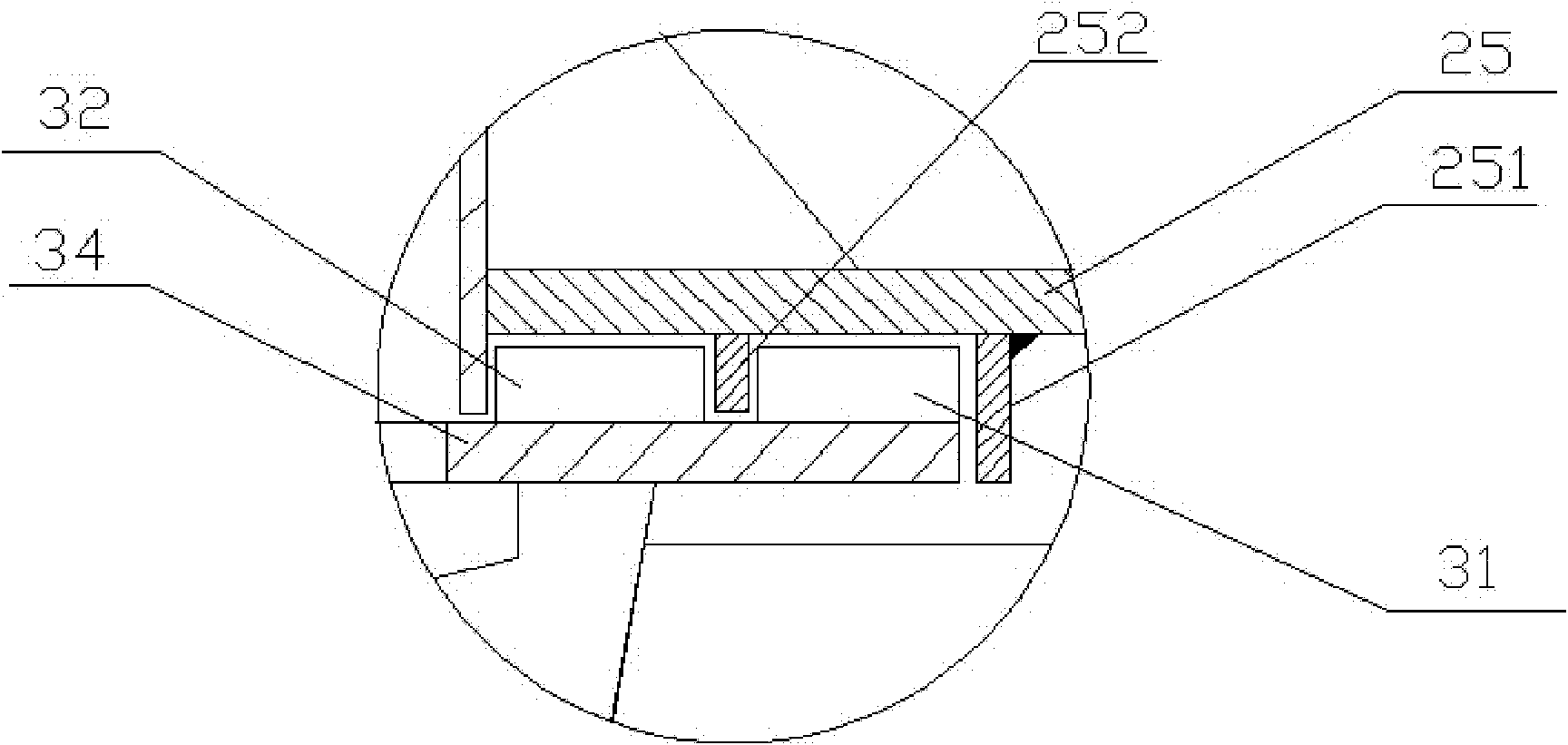

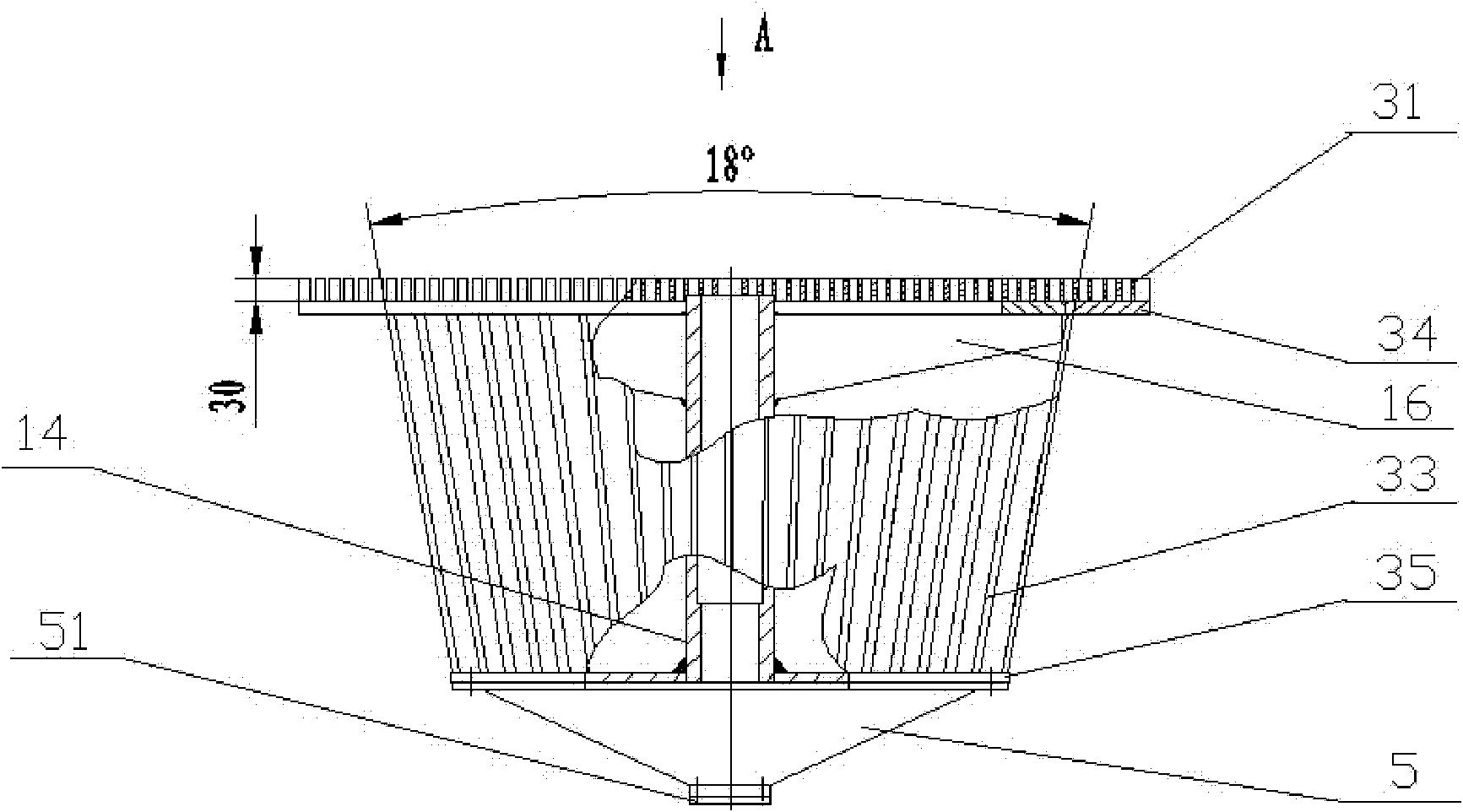

[0023] The overall structure of this ultrafine turbine classifier embodiment is as follows: figure 1 As shown, it includes a powder discharge chamber 2, a classification chamber 4 and a classification turbine assembly 3. The classification chamber 4 is a shell, and the classification turbine assembly 3 is arranged in the classification chamber 4. Above the classification chamber 4 is the powder discharge chamber 2. The powder outlet chamber 2 is also a shell with a powder outlet 21 on one side, and the powder outlet 21 is connected with the cyclone collector. The main shaft 1 passes through the center of the powder outlet chamber 2 and the classification chamber 4, and the main shaft 1 protrudes from the top of the powder outlet chamber 2, and a belt pulley 11 is installed on it to connect with the power mechanism. The main shaft 1 is installed on the bearing seat 12 in the powder outlet chamber 2 through bearings. The upper end flange 23 , the middle flange 22 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com