A solid waste cementitious material based on sulfate excitation

A technology of sulfate excitation and cementitious materials, applied in cement production and other directions, can solve the problems of high price, low economy, and large amount of water-reducing agent, and achieve strong cementing ability, realize economic benefits, and shorten initial setting time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

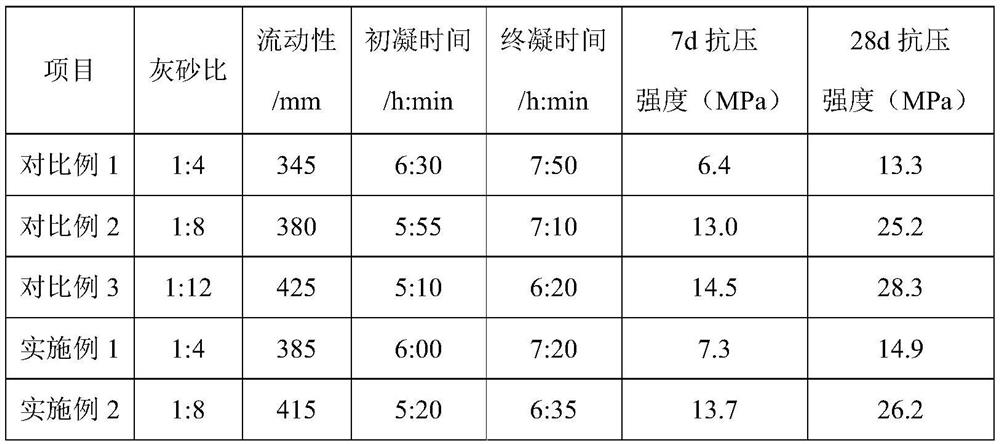

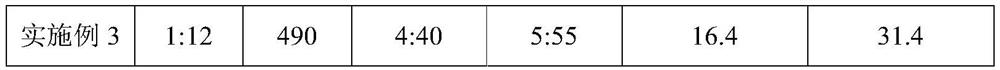

Examples

preparation example Construction

[0029] A kind of preparation method of solid waste cementitious material based on sulfate excitation, comprises the following steps:

[0030] 1) According to the aforementioned composition, weighing blast furnace slag, limestone, gypsum, admixture and water reducer, mixing, to obtain sulfate-activated gelling material;

[0031] 2) Mix and stir the sulfate-activated cementitious material and mine tailings according to the mass ratio of 1: (3-18);

[0032] 3) Add water and mix and stir to obtain solid waste gelling material based on sulfate excitation.

[0033] Preferably, in step 3) of the solid waste cementitious material preparation method, the water-cement ratio is (0.6-0.8): 1, and the water-cement ratio is the sum of the mass of water and solid components, sulfate-activated cementitious materials and mine tailings quality ratio.

preparation example 1

[0036] Mix 57 parts by mass of blast furnace slag, 14 parts by mass of limestone, 25 parts by mass of gypsum, 2 parts by mass of admixture and 2 parts by mass of water reducer to prepare a sulfate-activated gelling material.

preparation example 2

[0038] Mix 50 parts by mass of blast furnace slag, 16 parts by mass of limestone, 30 parts by mass of gypsum, 3 parts by mass of admixture and 1 part by mass of water reducer to prepare a sulfate-activated gelling material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com