A kind of gel plugging agent and its preparation method and application

The technology of a leak-stopping agent and gel is applied in the field of the gel-stopping agent and its preparation, which can solve the problems of easy re-leakage, weak pressure bearing capacity, difficult pumping, etc., and achieves good inter-compatibility and strong cementing ability. , the effect of good liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the gel plugging agent described in the above technical solution, comprising the following steps:

[0034] (1) mixing water and a thickener to obtain a mixed slurry;

[0035] (2) mixing the mixed slurry obtained in the step (1) with a density modifier to obtain a base liquid;

[0036] (3) mixing the base liquid obtained in the step (2) with the spherical gel to obtain a gel plugging agent precursor;

[0037] (4) Mix the precursor of the gel plugging agent obtained in the step (3) with the accelerator to obtain the gel plugging agent.

[0038] The invention mixes water and thickener to obtain mixed slurry. In the present invention, there is no special limitation on the mixing operation, and a mixing technical solution well known to those skilled in the art can be used. In the present invention, it is preferred to add the thickener to water under stirring conditions to obtain a mixed slurry. In the present in...

Embodiment 1

[0052] (1) At a stirring rate of 5000rpm, add 0.8 parts by weight of hydroxypropyl methylcellulose to 100 parts by weight of water to obtain a mixed slurry, and stir for 15 minutes;

[0053] (2) At a stirring rate of 5000 rpm, 35 parts by weight of potassium chloride were added to the mixed slurry to obtain a base liquid, and stirred for 15 minutes;

[0054] (3) At a stirring rate of 350rpm, 10 parts by weight of spherical gel with a particle size of 0.5-2 mm was added to the base liquid, and stirred for 4 minutes to obtain a gel plugging agent precursor;

[0055] (4) At a stirring rate of 350 rpm, 3 parts by weight of diethylaminopropylamine was added to the precursor of the gel plugging agent, and stirred for 4 minutes to obtain the gel plugging agent.

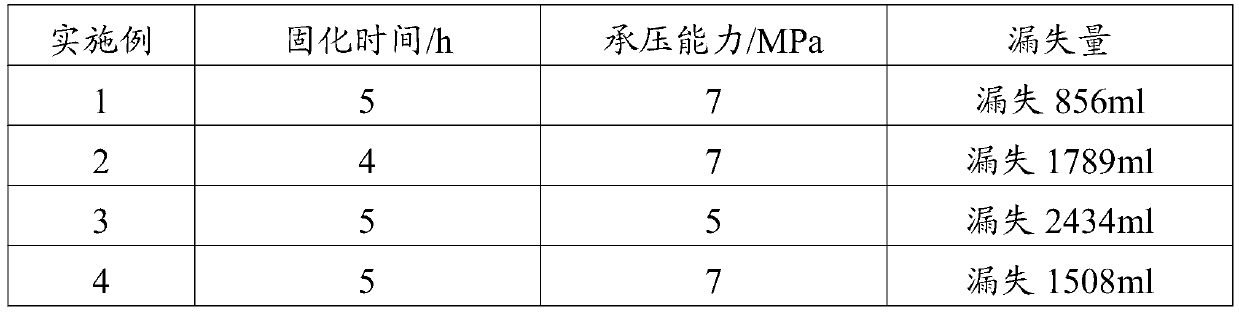

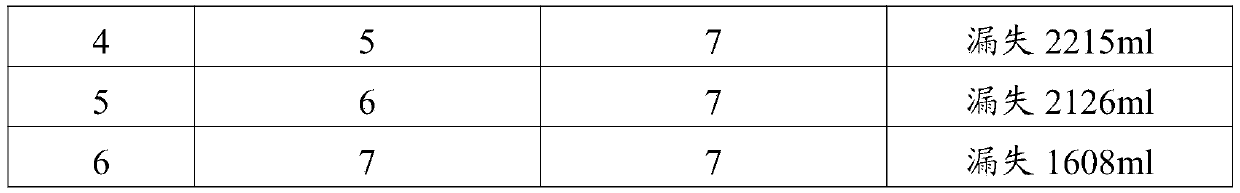

[0056] The gel plugging agent prepared in this example was tested with a high-temperature and high-pressure crack plugging instrument, and a crack with a width of 1.0 mm was plugged at 80°C. The performance test results are ...

Embodiment 2

[0058] (1) At a stirring rate of 4000rpm, 0.8 parts by weight of guar gum was added to 100 parts by weight of water to obtain a mixed slurry, and stirred for 20 minutes;

[0059] (2) At a stirring rate of 4000 rpm, 30 parts by weight of sodium chloride was added to the mixed slurry to obtain a base liquid, and stirred for 20 minutes;

[0060] (3) At a stirring rate of 300 rpm, 10 parts by weight of spherical gel with a particle size of 0.5-2 mm was added to the base liquid, and stirred for 5 minutes to obtain a gel plugging agent precursor;

[0061] (4) At a stirring rate of 300 rpm, 5 parts by weight of m-xylylenediamine was added to the precursor of the gel plugging agent, and stirred for 5 minutes to obtain the gel plugging agent.

[0062] The gel plugging agent prepared in this example was tested using a high-temperature and high-pressure crack plugging instrument, and a crack with a width of 2.0 mm was plugged at 80°C. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com