A Settlement Reinforcement Jacking Leveling Method Applicable to Independent Pile Foundations of Industrial Plants

A technology of industrial workshops and independent piles, which is applied in the field of pile foundation reinforcement, can solve the problems of reduced bearing capacity of the foundation, large slope of the rock surface, insufficient bearing capacity of the foundation, etc., and achieve the goal of improving bearing capacity, strong cementing ability and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

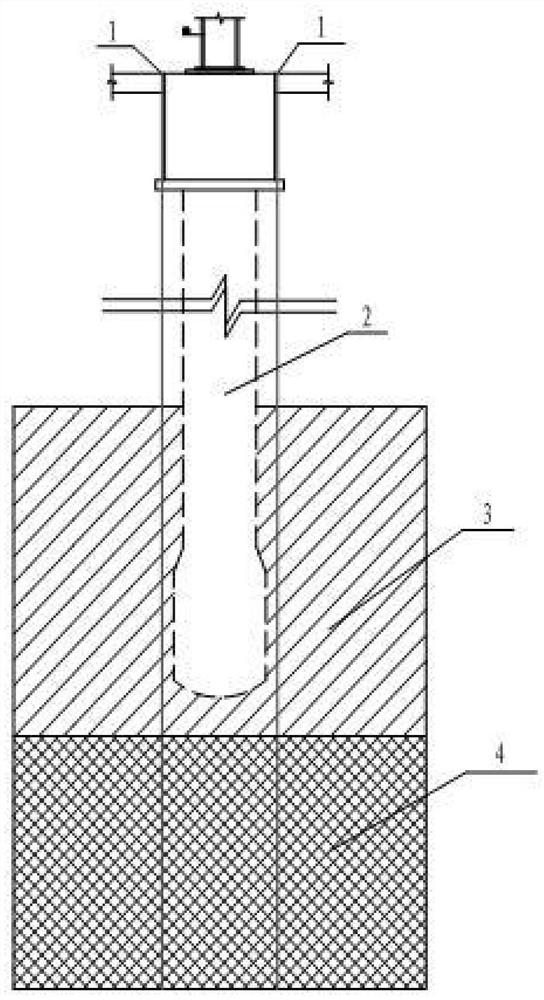

[0011] A settlement reinforcement jacking and leveling method suitable for independent pile foundations of industrial plants, such as figure 1 As shown in the figure, the weak soil layer around the pile is first reinforced by compaction and grouting. The reinforcement depth is from shallow to deep, and the layers are downward. The grouting pressure is from small to large. The length of each grouting section is 0.5-1.0m. After the first grouting section, continue drilling for 0.5-1.0m, carry out the grouting of the second grouting section, and go down section by section until the compaction grouting is completed. The scheme can avoid secondary settlement caused by the weakening of the soil layer when the soil layer encounters water during the drilling process. The compaction and grouting reinforcement of the soft soil layer around the pile can improve the compactness and friction coefficient of the soft soil layer around the pile. The layer is reinforced, and a concave-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com