Patents

Literature

54results about How to "Improve anti-segregation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-compacting concrete for CRTS III plate-type ballastless track filling layer and preparation method for self-compacting concrete

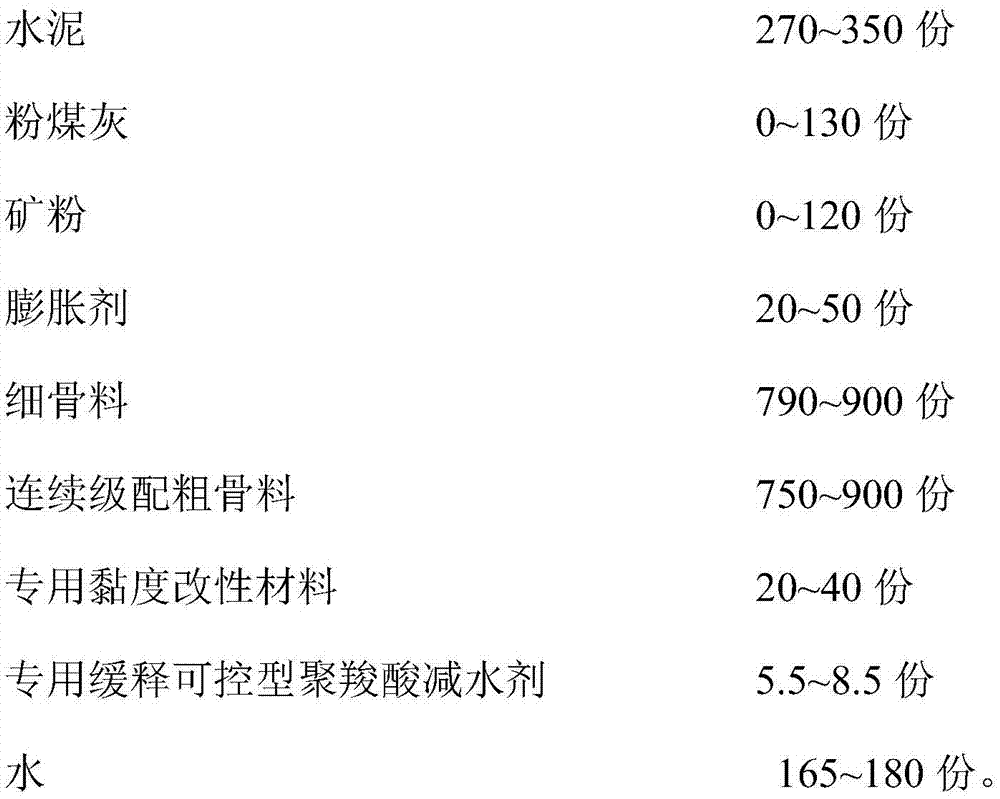

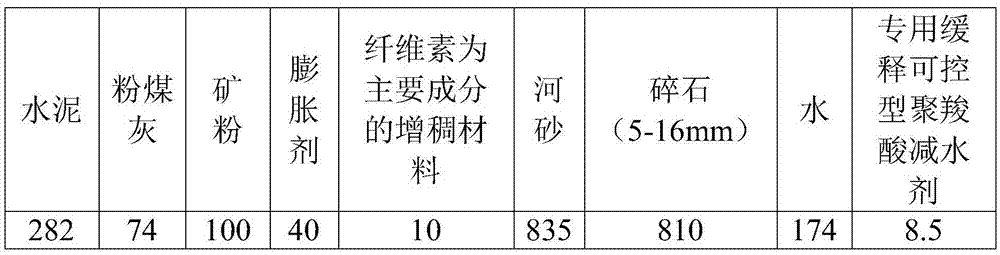

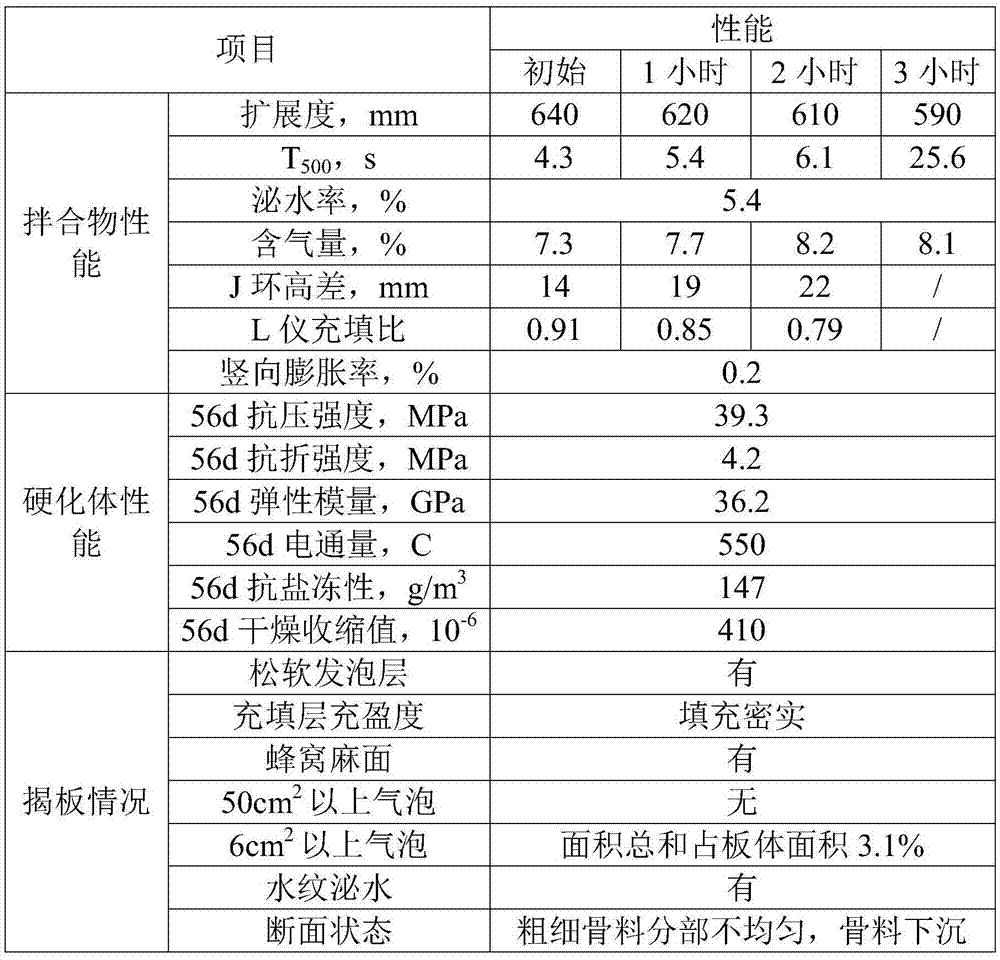

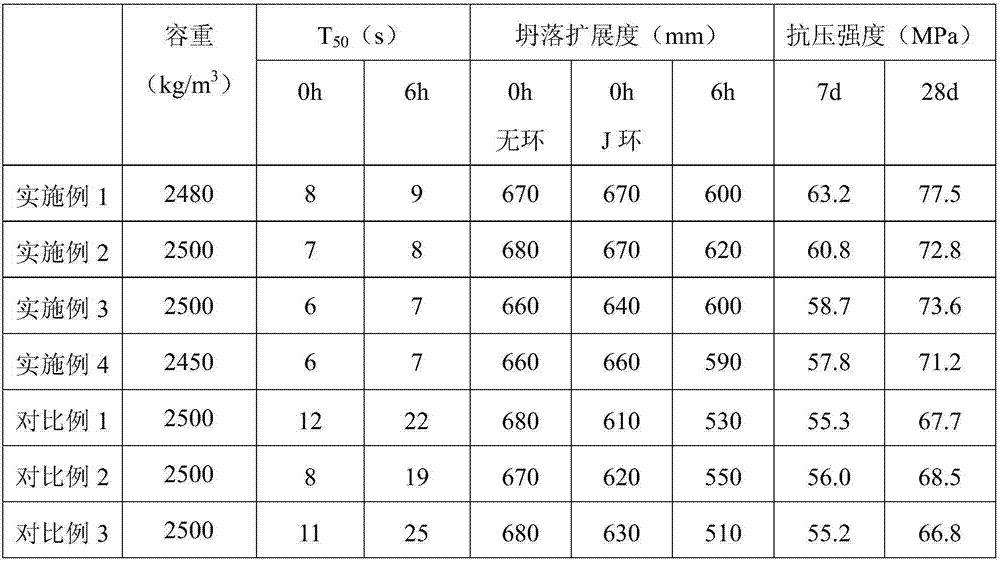

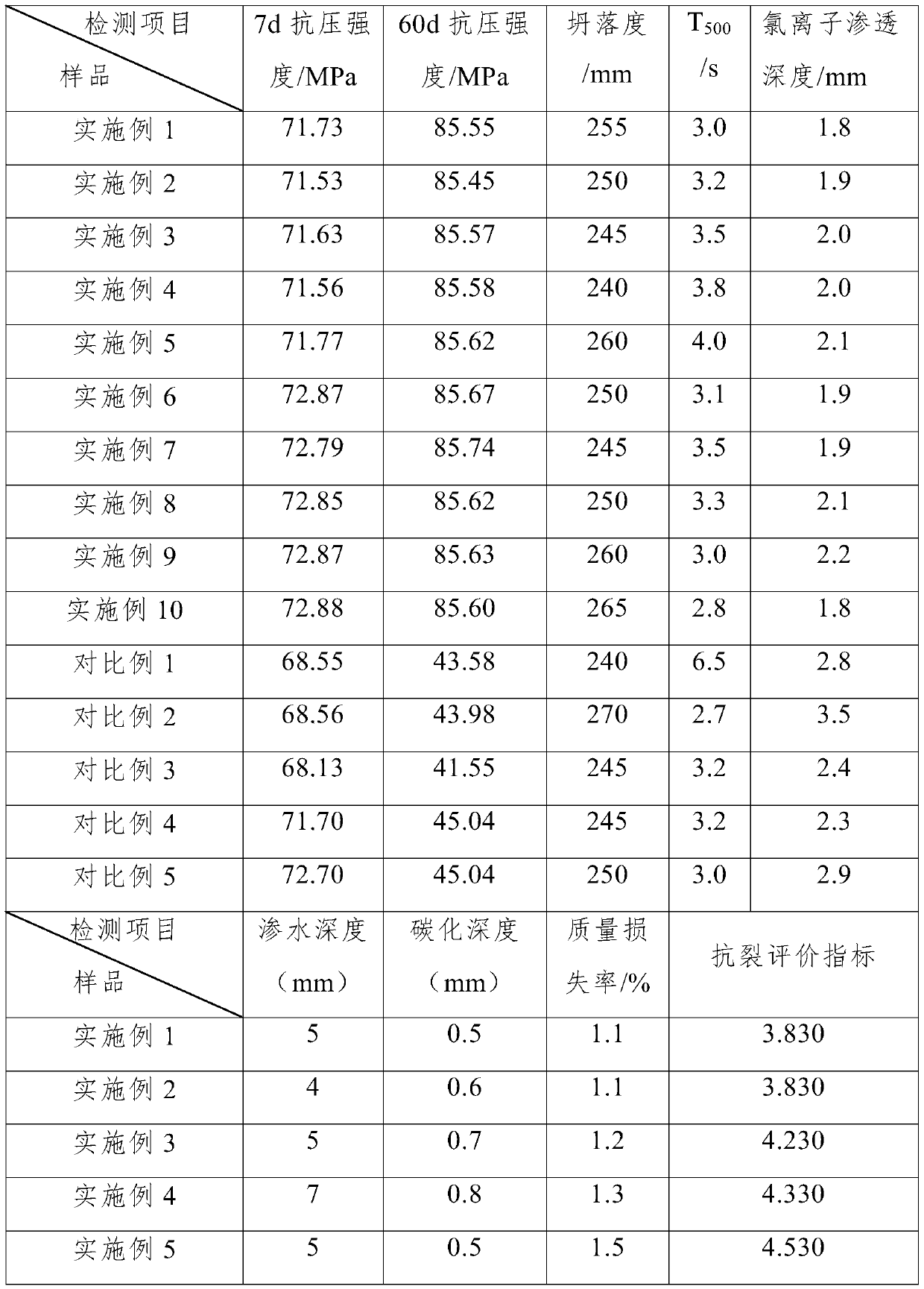

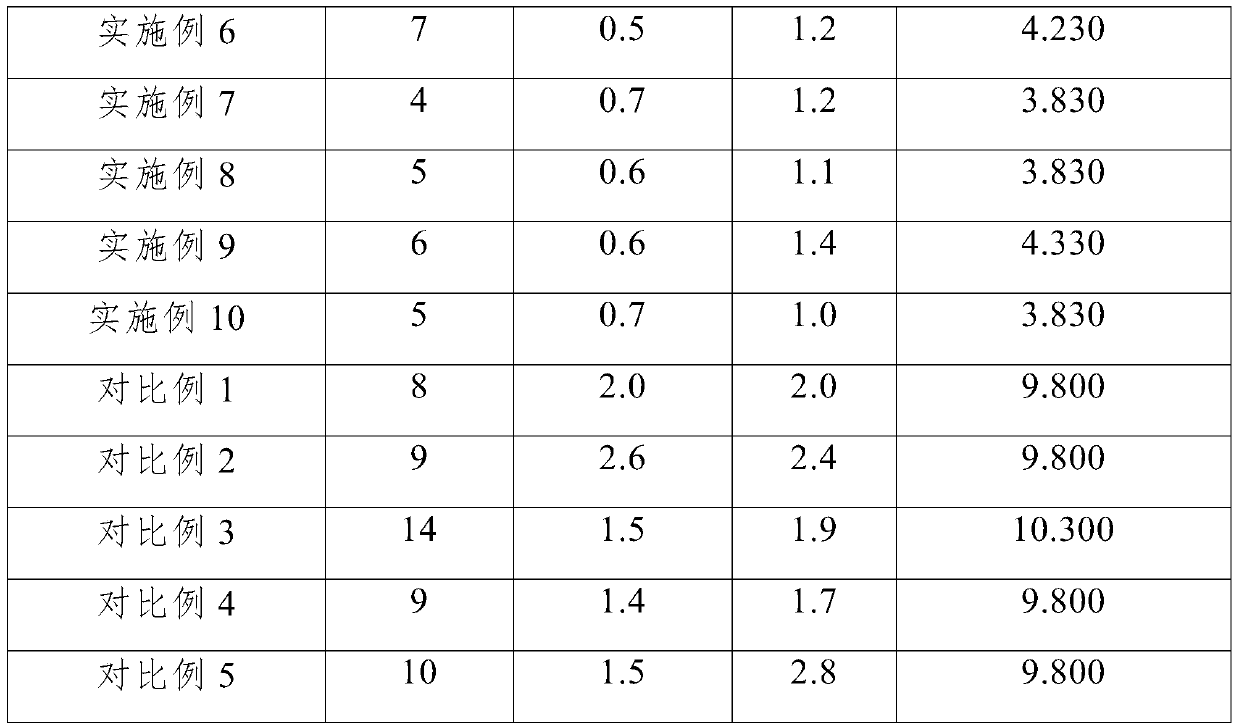

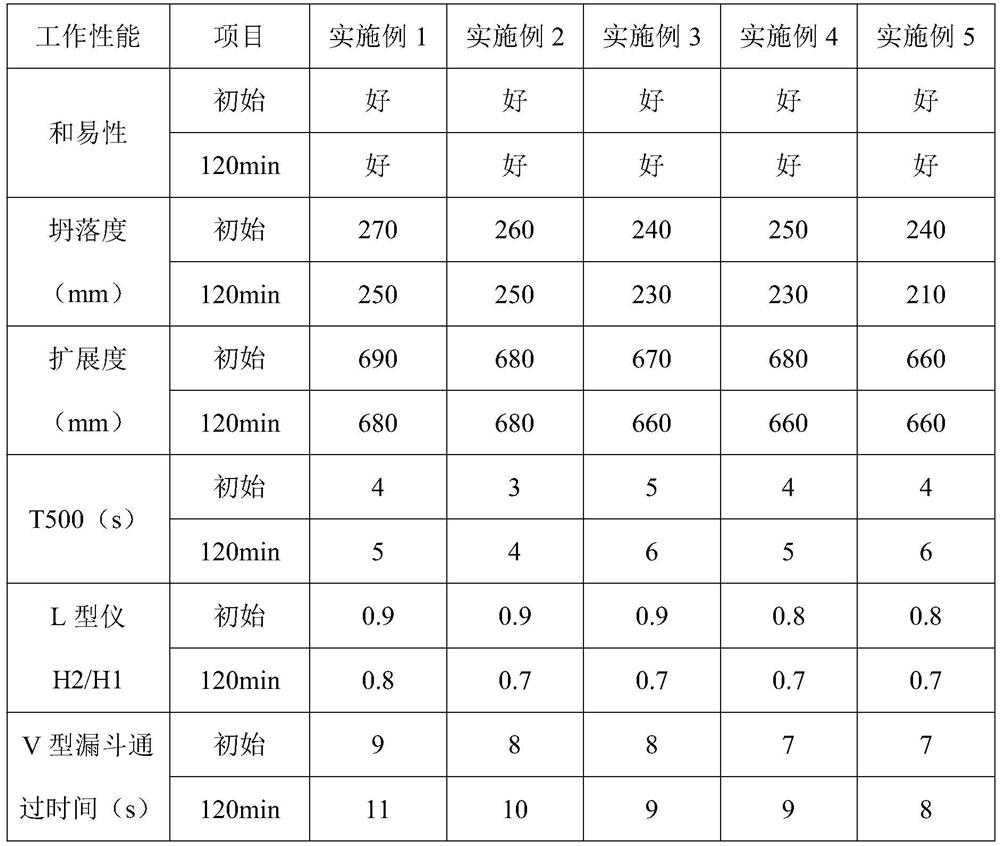

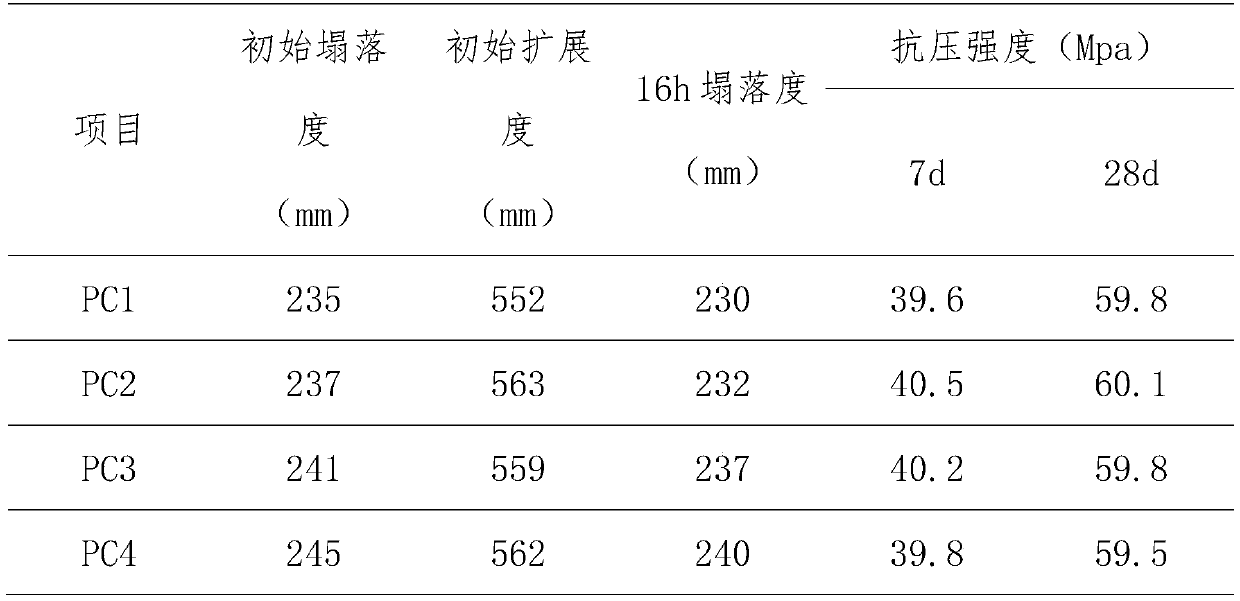

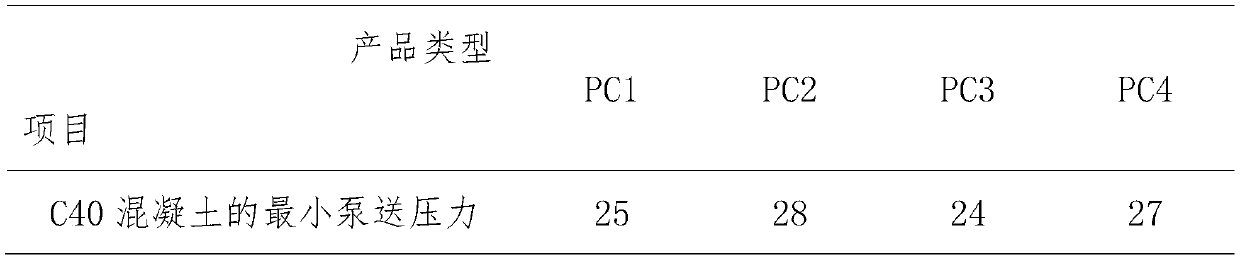

The present invention discloses a self-compacting concrete for CRTS III plate-type ballastless track filling layer. The concrete is prepared from the following raw materials in parts by weight: 270-350 parts of cement, 0-130 parts of coal fly ash, 0-120 parts of mineral powder, 20-50 parts of an expanding agent, 790-900 parts of fine aggregate, 750-900 parts of continuous gradation coarse aggregate, 20-40 parts specific viscosity modified materials, 5.5-8.5 parts of a specific sustained release controllable polycarboxylic acid water reducing agent and 165-180 parts of water. According to the invention, the specific viscosity modified materials and specific sustained release controllable polycarboxylic acid water reducing agent are used in combination to prepare the specific self-compacting concrete for filling layer with good flowability, strong volume stability, low sensitivity for water consumption, small thixotropic time change, low shrinkage and good longevity, thereby reducing theconstruction difficulty of the CRTS III plate-type filling layer and prolonging the sevice life of the ballastless track structure.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Clean water autodensing concrete almixture

InactiveCN100999404AImprove mechanical propertiesIncreased durabilitySolid waste managementHigh resistanceSlag

This invention relates to a clean water self-compacting concrete. According to the weight, it includes cement 1 share, water: 0.28 to 0.35, sand: 2.78 to 4.18, stone: 4.18 to 2.78, pulverized coal ash: 0 .34 to 1, slag: 0.34 to 1, carboxylic acid high performance water reducer: 0.021 to 0.043. Advantages of the invention: the concrete has high resistance to disintegrate, not secrete water, but also has high mobility, self-filling templates and pouring shape, gain a high quality compacting concrete; and when construction side use clean water template, concrete surface smooth, color uniform, has better visual effect; after hardening concrete has excellent mechanical and durability properties, the compressive strength can achieve not less than 50 MPa.

Owner:BEIJING HAORAN CONCRETE

Self-compacting non-shrinkage concrete-filled steel tube

The invention discloses a self-compacting non-shrinkage concrete-filled steel tube, belonging to the technical field of concrete. The self-compacting non-shrinkage concrete-filled steel tube is prepared from the following components in parts by weight: 360-400 parts of cement, 53-100 parts of coal ash, 15-35 parts of ground slag, 50-80 parts of a compound expansion agent, 700-770 parts of mixed sand, 1040-1070 parts of gravel, 150-160 parts of drinking water and a high performance admixture, wherein the amount of the high performance admixture accounts for 1.7-1.8% of the total mass of a cementing material by mass percent. The self-compacting non-shrinkage concrete-filled steel tube provided by the invention has good self-compacting property, expansibility, fluidity, slump loss resistance,cohesiveness, segregation resistance and higher compression strength; furthermore, the expansion process and strength of concrete-filled steel tube are synergistically developed.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

Maritime work concrete and construction method

InactiveCN101269937AGood durabilityImprove anti-segregation performanceSolid waste managementBridge erection/assemblyCorrosionMoisture

The present invention discloses maritime-works concrete and a method for constructing the maritime-works concrete, which is mainly composed of cement, blast-furnace slag powder, fly ash, sand, crushed stone, additive and water, and has favorable durance, and can meet the requirements of the ocean large engineering project on the favorable durance of the concrete system, and can effectively avoid the corrosion of the steel bar during the service life, and can maintain the favorable appearance. The construction method of the maritime-works concrete comprises adopting the mixing factory-orientation production, the integrated material supply, the conveying pump and the tank cart to transport the concrete to the pouring site, and adopting the material rod to distribute the materials, thus can effectively control the feeding point, the feeding quantity and the feeding speed, and can guarantee the concrete to meet the working indexes required for the construction such as the uniformity and the stipulated collapsed degree while effectively improving the construction progress, and can promote the successful completion of the engineering project. The moisture-preservation and temperature-preservation maintenance is adopted for the initial maintenance of the beam body, thereby improving the initial strength, accelerating the turnover of the beam holder and the die, and reducing the beam-making cost.

Owner:CHINA RAILWAY HI TECH IND CORP LTD

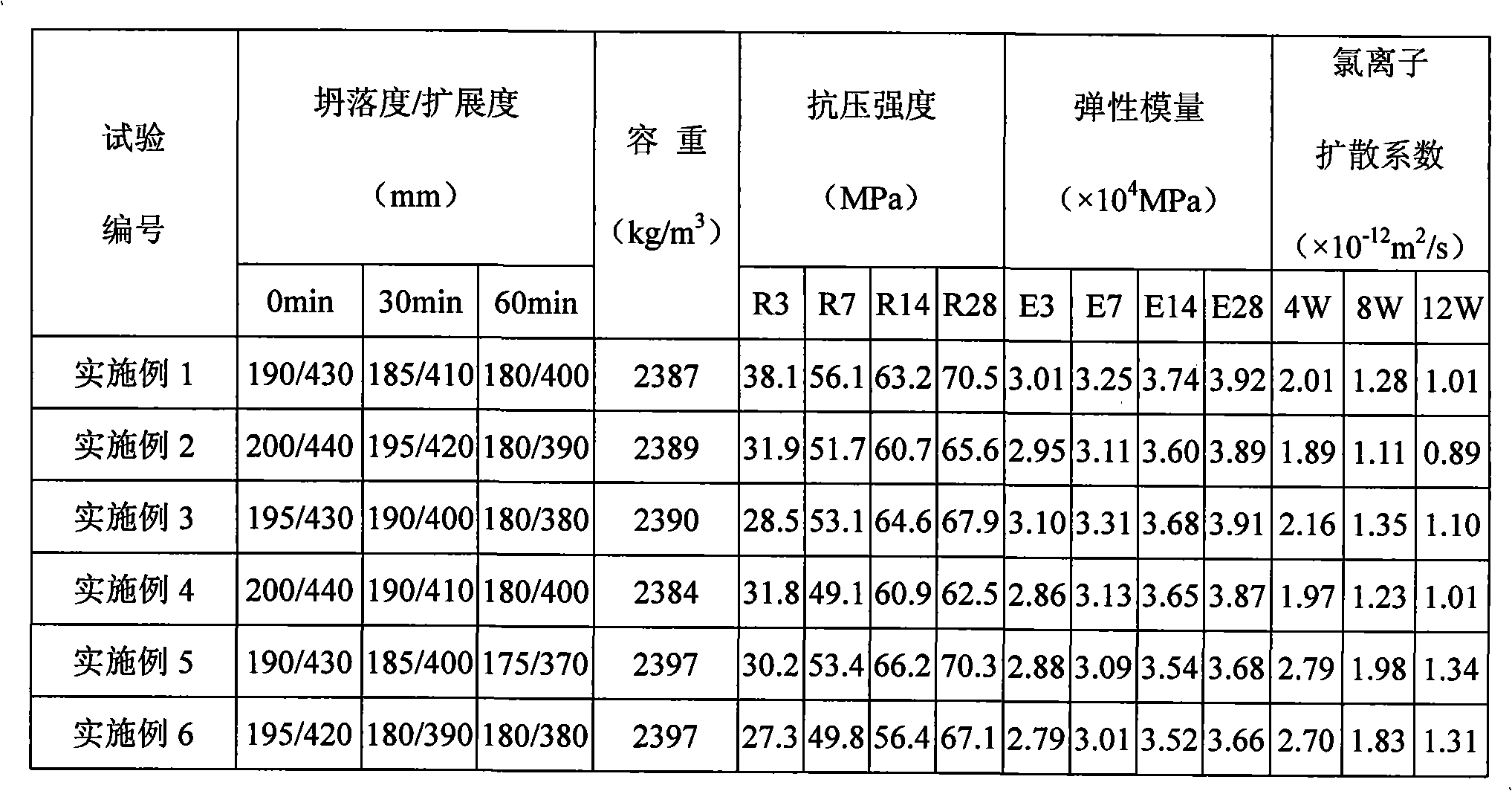

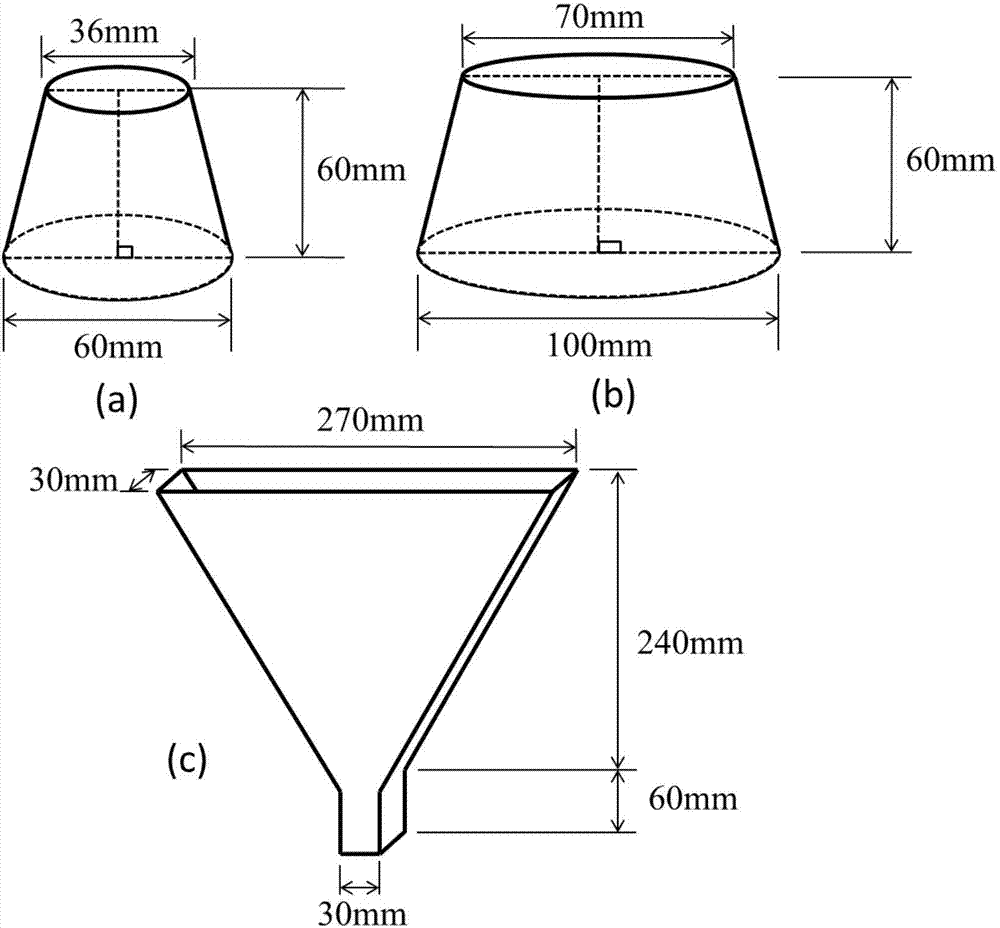

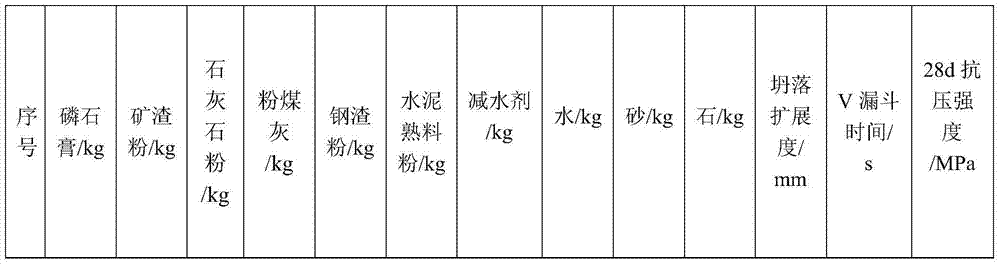

Self-compacting concrete prepared from industrial solid wastes and preparation method thereof

The invention belongs to building materials and especially relates to self-compacting concrete prepared from industrial solid wastes and a preparation method thereof. Single unit of the concrete including: a powder material accounting for 16-23% by absolute volume, coarse aggregate accounting for 28-35% by absolute volume, fine aggregate accounting for 23-38% by absolute volume and water accounting for 15-19% by absolute volume, wherein the solid substances in a concrete additive agent accounts for 0.05-0.5% by the mass of the powder material. The powder material is composed of following raw materials, by mass: 30-65% of phosphogypsum, 30-55% of ore slag powder, 2-10% of steel slag powder, 0-5% of Portland cement, 0-25% of limestone powder and 0-30% of fly ash. In the invention, the preparation method includes following steps: preparing modified phosphogypsum slurry in a wet-grinding manner, and preparing clear slurry, a mortar and the self-compacting concrete, which can satisfy requirements of flowing property and segregation resistant performance, according to the sequence from the clear slurry, the mortar to the self-compacting concrete in a step-by-step manner. The self-compacting concrete is high in flowing property and segregation resistant performance. The self-compacting concrete is low-carbon and low-cost and can consume the industrial solid waste, phosphogypsum, so that the self-compacting concrete is beneficial to environmental protection.

Owner:TSINGHUA UNIV

Steel slag concrete

The invention relates to steel slag concrete comprising the following components: cement, water, barite sand, stones, sintered pellets, a naphthalene high-efficiency water reducing agent, an expanding agent, and fly ash. The steel slag concrete has the advantages that the steel slag concrete is prepared by mixing the cement, water, the barite sand, the stones, the sintered pellets, the naphthalene high-efficiency water reducing agent, the expanding agent and the fly ash; the sintered pellets and the barite sand enable the density of the concrete to be effectively improved; with the use of the barite sand, the sintered pellets can be prevented from sinking, the separation resistance of the concrete is improved, and the amount of the cement is reduced; the fly ash effectively reduces the hydration heat of the concrete; with adulteration of the naphthalene high-efficiency water reducing agent, the work degree of the concrete is improved, the setting time of the concrete is delayed, the construction difficulty is effectively reduced, and the construction period is greatly shortened; and with reasonable utilization of the industrial waste residue sintered pellets, the energy is effectively saved, the environment is effectively protected, and the production cost is reduced.

Owner:ZHONGTIAN CONSTR GROUP

Full-lightweight ceramsite concrete and preparation method thereof

The invention relates to full-lightweight ceramsite concrete and a preparation method thereof. The full-lightweight ceramsite concrete is prepared from, by weight, 278-339 parts of cement, 318-344 parts of ceramsite, 334-382 parts of pottery sand, 50-55 parts of coal ash, 35-42 parts of silica fume, 0.001-3 parts of triisopropanolamine, 0.5-3 parts of a water reducing agent and 0.001-3 parts of athickening agent. The method includes steps: subjecting ceramsite and pottery sand to surface pretreatment through alkyl alkoxy silane, prewetting ceramsite and pottery sand to achieve a saturated surface dry state, then sequentially feeding lightweight aggregates, cement, silica fume and coal ash into a forced mixer, and well mixing to obtain the full-lightweight ceramsite concrete. The full-lightweight ceramsite concrete prepared according to the method has advantages of light weight, high peaceability and effectiveness in inhibition of ceramsite floating and has a promising application prospect in the field of energy-saving construction engineering.

Owner:CHINA THREE GORGES UNIV

High-strength high-performance concrete and preparation method thereof

The invention discloses high-strength high-performance concrete, components of which comprise (by weight): 100-300 parts of cement, 50-100 parts of silica sand, 10-30 parts of nanometer magnesia, 10-20 parts of fly ash, 5-15 parts of nanometer calcium carbonate, 30-60 parts of a water reducer, 10-25 parts of lignin sulfonate, 2-12 parts of titanium fiber, 4-18 parts of polytetrafluoroethylene powder, 3-15 parts of sodium alginate, 10-30 parts of a silane coupling agent, 10-20 parts of glass fibre powder, 20-40 parts of ultrafine mineral powder and 50-100 parts of purified water. The inventionalso discloses a preparation method of the high-strength high-performance concrete. The method is simple for construction. The prepared concrete has high strength (strength is 45-60 Mpa), good anti-permeability and good durability. Meanwhile, the prepared concrete has excellent high crack resistance and impermeability. Thus, the hidden trouble that concrete cannot be used due to leakage and ponding caused by poor crack resistance and impermeability is avoided. Strength of concrete in middle and late stages is enhanced.

Owner:CHINA MCC17 GRP

Preparation method of waterproof concrete

Provided is a preparation method of a waterproof concrete; raw material components comprising cement, sand, carpolite, water, a water reducing agent, a swelling agent and fly ash are stirred and mixed and cured to obtain the waterproof concrete; the swelling agent allows the concrete to swell in a constrained environment, communication holes in the concrete are significantly reduced, the anti-permeability waterproof properties are enhanced, and the strength is also increased significantly; with addition of the water reducing agent, the stability and performance of the concrete are enhanced, problems of common dissociation and water segregation and collapsed slump loss of large-liquidity pumped concrete are avoided, a non-vibrating self-compacting effect is achieved, and construction is convenient; with the use of the fly ash, concrete pores and capillary pores are filled, and with the addition of the fly ash, a pore structure of the concrete is improved and the compactness is increased; and the prepared waterproof concrete is good in self-compacting performance and excellent in anti-permeability and anti-crack performance, and has the later strength improved significantly.

Owner:XIJING UNIV

C70 mass concrete and preparation process thereof

The invention discloses C70 mass concrete. The C70 mass concrete is prepared from the following components by mass: 140 to 170 parts of water, 400 to 450 parts of cement, 1,000 to 1,200 parts of crushed stone, 550 to 650 parts of gravel, 70 to 110 parts of coal ash, 60 to 90 parts of mineral powder, 30 to 70 parts of silica fume, 8 to 10 parts of a pumping agent, 35 to 45 parts of an anti-crackingagent, and 0.3 to 0.4 part of an internal curing agent. The invention also discloses a preparation method for the C70 mass concrete. The method comprises a first step of uniformly mixing sand, graveland water and a second step of adding other components and carrying out uniform mixing under stirring. According to the composition of the mass concrete in the invention, mineral powder, silica fumeand fly ash are used as mineral admixtures and can delay the release rate of cement hydration heat and reduce the shrinkage and deformation of the concrete, and the mineral admixtures acts synergistically with the other components to inhibit the generation of cracks at the same time; and the preparation method of the invention is simple in process and easy to implement.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

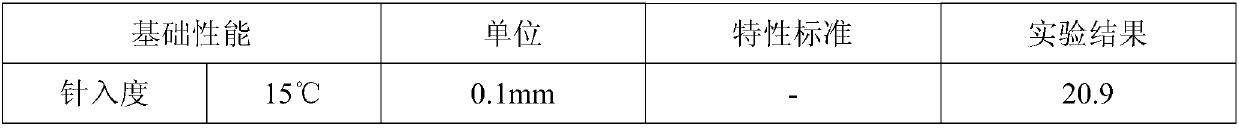

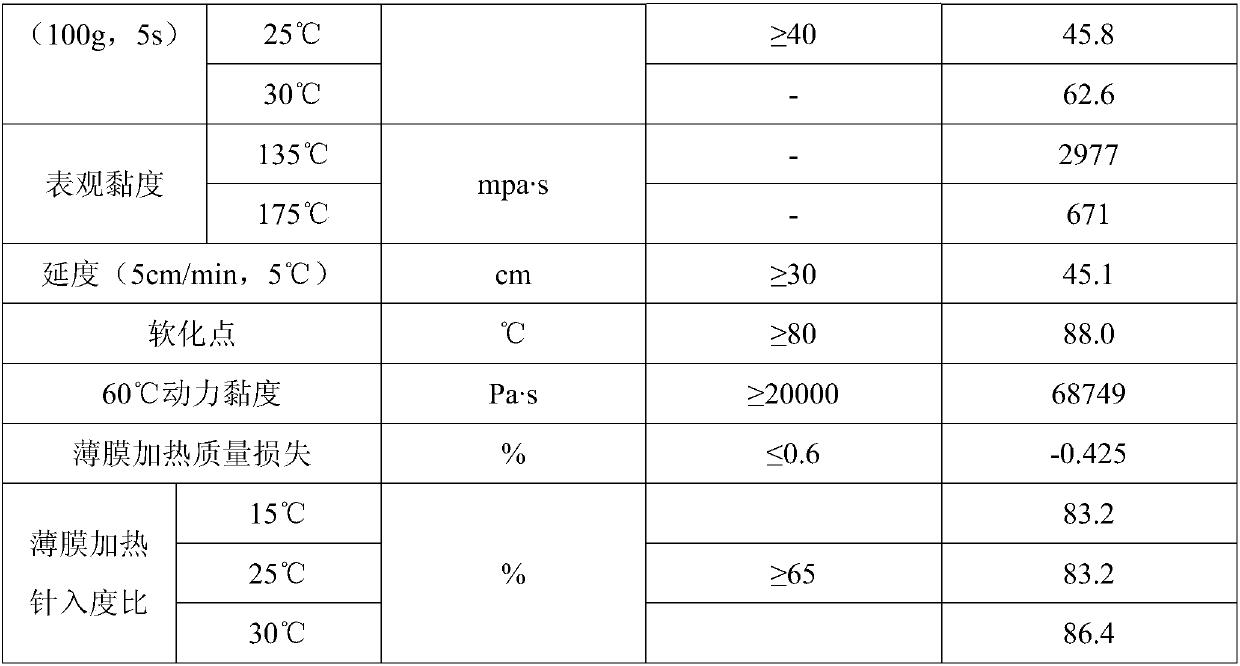

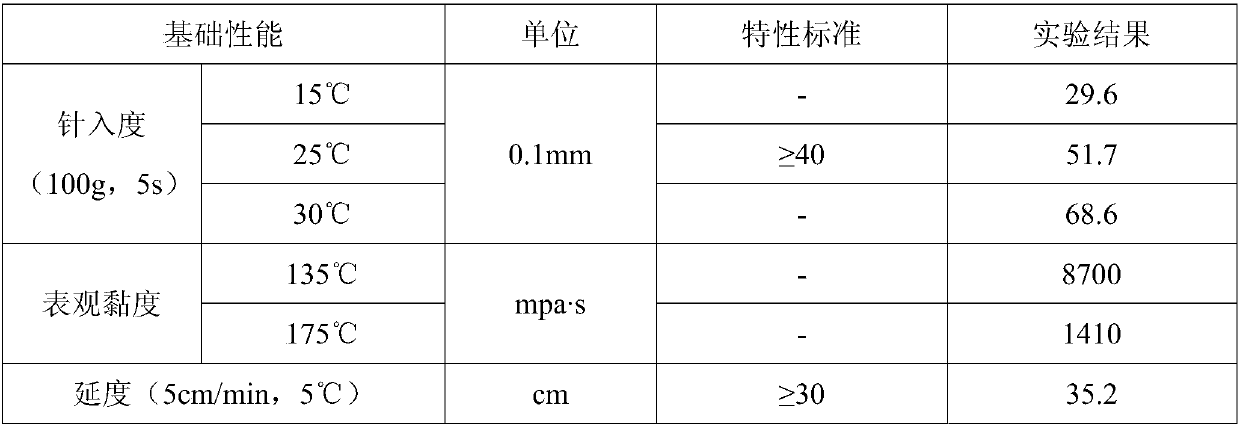

Environmentally-friendly high-viscosity modified asphalt and preparation method thereof

InactiveCN107722650AReduce dosageImprove anti-aging propertiesBuilding insulationsPlasticizerAging resistance

The invention discloses an environmentally-friendly high-viscosity modified asphalt and a preparation method thereof. The modified asphalt comprises, by mass, 55-70 parts of matrix asphalt, 3-15 partsof blend oil, 0-1 part of a plasticizer, 5-20 parts of a tackifier, 0.1-0.5 part of a stabilizer and 5-20 parts of a modifier, wherein the modifier is composed of waste tire rubber powder and SBS, and a mass ratio of the waste tire rubber powder to the SBS is (3-15):(2-10). The modified asphalt has the advantages of excellent adhesion, excellent aging resistance, low cost and simple preparation method.

Owner:CHANGAN UNIV

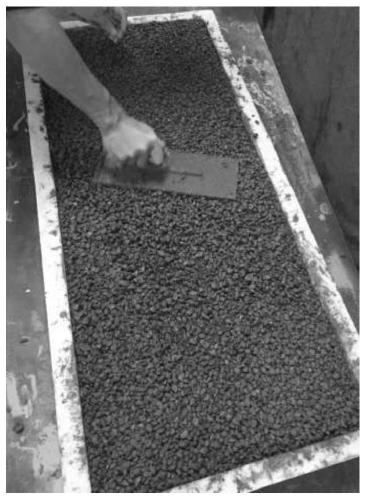

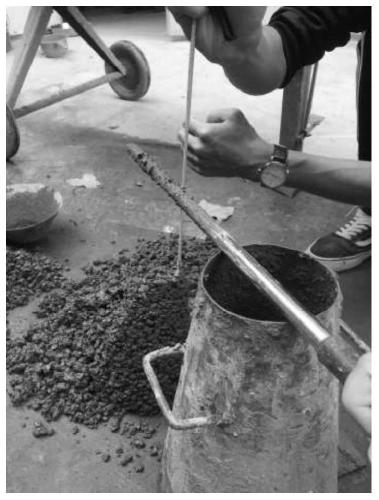

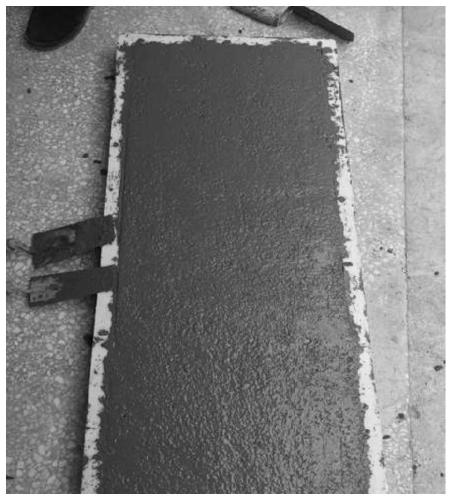

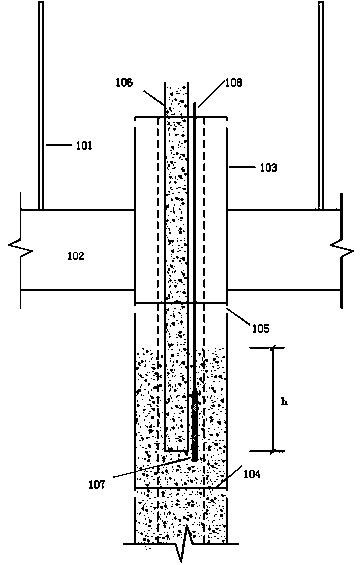

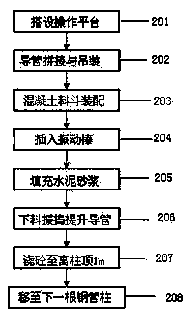

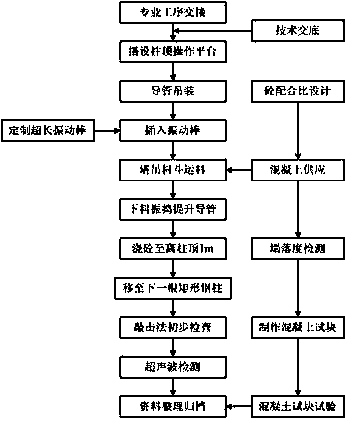

Method for pouring concrete in steel pipe column

ActiveCN104278841ALow requirements for conveying equipmentShort preparation time for constructionBuilding material handlingSteel tubeMaterials science

Owner:宏润建设集团上海有限公司

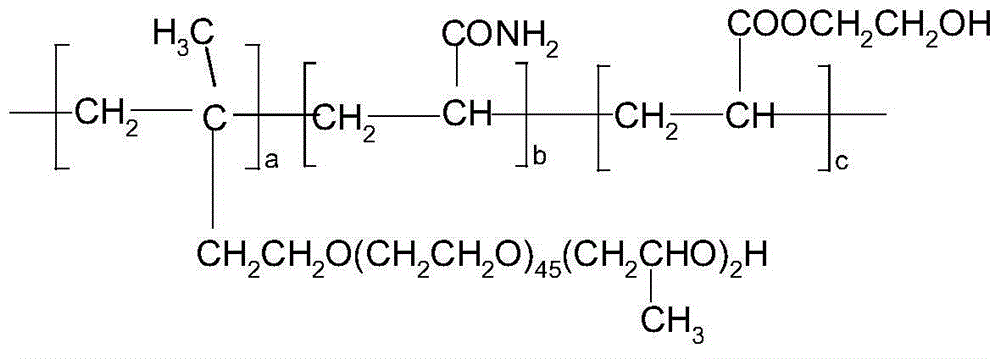

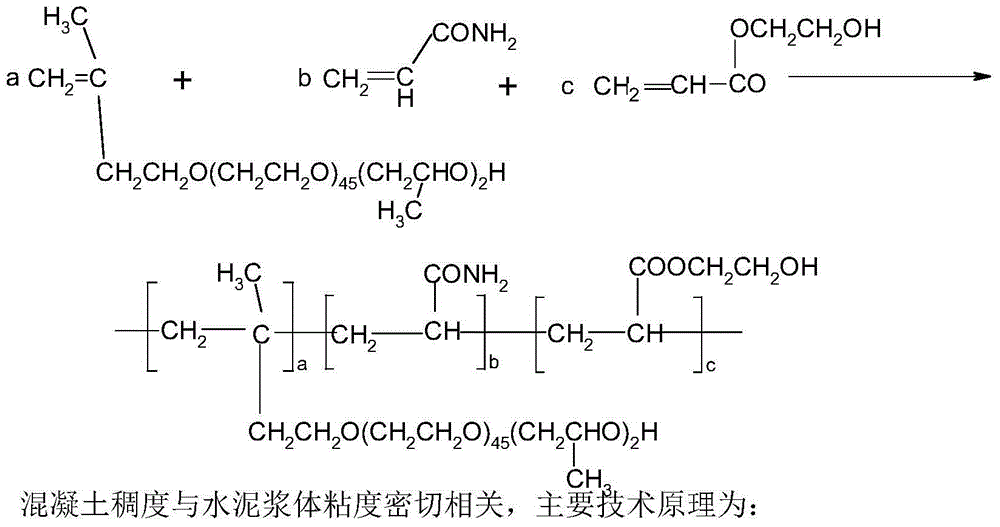

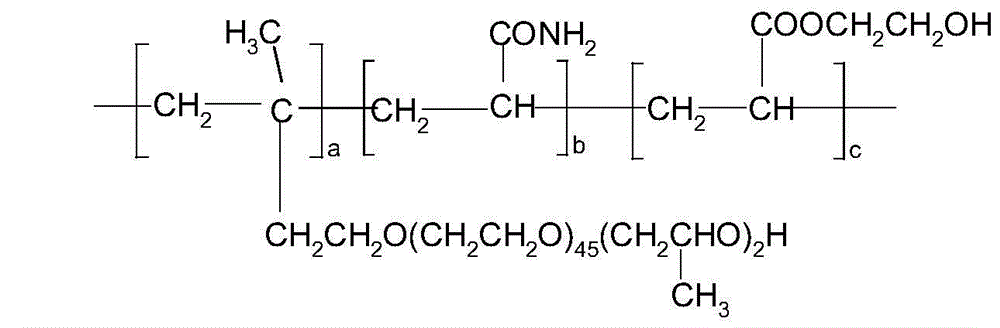

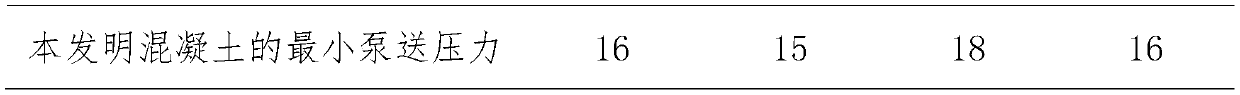

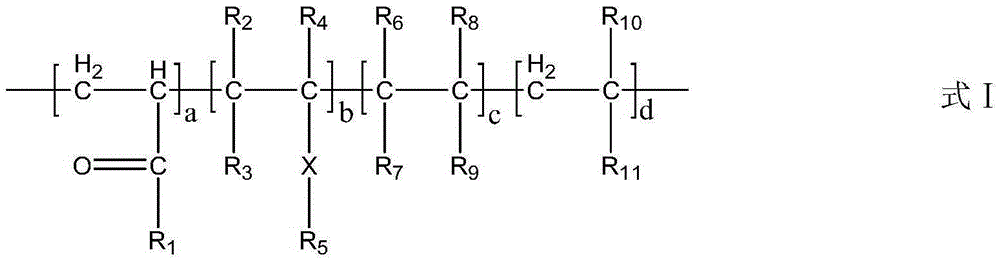

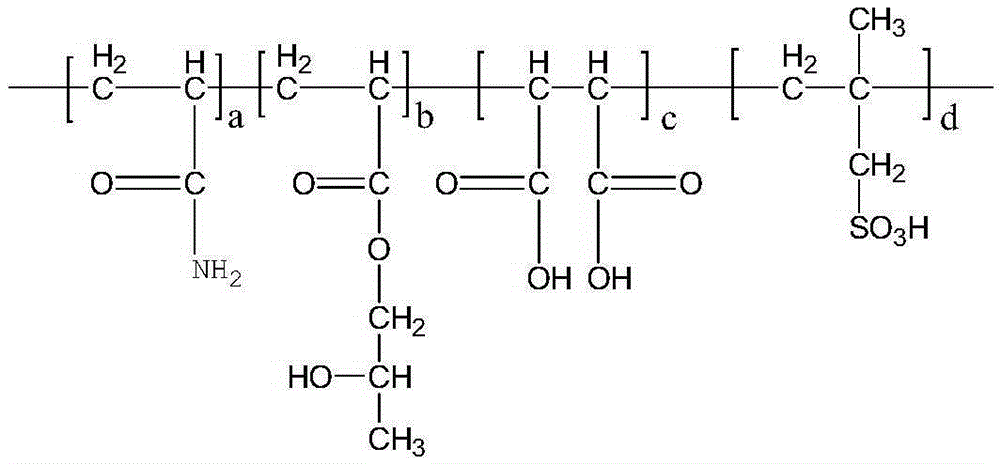

Epoxypropane embedded polyether modified concrete thickening agent and preparation method thereof

The invention discloses an epoxypropane embedded polyether modified concrete thickening agent and a preparation method thereof. The preparation method comprises the following steps: stirring and dissolving epoxypropane embedded polyether, heating, adding an oxidant, stirring, dripping a mixture of acrylamide and hydroxyethyl acrylate while dripping a mixture of a reducing agent and a chain transfer agent, further stirring after the dripping operation is completed, regulating the pH value, adding a proper amount of deionized water, thereby obtaining the thickening agent. According to the prepared thickening agent, 0.1 percent of the thickening agent is added into concrete, and when the water amount for unit volume concrete is increased by 10kg, the concrete is not subjected to dissociation and seepage, and the dissociation and seepage resistance of the concrete can be obviously improved. When 2-10 percent of the product disclosed by the invention is added into a commercial polycarboxylate superplasticizer, the concrete workability can be obviously improved, the water-retaining property of the concrete is improved, and the problems such as dissociation, seepage and concrete encasing property are solved.

Owner:WUHAN UNIV OF TECH

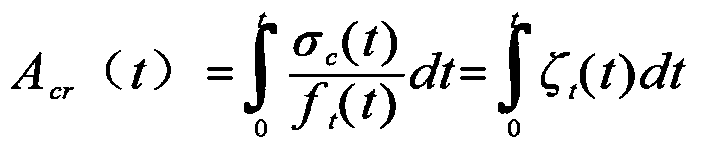

Anti-radiation concrete and preparation method thereof

The invention belongs to the technical field of preparation of building materials, and concretely relates to an anti-radiation concrete and a preparation method thereof. The preparation method comprises the following steps: mixing and crushing graphite and barite, carrying out sealed fermentation on the obtained crushed mixture and biogas slurry to obtain a fermentation product, centrifuging and sterilizing the fermentation product to obtain a modified filler, mixing and heating methylallyl alcohol, boric acid and anhydrous ether, reacting the obtained heated mixture with a sulfuric acid solution to obtain a product, distilling the product to obtain a methyallyl borate mixture, reacting and distilling the methyallyl borate mixture, N-hydroxymethylacrylamide and toluene to obtain an anti-segregation agent, mixing cement, the modified filler and fibers, stirring the obtained mixture, the anti-segregation agent, a water reducer and water, injecting the finally obtained mixture into a die, carrying out vibration molding, and demolding and curing the molded mixture to obtain the anti-radiation concrete. The anti-radiation concrete obtained in the invention has the advantages of good anti-segregation and anti-radiation performances, effective improvement of the construction performances of concrete, high mechanical strength, and effective prolongation of the service life of concrete buildings.

Owner:湖州三中混凝土有限公司

Self-compaction composite concrete, preparation method therefor and concrete wall bricks

ActiveCN109279861AImprove liquidityIncreased strength lossCeramic shaping apparatusBuilding componentsBrickSlag

The invention relates to the technical field of building materials and particularly relates to self-compaction composite concrete, a preparation method therefor and concrete wall bricks. According tothe self-compaction composite concrete, Portland cement and thiophosphate cement are compounded as a cement ingredient, and thiophosphate cement is creatively selected; specific furnace slag, steel slag and ferrum tailings are compounded as an aggregate ingredient; cellulose ether and beta-cyclodextrin are combined as a dispersant; the cement ingredient, the aggregate ingredient and an auxiliary ingredient are divided into three ingredients and are separately packaged to form the self-compaction composite concrete; and in a process of casting the concrete wall bricks by forming slurry by usingthe concrete disclosed by the invention, the ingredients can be added and mixed in groups according to characteristics of each ingredient. The fluidity, filling property, segregation resistance and strength of the self-compaction composite concrete disclosed by the invention are improved.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

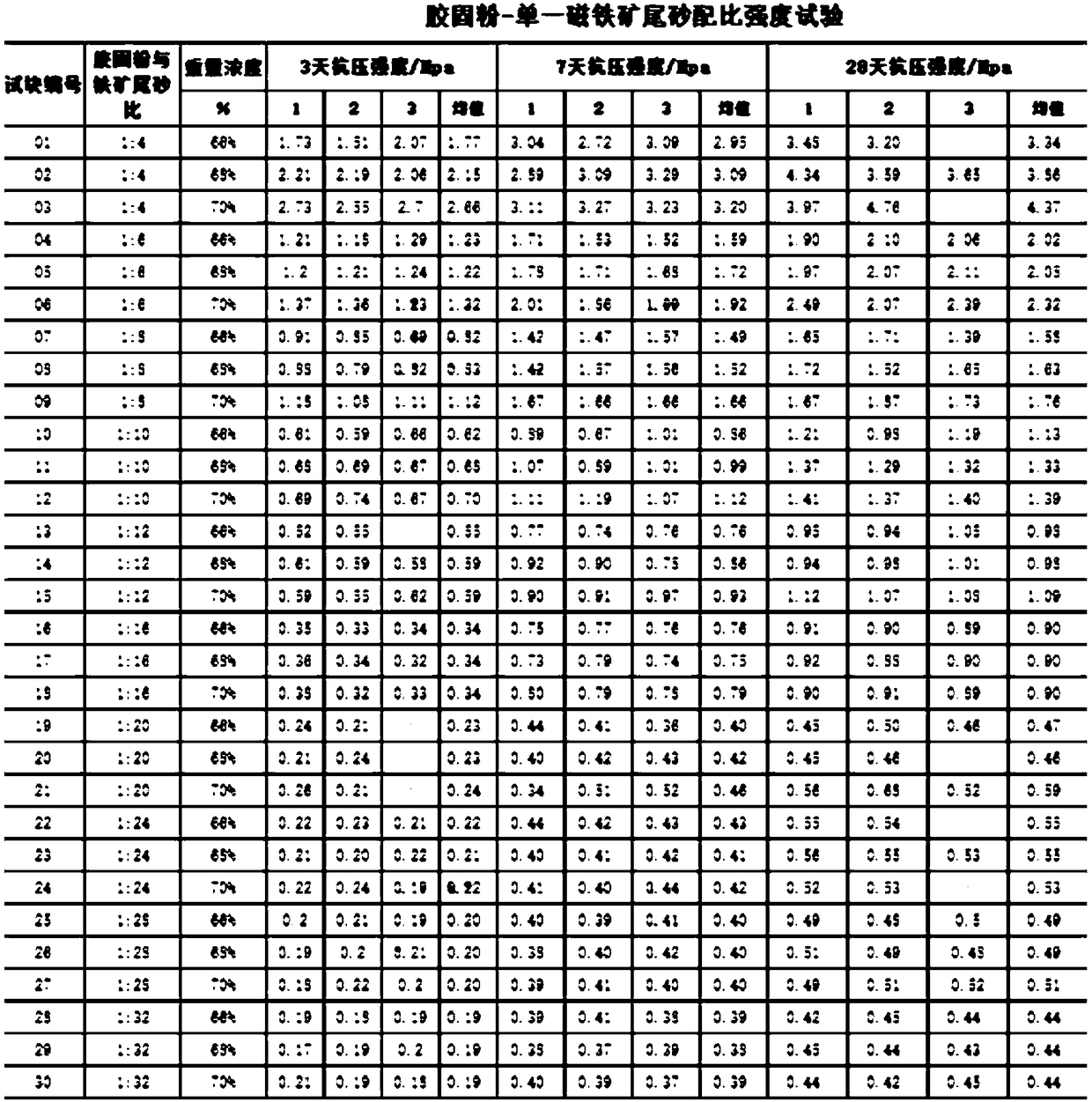

Formula and application method for filling cementing material

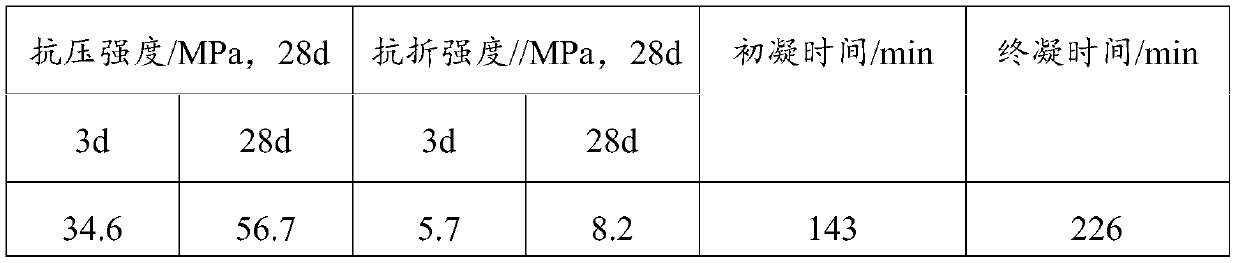

InactiveCN108147684AStrong cementing abilityHigh filling strengthCement productionSlagFlexural strength

The invention discloses a formula and application method for a filling cementing material. The formula for the filling cementing material adopts slag and other active materials as raw materials, and main chemical components of the formula comprise SiO2, Al2O3, Fe2O3, CaO, MgO and SO3; the formula comprises the following specific raw materials of: 80.2% of the slag, 15.01% of cement clinker, 3.63%of gypsum, 0.65% of solid sodium silicate and 0.51% of an early strength agent. The formula has the following advantages that the filling strength is high, the mortar strength of the cementing material is high, and after tests are conducted, flexural strength, compressive strength and the like can reach standards of P.O 42.5 ordinary cement; it is shown by actual application results that the cementing material has strong cementation ability for fine-grained tailings, and when the same cement-sand ratio and filling concentration are adopted, the filling strength of the filling cementing material is 40-60% higher than that of ordinary cement.

Owner:临沂会宝岭铁矿有限公司

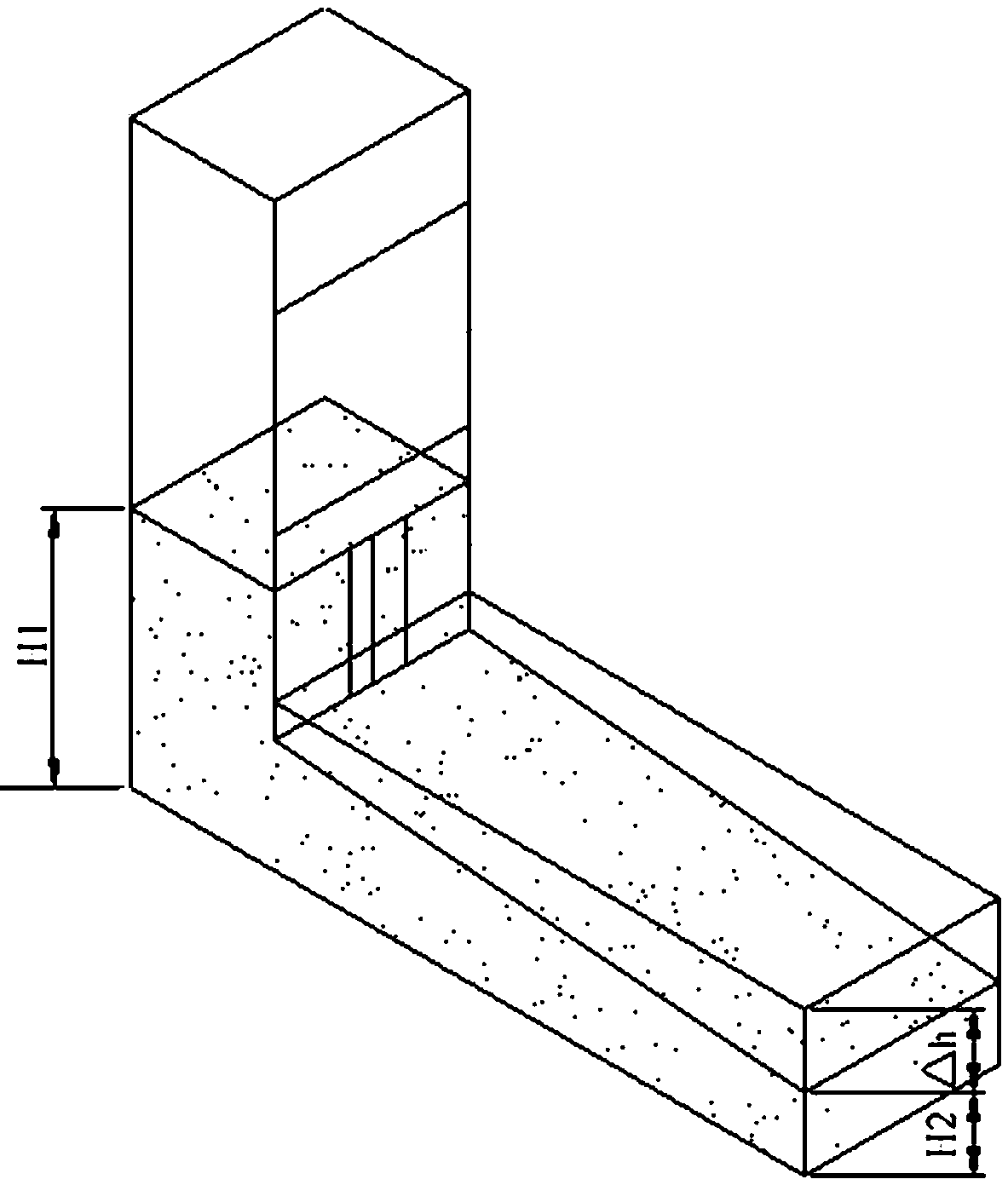

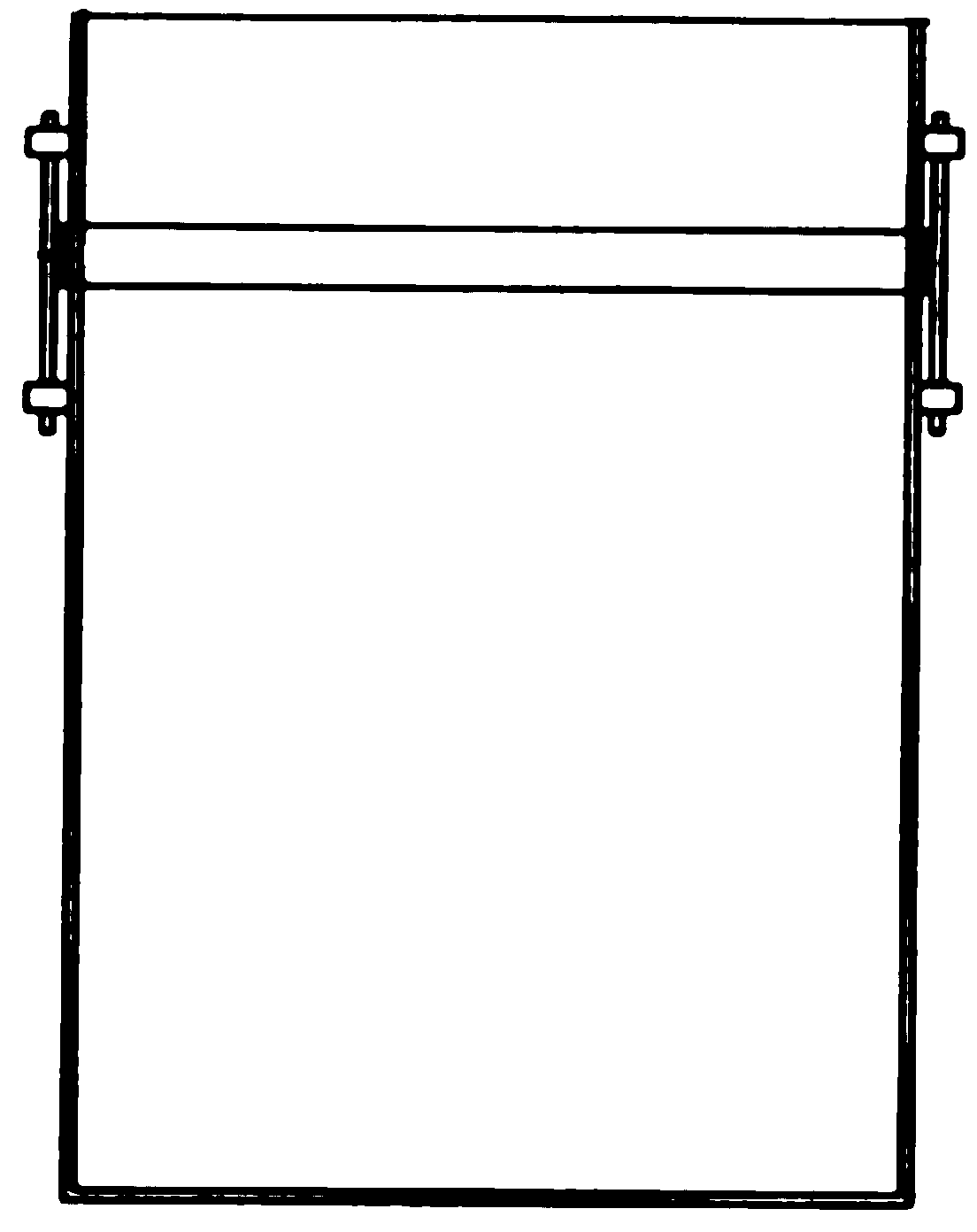

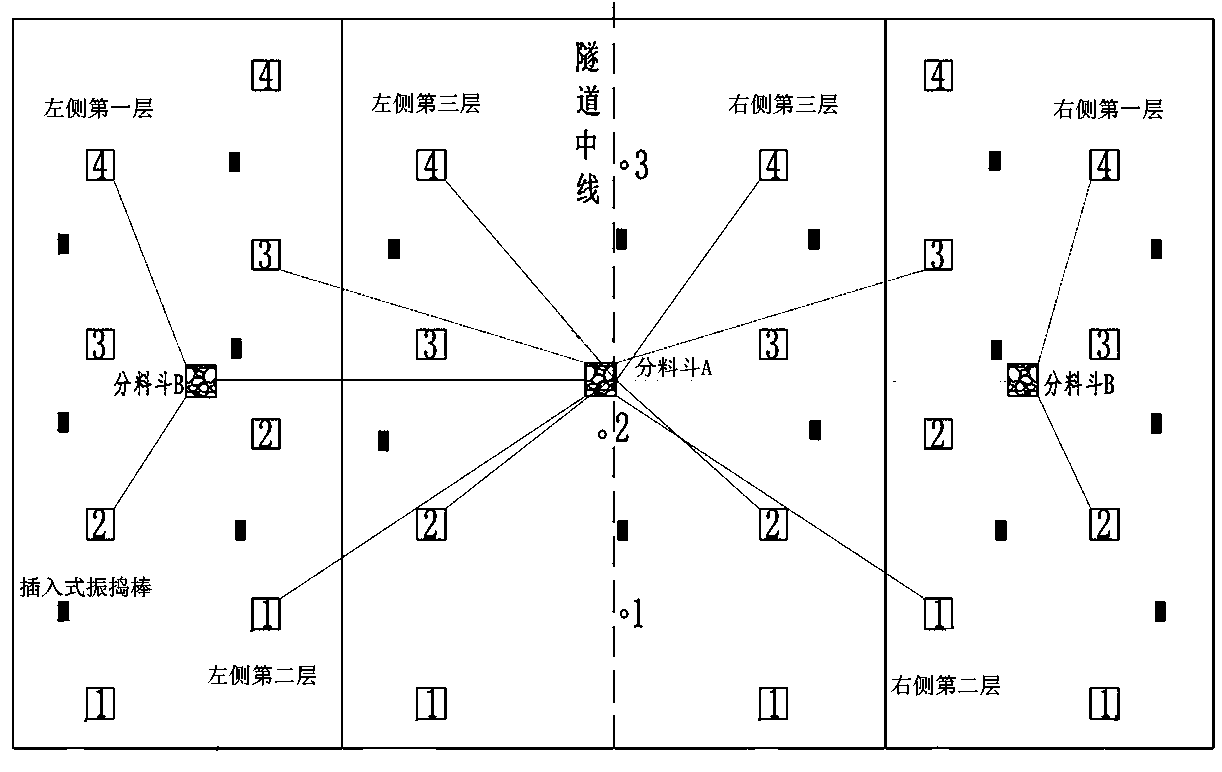

Construction method for stratified symmetric synchronous pouring of second lining concrete of tunnel

InactiveCN108868830AImprove cohesionImprove liquidityUnderground chambersTunnel liningMaterials science

The invention belongs to the field of the mix ratio design and construction of second lining concrete of tunnels and specifically relates to a construction method for stratified symmetric synchronouspouring of second lining concrete of a tunnel. The concrete mix ratio of the method is based on the principle of a low water-to-binder ratio and a large mixing number of mineral admixtures. A polycarboxylate water reducing agent is added to reduce the water-to-binder ratio, and the concrete viscosity is improved through the low water-to-binder ratio to ensure that concrete mixtures are not easilyseparated and stratified under high fluidity working conditions; II-level fly ash is adopted as the mineral admixtures, and under the combined action of a morphological effect of the fly ash and a filling effect of micro-aggregates, a large mixing amount of fly ash is added, so that the fluidity and compaction effect of the concrete are both greatly improved, and the production cost of the concrete is reduced at the same time. A stratified symmetric synchronous pouring distribution tool is adopted, and a multi-window, symmetric, stratified and staggered distribution mode is adopted, so that the uniformity of concrete pouring distribution is improved; the process of cooperatively using an inserted vibrating bar and an attached vibrator is adopted, so that the appearance and quality of the concrete are ensured.

Owner:CHINA RAILWAY SIXTH GRP TAIYUAN RAILWAY CONSTR +3

Self-compacting concrete for pumping

The invention discloses self-compacting concrete for pumping, which comprises a pumping base concrete component and a mineral admixture mixed with the pumping base concrete, the mineral admixture accounts for 3-10% of the total weight, the mineral admixture comprises a mixture of oxide at least containing Si, Al, Fe, Ca and S and inorganic acid salt, and the mineral admixture also comprises an additive accounting for not more than 0.5% of the total weight. The mineral admixture is combined into different oxides or inorganic acid salts, different activities, surface effects, filling effects orvolcanic ash effects are achieved, and when the mineral admixture is mixed into the self-compacting concrete, the slump, work-ability, cohesiveness, segregation resistance and later strength of the self-compacting concrete can be improved; the concrete has better flow-ability, compactness and homogeneity, and the production requirement of a solid square pile is met; the curing speed and the strength increasing speed of the concrete are increased, the curing time of the concrete is shortened, and the effect of rapid curing in the autoclaving-free process is achieved.

Owner:周兆弟

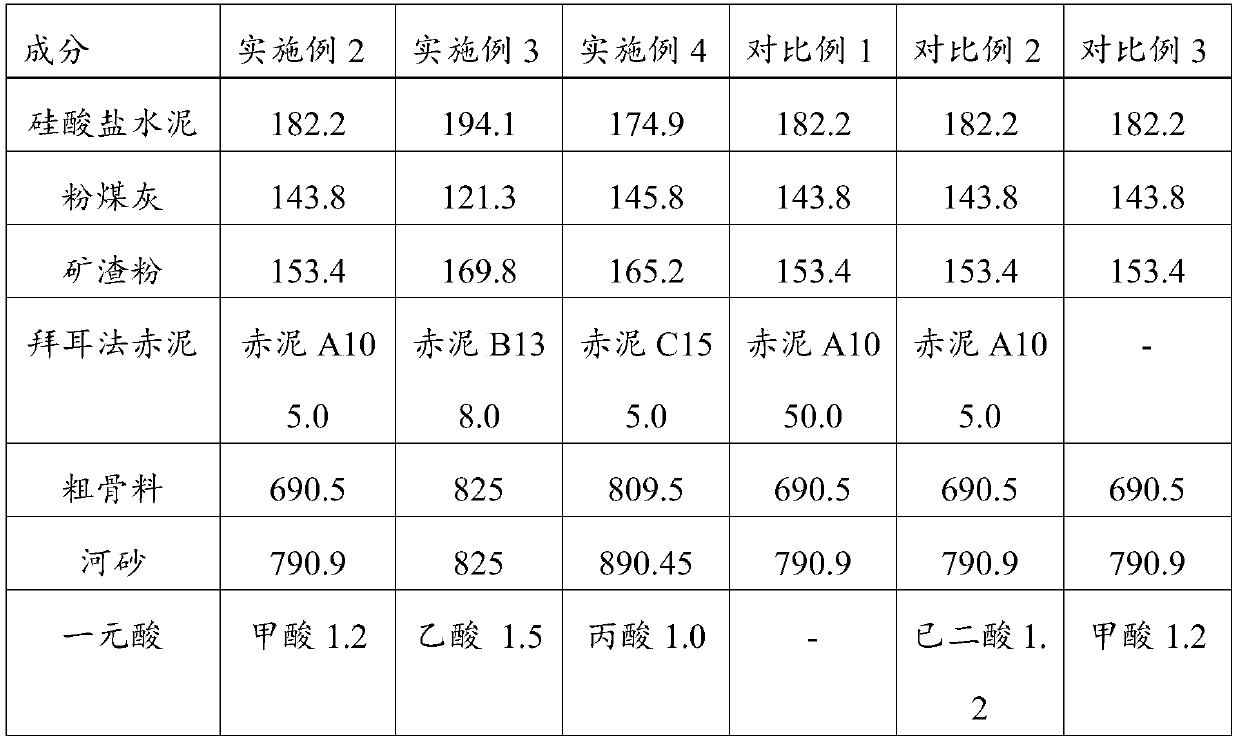

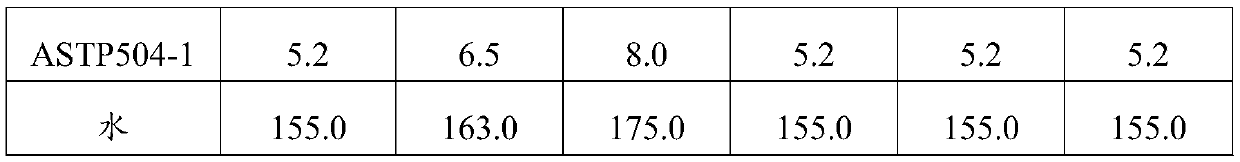

Self-compacting cement concrete mixed with Bayer process red mud, and preparation method thereof

The invention relates to the technical field of concrete materials, and concretely relates to a self-compacting cement concrete mixed with Bayer process red mud, and a preparation method thereof. Theself-compacting concrete comprises, by weight, 100-155 parts of thermal alteration treated Bayer process red mud, 375-546 parts of a cementing material, 1450-1700 parts of aggregates, 5-8 parts of a polycarboxylic water reducer and 150-175 parts of water. Porcelain stone tailings are adopted to carry out thermal alteration treatment on the volcanic ash-free Bayer process red mud, so the effect ofincreasing the strength of the concrete and improving the shrinkage performance of the concrete by adding a small amount of the thermal alteration treated Bayer process red mud to the concrete is achieved; and the self-compacting concrete has the advantages of good filling property, good fluidity, high segregation resistance and high gap-passing ability, and has significant progress compared withconcretes in the prior art.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

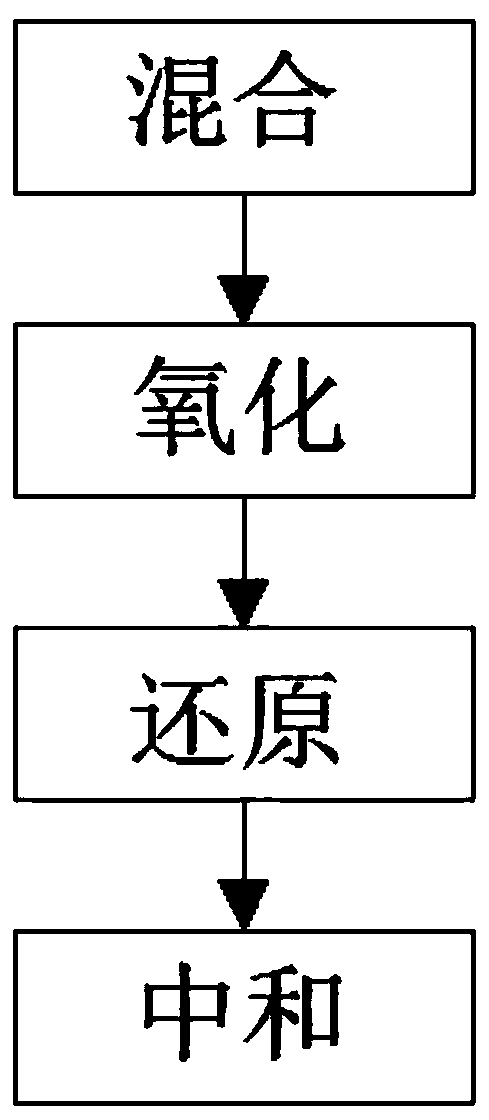

Anti-segregation agent for concrete and preparation method thereof

The invention discloses an anti-segregation agent for concrete, which belongs to the technical field of concrete additives. The anti-segregation agent for the concrete is prepared from the following components: 5 to 15 parts of coal ash, 5 to 15 parts of mineral powder, 1 to 2 parts of steel fibers, 1 to 2 parts of polyethylene glycol, 20 to 30 parts of polyhydroxy acid water reducing agent, 0.8 to 1.2 parts of tackifier, 0.5 to 0.9 part of coagulation accelerator, 200 to 300 parts of deionized water, a plurality of parts of liquid caustic soda, 5 to 10 parts of organic silicon monomers, 3 to 5 parts of oxidant and 1 to 3 parts of reduction agent. By adding the coal ash, the mineral powder and the steel fibers, not only can the compression resistance of the concrete be improved, but also the working performance and layering degree of the concrete can be effectively improved, and the anti-segregation performance is improved; and the PAM is used as the tackifier, and the PAM has a lot of -NH2, so that the tackifier has good hydrophilia, the concrete has characteristics of hydrophilia, water retention, thickening, resistance reduction, tackifying and the like. The anti-segregation agent for the concrete is wide in source of raw materials, low in cost, environment-friendly and simple in operation.

Owner:梁平县吉龙混凝土有限公司

High-performance concrete prepared from recycled slurry

The invention discloses high-performance concrete prepared from recycled slurry water. The concrete comprises the following components in parts by weight: 135-225 parts of cement, 8-12 parts of micropowder, 80-100 parts of coal ash, 750-900 parts of gravels, 500-750 parts of machine-made sand, 120-150 parts of water, 70-120 parts of slurry and 8-12 parts of an additive. The additive is prepared from the following raw materials in percentage by mass: 76% of a slump retaining agent, 6% of an expanding agent, 8% of a retarder and 10% of deionized water. By adjusting the ratio, the bleeding rateof the concrete is reduced. Meanwhile, the bleeding rate is reduced, the viscosity of the concrete is improved, and the segregation resistance is improved.

Owner:南宁市嘉旺水泥制品有限公司

Anti-segregation agent for concrete and preparation method thereof

ActiveCN103539889BDoes not affect strength developmentSolve the problem of segregated bleeding(Hydroxyethyl)methacrylateChemistry

Owner:中建西部建设西南有限公司

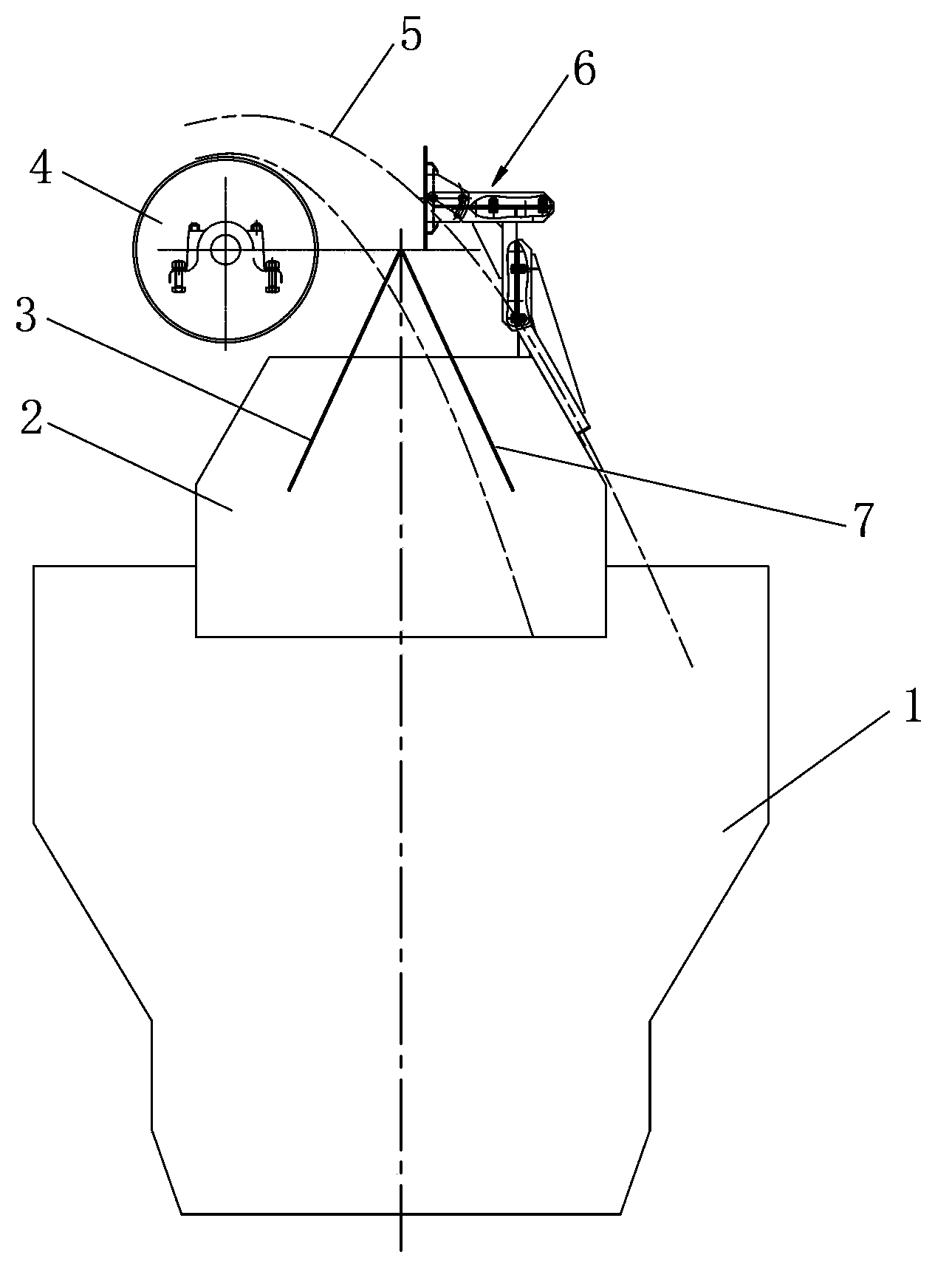

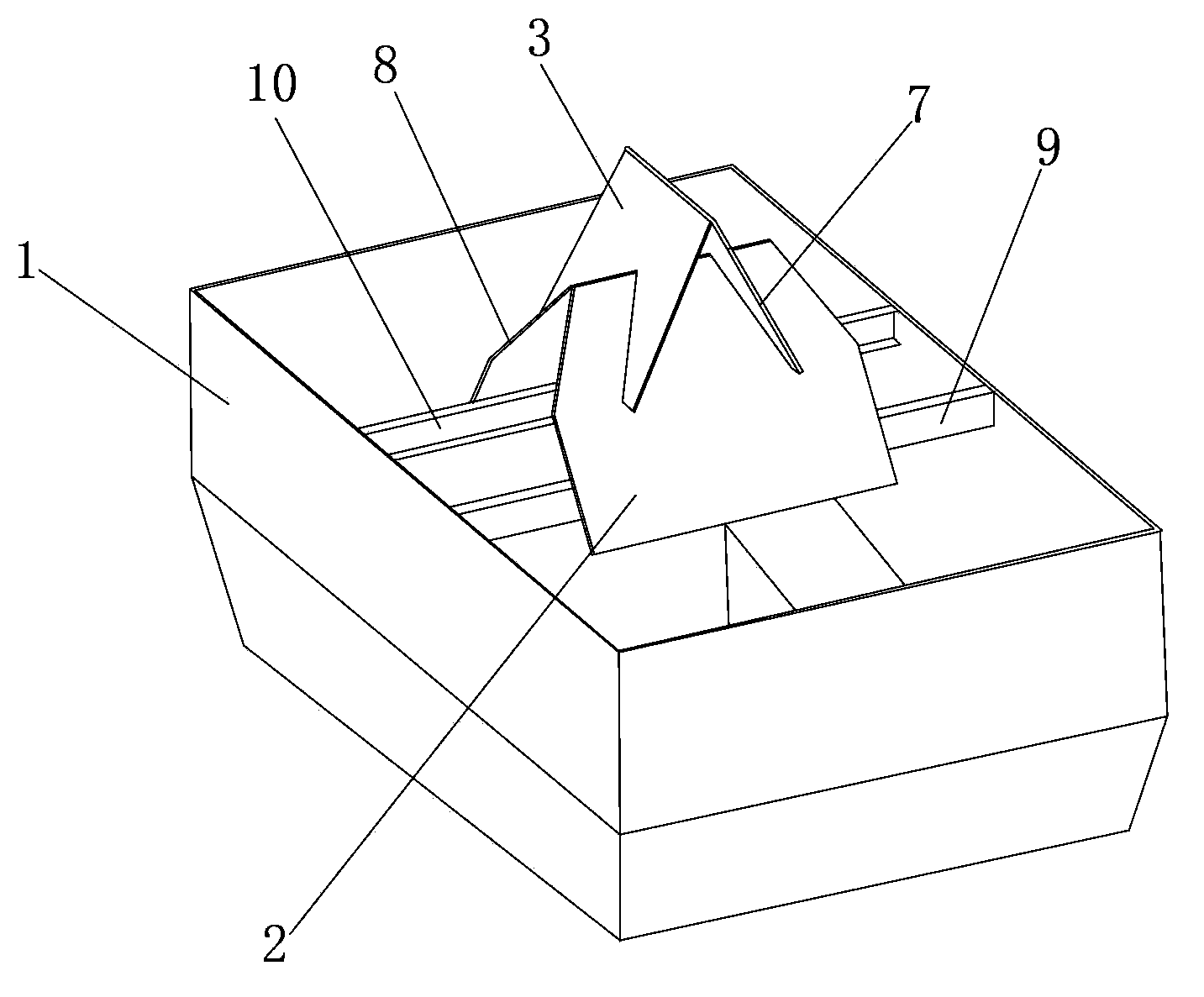

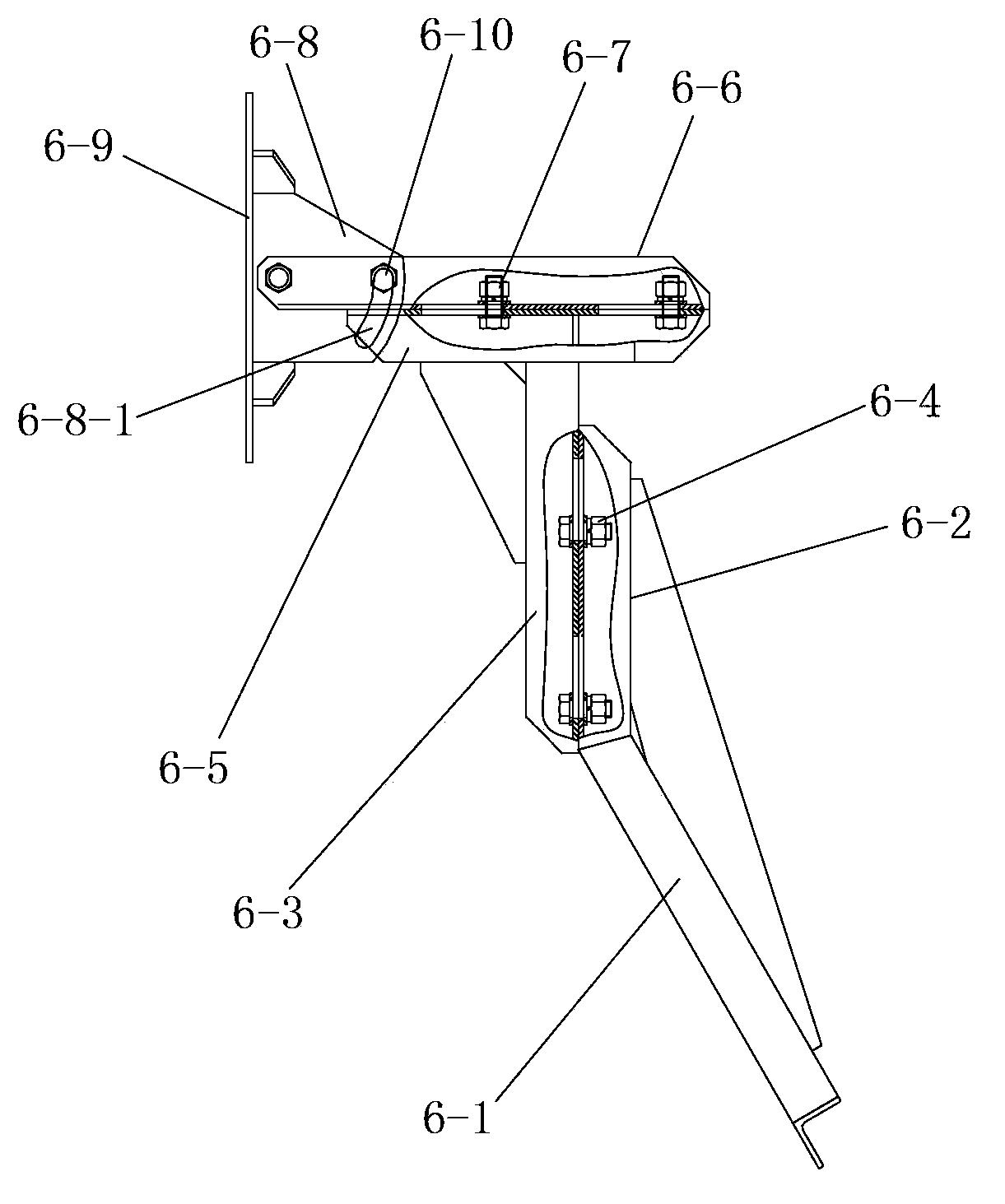

Distributing device for finished product bin

InactiveCN103803312ASimple structureNovel and reasonable designLoading/unloadingEngineeringMechanical engineering

Owner:SHAANXI JOINTARK MASCH GRP CO LTD

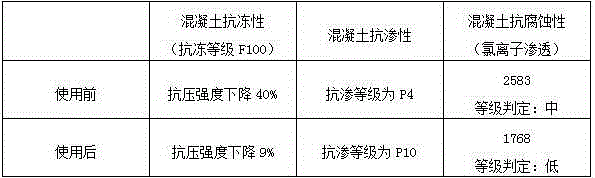

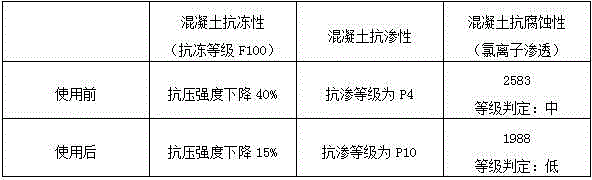

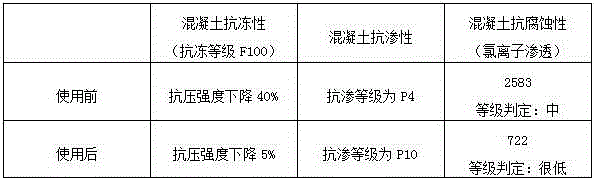

Concrete admixture for roads

InactiveCN105585275AHigh water reduction rateImprove anti-segregation performanceSodium BentoniteAnti freezing

The invention discloses a concrete admixture for roads. The concrete admixture comprises components in parts by weight as follows: 70-80 parts of mineral waste, 10-15 parts of bentonite, 8-15 parts of silica powder, 8-10 parts of stearic acid, 2-5 parts of methyl cellulose, 4-7 parts of polyacrylamide and 8-15 parts of sodium dodecyl sulfate. The concrete admixture for the roads has a good effect on improving the anti-freezing capability, the anti-permeability capability and the corrosion resisting capability of concrete and prolonging the construction period and further has better water reducing rate and anti-segregation performance.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

No. 0 colloidal crystal special for shrinkage-free large flow state cement mortar and cement mortar

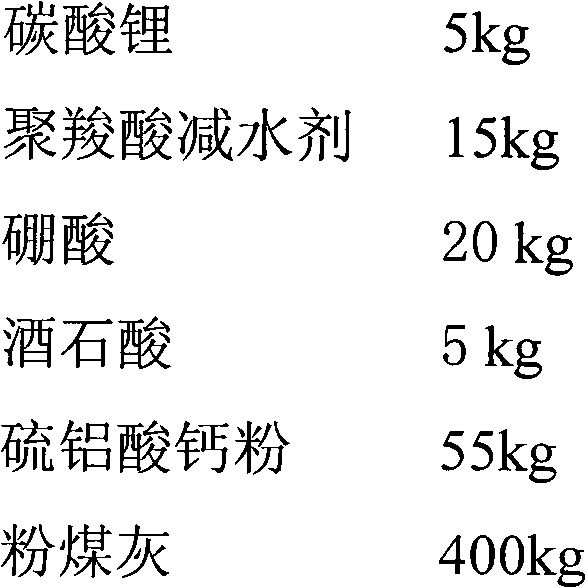

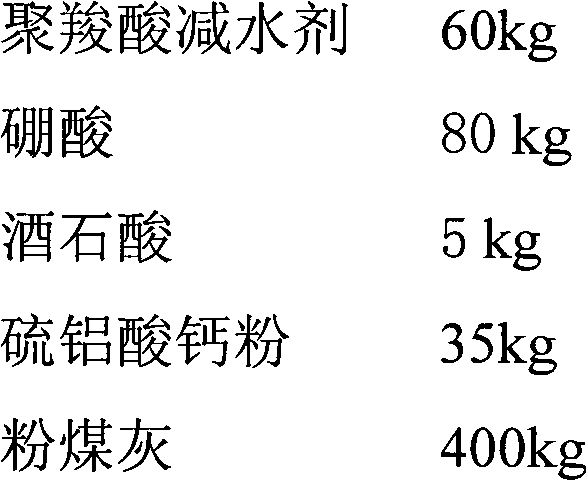

The invention discloses a No. 0 colloidal crystal special for shrinkage-free large flow state cement mortar. The colloidal crystal comprises 1 to 4 weight parts of lithium carbonate, 3 to 10 weight parts of polycarboxylic water reducing agent, 4 to 14 weight parts of boric acid, 0.5 to 1 weight part of tartaric acid, 6 to 11 weight parts of calcium sulfoaluminate powder and 67 to 80 weight parts of fly ash. A preparation method for the colloidal crystal comprises the following steps of: (a), stirring; (b), packing; and (c), storing. By adopting a unique proportion, the early strength of the cement mortar is quickly promoted, and the promoting time is 1 to 3 hours; the cement mortar can adapt to special environments such as iron, chromium and the like; the compactness is improved, and pores are reduced; the cement mortar is good in flowability, low in slump degree, micro-expansive and shrinkage-free; and the final compressive strength of the cement mortar is improved from C40 to C55, the low-temperature construction performance of the cement mortar is improved, and the cement mortar can be normally constructed in an environment of 10-15 DEG C below zero.

Owner:BEIJING HUAQIAN GROUTING MATERIAL CO LTD

Cement concrete additive for fast rehabilitating cement concrete road

The invention discloses a formula of a cement concrete additive for fast rehabilitating a cement concrete road. The formula comprises the following raw materials in parts by weight: 12-18 parts of bentonite, 20-23 parts of silicon powder, 0.5-2.5 parts of stearic acid, 2.5-6.5 parts of methylcellulose, 20-25 parts of inorganic matrix material, 13-17 parts of early strength agent, 22-28 parts of water reducing agent, 0.1-10.5 parts of thickening time control agent, 0.2-3.5 parts of corrosion inhibitor, 40-55 parts of slag, 22-27 parts of methacrylic acid, 13-19 parts of polyethylene glycol monoether acrylate monomer, 12-17 parts of sodium allysulfonate, 2.5-4.0 parts of polyether acrylate monomer, 21-24 parts of ferrous sulfate, 13-19 parts of industrial salt, 1.5-3.5 parts of coal ash, 2.5-4.0 parts of calcium carbonate powder, 3.5-5.5 parts of polyacrylamide and 2.0-3.5 parts of lauryl sodium sulfate. The formula of the cement concrete additive for fast rehabilitating the cement concrete road has the characters that cement concrete road maintenance operation time can be greatly shortened, hardening time and solidification time is adjustable, the applicable temperature range is wide, the admixture amount is low, and the like.

Owner:江苏兆佳建材科技有限公司

Low-alkali plant-growing concrete for protection and preparation method of low-alkali plant-growing concrete

ActiveCN114751693AImprove alkaline environmentEasy to operateSolid waste managementEpoxyOXALIC ACID DIHYDRATE

The invention discloses low-alkali plant-growing concrete for protection and a preparation method of the low-alkali plant-growing concrete. Portland cement, broken stone, fly ash, silica fume, slag, rice husk charcoal, water, a PCA polycarboxylate-type high-performance water reducer, amino-modified graphene oxide-carboxymethyl cellulose and amino acid modified molybdenum disulfide / epoxy resin are taken and evenly stirred, concrete is obtained and cured, an oxalic acid solution is sprayed to the surface of a concrete test piece, alkali reduction treatment is conducted, and the concrete is obtained. Therefore, the low-alkali vegetation concrete for protection is prepared. By controlling the particle size of the added gravel and the volume density of each component, the concrete which has excellent compressive property, water permeability and low alkali and is suitable for plant growth is obtained.

Owner:盐城市福奇混凝土有限公司

Additive capable of improving adsorption capacity of concrete to PM2.5, and preparation method and application thereof

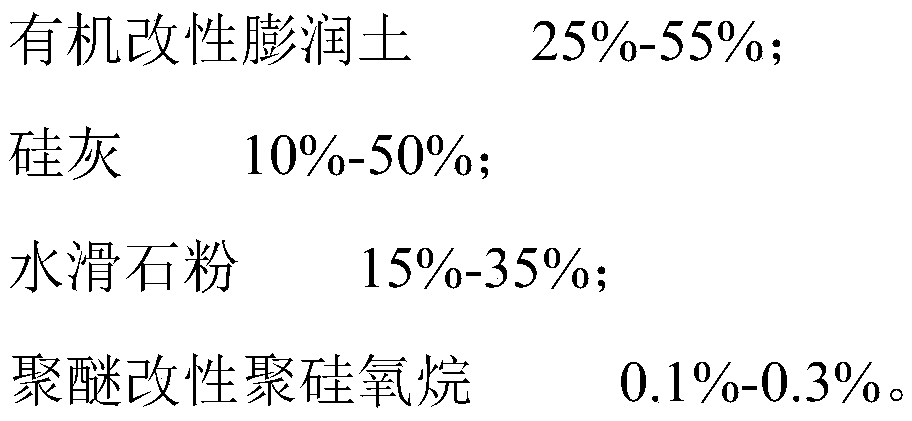

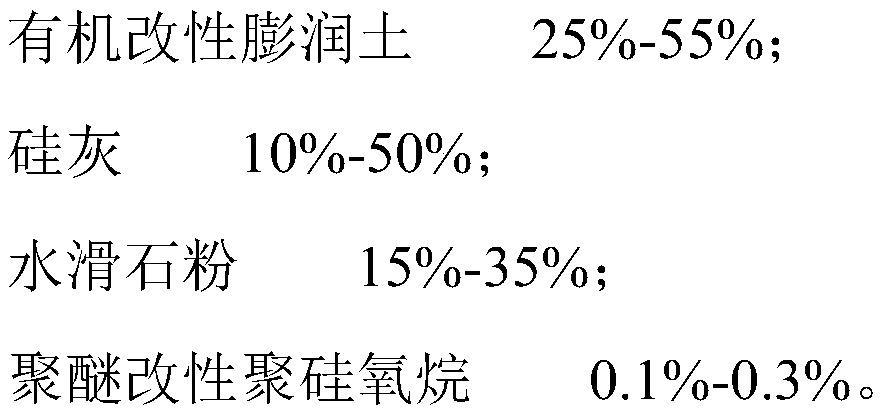

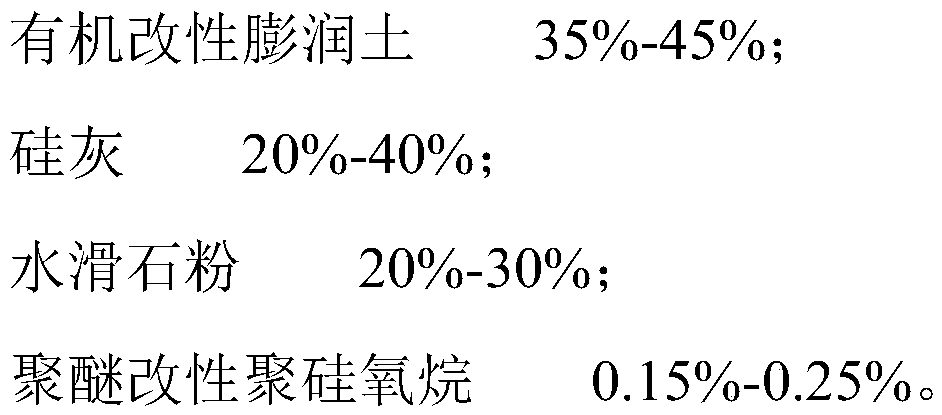

ActiveCN110423044AImprove the ability to absorb PM2.5Compensation for strength lossInorganic saltsHydrotalcite

The invention relates to an additive capable of improving the adsorption capacity of concrete to PM2.5, and a preparation method and an application thereof. The additive is prepared from the followingcomponents in percentages by mass: 25% to 55% of organic modified bentonite, 10% to 50% of silica fume, 15% to 35% of hydrotalcite powder and 0.1% to 0.3% of polyether modified polysiloxane. The preparation method provided by the invention comprises the following steps: uniformly mixing the above-mentioned raw materials, then placing an obtained mixture into a grinding machine, and carrying out grinding until the specific surface area of a powder reaches 400 m2 / kg or more so as to obtain the additive. When the additive obtained by using the preparation method provided by the invention is usedin concrete, the addition amount of the additive accounts for 5% to 20% of the total mass of a concrete cementing material. The additive provided by the invention adopts an inorganic salt mineral asa main raw material, can improve the adsorption capacity of the concrete to the PM2.5 when being applied in the concrete, can compensate the strength loss of the concrete through hydration of mineralcomponents in the additive, prolongs the hydration time of the concrete, and extends the adsorption effectiveness of the concrete.

Owner:CHINA BUILDING MATERIALS ACAD

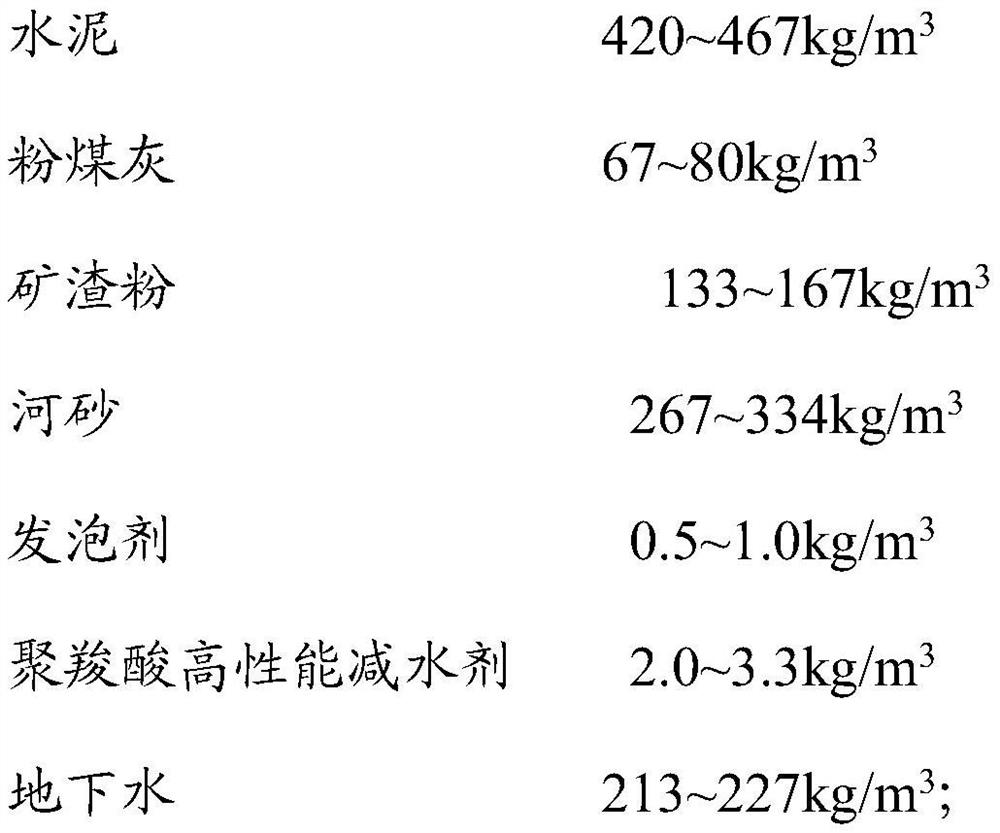

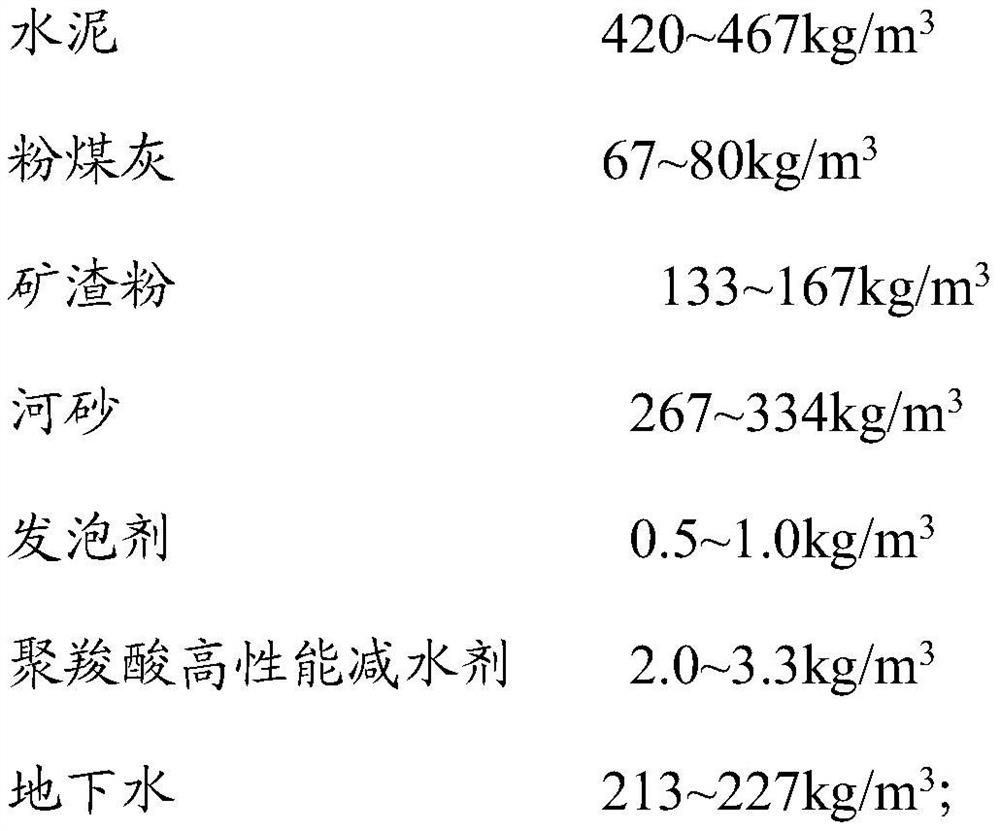

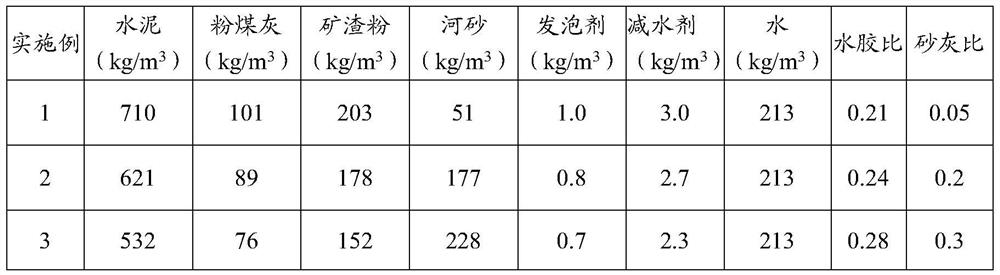

Foamed concrete for bridge deck pavement

ActiveCN112456921AHigh resistance to segregationGood foaming uniformityCeramicwareRiver sandStructural engineering

The invention discloses foamed concrete for bridge deck pavement. The foamed concrete is prepared from the following raw materials in proportion: 420-467 kg / m <3> of cement; 67-80 kg / m <3> of fly ash;133-167 kg / m <3> of slag powder; 267-334 kg / m <3> of river sand; 0.5-1.0 kg / m <3> of a foaming agent; 2.0-3.3 kg / m <3> of a polycarboxylic acid high-performance water reducing agent; and 213 to 227 kg / m <3> of underground water. The specification model of the foaming agent is an F-800 type efficient polymer cement foaming agent. The foamed concrete has good workability, segregation resistance, foaming uniformity and volume stability, can guarantee rapid completion of foamed concrete filling construction of a bridge deck; the strength grade of the foamed concrete can reach C5.0; the expansiondegree of the foamed concrete can reach a good state; and the wet density of the foamed concrete is proper, and the strength of thefoamed concrete meets the design requirement.

Owner:中铁大桥局集团第六工程有限公司 +1

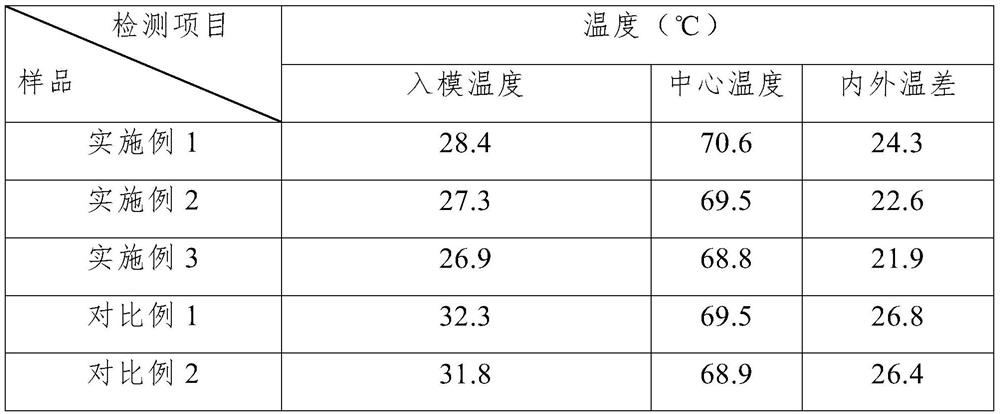

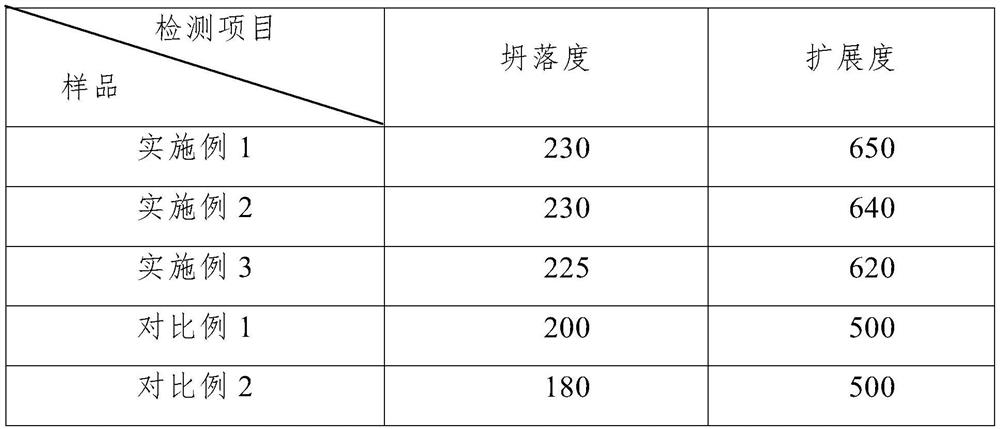

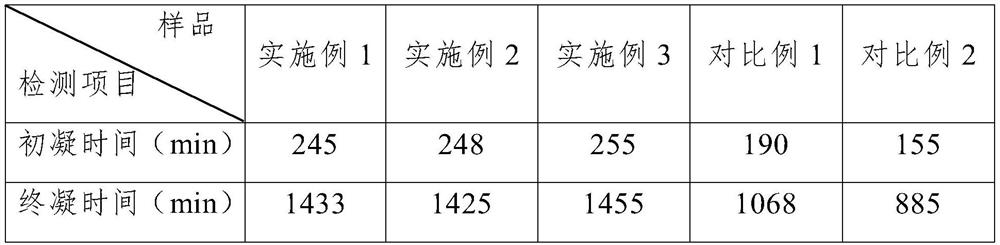

Low-temperature-difference mass concrete suitable for articulated chute construction and preparation process of low-temperature-difference mass concrete

The invention discloses low-temperature-difference mass concrete suitable for articulated chute construction. The low-temperature-difference mass concrete is prepared from the following components inparts by mass: 150-200 parts of cement, 260-320 parts of mineral powder, 80-120 parts of fly ash, 100-150 parts of water, 900-1200 parts of gravels, 700-800 parts of sand and 8-20 parts of a pumping agent. The invention further discloses a process for preparing the low-temperature-difference mass concrete suitable for articulated chute construction. The sand, gravels and water are evenly mixed, then the cement, the fly ash, the mineral powder and the pumping agent are added, and the mixture is evenly stirred. The fly ash and the mineral powder are adopted, the hydration heat of the cement is reduced, the temperature difference between the inside and the outside of the mass concrete is reduced, the segregation resistance of the mass concrete is improved, and the strength and the working performance of the mass concrete are ensured, so that shrinkage deformation and slurry-bone separation of the mass concrete are reduced, and the mass concrete is suitable for articulated chute construction; the preparation process is simple and easy to implement.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com