Distributing device for finished product bin

A finished product silo and distributor technology, applied in the field of distributors, can solve the problems of insignificant segregation phenomenon and low blanking height, and achieve the effects of low cost, high working reliability and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

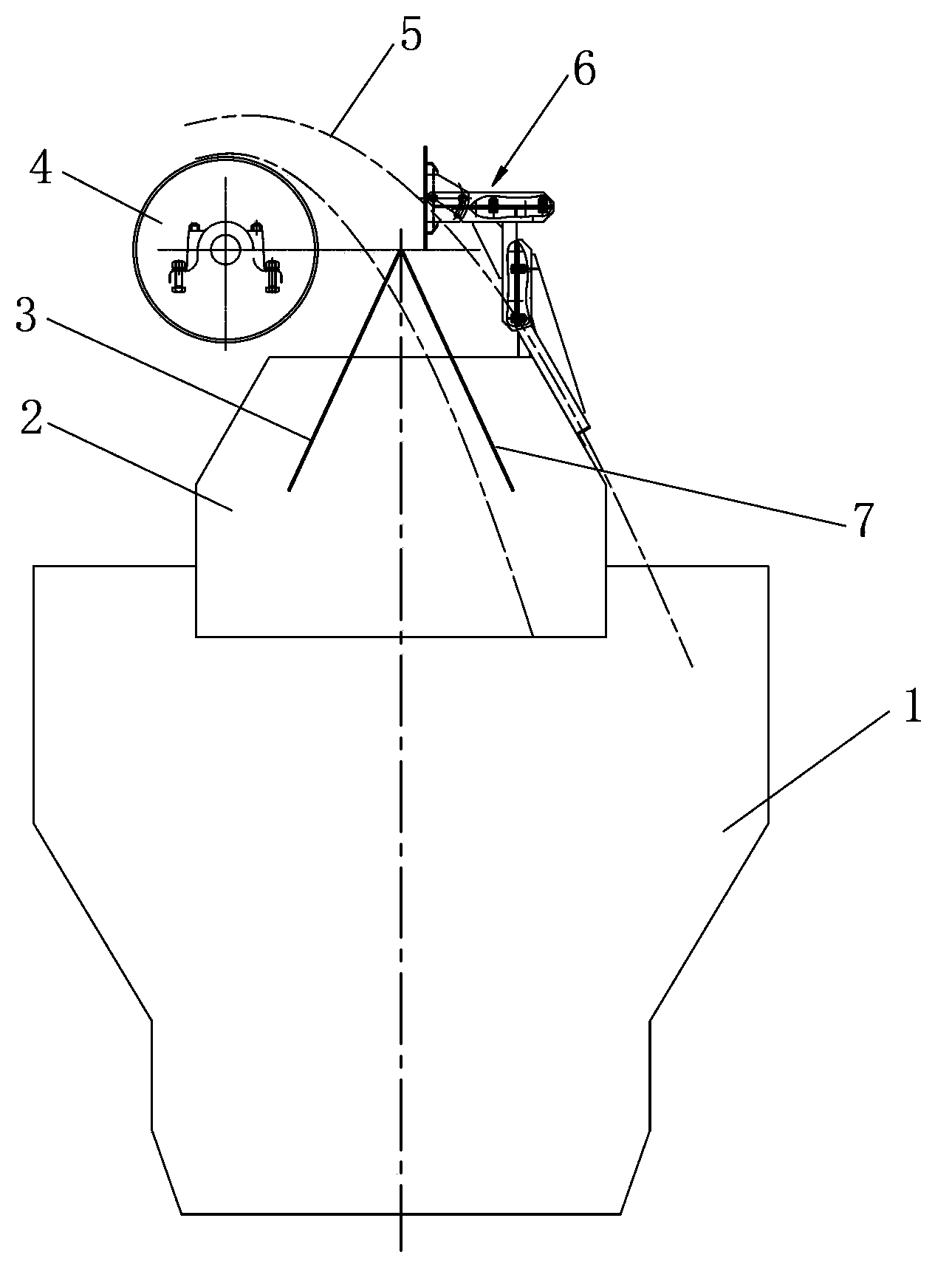

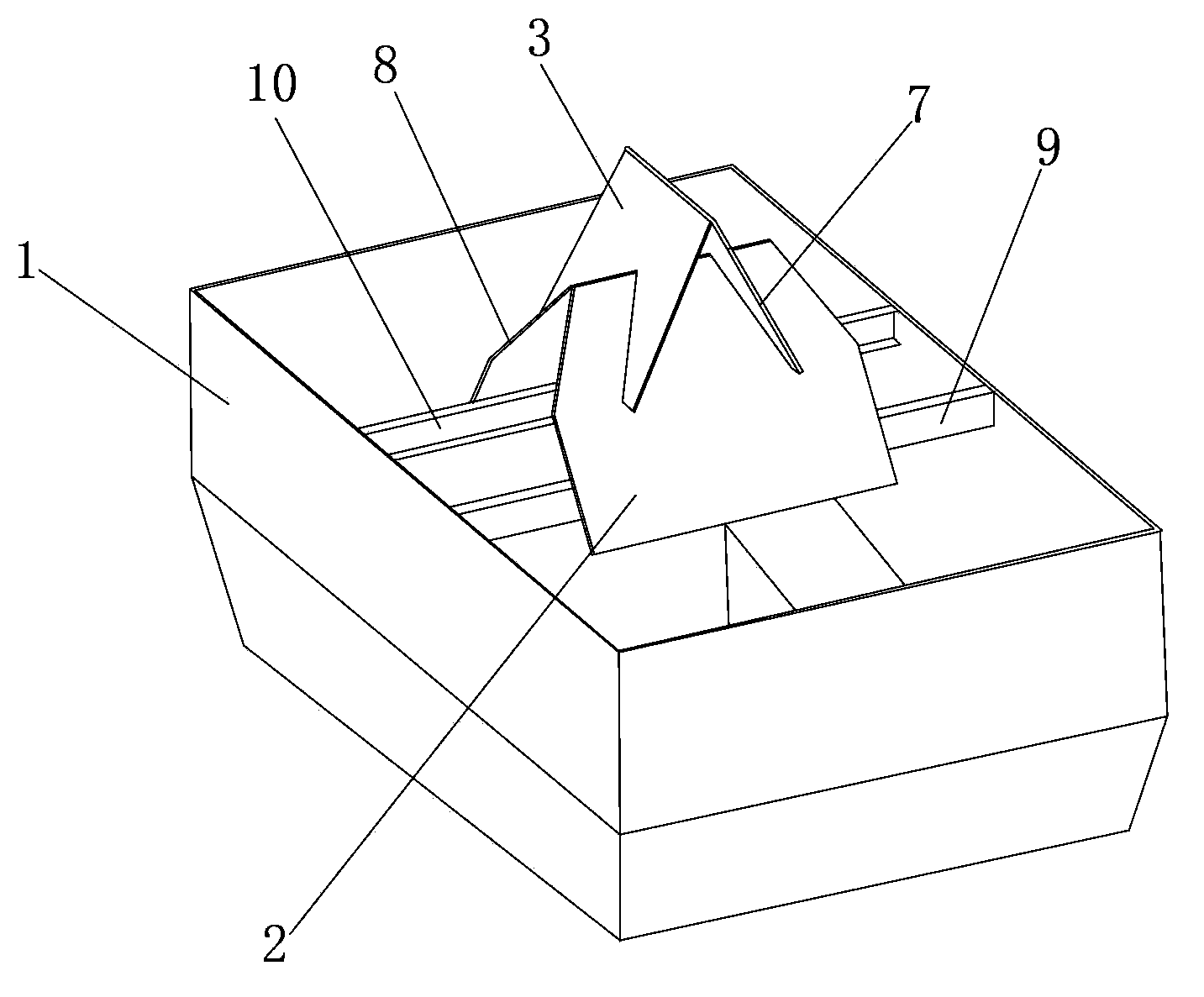

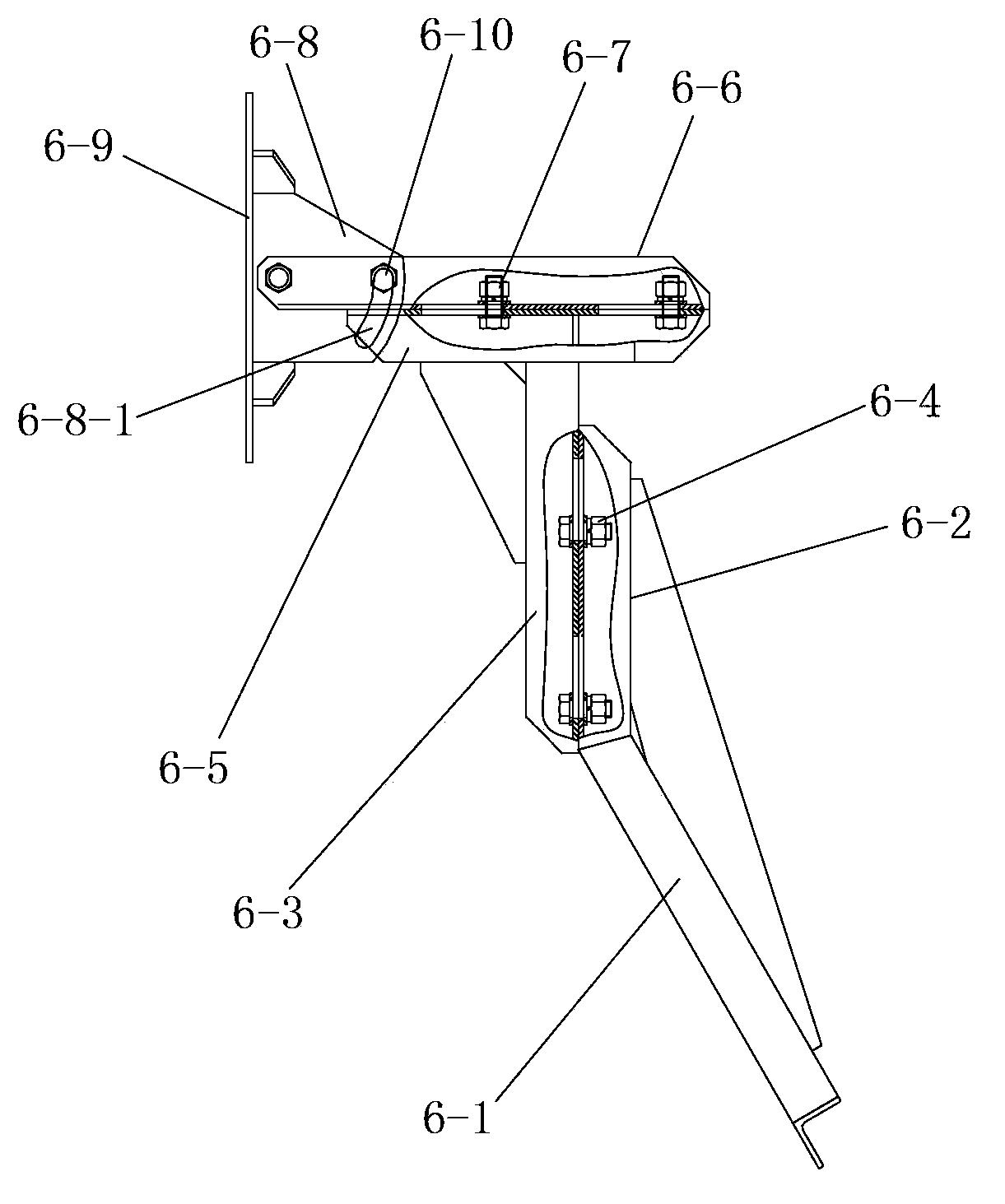

[0026] like figure 1 , figure 2 and image 3 The finished product silo distributor shown includes material guide plate 1 2, material guide plate 2 8, material guide plate 3 3 and Material guide plate four 7, described material guide plate one 2 and material guide plate two 8 are arranged along the length direction of feed bin 1, and described material guide plate three 3 and feed guide plate four 7 are arranged along feed bin 1 width direction, and described The first support rod 9 and the second support rod 10 parallel to each other are arranged in the feed bin 1, and the same side ends of the support rod one 9 and the second support rod 10 are connected with the side wall in the width direction of the feed bin 1. The other end of the same side of the rod one 9 and the support rod two 10 is connected with the other side wall in the width direction of the feed bin 1, and the material guide plate one 2 is clamped on the support rod one 9, and the material guide plate two 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com