Foamed concrete for bridge deck pavement

A foam concrete and bridge deck pavement technology, applied in the field of foam concrete, can solve the problems of unstable volume, large shrinkage, and poor load-bearing capacity, and achieve the effects of high segregation resistance, appropriate wet density, and low shrinkage

Active Publication Date: 2021-03-09

中铁大桥局集团第六工程有限公司 +1

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The invention provides a foam concrete for bridge deck pavement and a preparation method thereof to solve the problems of poor load-bearing capacity, large later shrinkage and unstable volume of the existing foam concrete

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-7

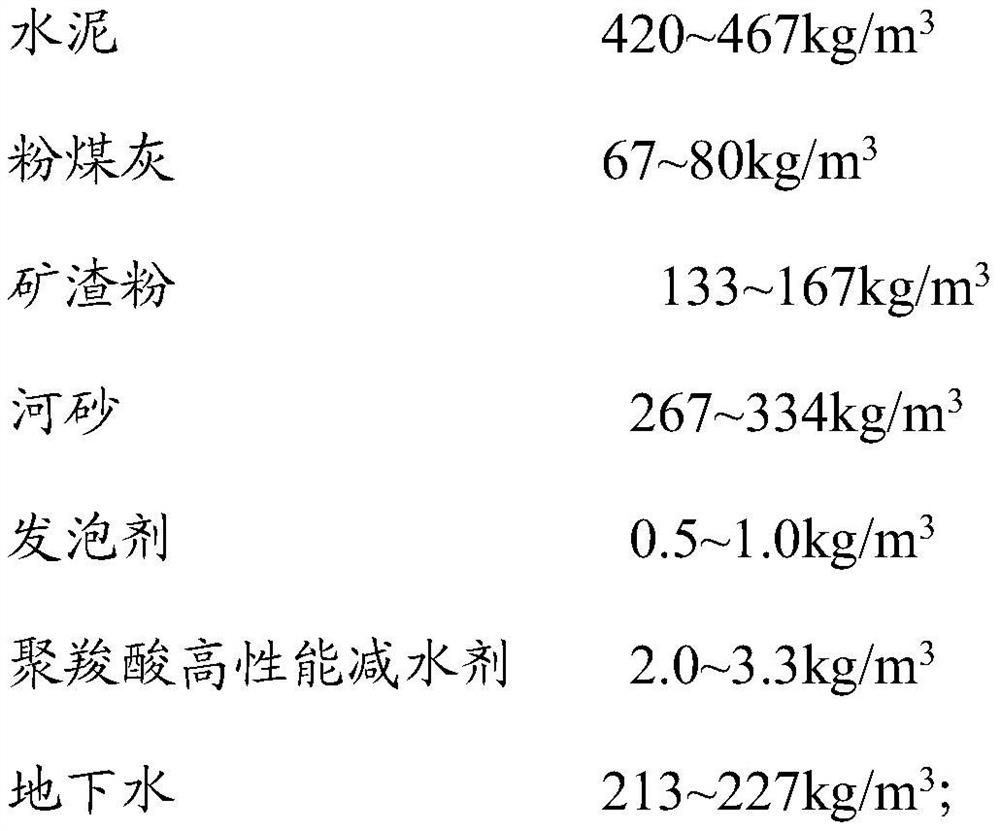

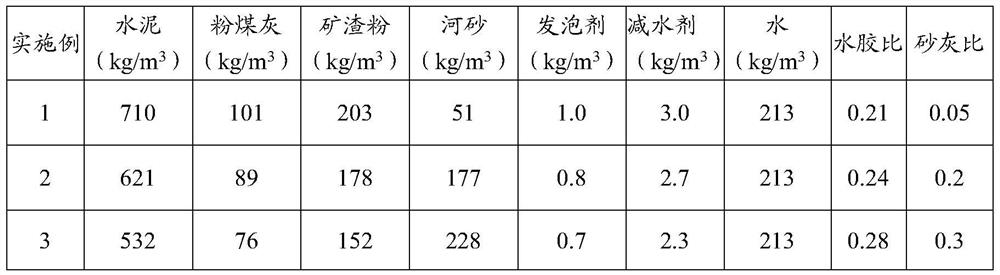

[0037] Prepare the raw materials according to the mixing ratio shown in Table 1. When the blowing agent is used, add water and dilute it 20 times to form a foam solution. The raw materials in the above mixing ratio are mixed evenly by a concrete mixer, and fully mixed by a foaming system to form foamed concrete.

[0038] The mix ratio of the foamed concrete that table 1 embodiment 1-7 provides

[0039]

[0040]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

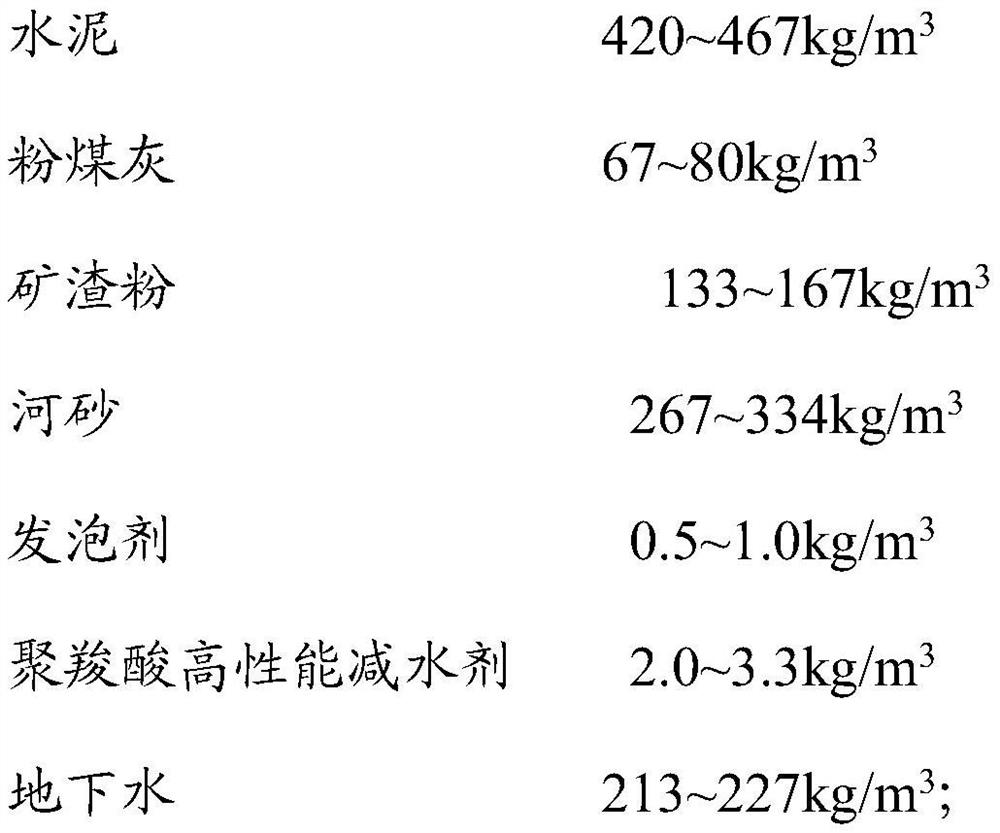

The invention discloses foamed concrete for bridge deck pavement. The foamed concrete is prepared from the following raw materials in proportion: 420-467 kg / m <3> of cement; 67-80 kg / m <3> of fly ash;133-167 kg / m <3> of slag powder; 267-334 kg / m <3> of river sand; 0.5-1.0 kg / m <3> of a foaming agent; 2.0-3.3 kg / m <3> of a polycarboxylic acid high-performance water reducing agent; and 213 to 227 kg / m <3> of underground water. The specification model of the foaming agent is an F-800 type efficient polymer cement foaming agent. The foamed concrete has good workability, segregation resistance, foaming uniformity and volume stability, can guarantee rapid completion of foamed concrete filling construction of a bridge deck; the strength grade of the foamed concrete can reach C5.0; the expansiondegree of the foamed concrete can reach a good state; and the wet density of the foamed concrete is proper, and the strength of thefoamed concrete meets the design requirement.

Description

technical field [0001] The invention relates to the field of foam concrete, in particular to a foam concrete used for bridge deck pavement. Background technique [0002] Foamed concrete is a new type of lightweight thermal insulation material containing a large number of closed pores. In the construction stage, the foamed concrete is poured on the roof of the building or indoors, which plays a role in heat preservation and heat insulation of the building. Due to the heightening of the entire bridge deck structure of arched bridges, the thickness of the bridge deck pavement layer increases accordingly. If all ordinary concrete is cast in place, the self-weight load of the entire bridge will be greatly increased, which is extremely detrimental to the structural safety of the entire bridge. [0003] In related technologies, in order to reduce the load of arch bridges, foam concrete can be used for construction. First pour foam concrete for filling, and then pour C50 pavement o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/04C04B38/10

CPCC04B28/04C04B38/10C04B2201/50C04B2201/20C04B2111/0075C04B18/08C04B18/141C04B14/06C04B2103/302C04B22/002

Inventor 吴传华刘琴梅朱昌华杨胜民李新华黄松吴金刚景昕

Owner 中铁大桥局集团第六工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com