Self-compacting concrete for pumping

A self-compacting concrete and concrete technology, applied in the field of construction, can solve problems such as difficult quality assurance, and achieve the effect of fast strength, good fluidity and improved slump in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

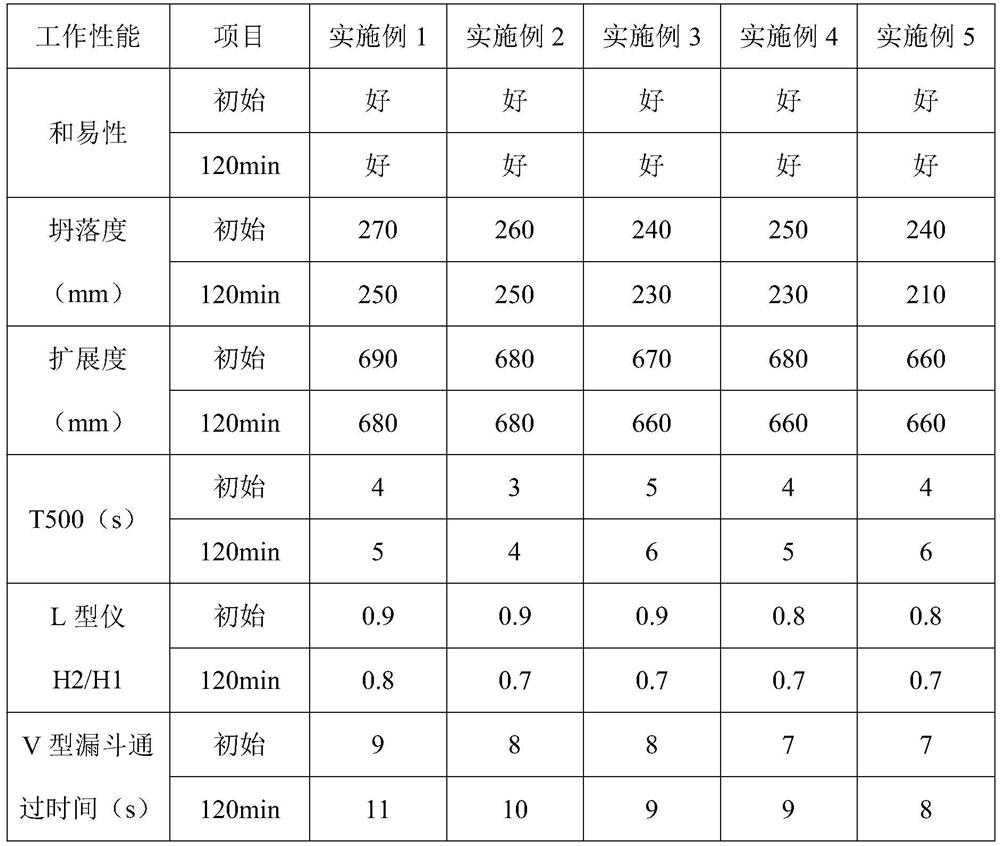

Examples

Embodiment 1

[0032] This embodiment provides a self-compacting concrete for pumping, which includes pumping basic concrete components, mineral admixtures mixed with the pumping basic concrete, and admixtures, with a capacity of 2550 kg per cubic meter.

[0033] Among them, the pumping foundation concrete includes the following ingredients in parts by weight: 305 parts of PII 52.5 cement, 797 parts of fine aggregate, 1202 parts of coarse aggregate, 125 parts of water and 8.5 parts of naphthalenesulfonate superplasticizer. Sand with a degree modulus of 2.2-3.7 and a mud content of no more than 1%; coarse aggregates are continuously graded stones with a maximum particle size of no more than 1 / 3 of the inner diameter of the pumping pipe and a mud content of no more than 1%.

[0034] The mineral admixture accounts for 3-5% of the total weight. The mineral admixture includes at least a mixture of oxides and inorganic acid salts containing Si, Al, Fe, Ca. Specifically, the mineral admixture includ...

Embodiment 2

[0037] This embodiment provides a self-compacting concrete for pumping, which includes pumping basic concrete components and mineral admixtures mixed with the pumping basic concrete, and also includes admixtures, with a capacity of 2580 kg per cubic meter.

[0038] Among them, the pumping foundation concrete includes the following components by weight: 275 parts of PII 52.5 cement, 818 parts of fine aggregate, 1165 parts of coarse aggregate, 132 parts of water and 7.2 parts of naphthalenesulfonate superplasticizer. Sand with a degree modulus of 2.5-3.5 and a mud content of no more than 1%; coarse aggregates are continuously graded stones with a particle size of 1-2cm and a mud content of no more than 1%.

[0039] The mineral admixture accounts for 3-5% of the total weight. The mineral admixture includes at least a mixture of oxides and inorganic acid salts containing Si, Al, Fe, Ca. Specifically, the mineral admixture includes the following powder by weight 50 parts of coal as...

Embodiment 3

[0042] This embodiment provides a self-compacting concrete for pumping, which includes pumping basic concrete components and mineral admixtures mixed with the pumping basic concrete, and also includes admixtures, with a capacity of 2530 kg per cubic meter.

[0043] Among them, the pumping foundation concrete includes the following components by weight: 328 parts of PII 52.5 cement, 835 parts of fine aggregate, 1235 parts of coarse aggregate, 142 parts of water and 5.6 parts of naphthalenesulfonate superplasticizer, and the fine aggregate is made of fine Sand with a degree modulus of 2.8-3.2 and a mud content of no more than 1%; coarse aggregate uses stones with a particle size of 1-2cm and a mud content of no more than 1%.

[0044] The mineral admixture accounts for 5-10% of the total weight. The mineral admixture includes a mixture containing at least Si, Al, Fe, Ca oxides and inorganic acid salts. Specifically, the mineral admixture includes the following powder by weight 51...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com