No. 0 colloidal crystal special for shrinkage-free large flow state cement mortar and cement mortar

A cement mortar, non-shrinkage technology, applied in the field of cement special additives, can solve the problems of difficult fluidity of cement mortar, improper watering and curing, etc., achieve good fluidity, excellent segregation resistance, and suppress construction quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Type C

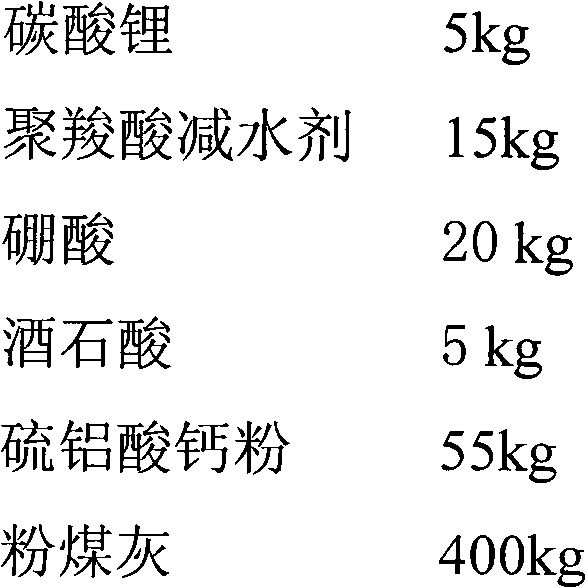

[0021] The non-shrinkage large flow state cement mortar Type A special 0# colloid crystal of the present embodiment is made up of the raw material of following weight:

[0022]

[0023] Its preparation method comprises the following steps:

[0024] a. Stirring: put 400kg fly ash and 55kg calcium sulfoaluminate powder into the mixing mixer according to the proportion, then put 5kg lithium carbonate, 15kg polycarboxylate superplasticizer, 20kg boric acid and 5kg tartaric acid, stir to make it completely mix;

[0025] b. Packing: Use kraft paper plastic film bags lined with moisture-proof plastic film to pack the mixture stirred in step a, and the packing specification is 25kg±0.5kg / bag;

[0026] c. Storage: Put the packaged finished bag in a dry and ventilated place, avoid sunlight, pay attention to moisture and water, and the storage period is 12 months.

[0027] In this embodiment, when the special 0# colloidal crystal is specifically prepared for cement ...

Embodiment 2

[0029] Type B

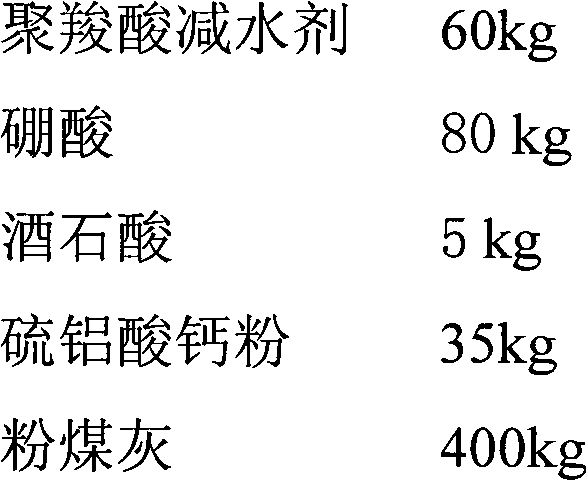

[0030] The non-shrinkage large flow state cement mortar B type special-purpose 0# colloidal crystal of the present embodiment is made up of the raw material of following weight:

[0031]

[0032]

[0033] Its preparation method comprises the following steps:

[0034] b. Stirring: Put 400kg of fly ash and 35kg of calcium sulfoaluminate powder into the mixing mixer according to the proportion, then put in 20kg of lithium carbonate, 60kg of polycarboxylate superplasticizer, 80kg of boric acid and 5kg of tartaric acid, and stir to make it completely mix;

[0035] b. Packing: Use kraft paper plastic film bags lined with moisture-proof plastic film to pack the mixture stirred in step a, and the packing specification is 25kg±0.5kg / bag;

[0036] c. Storage: Put the packaged finished bag in a dry and ventilated place, avoid sunlight, pay attention to moisture and water, and the storage period is 12 months.

[0037] In this embodiment, when the special 0# colloi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com