Self-compacting concrete prepared from industrial solid wastes and preparation method thereof

A technology of self-compacting concrete and solid waste, which is applied in the field of building materials, can solve the problems of self-compacting concrete working performance, etc., and achieve the effect of reducing consumption and project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

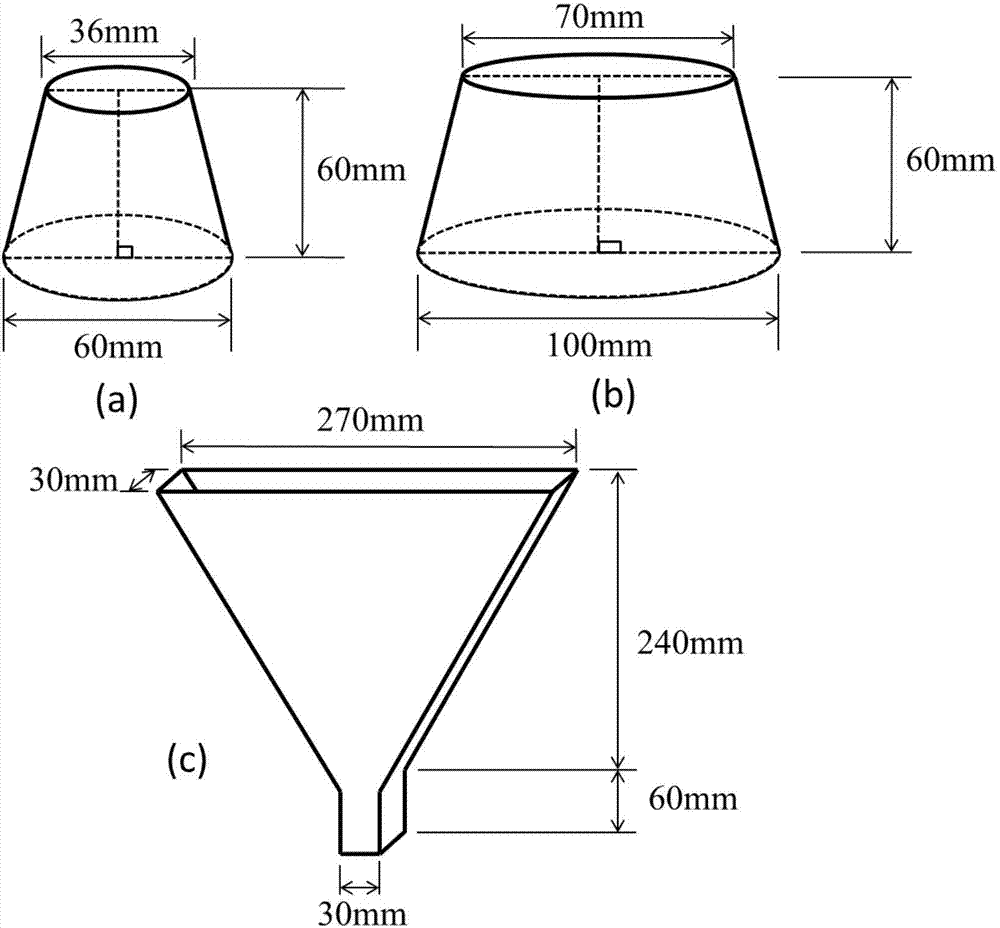

Method used

Image

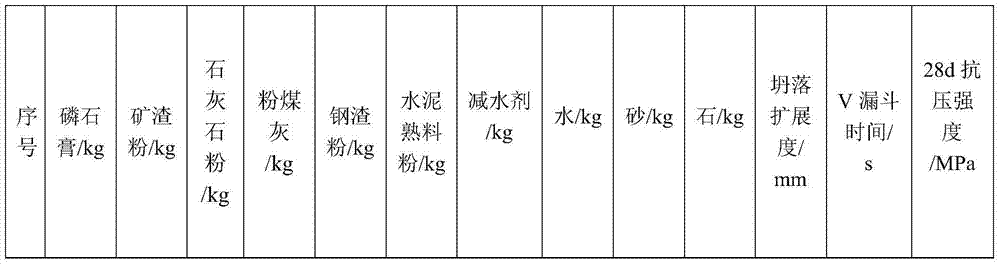

Examples

Embodiment 1

[0027] In the powder material of phosphogypsum-based self-compacting concrete in this embodiment, the mass fractions of phosphogypsum, slag powder, steel slag powder and Portland cement clinker powder in the proportioning of the first group are 47% and 47% respectively , 2% and 4%; the mass fractions of the proportioning phosphogypsum, slag powder, limestone powder, steel slag powder and cement clinker powder of the second group are 30%, 45%, 25%, 2% and 3% respectively; The mass fractions of phosphogypsum, slag powder, fly ash, steel slag powder and cement clinker powder in the proportion of the three groups are 30%, 35%, 30%, 2% and 3% respectively. Phosphogypsum is in powder form, with a mass moisture content of 11.5%, and some agglomerates, which need further grinding before it can be used in concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com