Additive capable of improving adsorption capacity of concrete to PM2.5, and preparation method and application thereof

A technology of concrete and additives, applied in the field of additives, can solve the problems of PM2.5 adsorption effect is not very ideal, the adsorption effect is not very ideal, the impact of concrete strength, etc., to improve the anti-segregation ability, prolong the hydration time, adsorption effectiveness prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

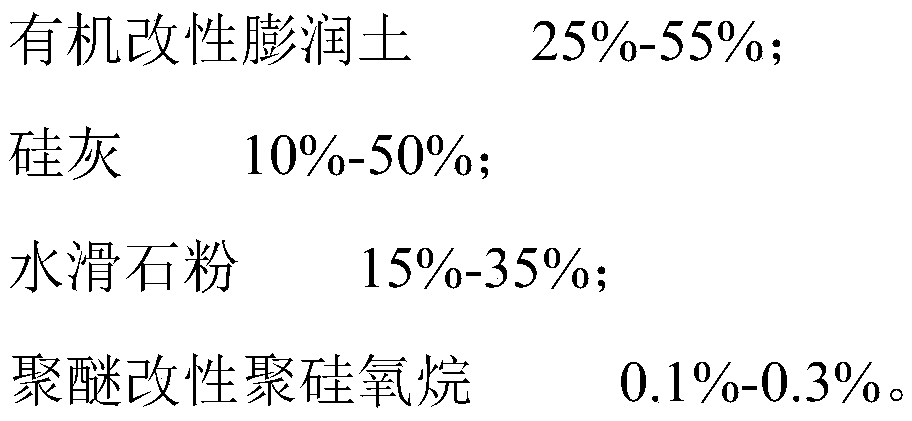

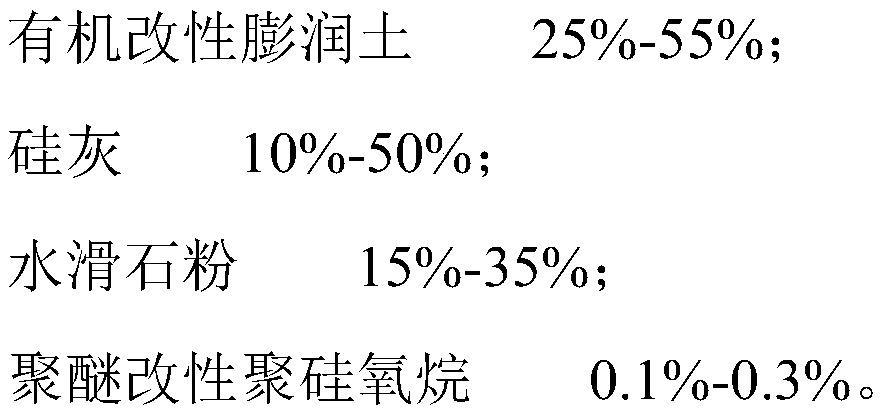

[0043] The embodiment of the present invention also proposes a preparation method of an additive to improve the ability of concrete to absorb PM2.5, which specifically includes the following steps: organically modified bentonite 25%-55%, silica fume 10%-50%, hydrotalcite powder 15% %-35% and polyether modified polysiloxane 0.1%-0.3%, mixed evenly, and ground until the specific surface area of the powder is greater than 400m 2 / kg, to obtain an additive that can effectively improve the ability of concrete to absorb PM2.5.

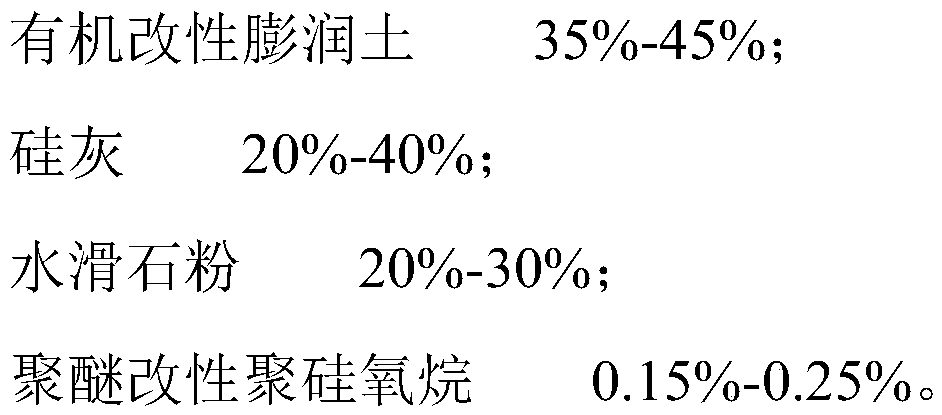

[0044] As a preferred embodiment, 35%-45% of organic modified bentonite, 20%-40% of silica fume, 20%-30% of hydrotalcite powder and 0.15%-0.25% of polyether modified polysiloxane.

[0045] The embodiment of the present invention also proposes a concrete composition, which includes concrete and the above-mentioned additive for improving the ability of the concrete to absorb PM2.5, and the dosage of the additive is 5%-20% of the total mass of the concrete. ...

Embodiment 1

[0052] An additive to improve the ability of concrete to absorb PM2.5. The components and mass percentages are as follows: 40% chitosan modified bentonite, and the specific surface area is 465m 2 / kg, the content of montmorillonite is 92%; silica fume is 39.8%, the sieve rate of 45μm square hole sieve is ≤2%, and the specific surface area is about 21m 2 / g; hydrotalcite powder 20%, whiteness 93%, average particle size 0.8 μm; polyether modified polysiloxane 0.2%.

[0053] The preparation method of the additive is as follows: uniformly mix organically modified bentonite, silica fume, hydrotalcite powder and polyether modified polysiloxane, put them into a grinder, and grind until the specific surface area of the powder is greater than 400m 2 / kg, bagged and sealed.

[0054] The additive can be applied to concrete to improve the ability of concrete to absorb PM2.5. The following concrete is taken as an example to illustrate the effect of the additive of the present invention...

Embodiment 2

[0064] An additive to improve the ability of concrete to absorb PM2.5, the components and mass percentages are as follows: chitosan modified bentonite 35%, specific surface area 475m 2 / kg, the content of montmorillonite is 94%; silica fume is 34.75%, the sieve rate of 45μm square hole sieve is ≤1%, and the specific surface area is about 22m 2 / g; hydrotalcite powder 30%, whiteness 91%, average particle size 0.6 μm; polyether modified polysiloxane 0.25%.

[0065] The preparation method of the additive is as follows: uniformly mix organically modified bentonite, silica fume, hydrotalcite powder and polyether modified polysiloxane, put them into a grinder, and grind until the specific surface area of the powder is greater than 400m 2 / kg, bagged and sealed.

[0066] The additive can be applied to concrete to improve the ability of concrete to absorb PM2.5. The following concrete is taken as an example to illustrate the effect of the additive of the present invention.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com