Anti-segregation agent for concrete and preparation method thereof

An anti-segregation agent and concrete technology, which is applied in the field of concrete admixture, can solve the problems of concrete loss of fluidity, strong flocculation of anti-segregation agent, and fast concrete settling speed, so as to improve work performance and layering degree, and reduce cost , Improve the effect of mild pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

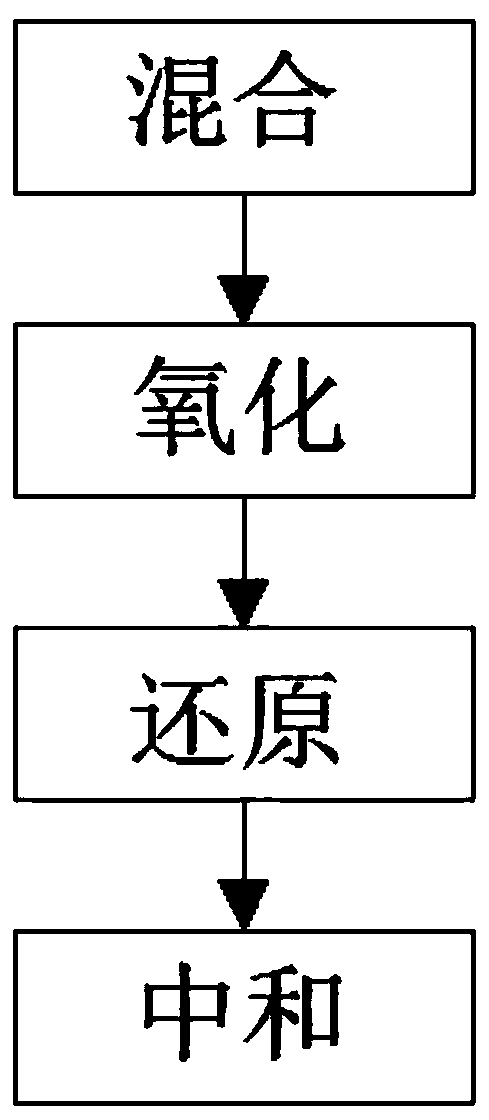

[0023] The preparation method of this concrete anti-segregation agent comprises the steps:

[0024] S1: Mixing: Add 5.5 parts of silicone monomer, 288 parts of deionized water, 29 parts of polycarboxylate superplasticizer and 1.1 parts of polyethylene glycol into the reactor for mixing;

[0025] S2: Oxidation: Mix the mixture in step S1 evenly by stirring, add 3.3 parts of oxidizing agent to oxidize;

[0026] S3: Reduction: Add 13.9 parts of fly ash, 5.9 parts of mineral powder and 1.1 parts of steel fiber to the oxidation mixture in step S2, and then add 1.1 parts of reducing agent;

[0027] S4: Neutralization: Add 1.16 parts of viscosifier and 0.58 parts of coagulant to the reduced mixture in step S3, stir continuously until the mixture is uniform, then add liquid caustic soda to adjust the pH, so that the pH is between 7-9 Time, you can get the anti-segregation agent for concrete.

Embodiment 2

[0029] The preparation method of this concrete anti-segregation agent comprises the steps:

[0030] S1: Mixing: Add 14.8 parts of silicone monomer, 215 parts of deionized water, 21.5 parts of polycarboxylate superplasticizer and 2 parts of polyethylene glycol into the reactor for mixing;

[0031] S2: Oxidation: Mix the mixture in step S1 evenly by stirring, add 4.7 parts of oxidizing agent to oxidize;

[0032] S3: Reduction: Add 6.4 parts of fly ash, 14.6 parts of mineral powder and 1.8 parts of steel fiber to the oxidation mixture in step S2, and then add 2.9 parts of reducing agent;

[0033] S4: Neutralization: Add 0.85 parts of viscosifier and 0.85 parts of coagulant to the reduced mixture in step S3, stir continuously until the mixture is uniform, then add liquid caustic soda to adjust the pH, so that the pH is between 7-9 Time, you can get the anti-segregation agent for concrete.

Embodiment 3

[0035] The preparation method of this concrete anti-segregation agent comprises the steps:

[0036] S1: Mixing: Add 7.5 parts of silicone monomer, 250 parts of deionized water, 25 parts of polycarboxylate superplasticizer and 1.5 parts of polyethylene glycol into the reactor for mixing;

[0037] S2: Oxidation: Mix the mixture in step S1 evenly by stirring, add 4 parts of oxidizing agent to oxidize;

[0038] S3: Reduction: Add 10 parts of fly ash, 10 parts of mineral powder and 1.5 parts of steel fiber to the oxidation mixture in step S2, and then add 2 parts of reducing agent;

[0039] S4: Neutralization: add 1 part of viscosifier and 0.75 part of coagulant to the reduced mixture in step S3, stir continuously until the mixture is uniform, then add liquid caustic soda to adjust the pH, so that the pH is between 7-9 Time, you can get the anti-segregation agent for concrete.

[0040] Based on the above, the best embodiment of the preparation method of this anti-segregation agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com