Environmentally-friendly high-viscosity modified asphalt and preparation method thereof

A modified asphalt, high-viscosity technology, used in building thermal insulation materials, building components, buildings, etc., can solve the problems of high unsaturation of the molecular main chain structure, high SBS price, easy to age, etc., to improve the bonding performance, The effect of reducing dosage and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

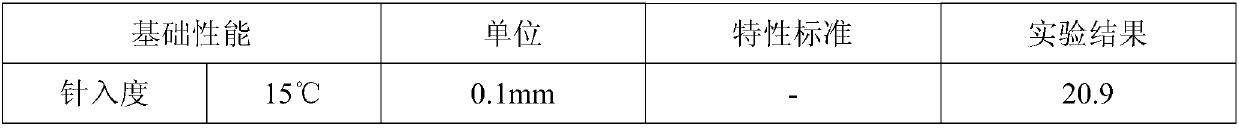

Embodiment 1

[0038] The environmentally friendly high-viscosity modified asphalt of the present invention consists of 67 parts by mass of base asphalt, 5 parts of blending oil, 1 part of plasticizer, 13 parts of tackifier, 0.2 part of stabilizer and 14 parts of Modifier composition, wherein the modifier is composed of waste tire rubber powder and SBS, and the mass ratio of waste tire rubber powder to SBS is 10:4.

[0039] The base asphalt is No. 90 petroleum asphalt for road use.

[0040] Blending oil is recovered and purified waste engine oil.

[0041] The plasticizer is dioctyl phthalate.

[0042] The tackifier is C5 / C9 copolymerized petroleum resin.

[0043] Waste tire rubber powder is waste bias tire rubber powder.

[0044] The stabilizer is a sulfur stabilizer.

[0045] The preparation method of the environment-friendly high-viscosity modified asphalt of the present invention comprises the following steps:

[0046] 1) Weigh base asphalt, blending oil, plasticizer, tackifier, stab...

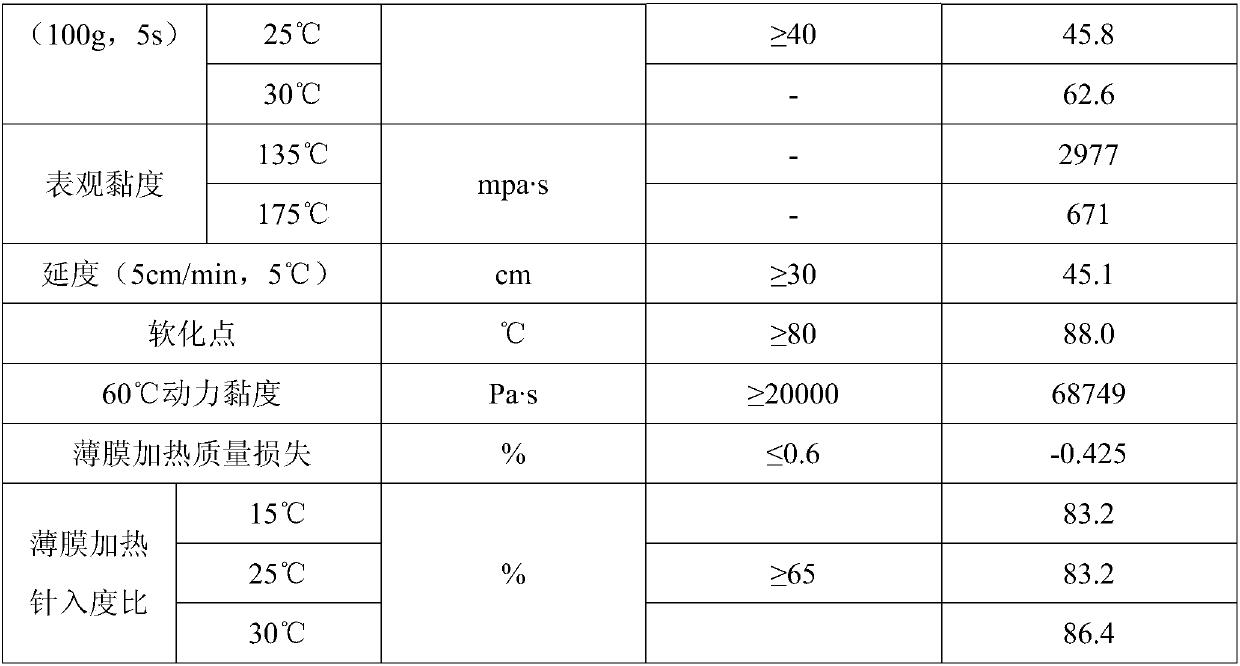

Embodiment 2

[0061] The environmentally friendly high-viscosity modified asphalt of the present invention is composed of 66 parts by mass of base asphalt, 5 parts of blending oil, 13 parts of tackifier, 0.2 part of stabilizer and 16 parts of modifier, wherein , The modifier is composed of waste tire rubber powder and SBS, and the mass ratio of waste tire rubber powder to SBS is 12:4.

[0062] The base asphalt is No. 90 petroleum asphalt for road use.

[0063] Blended oil is recovered and purified waste coal tar.

[0064] The tackifier is C5 petroleum resin.

[0065] Waste tire rubber powder is waste radial tire rubber powder.

[0066] The stabilizer is a polyamide stabilizer.

[0067] The preparation method of the environment-friendly high-viscosity modified asphalt of the present invention comprises the following steps:

[0068] 1) Weigh base asphalt, blending oil, plasticizer, tackifier, stabilizer and modifier;

[0069] 2) Preheat the base asphalt to 130°C, add blending oil and pla...

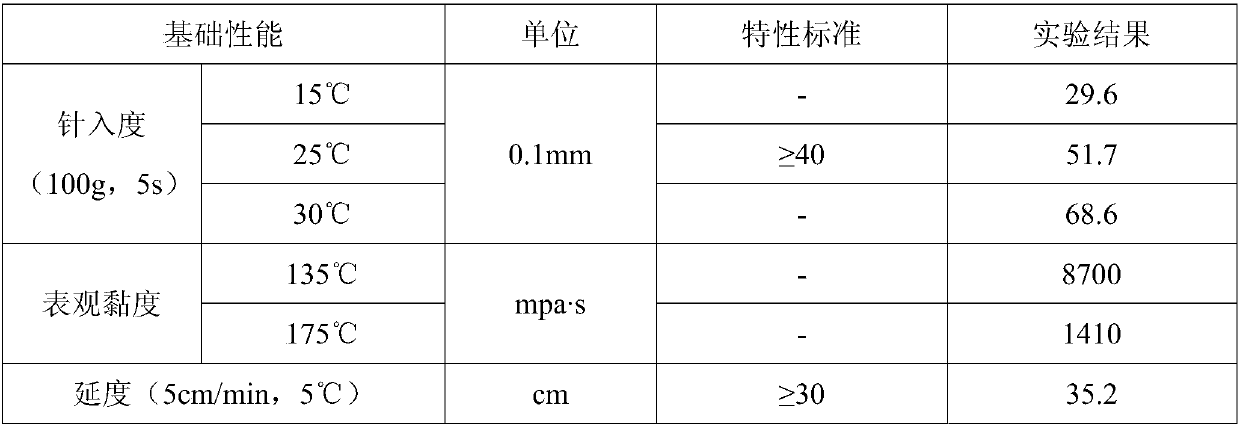

Embodiment 3

[0082] The environmentally friendly high-viscosity modified asphalt of the present invention consists of 65 parts by mass of base asphalt, 5 parts of blending oil, 1 part of plasticizer, 15 parts of tackifier, 0.4 part of stabilizer and 14 parts Modifier composition, wherein the modifier is composed of waste tire rubber powder and SBS, and the mass ratio of waste tire rubber powder to SBS is 10:4.

[0083] The base asphalt is No. 70 petroleum asphalt for road use.

[0084] Blending oil is recovered and purified waste heavy mineral oil.

[0085] The plasticizer is dioctyl phthalate.

[0086] The tackifier is dicyclopentadiene petroleum resin.

[0087] The waste tire rubber powder is a mixture of waste bias tire rubber powder and waste radial tire rubber powder in any proportion.

[0088] The stabilizer is a mixture of polyamide stabilizer and sulfur stabilizer in any proportion.

[0089] The preparation method of the environment-friendly high-viscosity modified asphalt of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com