Epoxypropane embedded polyether modified concrete thickening agent and preparation method thereof

A technology for modification of propylene oxide and polyether, which is applied in the field of building materials, can solve problems such as restrictions on the use of thickeners, lower fluidity of the system, and poor fluidity, so as to enhance segregation resistance, improve workability, and reduce sensitivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

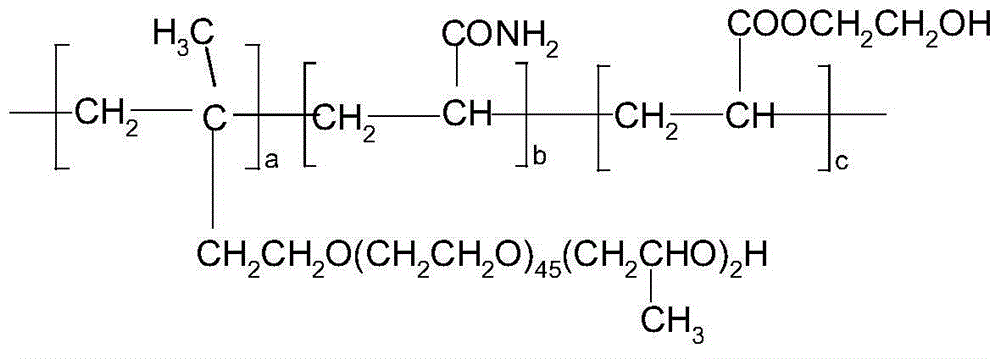

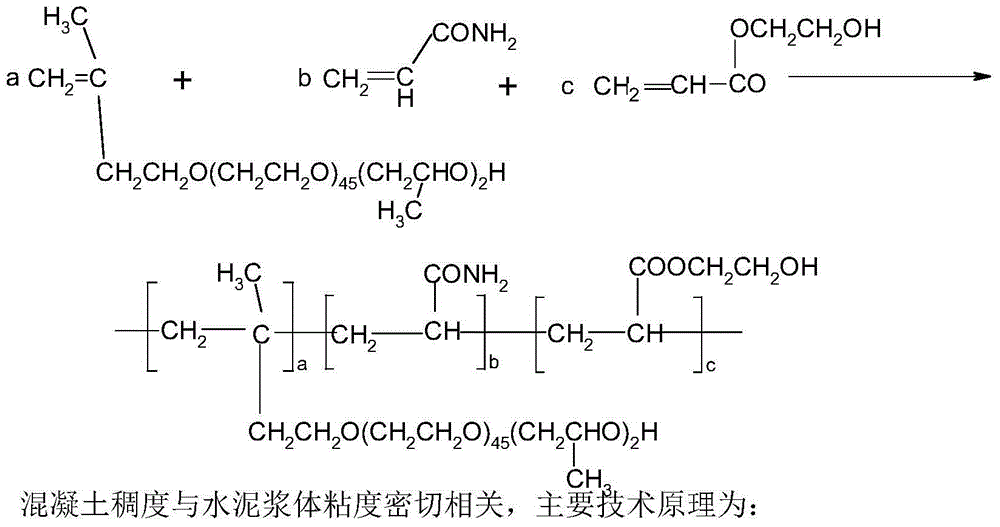

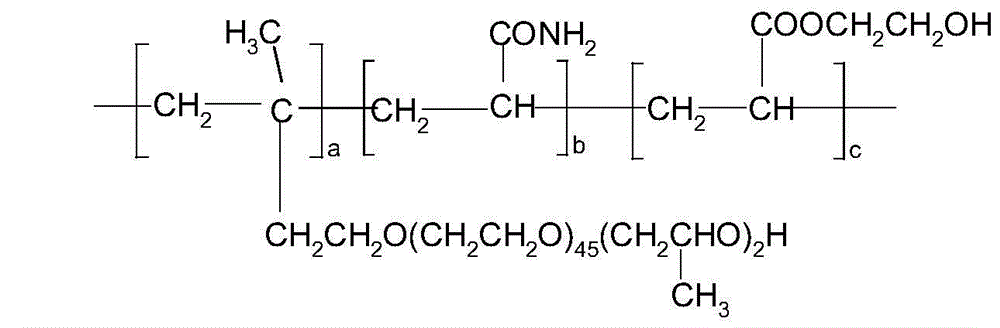

Method used

Image

Examples

Embodiment 1-10

[0029] The matching ratio is shown in Table 1, and the specific implementation process is as follows:

[0030] Stir and dissolve the polyether embedded in propylene oxide, heat to 50°C, then add the oxidizing agent, stir for 5 minutes, drop the mixture of acrylamide and hydroxyethyl acrylate, and drop the mixture of reducing agent and chain transfer agent, drop for 60 minutes After adding completely, continue to stir for 1 hour, adjust the pH to be neutral, and add an appropriate amount of deionized water to obtain a thickener with a concentration of 40%, wherein the polyether embedded in propylene oxide is prenyl alcohol-terminated and embedded in the ring Polyoxyethylene ether of oxypropylene, the oxidant is a mixture of hydrogen peroxide and tert-butyl hydroperoxide, the molar ratio is 5:1; the reducing agent used in Examples 1-5 is a mixture of sodium sulfite and sodium bisulfite formed, and its molar ratio is 1:1; embodiment 6-10 adopts sodium sulfite, sodium bisulfite, L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com