Self-compacting cement concrete mixed with Bayer process red mud, and preparation method thereof

A technology of cement concrete and Bayer red mud, which is applied in the field of concrete materials to achieve the effect of high fluidity and good filling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, preparation of thermally altered Bayer process red mud

[0028] A) Heat the crucible of the muffle furnace to 700°C, take out the crucible, put in a mixture of Bayer process red mud and porcelain stone tailings in a weight ratio of 1:0.5, and calcinate at 700°C for 2.0h;

[0029] B) The calcined product is naturally cooled in the muffle furnace, the calcined product is taken out, dry-milled with a ball mill, and passed through a 200-mesh sieve to obtain Bayer process red mud treated with thermal alteration.

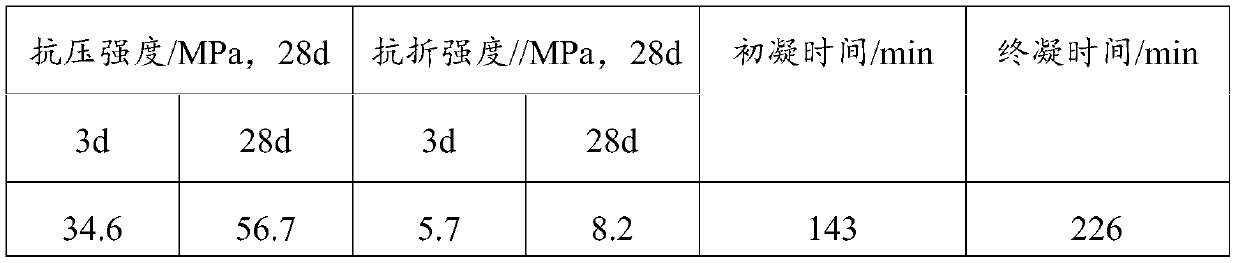

[0030] Table 1 Calcination parameters

[0031] sample Weight ratio of red mud to porcelain stone tailings Calcination temperature Calcination time Red mud A 1:0.5 700℃ 2.0h Red mud B 1:0.3 600℃ 2.0h red mud C 1:0.1 700℃ 2.0h

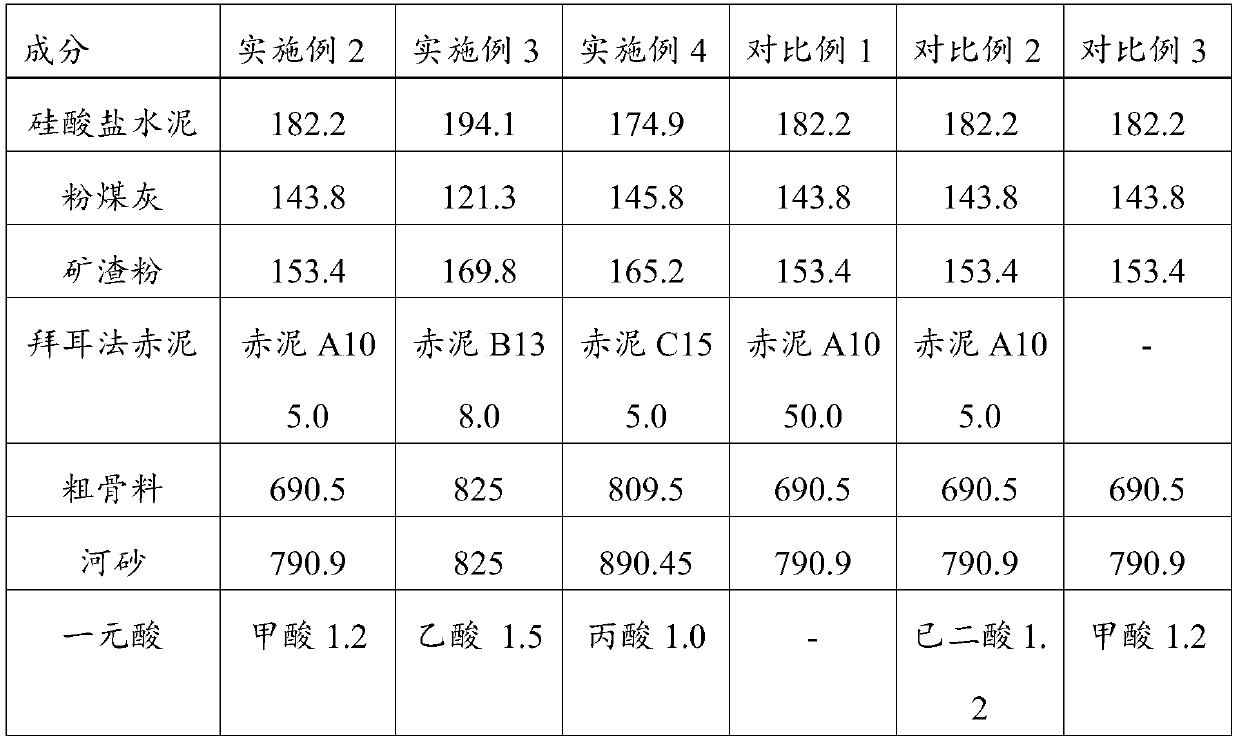

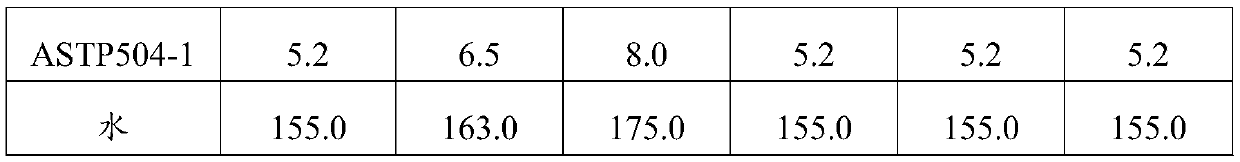

[0032] Table 2 Example 2-4 self-compacting concrete mix parameters (kg / m 3 ):

[0033]

[0034]

[0035] Note: Coarse aggregate is composed of gravel with a particle size of 5-...

Embodiment 2

[0048] Example 2. Research on thermal activity of red mud by different calcination processes

[0049] Based on the calcination process of Example 1 of the present invention, different calcination processes are set:

[0050]Conventional calcination process ① (slow heating and slow cooling, separate calcination method): Put the Bayer process red mud into the muffle furnace, heat up to 700°C, and calcine for 2 hours. The calcined product is naturally cooled in the muffle furnace, and the calcined product is taken out , dry milled with a ball mill, and passed through a 200-mesh sieve. (red mud D)

[0051] Calcination process ② (slow heating and slow cooling, mixed calcination method): Put the mixture of Bayer process red mud and porcelain stone tailings at a weight ratio of 1:0.5 into a muffle furnace, heat up to 700°C, and calcine for 2 hours. The calcined product is naturally cooled in a muffle furnace, and the calcined product is taken out, dry-milled with a ball mill, and pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com