Anti-segregation agent for concrete and preparation method thereof

An anti-segregation agent, concrete technology, applied in the field of concrete admixture, can solve the problems of concrete water consumption and slurry-bone ratio increase, concrete loss of fluidity, concrete settling speed and other problems, achieve low cost, improve anti-segregation Performance, the effect of solving concrete segregation and bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

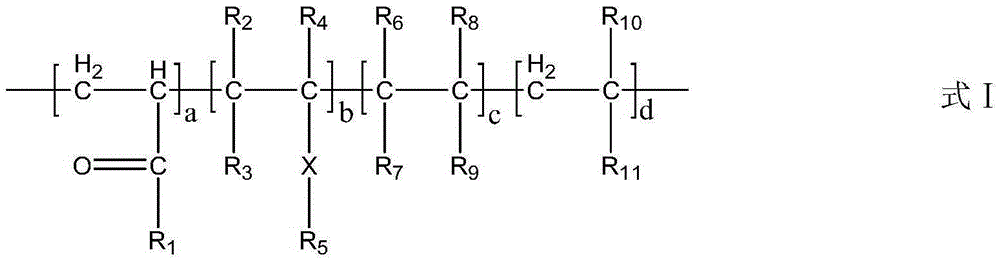

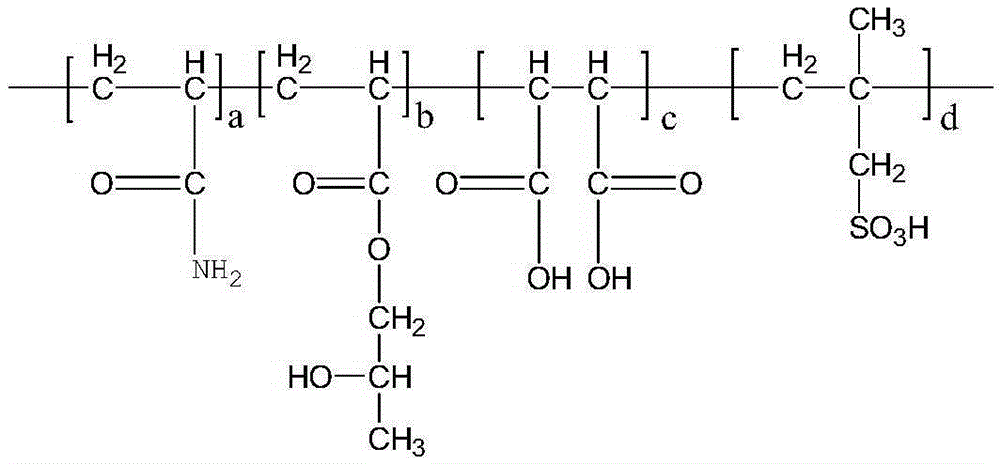

[0026] An anti-segregation agent for concrete, its structural formula is as follows:

[0027]

[0028] Prepare the anti-segregation agent for concrete described in this embodiment according to the following steps:

[0029] (1) Weigh the components according to the following weight ratio: 30 parts of acrylamide (type A monomer), 40 parts of hydroxypropyl acrylate (type B monomer), 9.8 parts of maleic anhydride (type B monomer), 3.2 parts of sodium methacrylate sulfonate (type B monomer), 450 parts of deionized water;

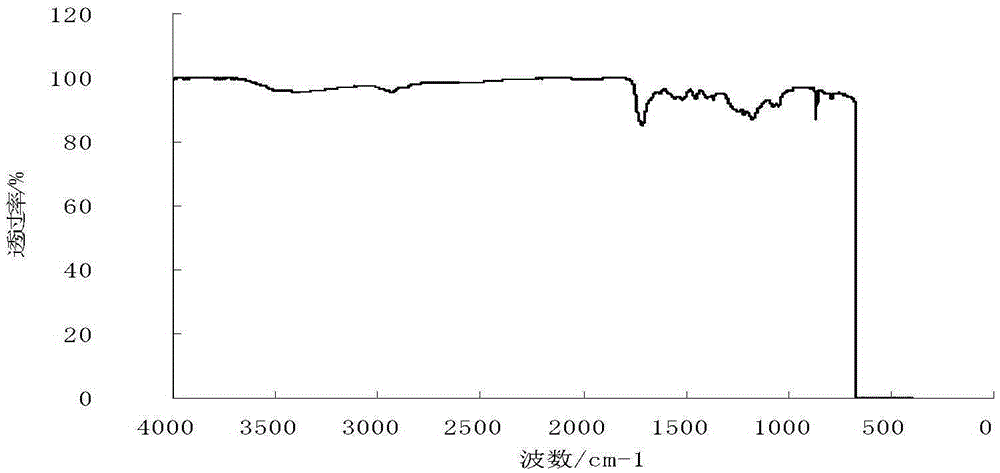

[0030] (2) Put the above components into a three-necked flask, turn on nitrogen to remove the air in the three-necked flask, slowly increase the temperature to 55°C, first add 0.3 parts of sodium hypophosphite, then 1.5 parts of ammonium persulfate, and keep it at 60°C for 3h Then, the temperature is lowered to 40°C, and 6 parts of 30wt% sodium hydroxide aqueous solution are added to obtain the anti-segregation agent for concrete, and the measured PH value is 8. At thi...

Embodiment 2

[0036] An anti-segregation agent for concrete, its structural formula is as follows:

[0037]

[0038] The anti-segregation agent for concrete described in this embodiment was prepared according to the following steps:

[0039] (1) Weigh the components according to the following weight ratio: 35 parts of N-methylolacrylamide (type A monomer), 19.8 parts of maleic anhydride (type B monomer), and 10 parts of hydroxypropyl methacrylate (Type B monomer), 5.2 parts of sodium methacrylate sulfonate (Type B monomer), 440 parts of deionized water.

[0040] (2) Put the above components into a three-necked flask, turn on nitrogen to remove the air in the three-necked flask, slowly raise the temperature to 70°C, add 1.2 parts of ammonium persulfate, keep it at 70°C for 3h, then lower the temperature to 40°C, add 9 A portion of 30wt% sodium hydroxide aqueous solution is used to obtain the product of the present invention, and the measured PH value is 7. At this time, the anti-segregation agent ...

Embodiment 3

[0044] An anti-segregation agent for concrete, its structural formula is as follows:

[0045]

[0046] The anti-segregation agent for concrete described in this embodiment was prepared according to the following steps:

[0047] (1) Weigh the components according to the following weight ratio: 25 parts of acrylamide (type A monomer), 20 parts of acrylic acid (type A monomer), 9.8 parts of mesaconic acid (type B monomer), maleic acid 120 parts of polyethylene glycol ester (type B monomer), 350 parts of deionized water.

[0048] (2) Put the above components into a three-necked flask, turn on nitrogen to remove the air in the three-necked flask, slowly raise the temperature to 65°C, add 1.9 parts of ammonium persulfate, keep it at 65°C for 3h, then lower the temperature to 40°C, add 15 A portion of 30wt% sodium hydroxide aqueous solution and the measured PH value is 8. At this time, the anti-segregation agent for concrete can be obtained.

[0049] The anti-segregation agent for concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com