A kind of high temperature resistant cement concrete pavement stone exposure agent and its preparation method and application

A concrete pavement and high-temperature-resistant cement technology, which is applied in the field of highway engineering, can solve the problems that affect the depth of pavement texture structure, surface three-dimensional shape characteristics and distribution, the spraying window period cannot meet the requirements of on-site construction, cannot reach high temperature and aging, etc. Achieve the effect of good spraying effect, rich texture structure and good retarding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides the preparation method of the high-temperature-resistant cement concrete pavement exposed stone agent described in the above scheme, comprising the following steps:

[0038] A low-temperature retarder, a high-temperature retarder, a super retarder, a film-forming aid, a penetrating agent, a surfactant, a colorant and water are mixed to obtain the high-temperature-resistant cement concrete pavement exposure agent.

[0039]The present invention has no special requirements on the adding order of each component and mixing conditions, as long as the components can be mixed evenly. The preparation method provided by the invention has simple steps, easy operation and easy industrial production.

[0040] The present invention also provides the application of the high-temperature-resistant cement concrete pavement exposure agent described in the above proposal in the treatment of exposed stone cement concrete pavement. In the present invention, th...

Embodiment 1

[0044] A high temperature resistant cement concrete pavement stone exposure agent, in terms of mass percentage, comprising 5% of α-D xylose, 5% of polyaluminum sulfate, 10% of sodium gluconate; 0.3% of styrene-acrylic polymer emulsion; methyl silicon Sodium alkoxide 5%; tea saponin 5%, phthalocyanine pigment 2%, water 67.7%.

[0045] The above-mentioned components are uniformly mixed according to the mass percentages to obtain the high-temperature-resistant cement concrete pavement exposure agent.

[0046] Performance Testing:

[0047] (1) Penetration depth test:

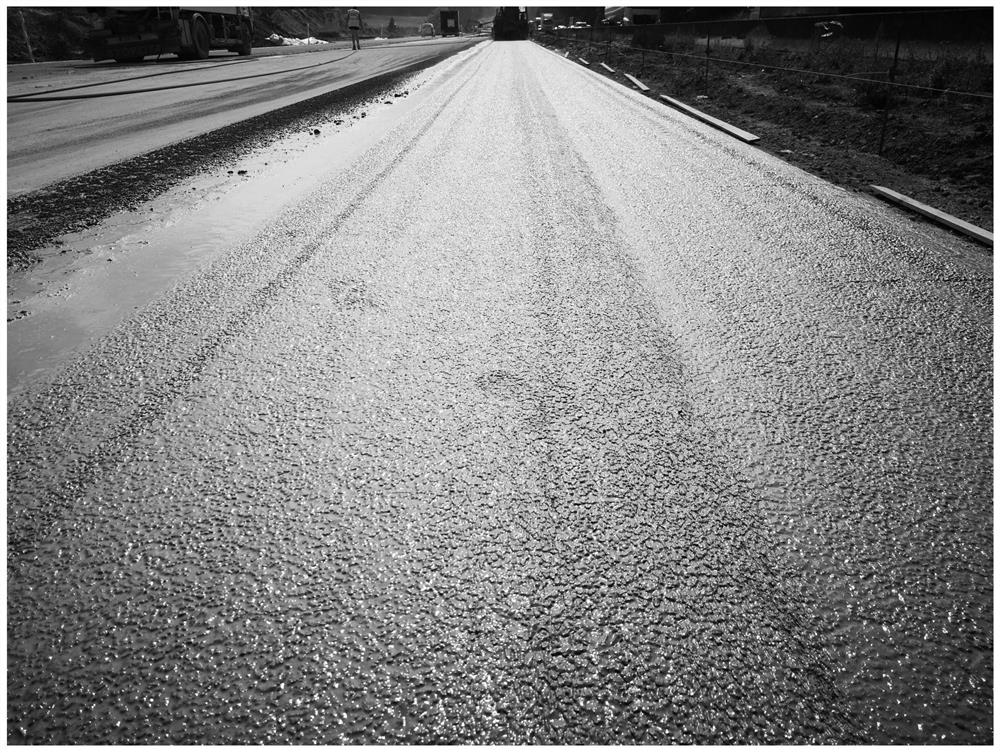

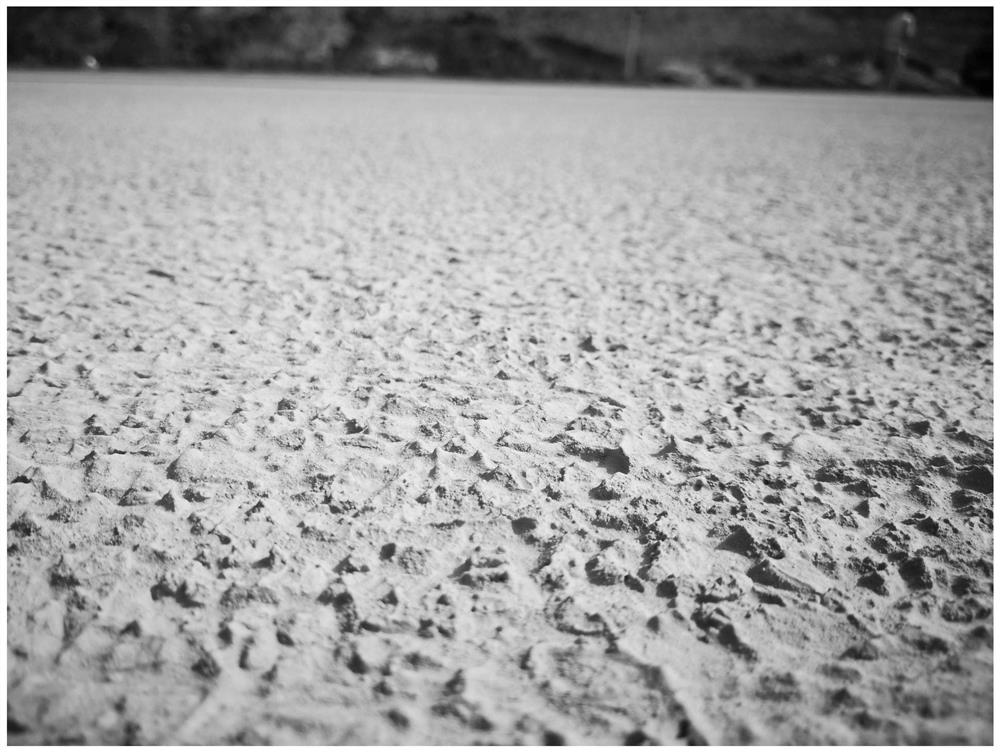

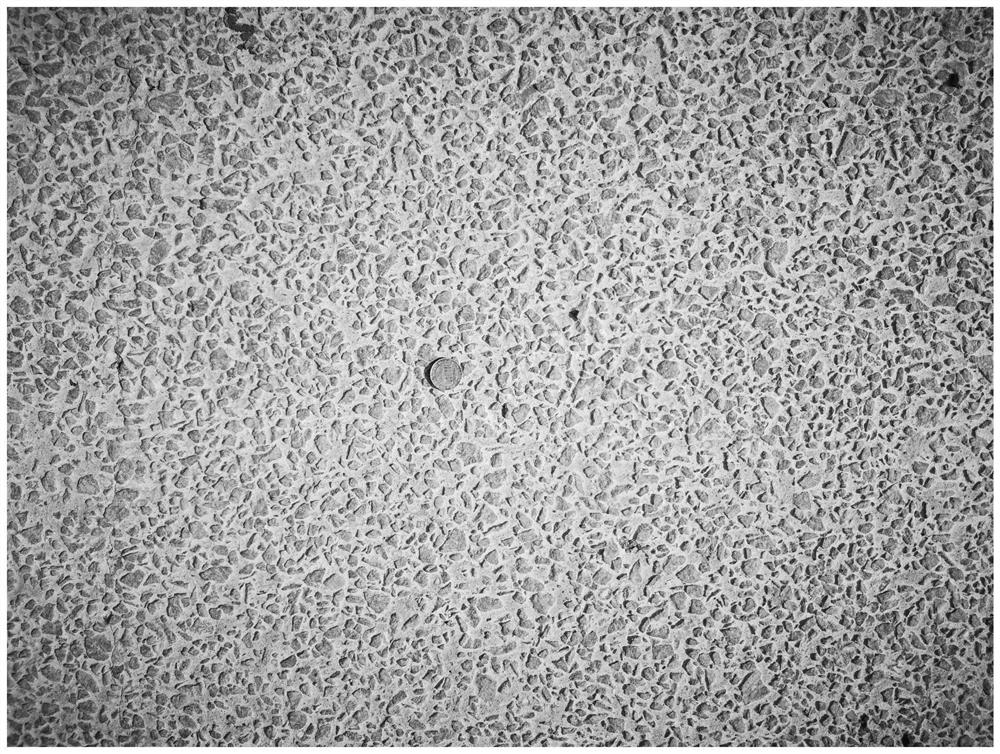

[0048] The test section is a highway tunnel section, which adopts the double-layer paving construction method. The thickness of the upper layer of exposed stone cement concrete pavement is 6cm, and the thickness of the lower layer of ordinary cement concrete is 22cm. Construction steps: first pave the lower layer of ordinary cement concrete, operate and vibrate according to the normal vibration process of ordinary...

Embodiment 2

[0070] A high-temperature-resistant cement concrete pavement exposure agent, in terms of mass percentage, including α-D xylose 10%, polyaluminum sulfate 15%, sodium gluconate 15%; styrene-acrylic polymer emulsion 0.1%; methyl silicon Sodium alkoxide 2%; tea saponin 0.1%, phthalocyanine pigment 1%, water 56.8%.

[0071] The above-mentioned components are uniformly mixed according to the mass percentages to obtain the high-temperature-resistant cement concrete pavement exposure agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com