Method for preparing blocky carbon nano fibers composite material

A technology of carbon nanofibers and composite materials, which is applied in the field of preparation of bulk carbon nanofiber composites, which can solve the problem of unfavorable electrical and thermal conduction of carbon nanofiber composites, the inability to achieve uniform dispersion of carbon nanofibers, and the length of fibers weakening electricity and heat conduction and other issues to achieve the effect of multi-functionality, similar chemical properties and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

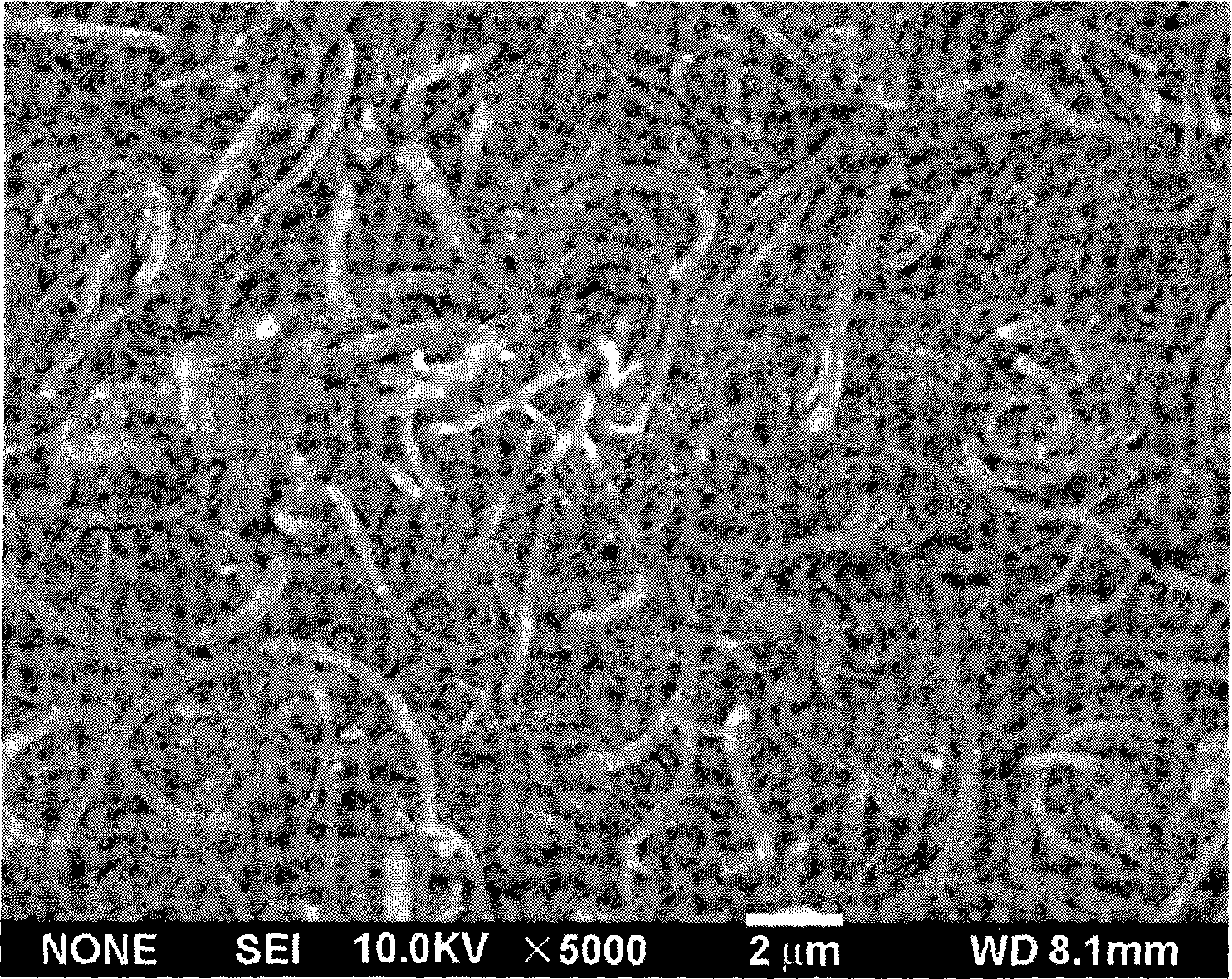

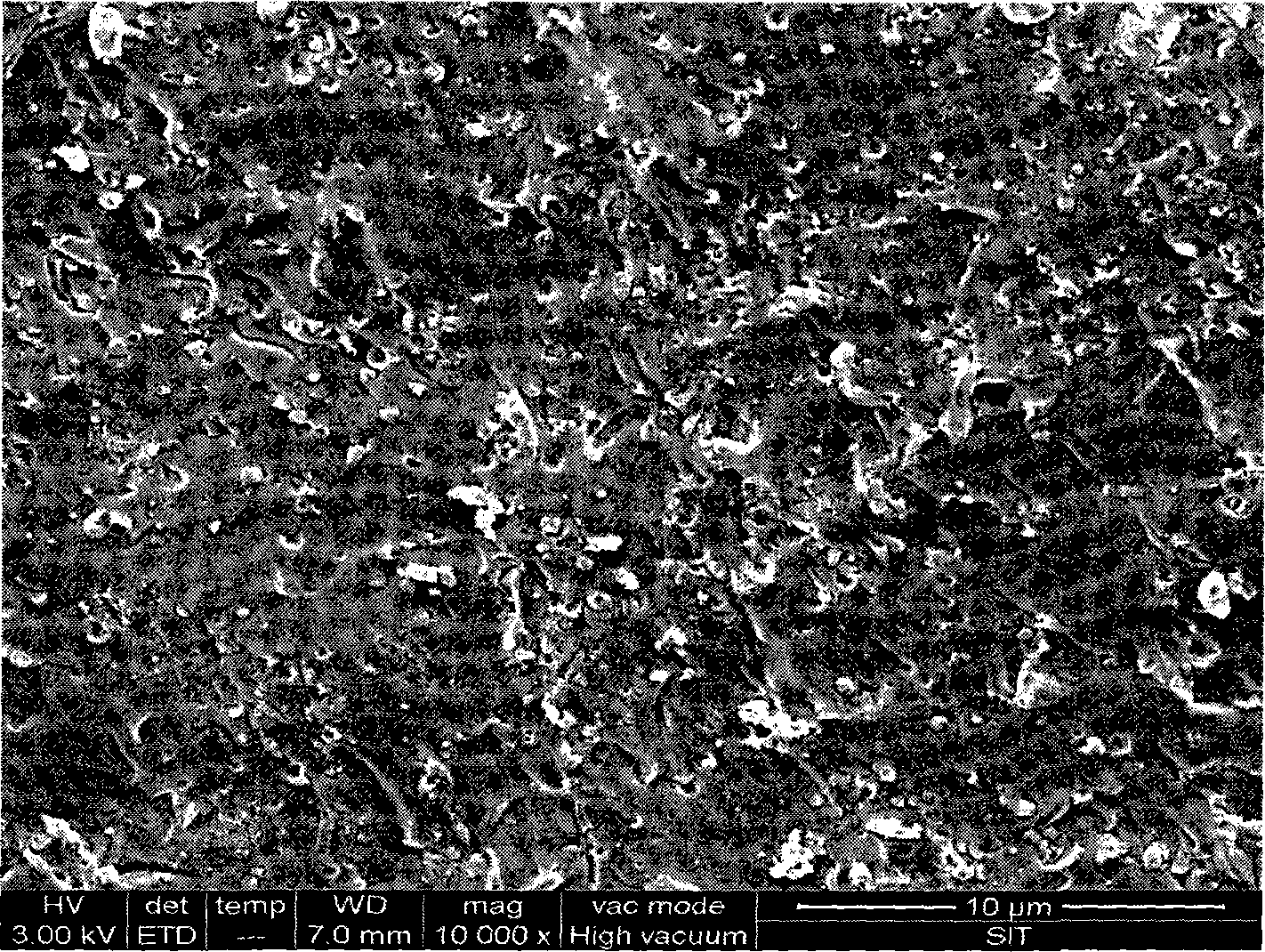

Image

Examples

Embodiment 1

[0030] Put the mold containing 20mg of copper-nickel catalyst into a quartz tube furnace, 2 (volume fraction is 20%) He gas flow, the mixed gas flow rate is 200ml / min, the temperature is raised to 600°C and kept for 3h, and then switched to H 2 / C 2 h 4 (H 2 The volume fraction is 20%) of the mixed gas, the mixed gas flow rate is 200ml / min, the catalytic growth reaction of the bulk carbon nanofiber is carried out, the growth time is 3h, and the bulk carbon nanofiber is obtained after cooling;

[0031] The purchased liquid phenolic resin (PF-23 type, Shanghai Qinan Adhesive Material Factory) was diluted with absolute ethanol until the quality of the phenolic resin accounted for 45% of the solution mass, stirred to make the solution evenly mixed, and the phenolic resin-ethanol Solution 150g.

[0032] Take one block carbon nanofiber with a size of Φ24*30 (mm) and a mass of 2.08g, and soak it in the above solution for 12 hours.

[0033] After taking it out, remove the excess ...

Embodiment 2

[0036]Put the mold containing 20mg of copper-nickel catalyst into a quartz tube furnace, 2 (volume fraction is 50%) He gas flow, the mixed gas flow rate is 200ml / min, the temperature is raised to 500°C and kept for 7h, and then switched to H 2 / C 2 h 4 (H 2 The volume fraction is 20% of the mixed gas, the mixed gas flow rate is 200ml / min, the catalytic growth reaction of the bulk carbon nanofiber is carried out, the growth time is 18h, and the bulk carbon nanofiber is obtained after cooling;

[0037] Dilute the purchased liquid phenolic resin with absolute ethanol until the mass of the phenolic resin accounts for 60% of the solution mass, stir to mix the solution evenly, and take 200 g of the phenolic resin-ethanol solution.

[0038] Take one block carbon nanofiber with a size of Φ24*30 (mm) and a mass of 1.96 g, and soak it in the above solution for 24 hours.

[0039] After taking it out, remove the excess solution on the surface, and dry it in vacuum at 60°C for 24h. Pl...

Embodiment 3

[0042] Put the mold containing 20mg of copper-nickel catalyst into a quartz tube furnace, 2 (volume fraction is 50%) He gas flow, the mixed gas flow rate is 200ml / min, the temperature is raised to 600°C and kept for 7h, and then switched to H 2 / C 2 h 4 (H 2 The volume fraction is 60%) of the mixed gas, the mixed gas flow rate is 200ml / min, the catalytic growth reaction of the bulk carbon nanofiber is carried out, the growth time is 3h, and the bulk carbon nanofiber is obtained after cooling;

[0043] Dilute the purchased liquid phenolic resin with absolute ethanol until the mass of the phenolic resin accounts for 45% of the solution mass, stir to make the solution evenly mixed, and take 200 g of the phenolic resin-ethanol solution.

[0044] Take one bulk carbon nanofiber with a size of Φ24*30 (mm) and a mass of 1.83 g, and soak it in the above solution for 24 hours.

[0045] After taking it out, remove the excess solution on the surface, and dry it in vacuum at 50°C for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com