A kind of environment-friendly interfacial compatibilizer and preparation method thereof

An interface compatibilizer, an environment-friendly technology, applied in the preparation of the above-mentioned interface compatibilizer, the field of environment-friendly interface compatibilizer, can solve the problems of high maleic anhydride residue, low grafting rate, low grafting rate, etc. , to achieve good physical compatibility, large polarity and activity, and increase the effect of grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

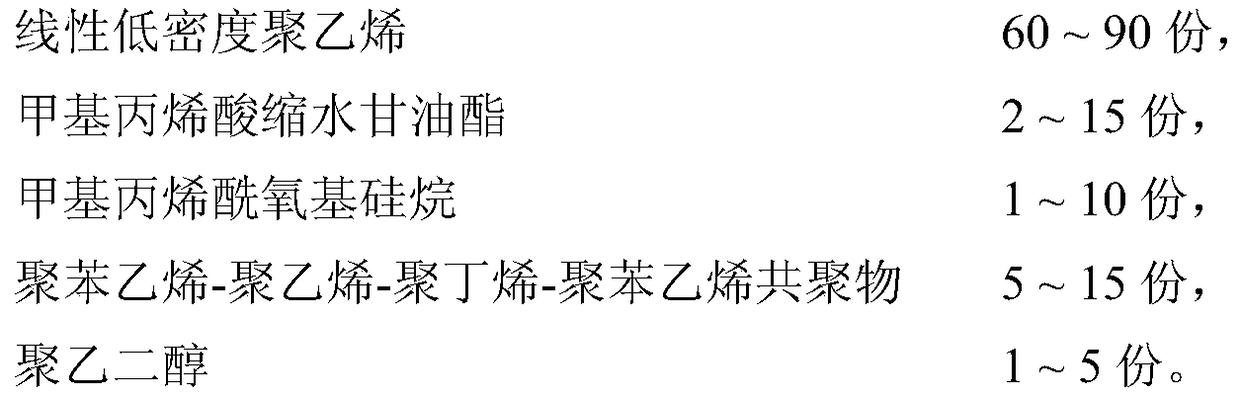

[0030] The environmentally friendly interface compatibilizer in this embodiment includes the following components by weight:

[0031]

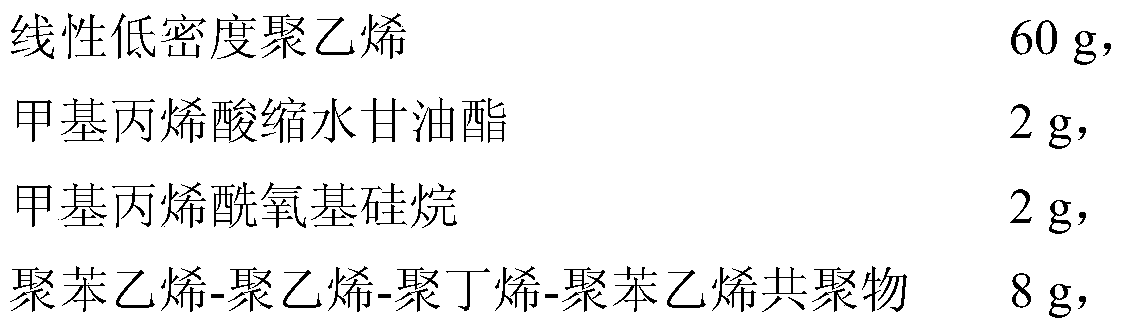

[0032]

[0033] Among them, the polystyrene-polyethylene-polybutene-polystyrene copolymer contains 4g of polystyrene-polyethylene-polybutene-polystyrene copolymer with a weight average molecular weight of 160,000 and a weight average molecular weight of 160,000. 4g of 10,000 polystyrene-polyethylene-polybutene-polystyrene copolymer.

[0034] The preparation method of the aforementioned environmentally friendly interface compatibilizer includes the following steps:

[0035] (1) Perform electron beam pre-irradiation on linear low-density polyethylene, the irradiation dose is 10kGy, and the irradiation time is 8min;

[0036] (2) Sprinkle the methacryloxysilane evenly on the surface of the linear low-density polyethylene after the pre-irradiation in step (1), and stir in a mixer at a speed of 1000r / min for 10 minutes to obtain a mixture A;

[0037] (3) Add...

Embodiment 2

[0040] The environmentally friendly interface compatibilizer in this embodiment includes the following components by weight:

[0041]

[0042] Among them, the polystyrene-polyethylene-polybutene-polystyrene copolymer contains 3g of polystyrene-polyethylene-polybutene-polystyrene copolymer with a weight average molecular weight of 180,000, and a weight average molecular weight 12g of 20,000 polystyrene-polyethylene-polybutene-polystyrene copolymer.

[0043] The preparation method of the environmentally friendly interface compatibilizer includes the following steps:

[0044] (1) Perform electron beam pre-irradiation on linear low-density polyethylene, the irradiation dose is 20kGy, and the irradiation time is 7min;

[0045] (2) Sprinkle the methacryloxysilane evenly on the surface of the linear low density polyethylene after the pre-irradiation in step (1), and stir in the mixer at a speed of 2000r / min for 7 minutes to obtain a mixture A;

[0046] (3) Add glycidyl methacrylate, polystyre...

Embodiment 3

[0049] The environmentally friendly interface compatibilizer in this embodiment includes the following components by weight:

[0050]

[0051] Among them, the polystyrene-polyethylene-polybutene-polystyrene copolymer contains 4g of polystyrene-polyethylene-polybutene-polystyrene copolymer with a weight average molecular weight of 220,000 and a weight average molecular weight of 220,000. 6g of 5,000 polystyrene-polyethylene-polybutene-polystyrene copolymer.

[0052] The preparation method of the environmentally friendly interface compatibilizer includes the following steps:

[0053] (1) Perform electron beam pre-irradiation on linear low-density polyethylene, the irradiation dose is 30kGy, and the irradiation time is 6min;

[0054] (2) Sprinkle the methacryloxysilane evenly on the surface of the linear low density polyethylene after pre-irradiation in step (1), and stir in the mixer at a speed of 3000r / min for 5 minutes to obtain a mixture A;

[0055] (3) Add glycidyl methacrylate, poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com