A high strength gap blend

A blend and high-strength technology, applied in the field of high-strength GAP/HTPE blends, can solve problems such as high viscosity, and achieve the effect of simple selection and good physical compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The present invention is implemented with reference to the following composition by mass percentage: 55.51% GAP, 41.00% HTPE, 3.49% curing agent N-100, 0.02% catalyst TPB.

[0016] Preparation:

[0017] (1) Raw material pretreatment

[0018] Weigh 55.51g of GAP and 41.00g of HTPE into the kneading pot, and mix under vacuum at 60°C for 2 hours.

[0019] (2) glue mixing

[0020] Weigh 3.49g of curing agent N-100 and add it to the glue solution for vacuum mixing for 30min. Weigh 0.02g of TPB into the kneading pot, vacuumize and mix and stir for 15min.

[0021] (3) Test sample preparation

[0022] Pour the glue solution into a polytetrafluoroethylene mold, cure at 40°C for 3 days, and cure at 60°C for 4 days.

Embodiment 2

[0024] The present invention is implemented with reference to the following composition by mass percentage: 57.00% GAP, 40.00% HTPE, 3.00% curing agent N-100, 0.02% catalyst TPB.

[0025] Preparation:

[0026] (1) Raw material pretreatment

[0027] Weigh 57.00gGAP and 40.00gHTPE into the kneading pot, and mix under vacuum at 60°C for 2h.

[0028] (2) glue mixing

[0029] Weigh 3.00g of curing agent N-100 and add it to the glue solution for vacuum mixing for 30min. Weigh 0.02g of TPB into the kneading pot, vacuumize and mix and stir for 15min.

[0030] (3) Test sample preparation

[0031] Pour the glue solution into a polytetrafluoroethylene mold, cure at 40°C for 3 days, and cure at 60°C for 4 days.

Embodiment 3

[0033] The present invention is implemented with reference to the following composition by mass percentage: 50.00% GAP, 46.00% HTPE, 4.00% curing agent N-100, and 0.02% catalyst TPB.

[0034] Preparation:

[0035] (1) Raw material pretreatment

[0036] Weigh 50.00gGAP and 46.00gHTPE into the kneading pot, and mix under vacuum at 60°C for 2h.

[0037] (2) glue mixing

[0038] Weigh 4.00g of curing agent N-100 and add it to the glue solution for vacuum mixing for 30min. Weigh 0.02g of TPB into the kneading pot, vacuumize and mix and stir for 15min.

[0039] (3) Test sample preparation

[0040] Pour the glue solution into a polytetrafluoroethylene mold, cure at 40°C for 3 days, and cure at 60°C for 4 days.

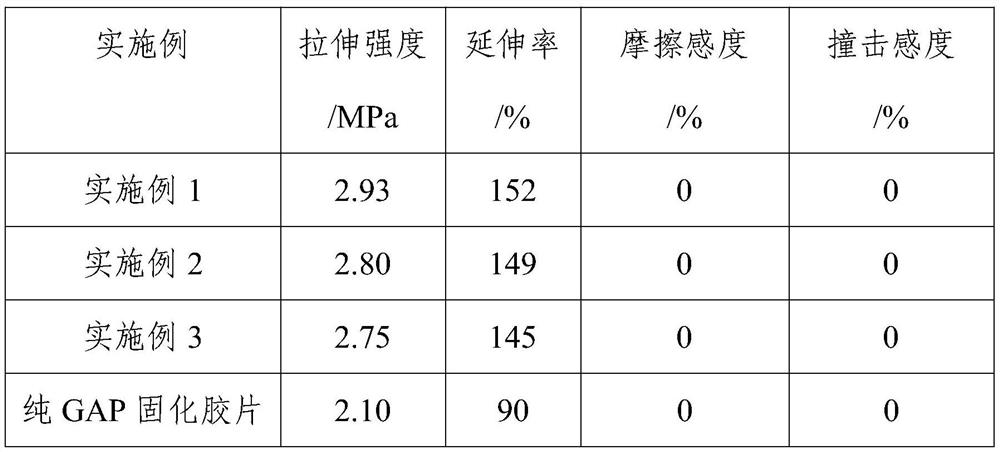

[0041] The cured elastomer film is made into a standard dumbbell shape, and the tensile strength and elongation of the sample are tested by an Instron-4505 material testing machine. The method is based on GJB770B-2005, the tensile rate is 500mm / min, and the test temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com