A kind of polymolybdenum oxide cluster-polyethylene glycol hybrid and its preparation method

A technology of polymolybdenum oxide clusters and polyethylene glycol, which is applied in the field of material chemistry, can solve problems such as poor compatibility, hindering practical application, and poor solubility of inorganic crystals, and achieves easy acquisition, large-scale production and popularization and application, and good The effect of physical compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Synthesis of polymolybdenum oxide cluster-maleimide hybrids.

[0045] Dissolve 0.21g of 3-maleimidopropionic acid and 0.44g of 2-ethoxy-1-ethoxycarbonyl-1,2-dihydroquinoline in 50mL of acetonitrile, heat up to 81°C and stir for 20min , Add 1g of polymolybdenum oxide clusters to react for 24h, stop the reaction. After the reaction product was concentrated by rotary evaporation, it was added to precipitate in chloroform, and the separated precipitate was dissolved in 7 mL of acetonitrile, placed in ether vapor to precipitate, filtered by suction, and dried in vacuum to obtain 0.95 g of polymolybdenum oxide cluster-maleimide hetero Compound orange solid, yield 82%.

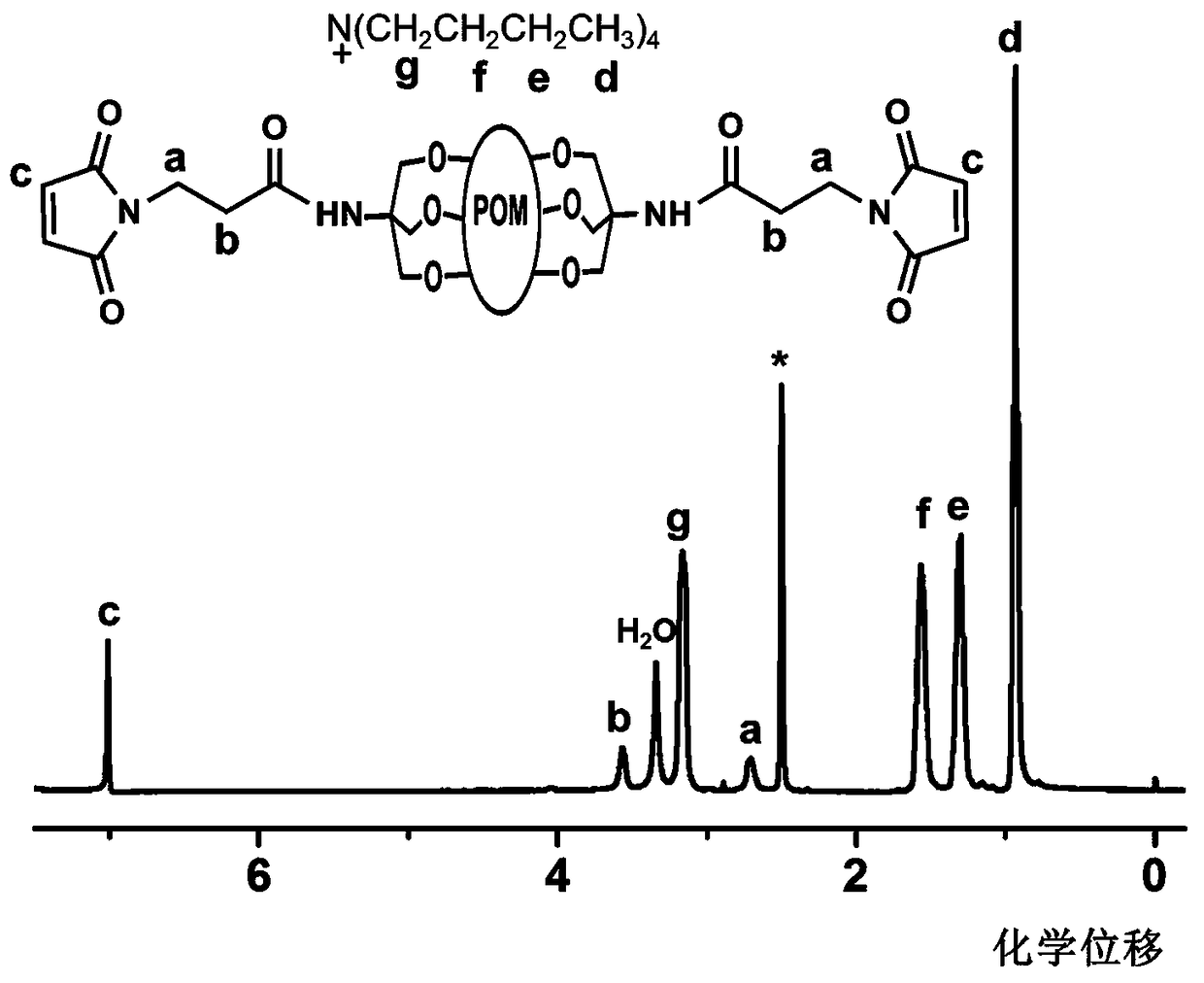

[0046] figure 1 It is the H NMR spectrum of the polymolybdenum oxygen cluster-maleimide hybrid. The * in the spectrogram indicates the solvent peak, and all the characteristic peaks are clearly assigned, and there are no miscellaneous peaks in the spectrogram, which proves that the prepared polymolybden...

Embodiment 2

[0054] 1) Synthesis of polymolybdenum oxide cluster-maleimide hybrids.

[0055] Dissolve 0.38g of 3-maleimidopropionic acid and 0.81g of 2-ethoxy-1-ethoxycarbonyl-1,2-dihydroquinoline in 80mL of acetonitrile, heat up to 83°C and stir for 25min , Add 1.5g polymolybdenum oxide clusters to react for 48h, stop the reaction. After the reaction product was concentrated by rotary evaporation, it was added to precipitate in chloroform, and the separated precipitate was dissolved in 11 mL of acetonitrile, placed in ether vapor to precipitate, filtered by suction, and dried in vacuum to obtain 1.39 g of polymolybdenum oxide cluster-maleimide hetero Compound orange solid, yield 80%.

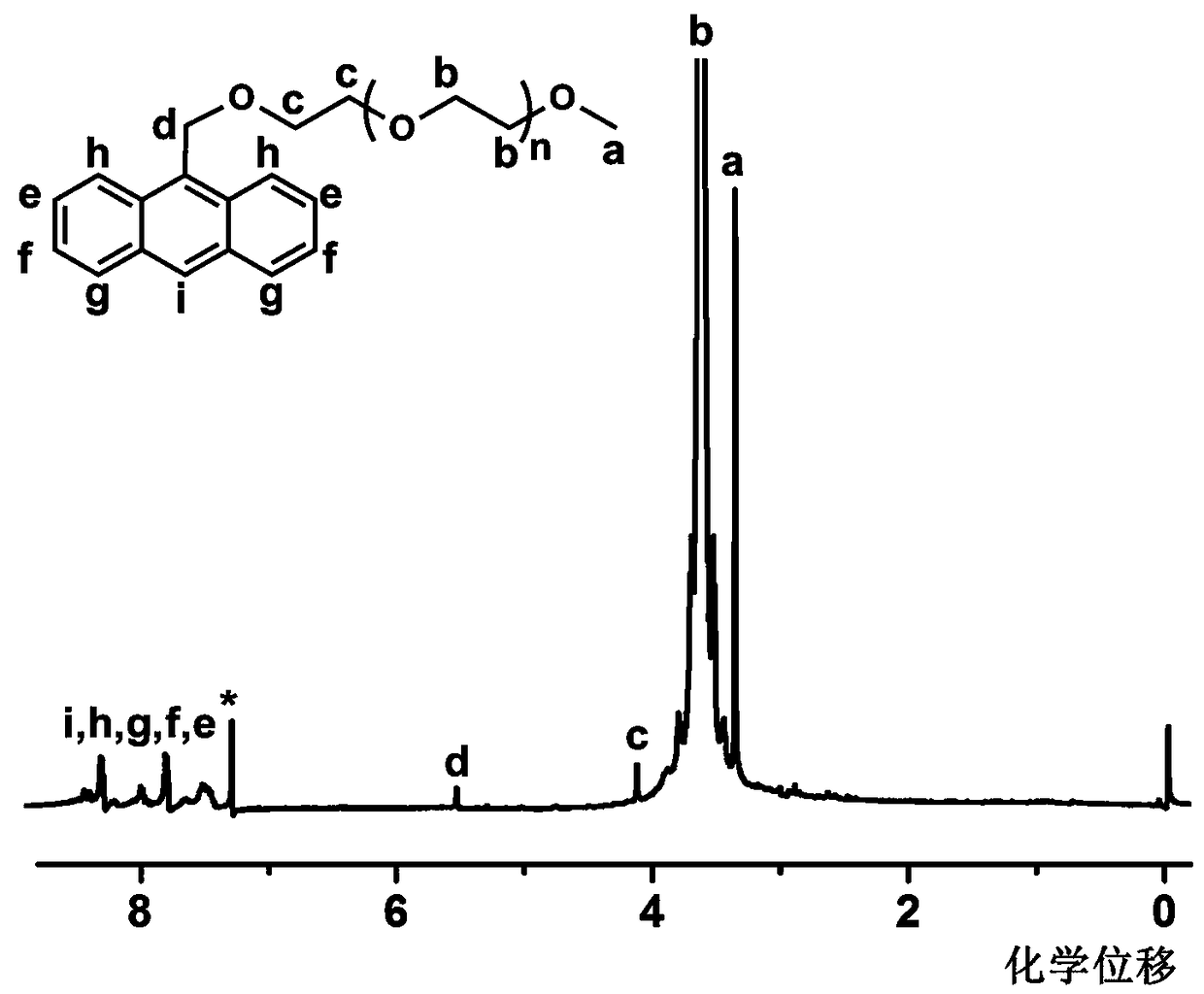

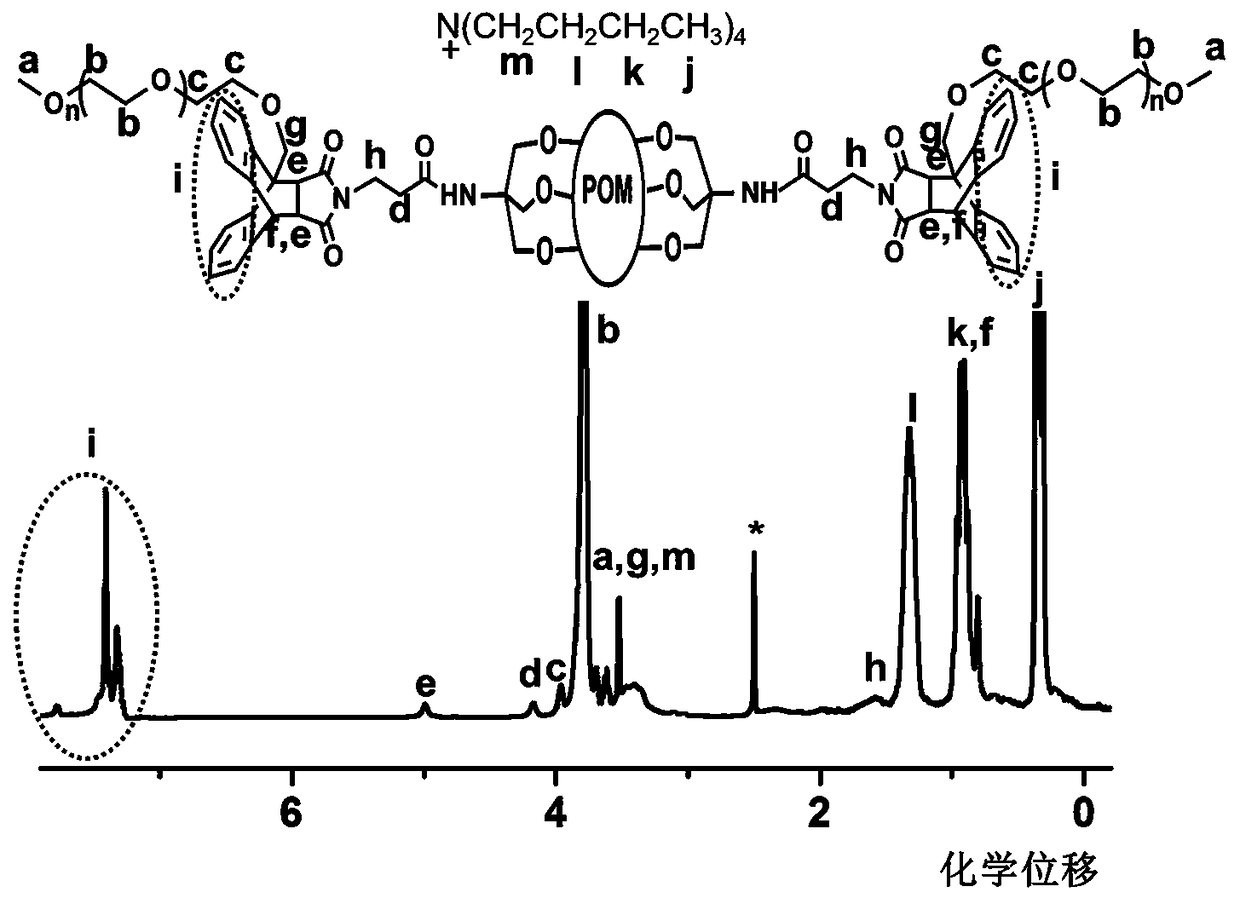

[0056] 2) Synthesis of anthracenyl polyethylene glycol monomethyl ether.

[0057] Dissolve 1.50g of polyethylene glycol monomethyl ether with an average molecular weight of 2000, 0.42g of 9-chloromethylanthracene and 0.11g of sodium hydride in 41mL of toluene, raise the temperature to 105°C and stir for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com