Water-retaining thickening agent for composite dry mortars and preparation method thereof

A water-retaining thickener and dry powder mortar technology are applied in the field of dry-powder mortar water-retaining thickener, can solve the problems of producing a composite water-retaining thickener and the like, and achieve good application prospects, low cost, and the effect of enhancing construction and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

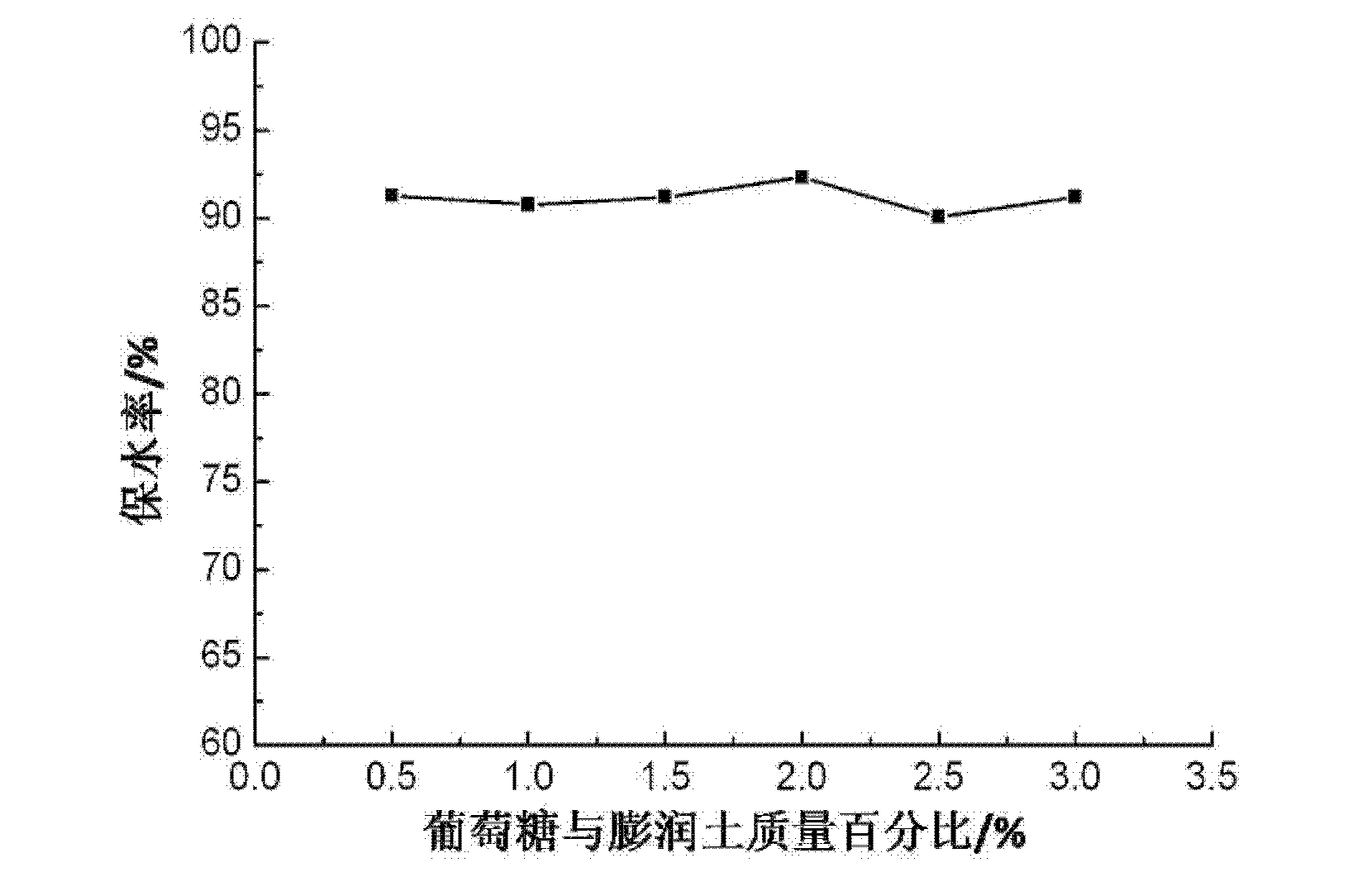

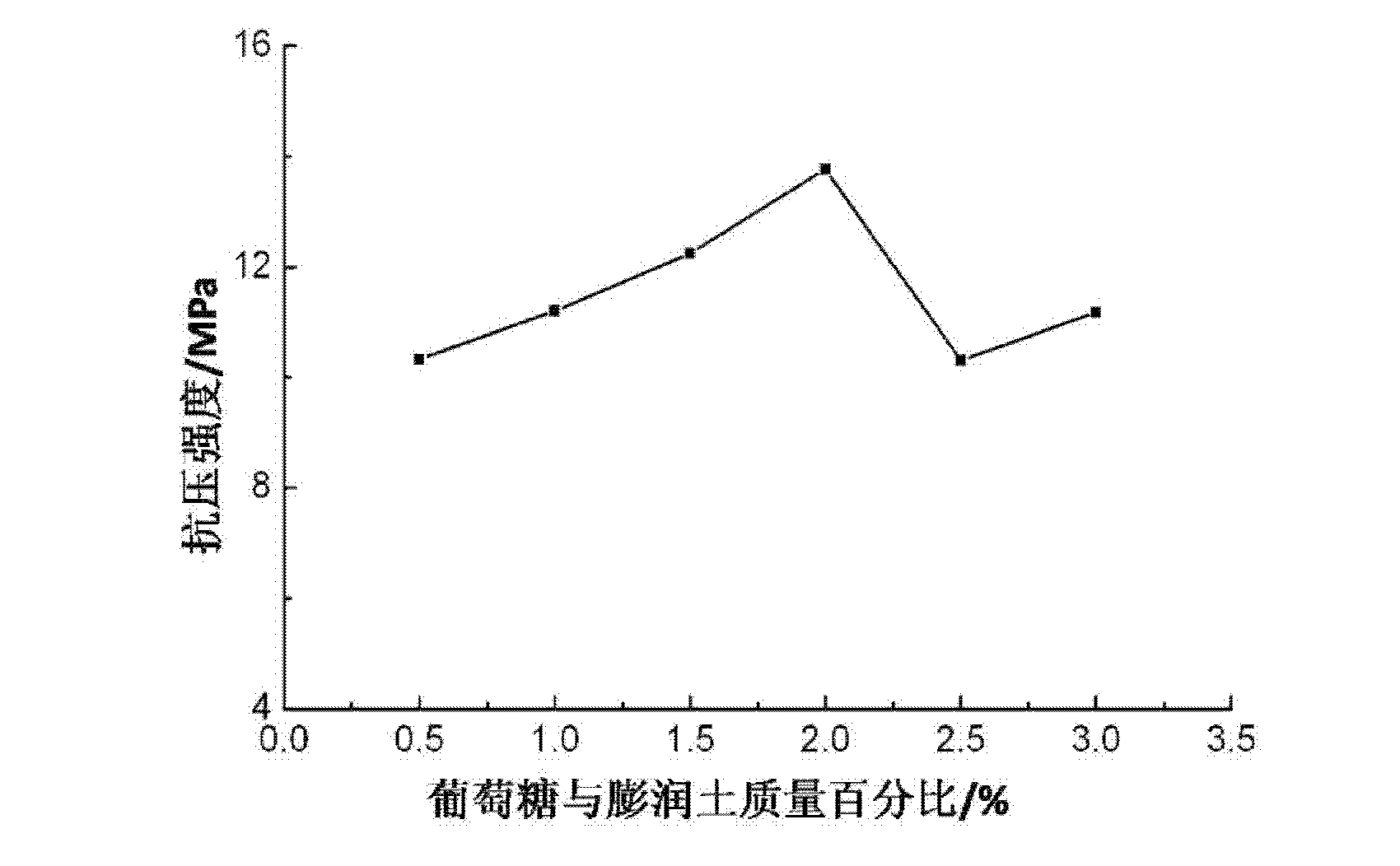

Embodiment 1

[0028] Dissolve 0.4g of glucose in water, stir well to dissolve, then add 80g of bentonite, stir and mix for 3h, then let stand at room temperature for 24h. After fully drying at 110°C, it is ground into powder, which is the new water-retaining thickener. Mix the prepared water-retaining thickener with 800g of 42.5 cement and 4000g of river sand, add 1000g of water, and test the water retention rate of the mortar after stirring. Then use the mold to make the freshly mixed mortar into a 40mm×40mm×160mm mortar test block; put it into a standard curing box, maintain it at 20°C and a relative humidity of 90%, and test the compressive strength for 28 days.

Embodiment 2

[0030] Dissolve 0.8g of glucose in water, stir well to dissolve, add 80g of bentonite, stir and mix for 3h, then let stand at room temperature for 12h. After fully drying at 150°C, it is ground into powder, which is the new water-retaining thickener. Mix the prepared water-retaining thickener with 800g of 42.5 cement and 4000g of river sand, add 1000g of water, and test the water retention rate of the mortar after stirring. Then use the mold to make the freshly mixed mortar into a 40mm×40mm×160mm mortar test block; put it into a standard curing box, maintain it at 20°C and a relative humidity of 90%, and test the compressive strength for 28 days.

Embodiment 3

[0032] Dissolve 1.2g of glucose in water, stir well to dissolve, then add 80g of bentonite, stir and mix for 3h, then let stand at room temperature for 72h. After being fully dried at 130°C, it is ground into powder, which is the new water-retaining thickener. Mix the prepared water-retaining thickener with 800g of 42.5 cement and 4000g of river sand, add 1000g of water, and test the water retention rate of the mortar after stirring. Then use the mold to make the freshly mixed mortar into a 40mm×40mm×160mm mortar test block; put it into a standard curing box, maintain it at 20°C and a relative humidity of 90%, and test the compressive strength for 28 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com