A high-temperature oil well cement retarder capable of inhibiting abnormal gelation and its preparation method

A technology of oil well cement and retarder, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as abnormal thickening curve and abnormal gelation of cement slurry, achieve stable product performance, and improve high temperature stability , Improve the effect of consistency and rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

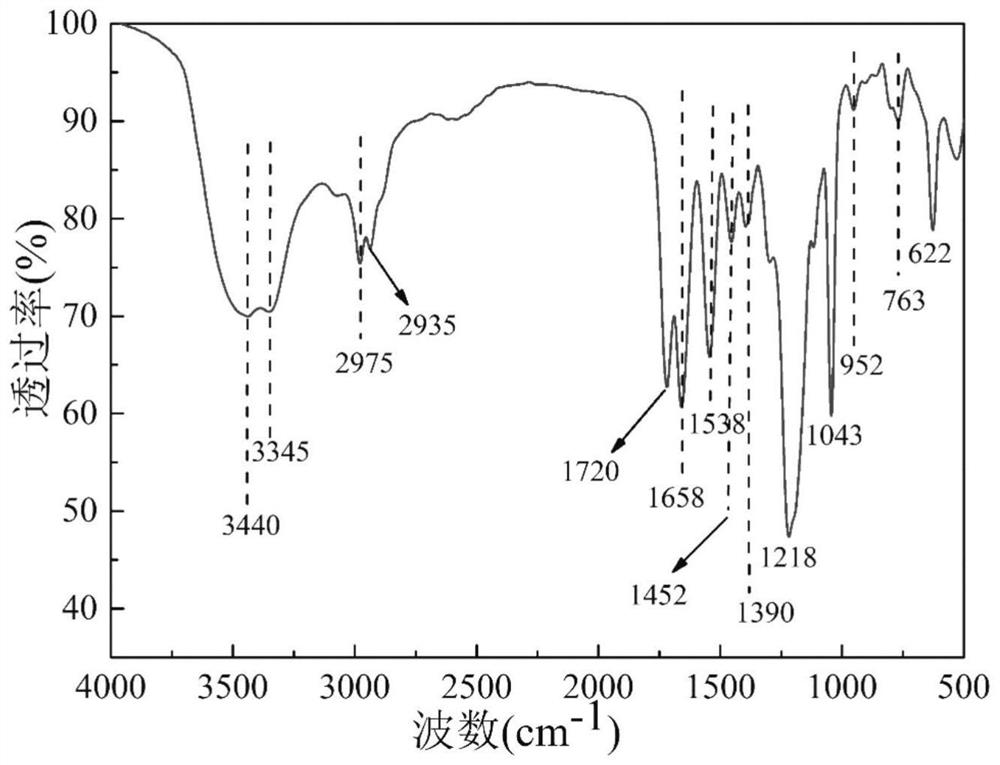

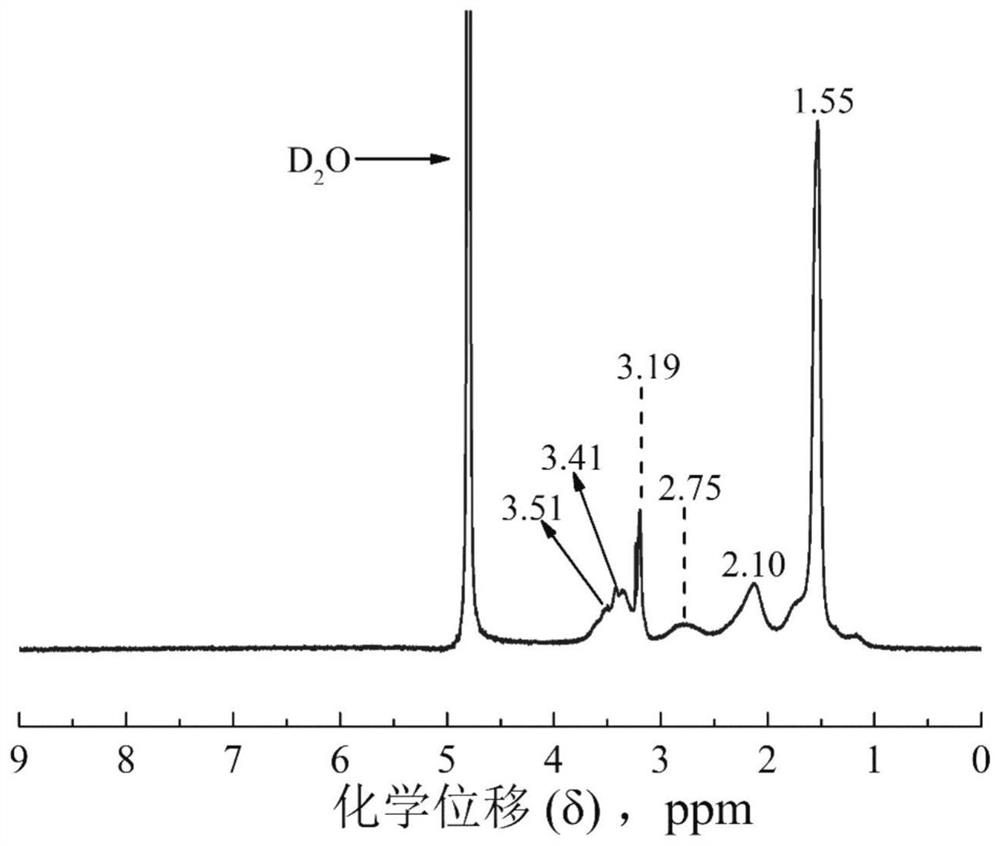

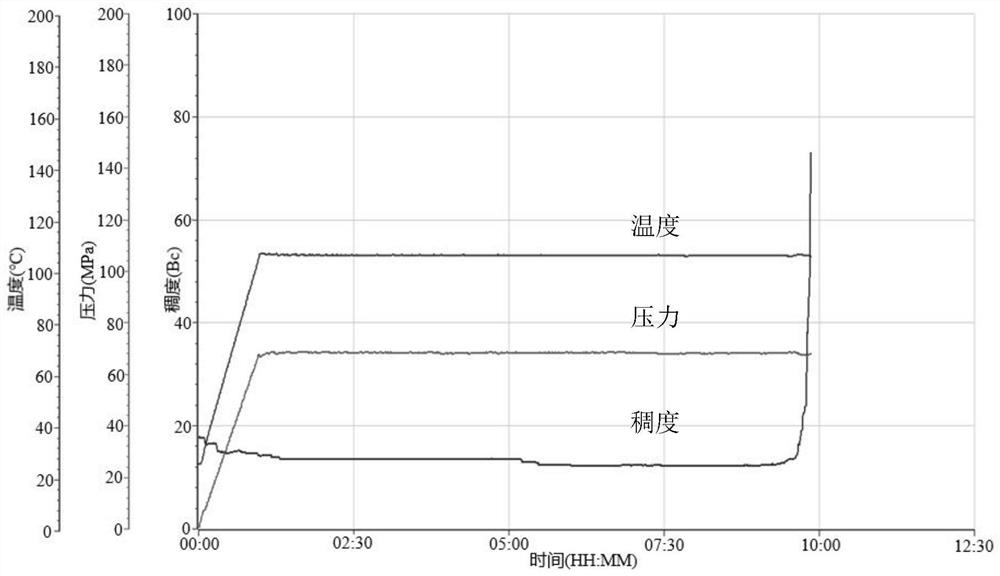

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of a high-temperature oil well cement retarder capable of inhibiting abnormal gelation, comprising the steps of:

[0045] (1) Dissolve 22.75g of 2-acrylamido-2-methylpropanesulfonic acid and 7g of itaconic acid in 55g of deionized water, stir well, and adjust the pH to 5.5 with 0.5mol / L sodium hydroxide solution;

[0046](2) Weigh 3.5g of N-vinylcaprolactam and 3.5g (50wt% aqueous solution) of methacryloylpropyltrimethylammonium chloride into the solution obtained in step (1), stir evenly, and heat up to 60°C;

[0047] (3) Weigh 0.7g of ammonium persulfate and dissolve it in 9.3g of deionized water to make a solution, add it into the solution obtained in step (2) under stirring at a speed of 215r / min, keep it warm at 60°C for 30min, and heat up to 80°C React at a constant temperature for 3 hours to obtain a high-temperature oil well cement retarder that can inhibit abnormal gelation.

Embodiment 2

[0049] A preparation method of a high-temperature oil well cement retarder capable of inhibiting abnormal gelation, comprising the steps of:

[0050] (1) Dissolve 23g of 2-acrylamido-2-methylpropanesulfonic acid and 6g of maleic anhydride in 50g of deionized water, stir evenly, and adjust the pH to 6 with 0.5mol / L potassium hydroxide solution;

[0051] (2) Weigh 4g of N-vinylpyrrolidone and 2g (75wt% aqueous solution) of methacryloyloxyethyltrimethylammonium chloride into the solution obtained in step (1), stir evenly, and heat up to 55°C;

[0052] (3) Weigh 0.9g of potassium persulfate and dissolve it in 12g of deionized water to make a solution, add it into the solution obtained in step (2) under stirring at a rotation speed of 180r / min, keep it warm at 55°C for 20min, and heat up to 70°C at a constant temperature After reacting for 2 hours, a high-temperature oil well cement retarder capable of inhibiting abnormal gelation was obtained.

Embodiment 3

[0054] A preparation method of a high-temperature oil well cement retarder capable of inhibiting abnormal gelation, comprising the steps of:

[0055] (1) Dissolve 21g of 2-acrylamido-2-methylpropanesulfonic acid and 8g of mesaconic acid in 60g of deionized water, stir well, and adjust the pH to 5 with 0.5mol / L sodium hydroxide solution;

[0056] (2) Weigh 3g of 2-vinylmorpholine and 4.5g (50wt% aqueous solution) of methacryloylpropyltrimethylammonium chloride into the solution obtained in step (1), stir evenly, and heat up to 65°C ;

[0057] (3) Weigh 0.5g of azobisisobutylimidazoline hydrochloride and dissolve it in 8g of deionized water to form a solution, add it into the solution obtained in step (2) under stirring at a speed of 250r / min, and keep it warm at 65°C After 40 minutes, the temperature was raised to 85°C for 4 hours of constant temperature reaction to obtain a high-temperature oil well cement retarder that can inhibit abnormal gelation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com