High-performance concrete prepared from recycled slurry

A technology of high-performance concrete and recycled slurry, which is applied in the field of high-performance concrete, can solve the problems of poor concrete pumping performance and other performance, less research on machine-made sand and gravel concrete, and poor workability of concrete, so as to maintain Plasticity, improve segregation resistance, increase viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

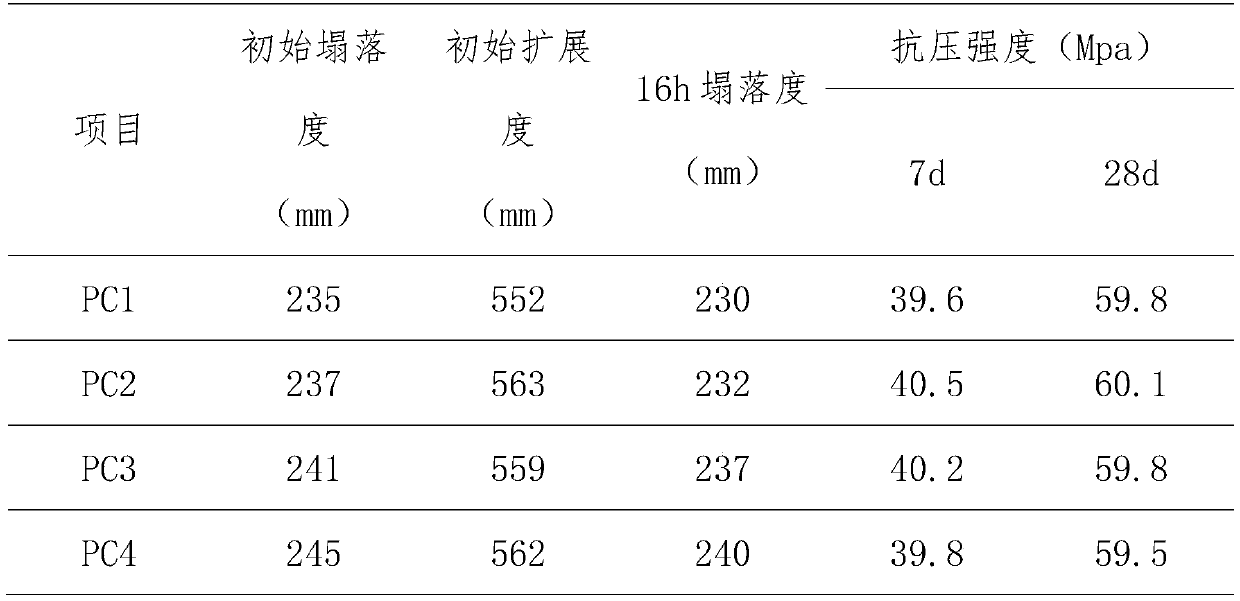

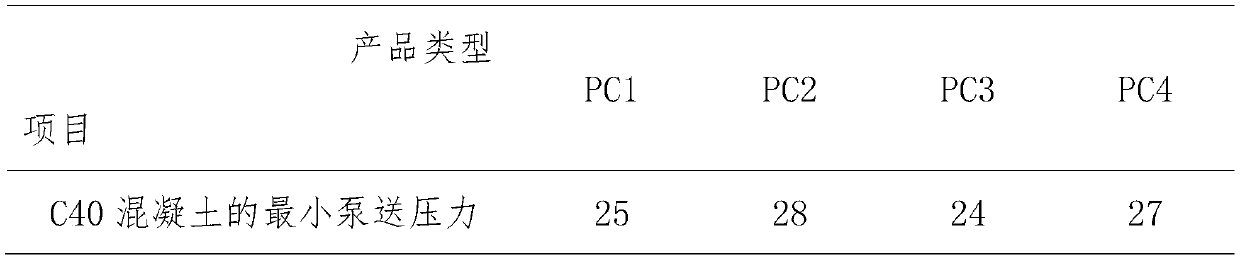

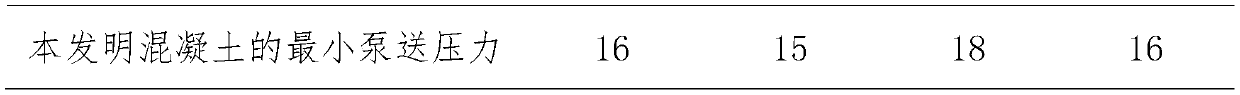

Embodiment 1

[0038] Machine-made sand concrete preparation:

[0039] The composition includes the following components in parts by weight: 135 parts of cement, 8 parts of fine powder, 100 parts of coal ash, 900 parts of gravel, 500 parts of machine-made sand, 135 parts of water, 80 parts of slurry and 8 parts of admixture.

[0040] Prepare the concrete of the present invention after configuring the raw material components. During the preparation, first add machine-made sand, coal ash and water to the main machine of the concrete mixer, and stir for 60 seconds; then add the admixture to the main engine of the mixer, and stir for 20 to 30 seconds; finally Add crushed stone and fine powder into the main mixer, and stir evenly. The product is recorded as PC1. When preparing, mix the cementitious material first and then add the crushed stone. The crushed stone can well disperse the cementitious material particles in the concrete, achieve the purpose of homogenizing the concrete, and effectively...

Embodiment 2

[0042] The raw materials were weighed according to the following parts by weight: 225 parts of cement, 9 parts of fine powder, 85 parts of coal ash, 845 parts of crushed stone, 550 parts of machine-made sand, 120 parts of water, 95 parts of slurry water and 9.5 parts of admixture.

[0043] After configuring the raw materials, the concrete of this embodiment was prepared according to the method of embodiment 1, and the product was recorded as PC2.

Embodiment 3

[0045] Machine-made sand selection:

[0046] Weigh raw materials according to the following parts by weight: components including the following parts by weight: 175 parts of cement, 12 parts of micropowder, 80 parts of coal ash, 885 parts of gravel, 658 parts of machine-made sand, 150 parts of water, and 102 parts of slurry And 10.5 parts of admixture.

[0047] After configuring the raw materials, prepare the concrete of this embodiment according to the method of embodiment 1, and the product is denoted as PC3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com