Construction method for stratified symmetric synchronous pouring of second lining concrete of tunnel

A technology of simultaneous pouring and concrete, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problem of uneven distribution of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

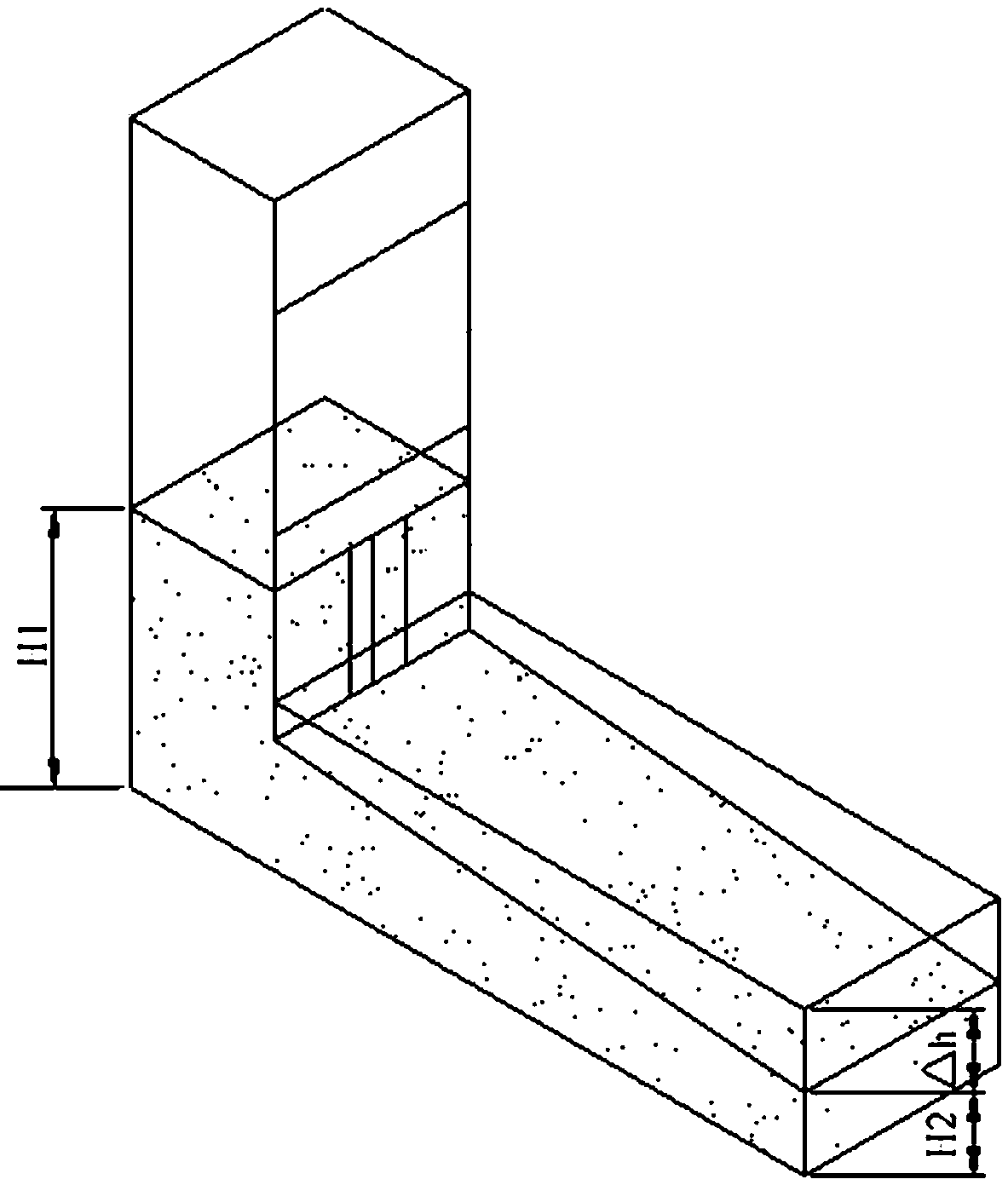

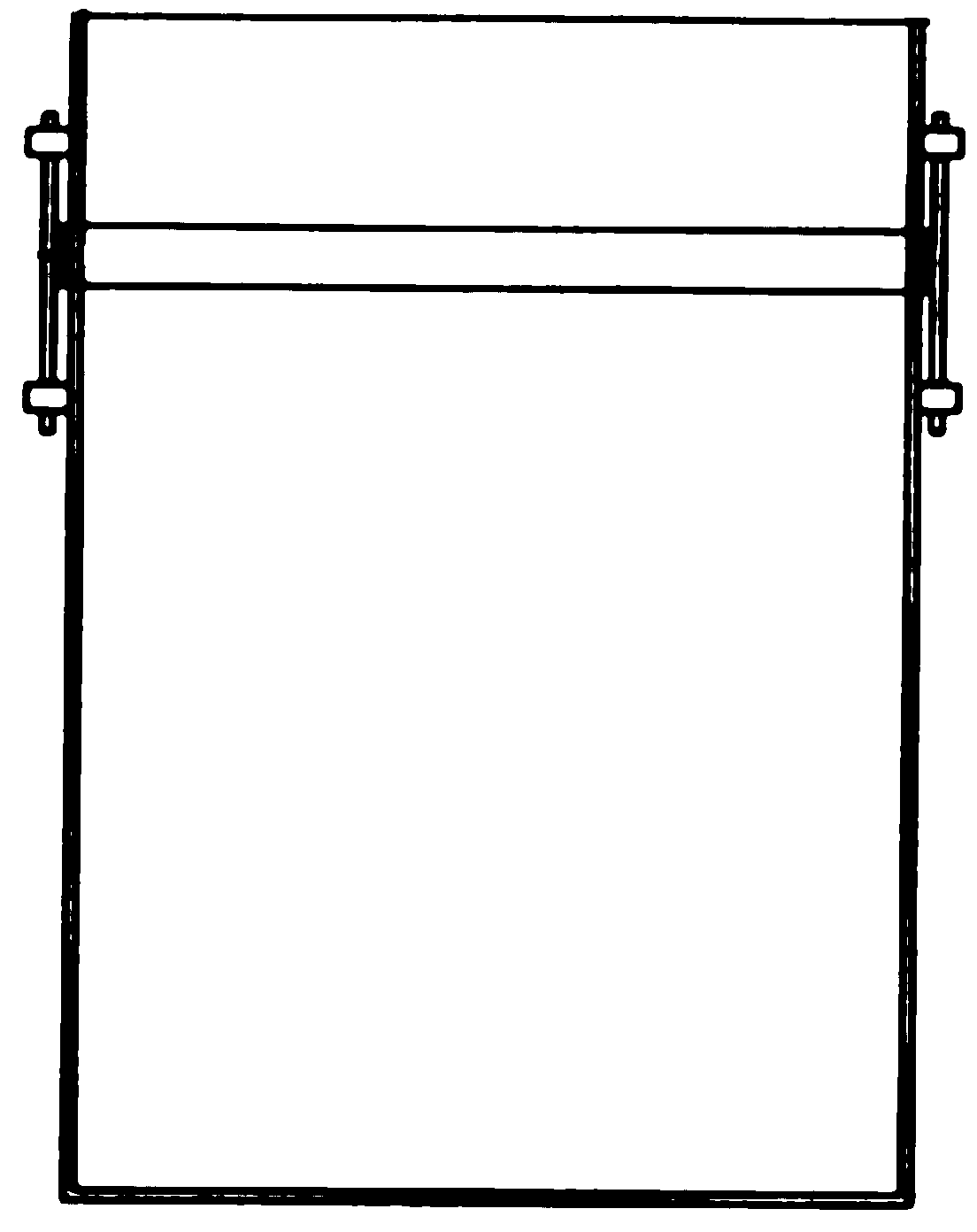

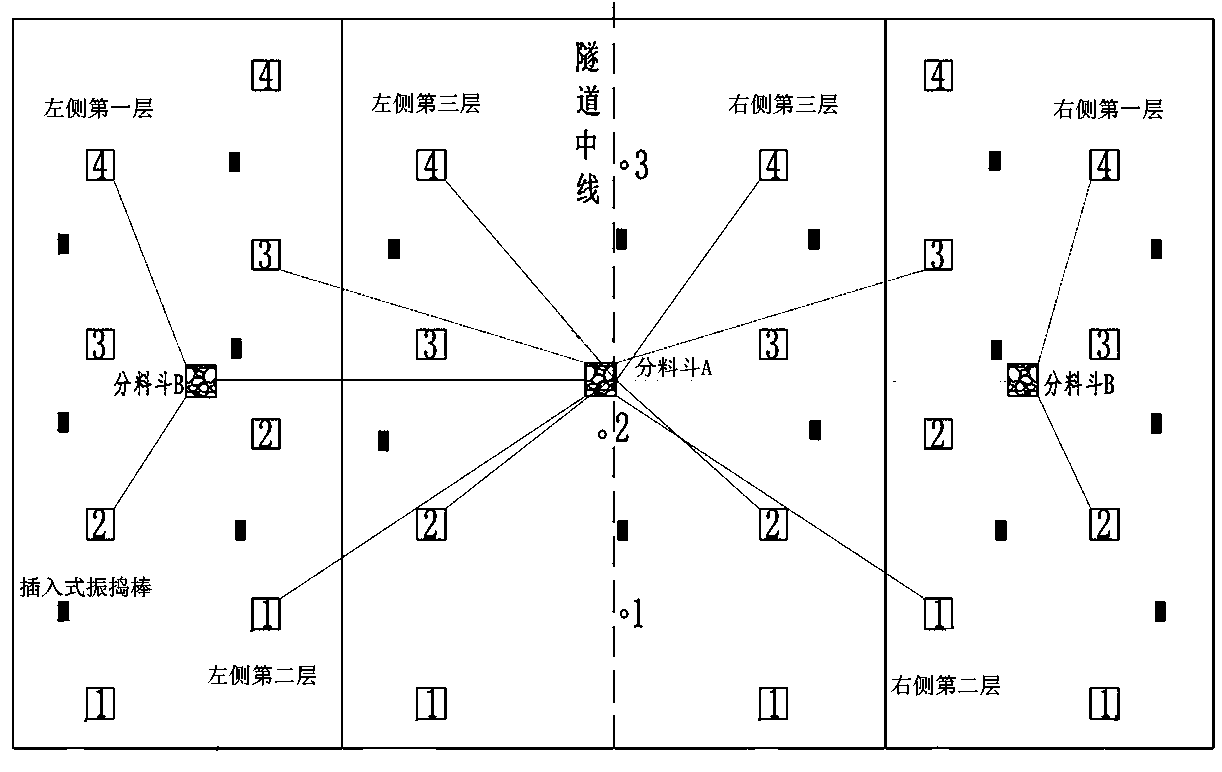

[0019] Combined with the accompanying drawings, the main points of operation of this construction method will be described in detail.

[0020] Concrete Mix Design

[0021] The design requires the secondary lining of the tunnel to be C35 concrete. Combined with the characteristics of the engineering site and construction tooling, due to the long flow distance, gentle slope and many branches of the chute tooling, high fluidity and anti-segregation performance of the concrete must be considered in the mix ratio design; At the same time, in view of the loss of slurry in the long-distance chute, an appropriate increase in the amount of slurry should also be considered in the design of the mix ratio.

[0022] The mix design adopts the principle of low water-binder ratio and large amount of mineral admixture. Add high-performance polycarboxylate water reducer to reduce the water-binder ratio, improve the cohesion of concrete through low water-binder ratio, and ensure that the concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com