Concrete admixture for roads

A concrete admixture and road technology, applied in the field of road traffic engineering, can solve the problems of increased bleeding rate, poor adaptability of cement varieties, early setting of concrete, etc., achieve high water reducing rate, improve frost resistance, and extend construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The preparation of the concrete admixture for highway of the present invention: take 70 parts of slag, 15 parts of bentonite, and 10 parts of silicon powder in parts by weight and mix evenly, and grind it to 100 mesh to 150 mesh for later use; choose 8 parts of stearic acid, methyl 3 parts of cellulose, 5 parts of polyacrylamide, and 12 parts of sodium lauryl sulfate are put into a closed mixer, stirred and mixed evenly, and sealed and packed into bags.

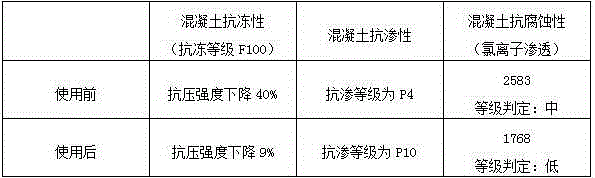

[0012] When in use, the admixture of the present invention is added to concrete in an amount of 0.05%-0.10%. The performance parameters of concrete after adding the admixture of the present invention are as follows:

[0013]

Embodiment 2

[0015] The preparation of the concrete admixture for highways of the present invention: take 70 parts of slag, 10 parts of bentonite, and 8 parts of silicon powder in parts by weight and mix them evenly, and grind them to 100 to 150 meshes for later use; choose 8 parts of stearic acid, methyl 2 parts of cellulose, 4 parts of polyacrylamide, and 8 parts of sodium lauryl sulfate are put into a closed mixer, stirred and mixed evenly, and sealed and packed into bags.

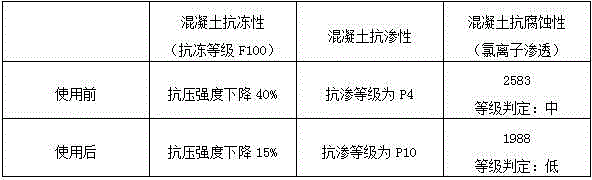

[0016] When in use, the admixture of the present invention is added to concrete in an amount of 0.05%-0.10%. The performance parameters of concrete after adding the admixture of the present invention are as follows:

[0017]

Embodiment 3

[0019] The preparation of the concrete admixture for highway of the present invention: take 80 parts of slag, 15 parts of bentonite, and 15 parts of silicon powder in parts by weight and mix evenly, and grind it to 100 mesh to 150 mesh for later use; choose 10 parts of stearic acid, methyl 5 parts of cellulose, 7 parts of polyacrylamide, and 15 parts of sodium lauryl sulfate are put into a closed mixer, stirred and mixed evenly, and sealed and packed into bags.

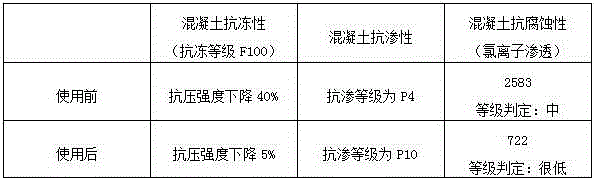

[0020] When in use, the admixture of the present invention is added to concrete in an amount of 0.05%-0.10%. The performance parameters of concrete after adding the admixture of the present invention are as follows:

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com