Method for manufacturing aluminum liner of double-layer passivation protection layer

A technology of passivation protective layer and manufacturing method, which is applied in the field of aluminum pad manufacturing, can solve problems such as difficult removal of titanium/titanium nitride anti-reflective layer, soft failure of chips, increase of contact resistance of aluminum pad, etc., to achieve filling Effect of smoothness, less residue, and improved filling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with principle diagrams and specific operation examples.

[0029] The passivation protection layer and the aluminum pad layer are the final steps in the manufacture of semiconductor chips. In industrial production, according to the requirements of the actual application environment, there are different options for single passivation protection layer or double passivation protection layer. The present invention relates to the case of a single passivation protection layer.

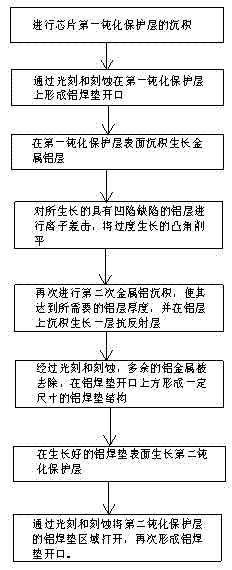

[0030] Such as figure 1 As shown, the manufacturing method of the aluminum liner of the double passivation protection layer of the present invention specifically comprises the following steps:

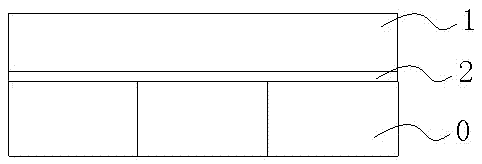

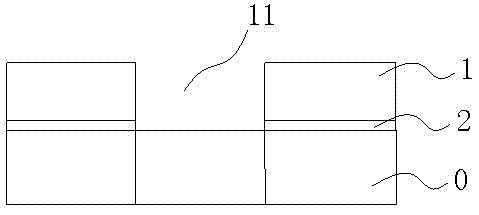

[0031] first step, such as Figure 2a As shown, the deposition of the first passivation protection layer of the chip is carried out. A first passivation protection layer 1 with a certain thickness is grown on the chip substrate 0 with int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com