Large-flowability and high-strength concrete

A high-strength, concrete technology, applied in the field of concrete, can solve problems such as the inability to meet high-rise and super-high-rise buildings, less high-fluidity and high-strength concrete, and the fluidity and strength need to be improved, so as to improve construction efficiency and construction quality, Excellent fluidity, the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The high-fluidity high-strength concrete of the present invention is characterized in that comprising the following components by weight:

[0019] Cement: 350-450, silica fume: 30-60, slag powder: 40-90, fly ash: 40-60, fine aggregate: 650-700, coarse aggregate: 1000-1250, water: 150-180, Pumping agent: 10-15;

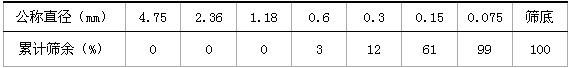

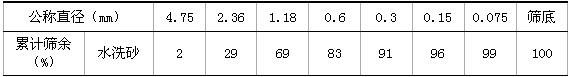

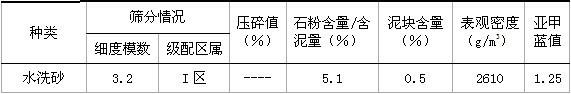

[0020] Among them, the cement is selected from qualified products produced by large-scale cement production enterprises, such as P042.5R cement produced by Chongqing Lafarge Cement Co., Ltd., or P042.5R cement produced by Chongqing Xiaonanhai Cement Co., Ltd.; silica fume, select large-scale silica fume Qualified products produced by manufacturers, such as Elkem (Norway) silica fume; slag powder, select S95 grade slag powder from Chongqing Ruiliang Building Materials Co., Ltd.; fly ash, select Class II products produced by Chongqing Huaneng Jiaohuang Power Plant; The material is a mixture of artificial machine-made sand and Yangtze River sand. The artificial ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com