Precesion casting method for high temperature alloy complex thin-walled castings

A technology of thin-walled castings and precision casting, which is applied in the precision casting of high-temperature alloy complex thin-walled castings and the field of investment casting precision casting of high-temperature alloy thin-walled castings. problems, to achieve the effect of improving filling capacity, reducing requirements, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

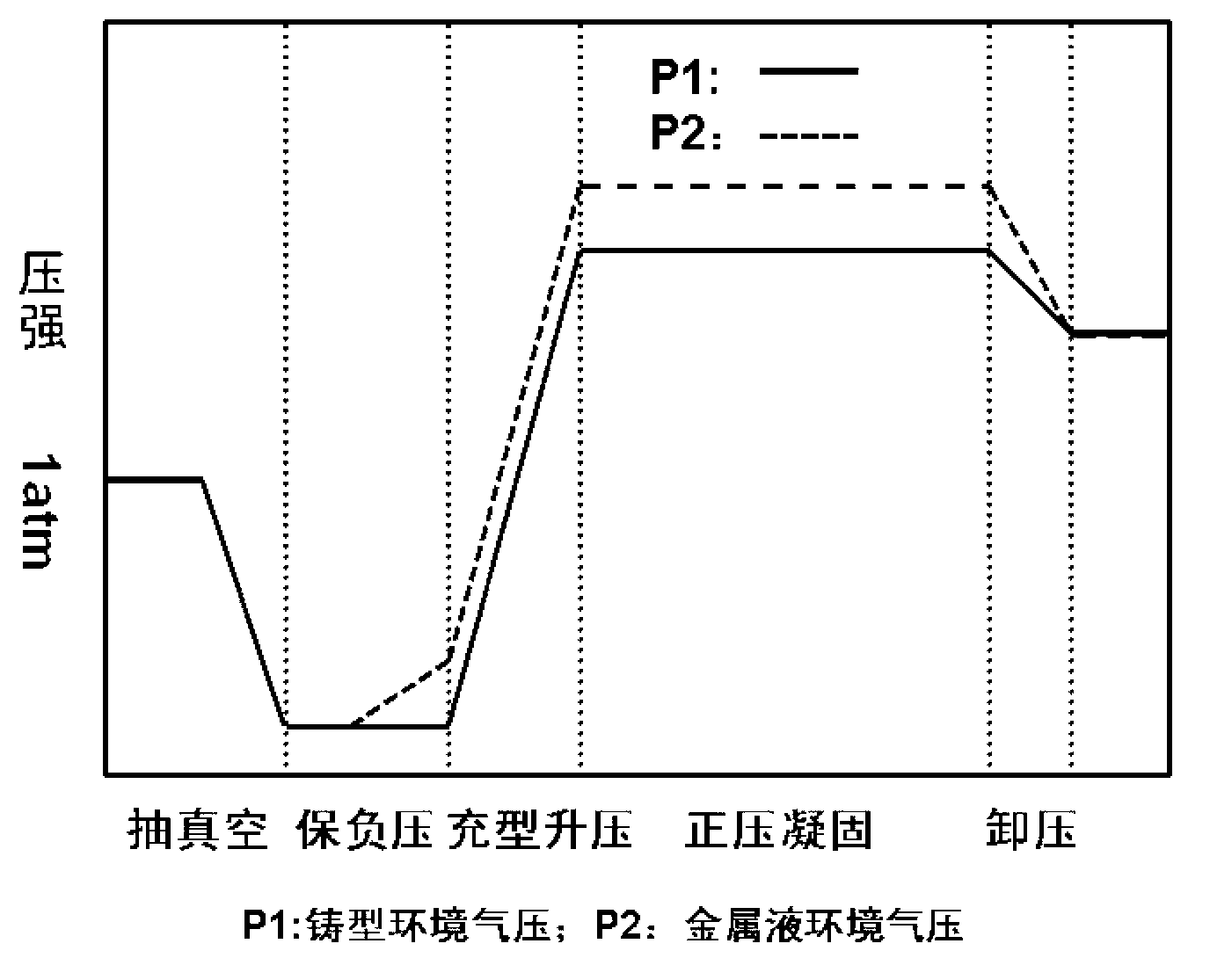

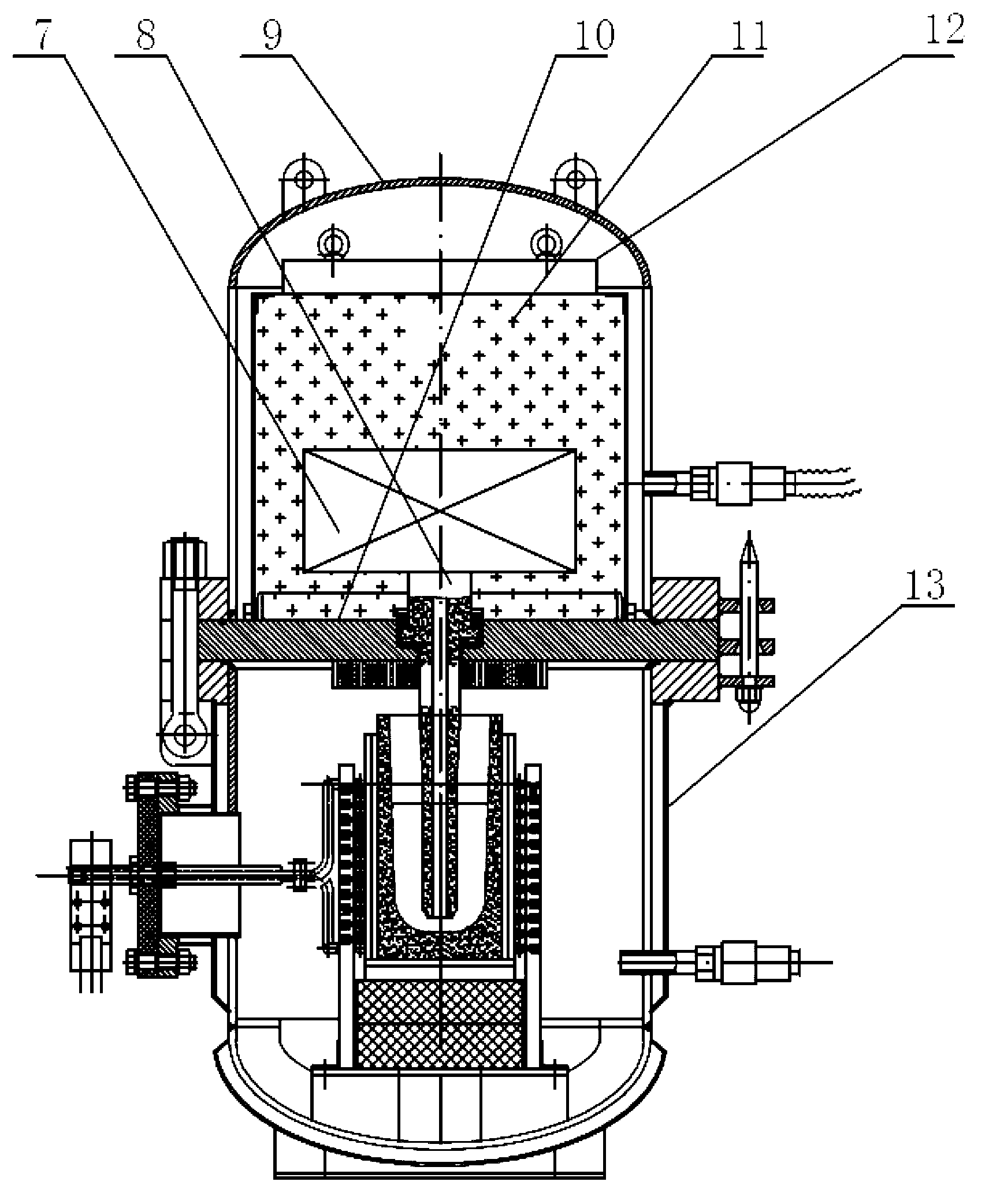

[0039] Using the precision casting method of superalloy complex thin-walled castings, the diameter of the riser is 40mm, and the liquid surface area of the liquid metal in the crucible is 70000mm 2 , the pressure of the upper tank is 1.0MPa, the pressure of the lower tank is 1.5MPa, the pressure difference is 0.5MPa, the rising speed of the liquid metal is 100mm / s, and the thin-walled area of the casting is 200mm×200mm and the minimum wall thickness is obtained by the pressure-regulating precision casting method. 3.0mm, the internal quality of the casting is better.

Embodiment 2

[0041] Using the precision casting method of superalloy complex thin-walled castings, the diameter of the riser is 35mm, and the liquid surface area of the liquid metal in the crucible is 70000mm 2 , the pressure of the upper tank is 0.8MPa, the pressure of the lower tank is 1.5MPa, the pressure difference is 0.7MPa, the rising speed of the liquid metal is 120mm / s, and the thin-walled area of the casting is 300mm×300mm and the minimum wall thickness is obtained by the pressure-regulating precision casting method. It is 2.6mm, and the internal quality of the casting is better.

Embodiment 3

[0043] Using the precision casting method of superalloy complex thin-walled castings, the diameter of the riser is 30mm, and the liquid surface area of the liquid metal in the crucible is 70000mm 2 , the pressure of the upper tank is 0.6MPa, the pressure of the lower tank is 1.5MPa, the pressure difference is 0.9MPa, the rising speed of the liquid metal is 135mm / s, and the thin-walled area of the casting is 400mm×400mm and the minimum wall thickness is obtained by the pressure-regulating precision casting method. It is 2.2mm, and the internal quality of the casting is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com