Crankshaft forging die

A technology for molds and crankshafts, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of high production costs, low material and energy utilization rates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

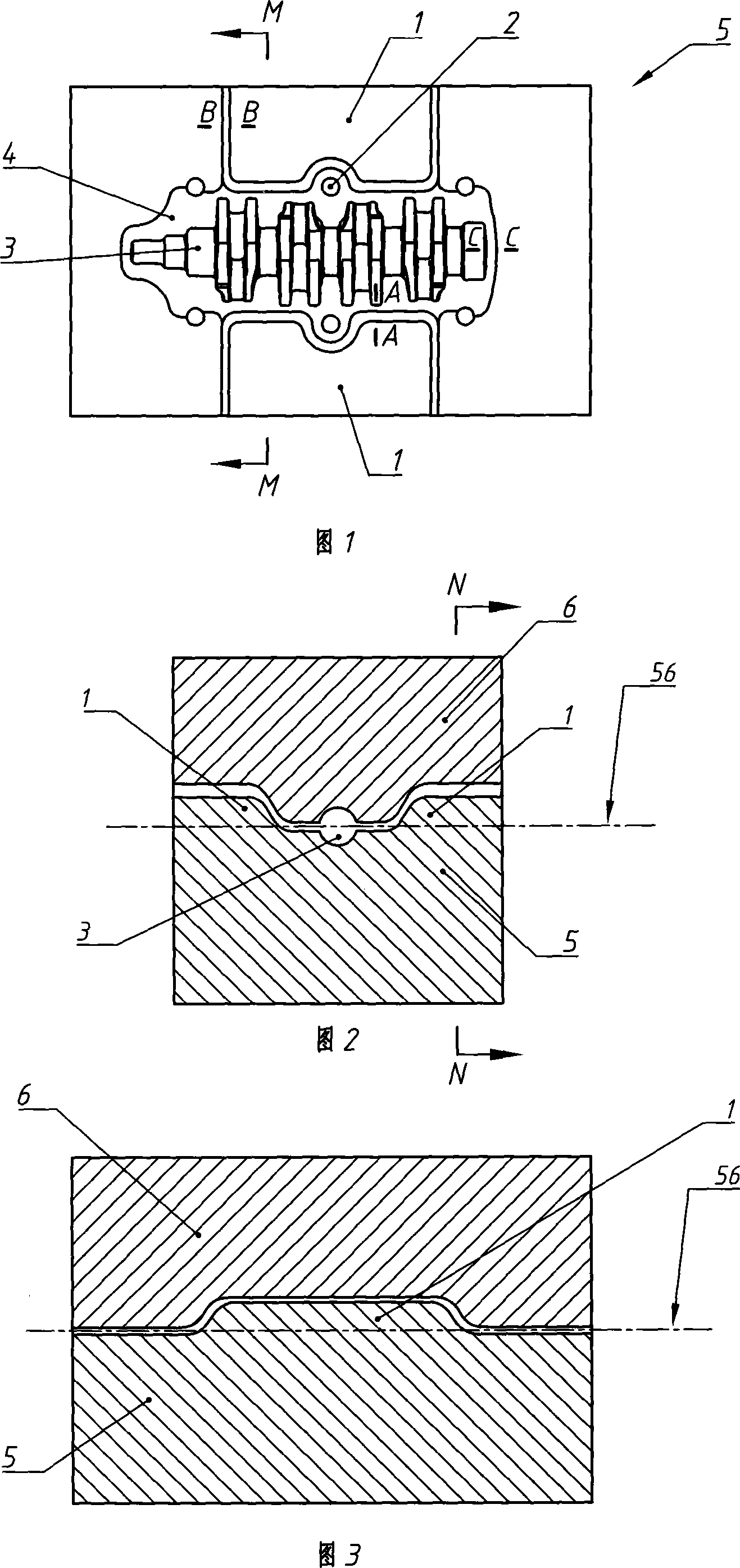

[0013] Embodiment 1 (with reference to Fig. 1,2,3,4):

[0014] A die for forging a crankshaft. At the parting surface 56 of the upper and lower molds of the mold, a flash groove formed by a flash bridge 4 and a flash bin 7 surrounding the outer periphery of the flash bridge 4 is provided along the periphery of the cavity 3 of the mold. . In the flash groove of the present invention, corresponding to the original flash warehouse part 7 on both sides of the cavity part of the crankshaft balance weight, the wall body 1 exceeding its parting surface 56 is provided on one side of the lower die 5 (obviously, when necessary , the wall 1 needs to give way to the forging die ejector pin hole 2); between the protruding wall 1 and the concave part of the corresponding original flash warehouse part 7 in the upper mold 6, there is a width and a flash The height of the bridge portion 4 corresponds to the gap h3. That is to say, at the original flash bin portion 7 on both sides of the mol...

Embodiment 2

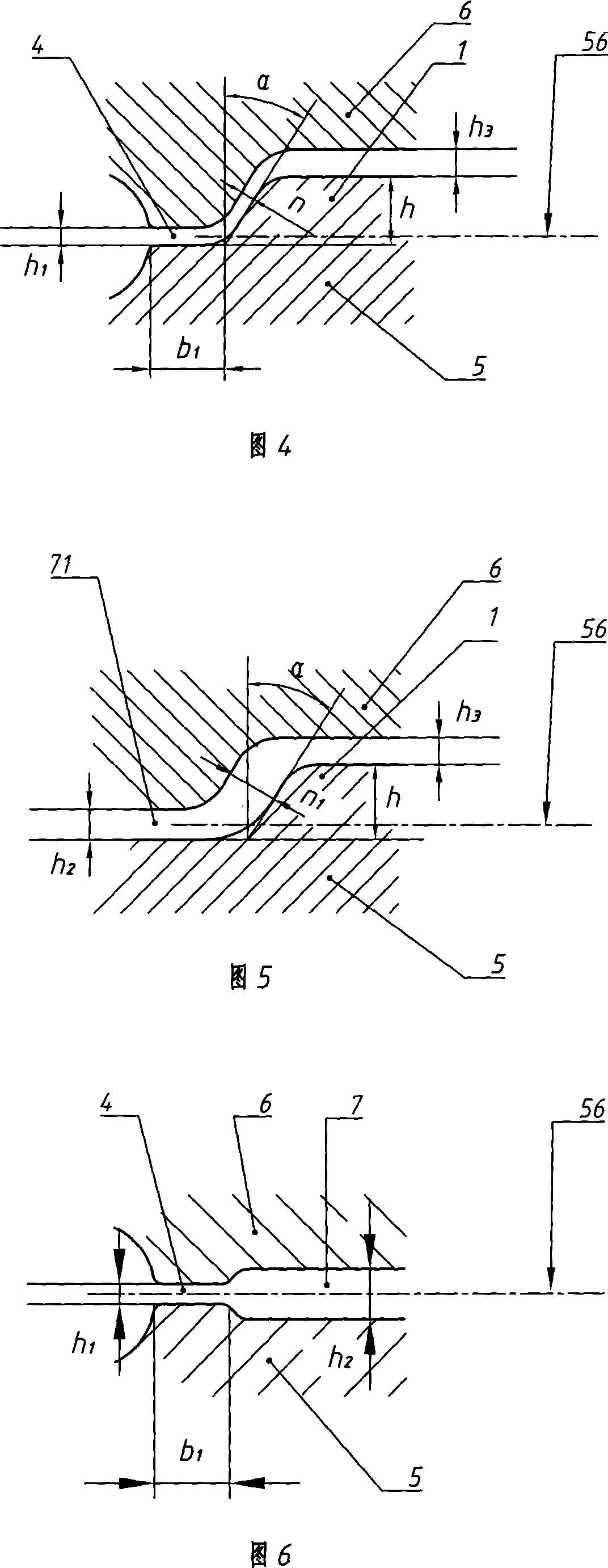

[0022] A die for forging a crankshaft. At the parting surface 56 of the upper and lower molds of the mold, a flash groove formed by a flash bridge 4 and a flash bin 7 surrounding the outer periphery of the flash bridge 4 is provided along the periphery of the cavity 3 of the mold. . In the flash groove of the present invention, at the original flash warehouse part 7 on both sides of the mold cavity part corresponding to the crankshaft balance weight, the wall body 1 exceeding its parting surface 56 is provided on one side of the upper mold 6 (obviously, in If necessary, the body of wall 1 needs to make way for the forging die ejector pin hole 2); between the protruding body of wall 1 and the concave part at the corresponding original flash bin part 7 in the lower die 5, there is a width and There is a gap corresponding to the width of the flash bridge portion 4 .

[0023] Apparently, the difference between this embodiment and the embodiment only lies in that the resistance w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com