Ultrasonic vibration-assisted mould pressing forming method based on tin liquid medium and special forming device thereof

An ultrasonic vibration, auxiliary mold technology, applied in glass forming, glass pressing, glass manufacturing equipment, etc., can solve the problems of difficult to fill the mold, inconsistent filling rate, low filling rate, etc., to improve fluidity and uniformity, The effect of improving the filling rate inconsistency and improving the filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

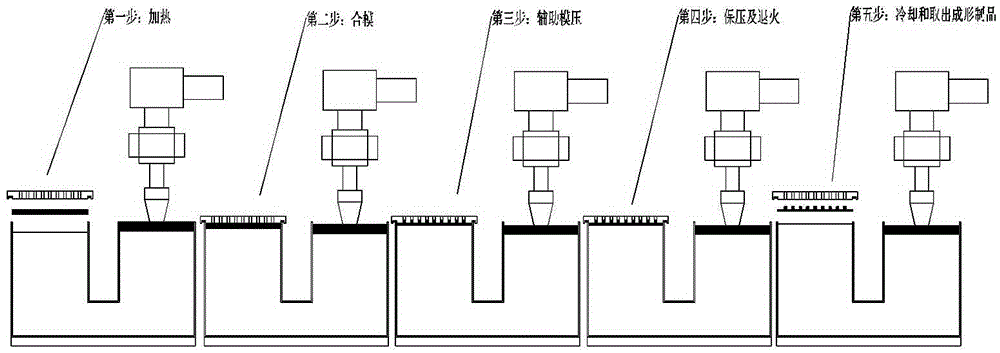

[0028] Embodiment 1: The implementation process of the present invention includes heating, clamping, auxiliary molding based on tin liquid medium ultrasonic vibration, holding pressure and annealing, cooling and taking out operations such as shaped products, refer to Figure 1 to Figure 6 . The specific steps are as follows:

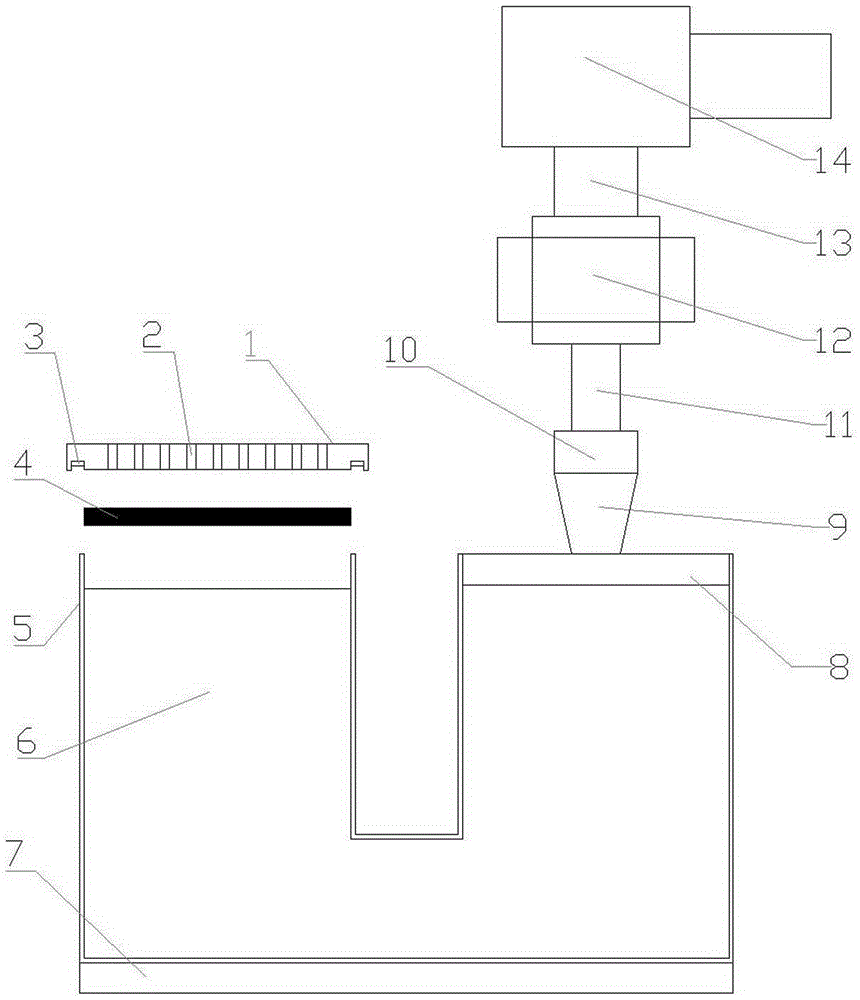

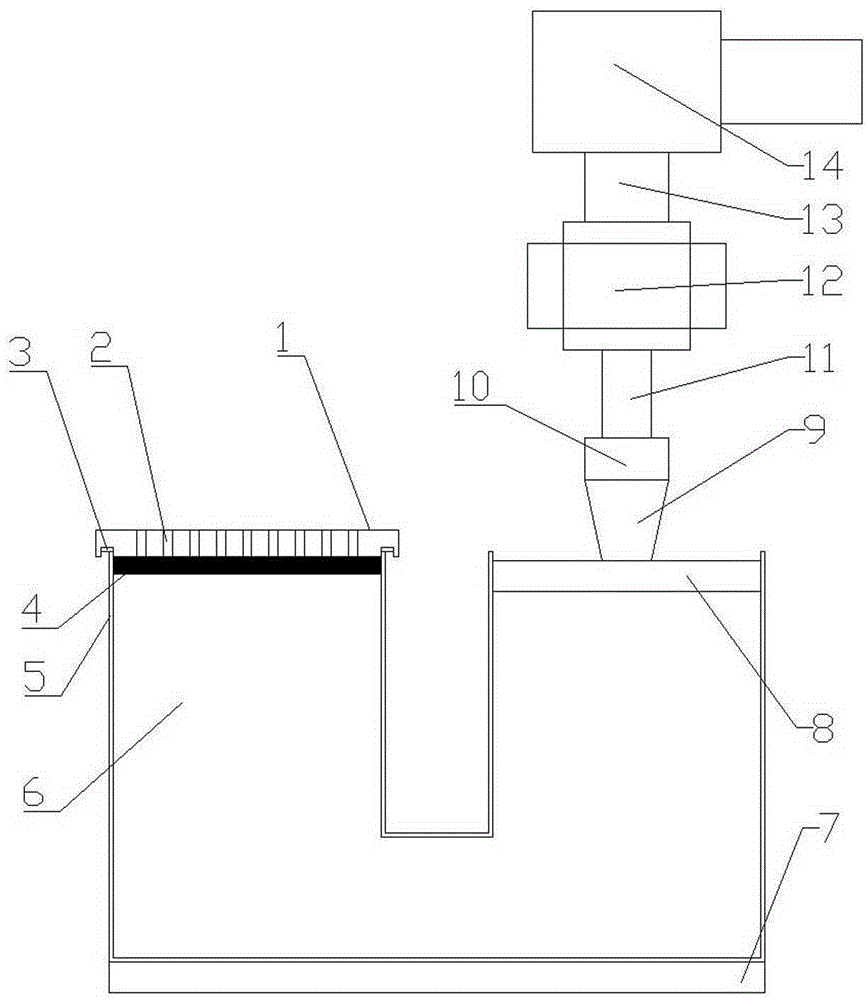

[0029] Step one, heating. use as figure 2 The microstructured thin glass element shown is based on the ultrasonic vibration assisted molding device of liquid tin medium. Enough metal tin is put into a U-shaped groove with similar opening diameters at both ends, and nitrogen gas is introduced to drive away the oxygen in the U-shaped groove. , The tin liquid exposed at the left end of the U-shaped groove needs an oxygen-free environment to prevent the tin liquid from being oxidized. In addition, the entire molding process is under anaerobic conditions. In an environment filled with nitrogen, oxygen in the air is prevented from oxidizing the mold. At th...

Embodiment 2

[0034] Example 2: Reference Figure 1 to Figure 6 . to use as figure 2 The shown forming device produces micro-cylindrical array lens as an example, and describes the technological process of the present invention in detail:

[0035] Step 1. Use such as figure 2 The micro-structured thin glass element shown is based on the ultrasonic vibration-assisted molding device of liquid tin medium. Sufficient metal tin with a melting point of 231.89°C is put into a U-shaped groove 5 with openings at both ends having similar diameters. The material of the U-shaped groove 5 is Stainless steel. Nitrogen gas is introduced to drive away the oxygen in the U-shaped groove 5. The tin liquid 6 exposed at the left end of the U-shaped groove 5 requires an oxygen-free environment to prevent the tin liquid 6 from being oxidized. And the entire molding process requires an oxygen-free state. In an environment filled with nitrogen, oxygen in the air can be prevented from oxidizing the mold 1. At ...

Embodiment 3

[0040] Example 3: Reference Figure 1 to Figure 6 . to use as figure 2 The shown forming device is used as an example to manufacture a Fresnel lens, and the process method of the present invention is described in detail.

[0041] Step 1. Use such as figure 2 The micro-structured thin glass element shown is based on the ultrasonic vibration assisted molding device of liquid tin medium. Sufficient metal tin with a melting point of 231.89°C is put into a U-shaped groove 5 with openings at both ends having similar diameters. The material of the U-shaped groove 5 is Stainless steel. Nitrogen gas is introduced to drive away the oxygen in the U-shaped groove 5. The tin liquid 6 exposed at the left end of the U-shaped groove 5 requires an oxygen-free environment to prevent the tin liquid 6 from being oxidized. Moreover, the entire compression molding process requires an oxygen-free state. In an environment filled with nitrogen, oxygen in the air is prevented from oxidizing the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com