Coal mine bulk stock cut and fill mining method

A coal mine and filling technology, which is applied to filling materials, mining equipment, earth square drilling and mining, etc., can solve problems such as high price of filling materials, large interference between filling and coal mining, and difficulty in grouting, so as to reduce filling production costs and improve filling quality. Small interference with coal mining, good subsidence control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

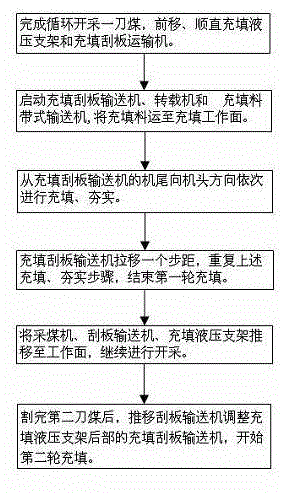

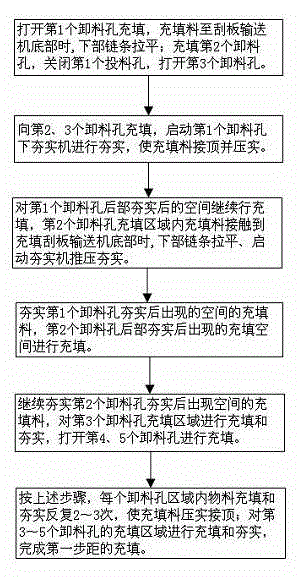

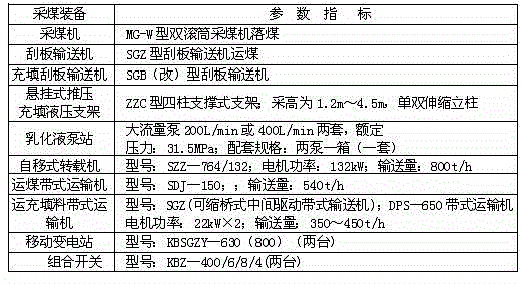

[0026] The coal mining method adopts longwall fully mechanized mining, the operation method is "three mining and one standard", and the double-drum shearer with a cutting depth of 500~800mm is adopted, and the mining process is basically the same as that of ordinary fully mechanized mining. The main equipment of the coal mining face with filling mining method is shown in Table 1. The filling work is carried out after the one-cut coal mining operation is completed. After straightening the filling hydraulic support, adjust the hanging filling scraper conveyor at the rear of the filling hydraulic support, and start the filling scraper conveyor, self-moving transfer machine, Gangue belt conveyor and other equipment are used to fill the goaf. The filling work is mainly completed by the filling scraper conveyor and the pushing and compacting mechanism. The mixture of was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com