Pump integrity monitoring

a technology of integrity monitoring and pump, applied in the direction of positive displacement liquid engine, pump parameter, instruments, etc., can solve the problems of affecting uptime or efficiency, prone to failure of internal valve seals of pumps, and easy natural wear of pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

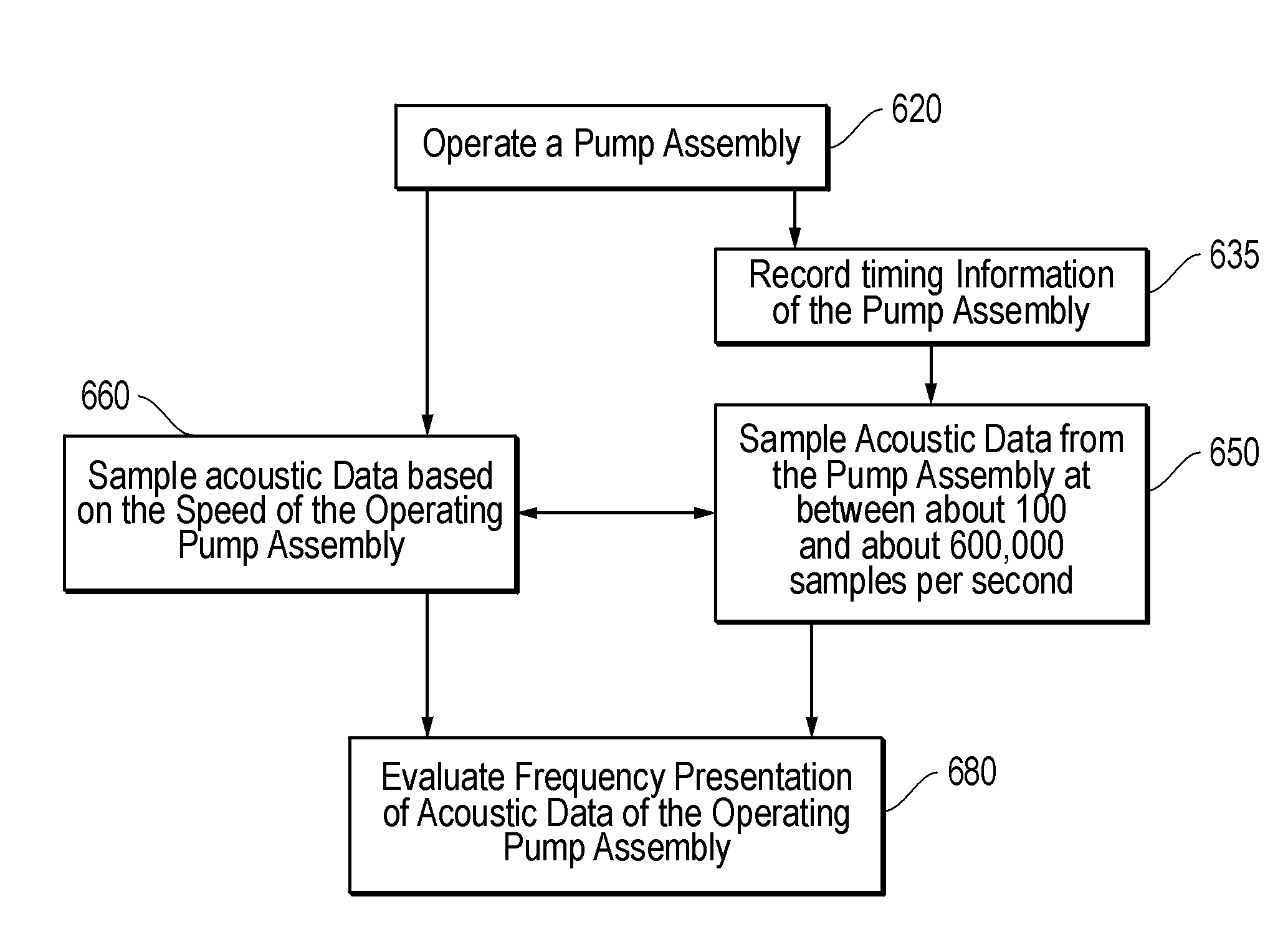

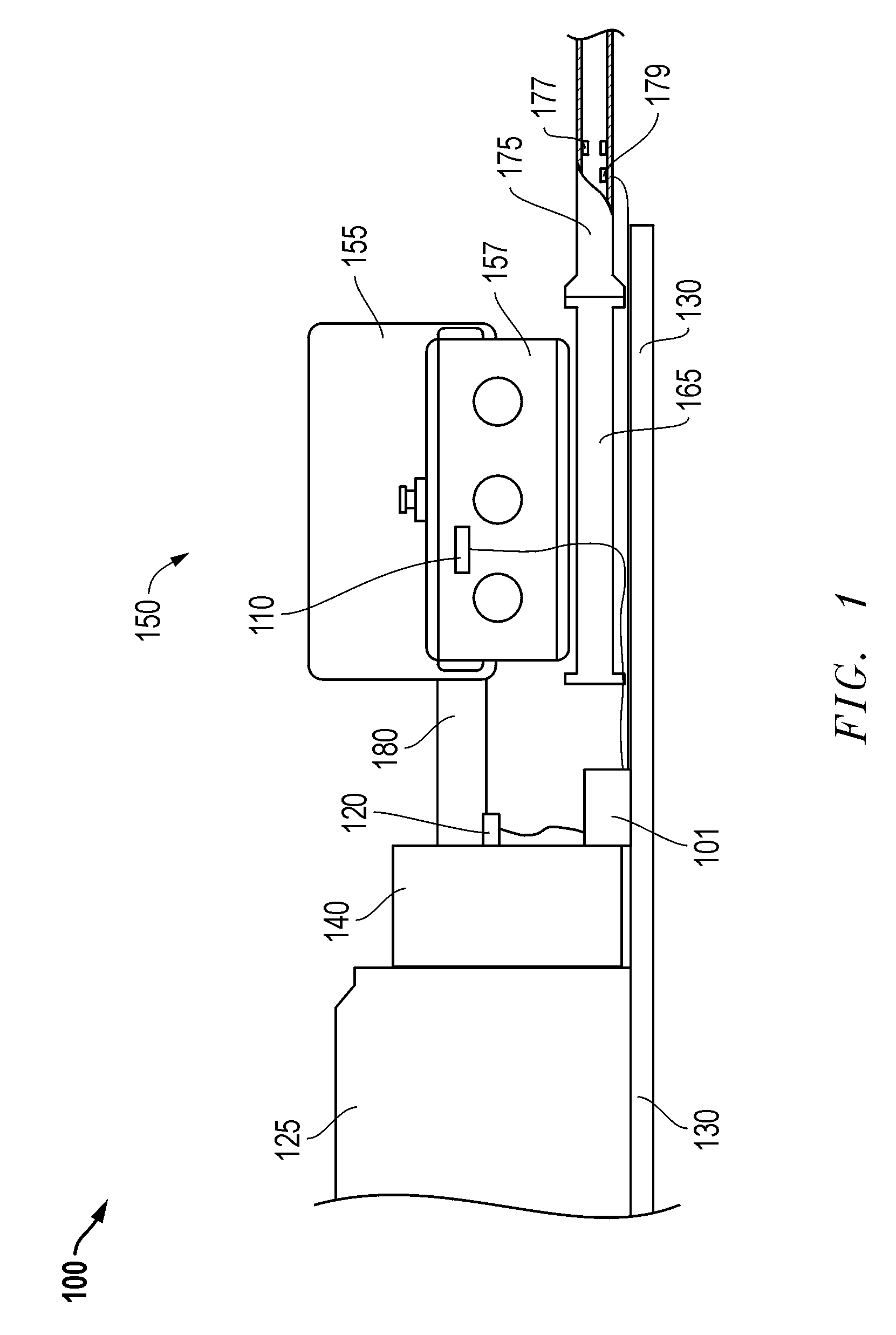

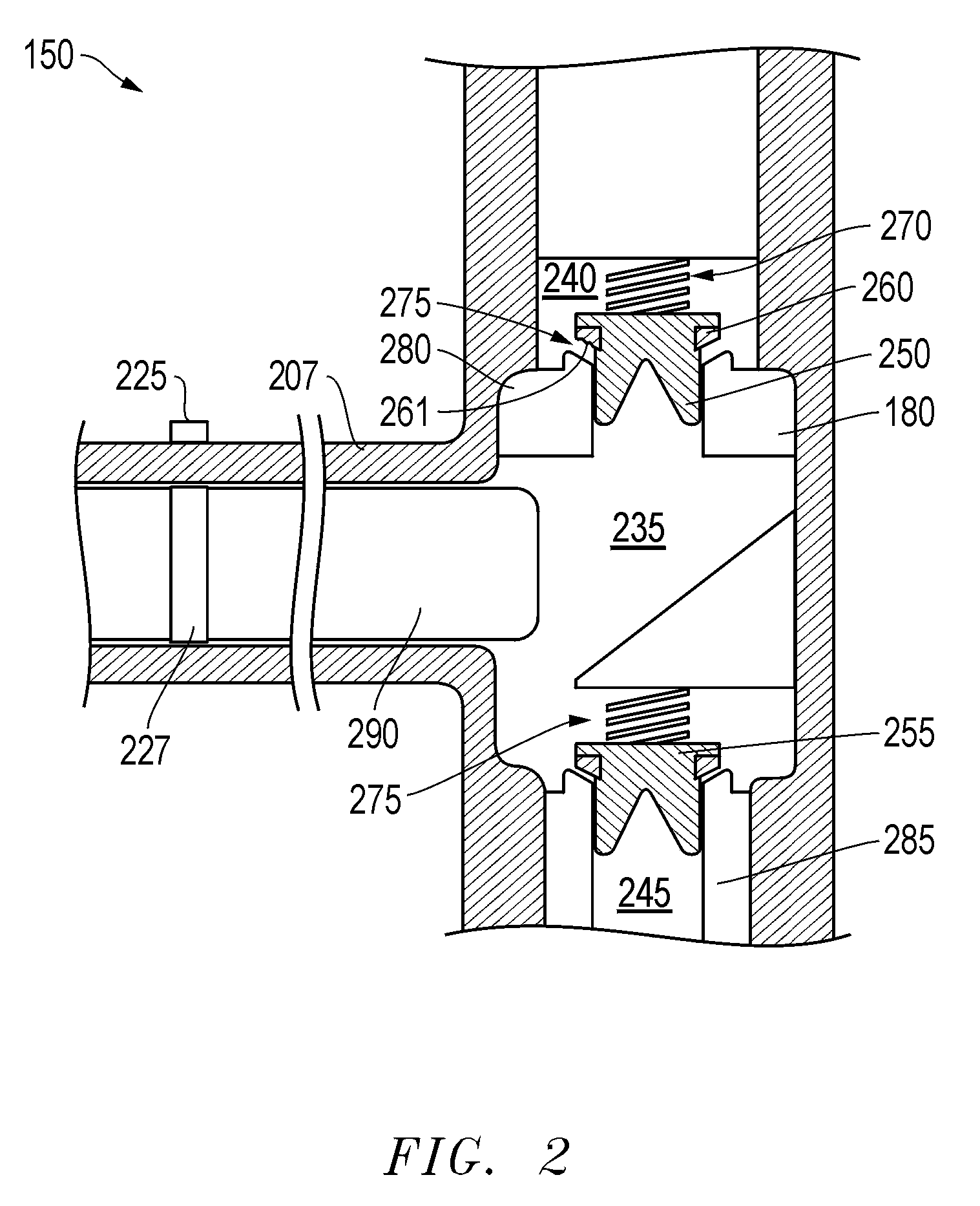

[0019]Embodiments are described with reference to certain positive displacement pump assemblies for fracturing operations. However, other types of pumps may be employed for a variety of operations. Regardless, embodiments described herein include a pump assembly 100 that incorporates a pump integrity monitor 101 having particular capabilities. For example, the pump integrity monitor 101 may employ particularly located sensors in conjunction with a high speed data acquisition board that takes up acoustic data from the pump assembly 100 a rate algorithmically adjusted to minimize the effect of noise from neighboring equipment, including noise from equipment and pumps that are in fluid coupling with the pump assembly 100. Furthermore, the pump integrity monitor 101 may acquire data at a lower non-uniform sampling rate based on operating speed of equipment of the pump assembly 100, thereby drastically increasing processing capacity. In a particular example, the pump integrity monitor 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequencies | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com