Environmental protection plate rapid cutting equipment

A fast cutting and plate technology, applied in metal processing and other directions, can solve the problems of plate movement, inaccurate cutting, physical harm, etc., and achieve the effects of avoiding cutter damage, scientific and reasonable structure, and safe and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

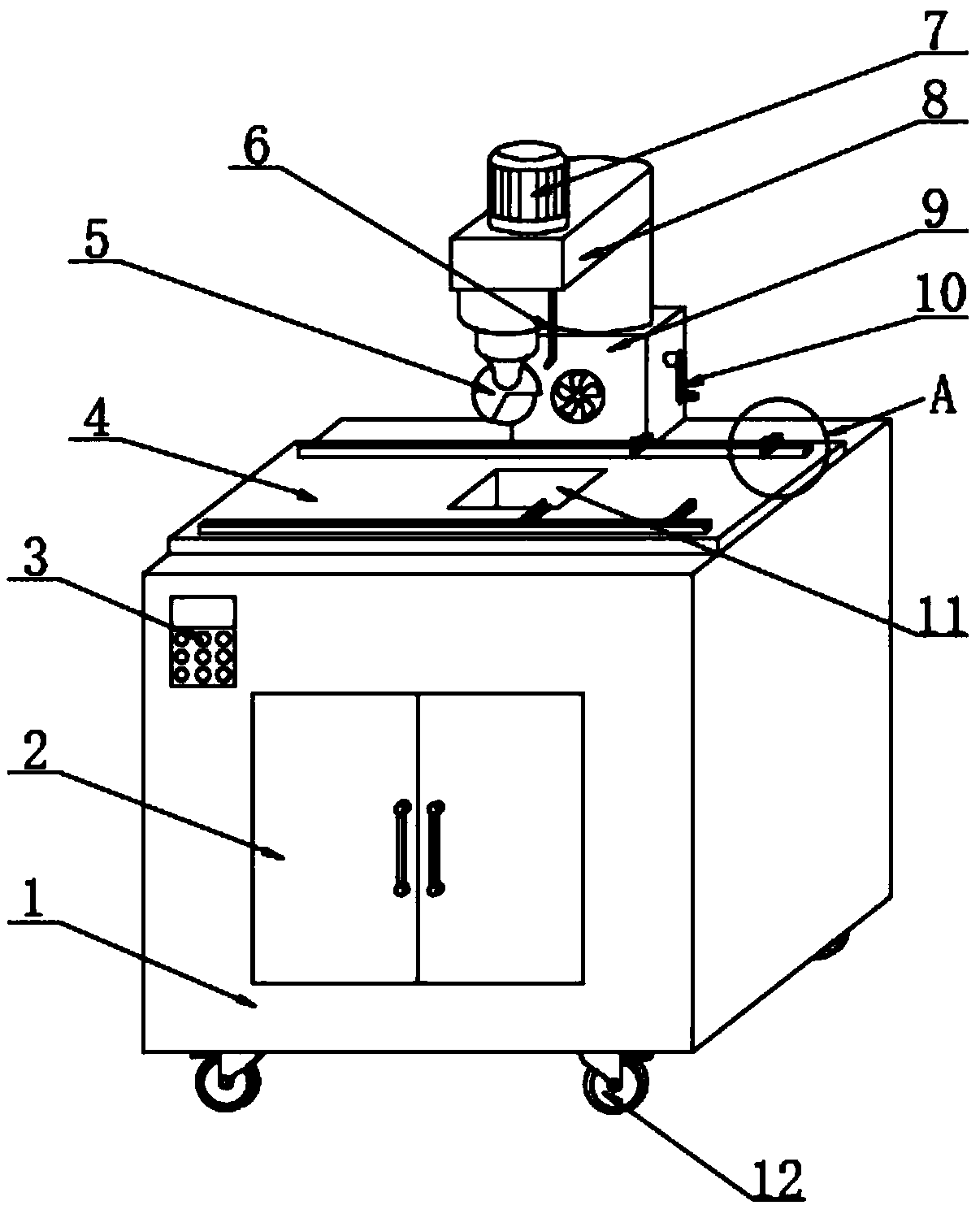

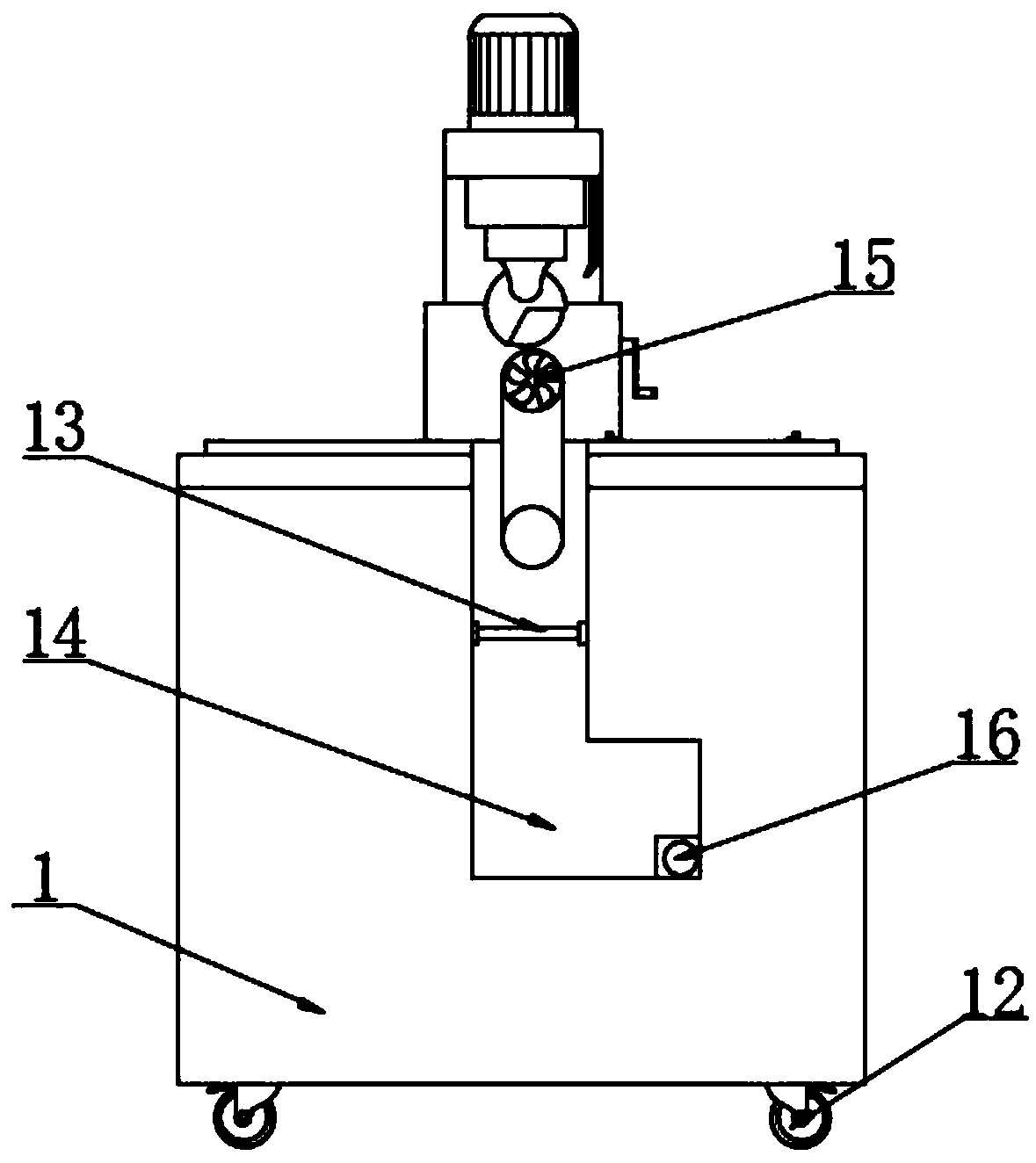

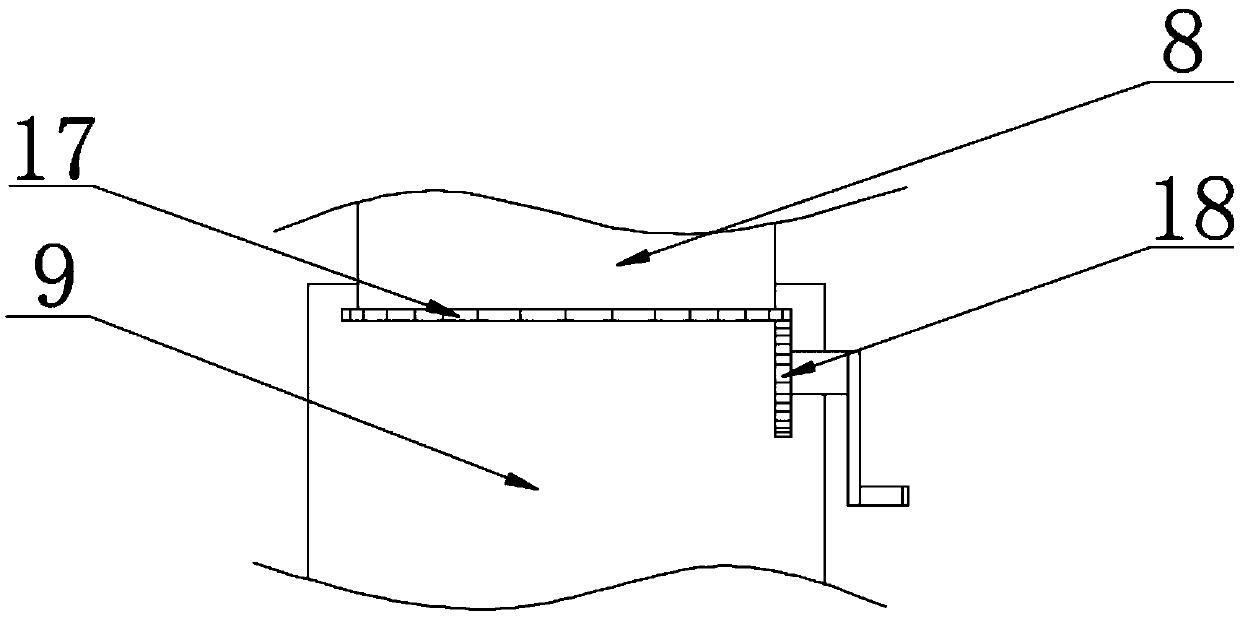

[0022] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a rapid cutting equipment for environmentally friendly plates, including a box body 1, a box door 2, a control switch 3, a work surface 4, a cutter 5, a water spray pipe 6, a motor 7, and a rotating seat 8. Fixed seat 9, crank handle 10, drain 11, universal wheel 12, filter screen 13, water storage bin 14, fan 15, micro water pump 16, first transmission gear 17, second transmission gear 18, fastening knob 19, The chute 20, the fixed splint 21 and the telescopic splint 22, one side of the box body 1 is connected with the box door 2 through the hinge, the control switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com