Automatic paper feeding system of corrugated paper board production line

A corrugated cardboard and production line technology, which is applied in the directions of coiling strips, thin material handling, transportation and packaging, etc. It can solve the problems of easily damaged paper tubes, complicated operation, low efficiency, etc., and achieves manpower saving and precise clamping and positioning convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

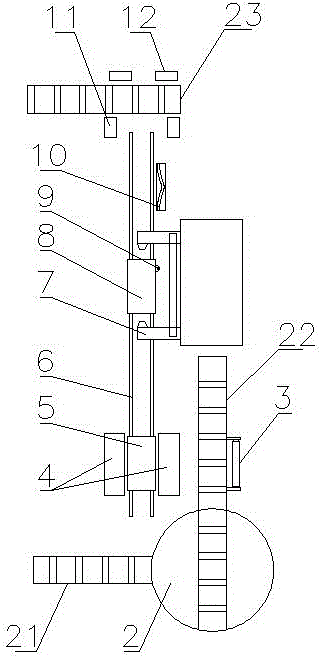

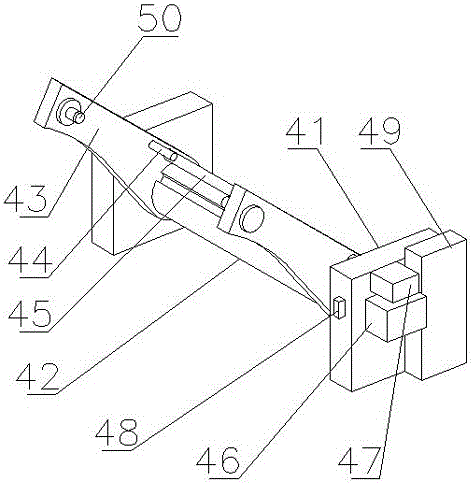

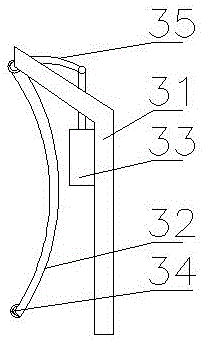

[0013] Such as figure 1 , 2 , 3, and 4, the present invention includes A conveyor 21, B conveyor 22, C conveyor 23, electric turntable 2, paper kicker 3, a pair of paper turning board 4, paper car 5, lifting arm 7 , unwinding car 8 and remnant roll steering and unloading device, a conveyor belt is provided on the electric turntable 2, the electric turntable 2 is located between the A conveyor 21 and the B conveyor 22, the kicker 3 and a pair of paper turning plates 4 are respectively Located on both sides of the B conveyor 22, a track 6 is set between a pair of paper loading flaps 4, the paper loading vehicle 5 and the paper unloading vehicle 8 walk on the track 6 respectively, and the lifting arm 7 is located on the side of the track 6; The unwinding device includes a guide plate 10, a pair of flaps 11 and a pair of baffle plates 12, the guide plate 10 is provided with a guide groove, and the side of the unwinding car 8 is provided with a slide block 9 that cooperates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com