Welding fixture tool with adjustable angle

A welding fixture and tooling technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of inability to adjust the angle, and achieve the effect of improving welding strength, avoiding welding strength, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

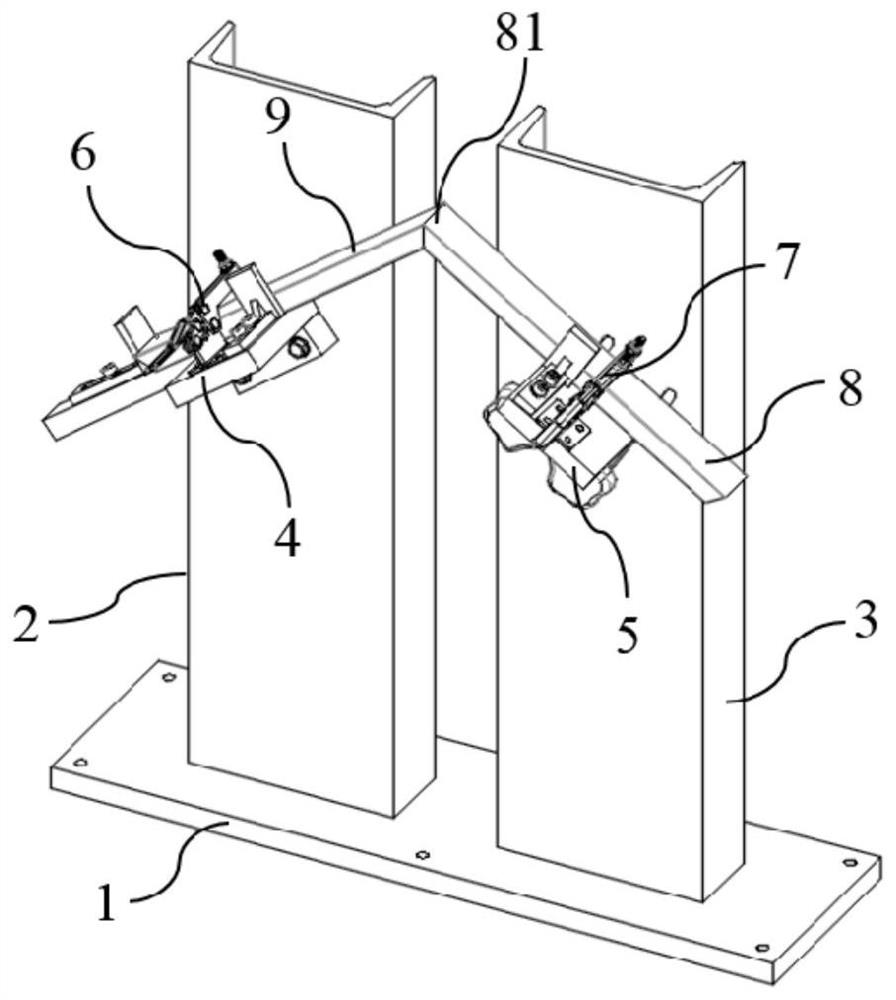

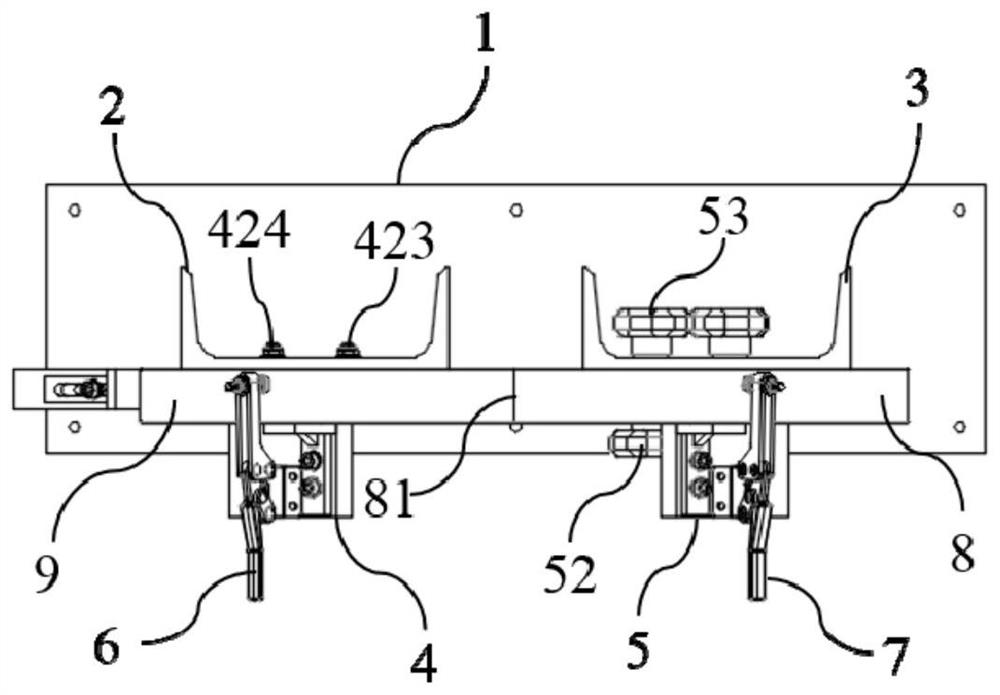

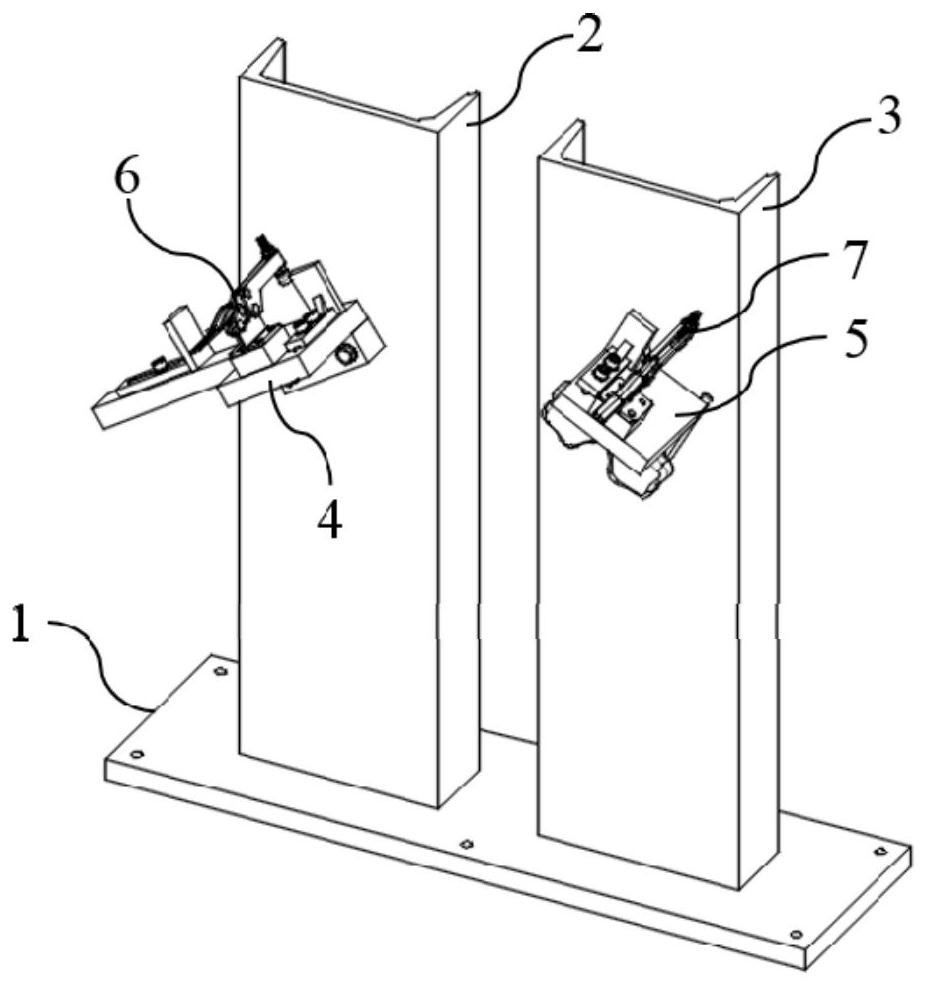

[0035] An angle-adjustable welding fixture tooling of this embodiment, such as figure 1 As shown, the base plate 1 is included, and the upper surface of the base plate 1 is vertically installed with a left column 2 and a right column 3 symmetrically. The front part of the left column 2 is detachably equipped with a left positioning module 4, and the left positioning module On 4, the workpiece II9 is clamped by the positioning clamp I6; as Figure 6 As shown, the middle part of the left column 2 is horizontally provided with positioning holes 21, and several groups of adjustment holes 22 are also provided at equal intervals on the left column 2. The adjustment holes 22 are located at the center of the circle with the position of the positioning holes 21 On an arc made with a distance of a radius, so that the left positioning module 4 fixed on it can realize angle adjustment, and the structure is easy to disassemble; as Figure 3-5 As shown, the left positioning module 4 incl...

Embodiment 2

[0038] An angle-adjustable welding fixture tooling of this embodiment has the same basic structure as that of Embodiment 1, the differences and improvements are as follows: Figure 6 As shown, the middle part of the right column 3 is provided with a chute 31, and several groups of the chute 31 are equidistantly arranged in parallel, so that the stability of the angle adjustment is better, and any rear fastening in the chute 31 is avoided. Knob 53 is loosened, and the position of right positioning module 5 changes, and then affects the inclination angle of workpiece 18 clamped thereon, thereby affects the weld seam of welding place, finally affects the welding strength of welding place and the service life of workpiece. Described left column 2 and right column 3 are channel steel structures, and its groove surface is the back side, and the corresponding surface of described groove surface is front, is respectively used for fixing left positioning module 4 and right positioning m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com