Rapid positioning and welding tool for automobile exhaust pipe

A technology for positioning welding tooling and automobile exhaust, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of slow speed, troublesome tool operation, etc., to improve work efficiency, tight contact is not easy, Quick clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

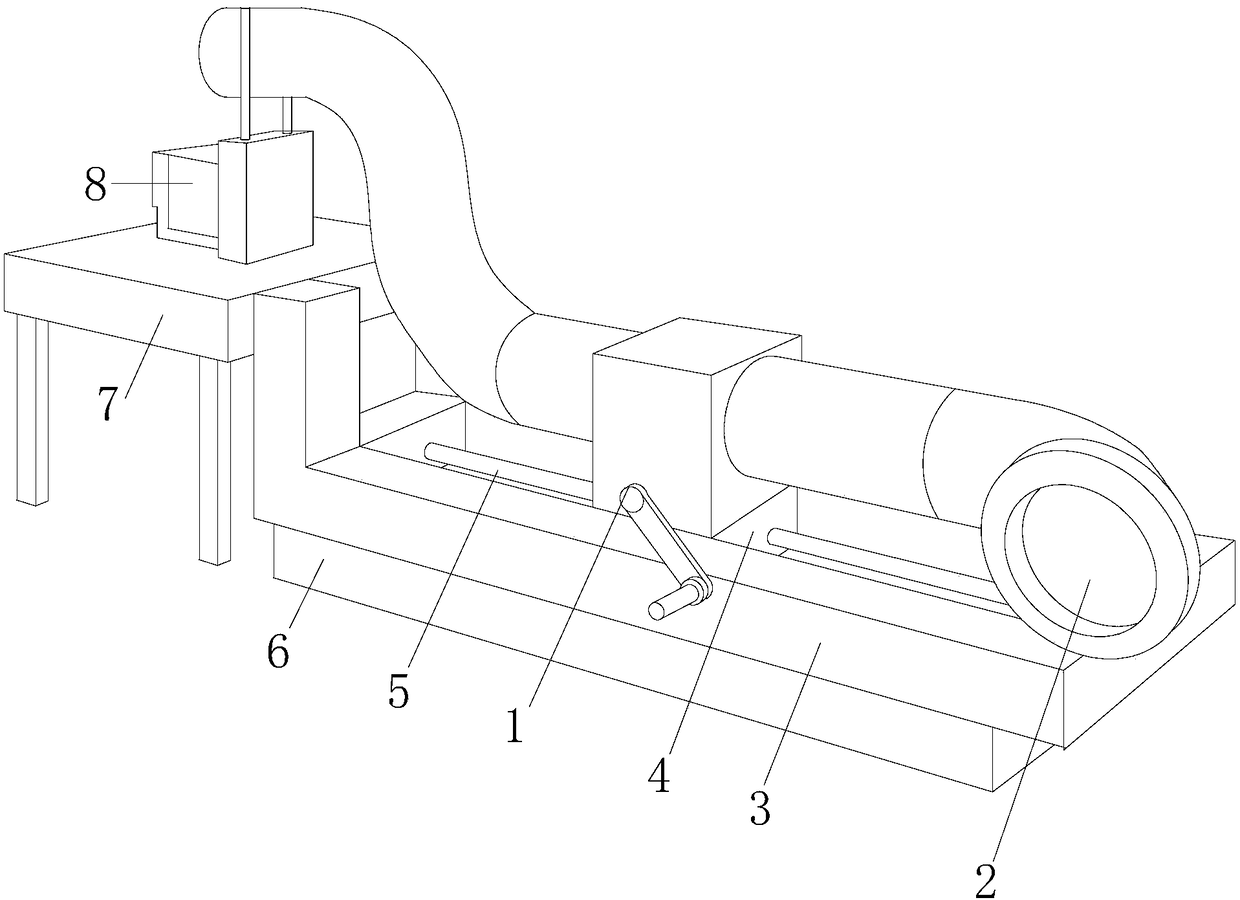

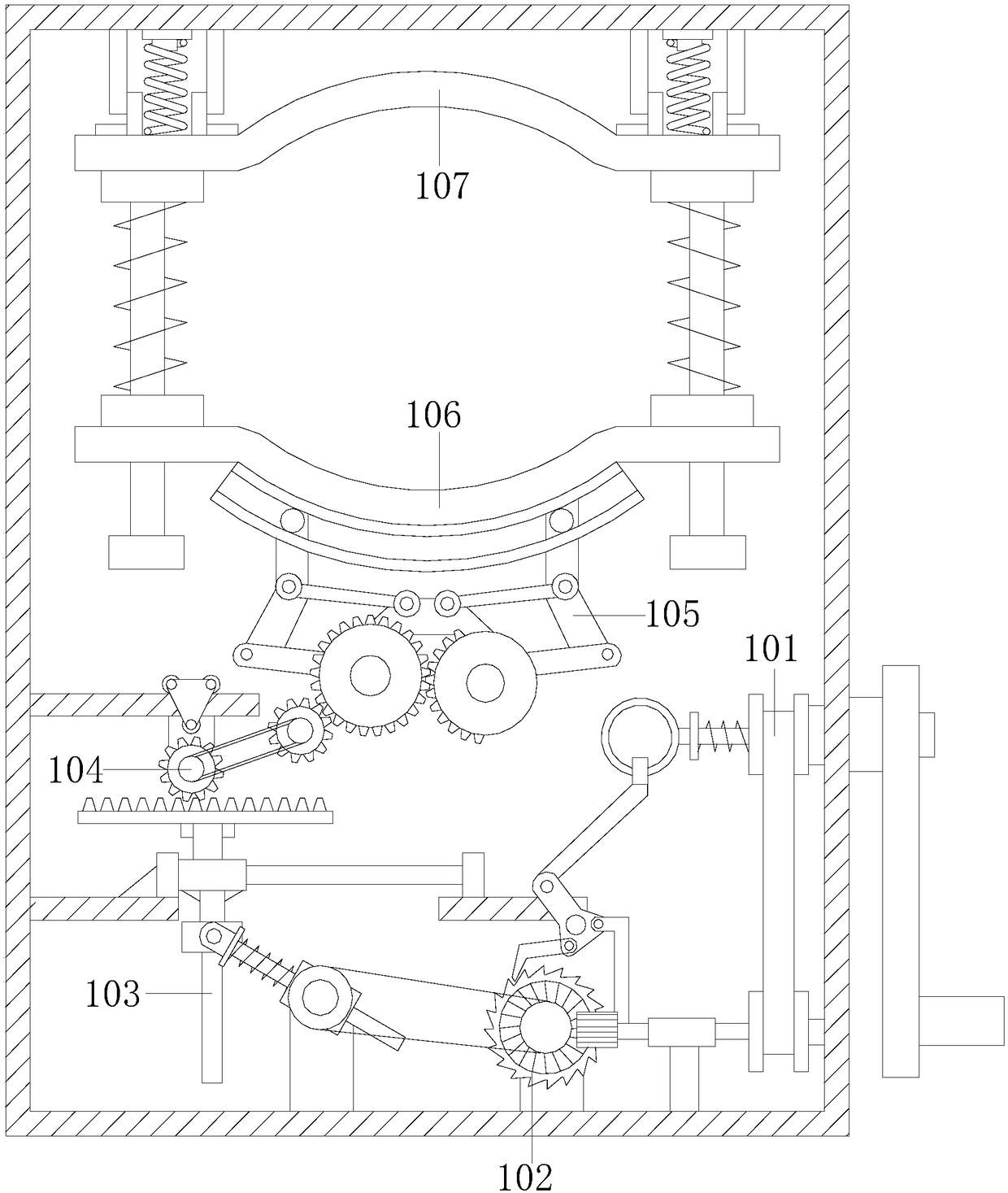

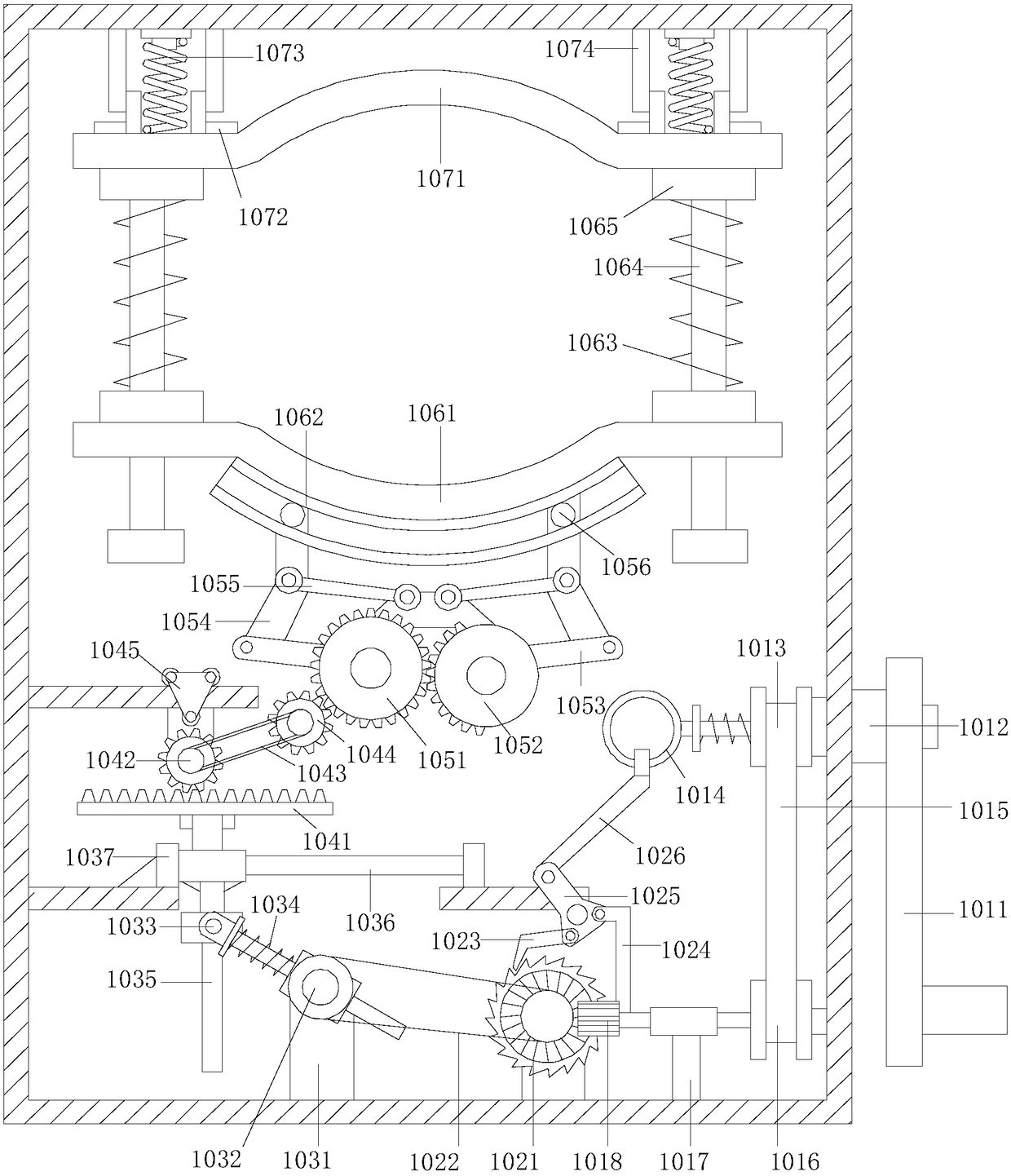

[0014] Such as Figure 1-Figure 4As shown, the present invention provides a quick positioning welding tool for an automobile exhaust pipe, and its structure includes a free regulator 1, an exhaust pipe 2, a movable rail 3, a movable bottom plate 4, a slide bar 5, a base 6, a top support platform 7, The end fixing frame 8, the chuck inside the free regulator 1 is movably connected with the connecting pipe wall of the exhaust pipe 2, and the housing of the free regulator 1 is fixed on the top of the movable bottom plate 4 by bolts and connected with the movable rail 3 are parallel to each other, the movable rail 3 is welded and fixed on the top of the base 6, the middle groove is in interference fit with the slide bar 5, the top supporting platform 7 is vertically fixed on the bottom of the terminal fixing frame 8, and the free adjuster 1. Adjusting handle 101, limit ratchet 102, transmission rod 103, transmission gear 104, lifting arm 105, clamping base 106, fixed top seat 107 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com