Leveling tool

A tooling and leveling technology, applied in the field of mechanical devices, can solve the problems of low work efficiency, single clamping method, inability to meet different surface shapes, etc., to achieve the effect of ensuring reliability, eliminating backlash, and supporting rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

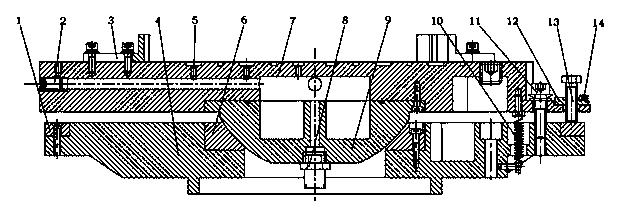

[0011] figure 1 Among them, a leveling tool is mainly composed of a collar 1, an airway sealing nail 2, a mechanical clamping block 3, a lower plate 4, an airway sealing nail 5, a lower ball recess 6, an upper plate 7, a vacuum suction joint 8, The upper ball convex 9, the tension spring 10, the locking screw 11, the adjusting nut 12, the adjusting screw 13 and the anti-loosening screw 14 are composed; wherein, the shape of the whole set of tooling is a rotary shape, the adjusting nut 12 is connected with the adjusting screw 13, and the upper plate 7 There are 4 vacuum adsorption air passages evenly distributed on the circumference of the side surface, and the upper surface is provided with an annular air passage and sealed by the air passage sealing nail 5. Solid connection, the outer spherical surface of the upper ball convex 9 and the inner spherical surface of the lower ball concave 6 are ground, and the spherical pair is in good contact. After the tooling is assembled, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com