Connector cover plate clamping conveying mounting mechanism

A technology of clamping, conveying and installing mechanisms, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problems of difficulty in production and processing, affecting processing, prone to errors, etc., to facilitate subsequent processing, high stability , The effect of fast clamping cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

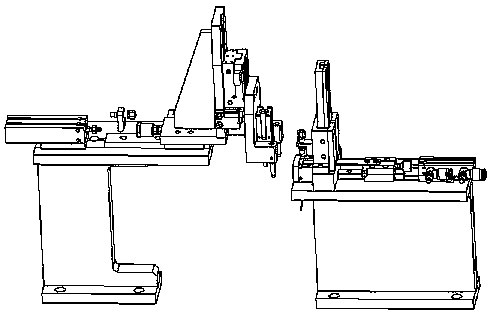

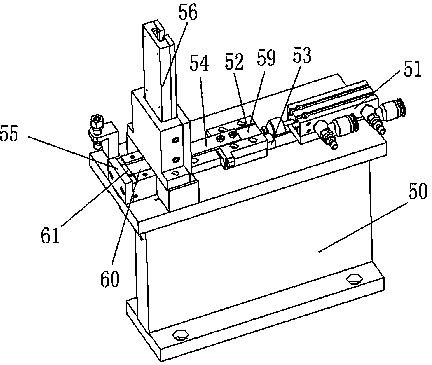

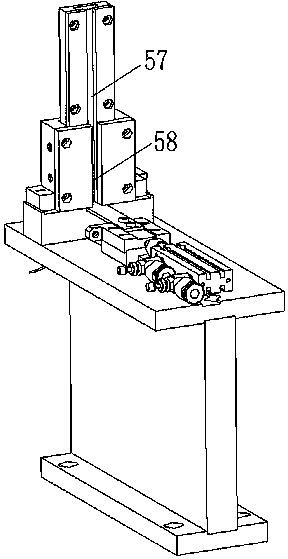

[0019] Such as Figure 1-4 As shown, a clamping, conveying and installing mechanism for a connector cover includes a conveying mechanism and a clamping and moving mechanism. Clamping plate 56, is provided with cylinder 51 on base 50, is provided with guide rail 53 at the front portion of cylinder 51, is provided with the slide seat 52 that is connected with the cylinder rod of cylinder 51 on guide rail 53, is fixed on the top of slide seat 52 The push plate 54 is provided with a clamping plate 56 at the front end of the guide rail 53, and a vertical chute 57 for placing the cover plate 58 is provided in the clamping plate 56, and the push plate 54 can pass through the opening below the vertical chute 57, A placement seat 55 for placing a cover plate 58 is provided at the front end of the opening.

[0020] A slideway 60 adjoining the opening is provided on the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com