Combined measuring method and device for stretching, compressing, bursting and prick-cut

A technology for textile materials and measuring devices, which is applied to measuring devices, using stable shear force to test material strength, and using stable tension/pressure to test material strength, etc. It can solve the problem of single measurement mode and single textile material bursting. Strength, inability to measure tension, compression and puncture cutting, etc., to achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1, the induced force-displacement curve of the double-ended sensor under tension.

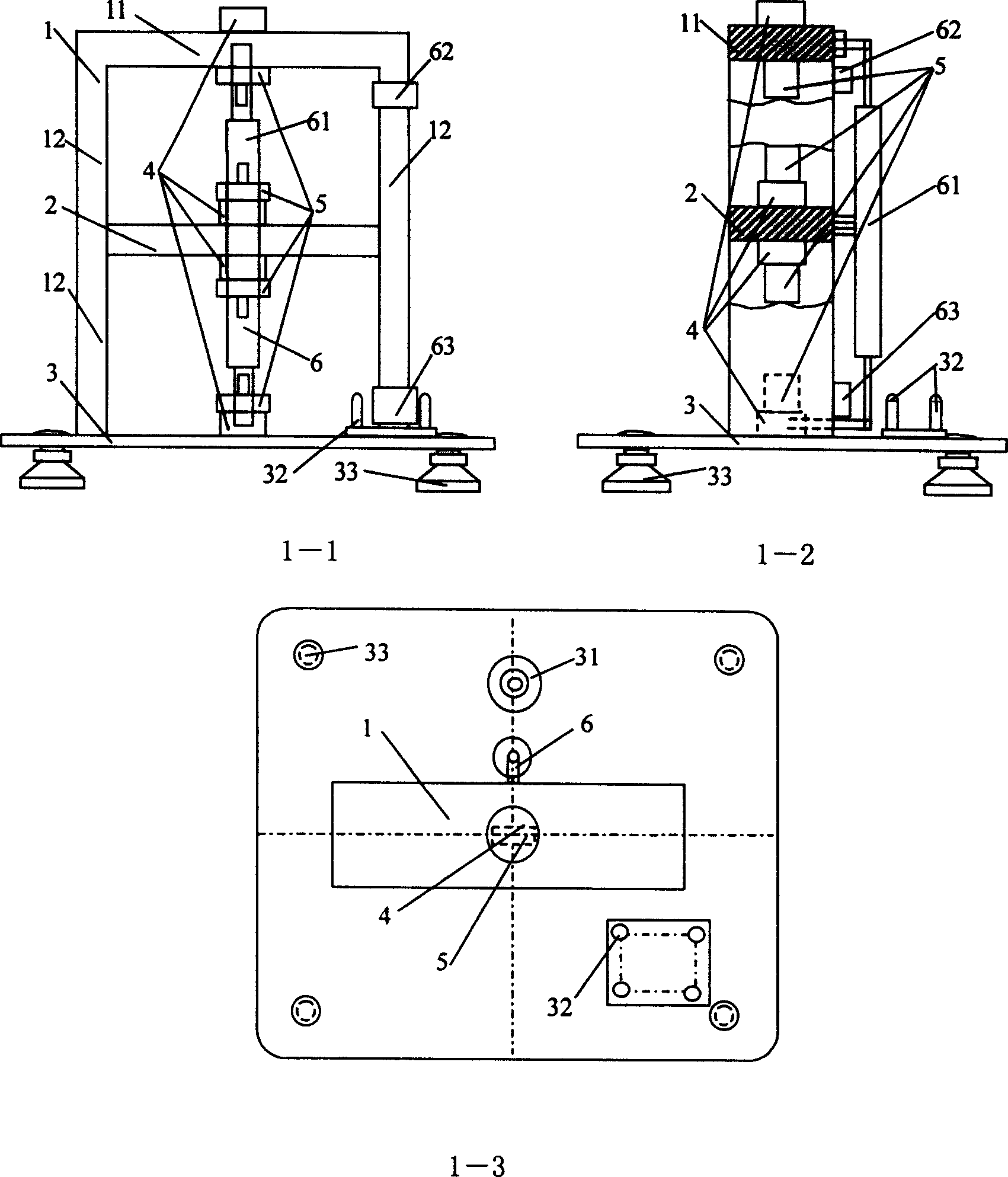

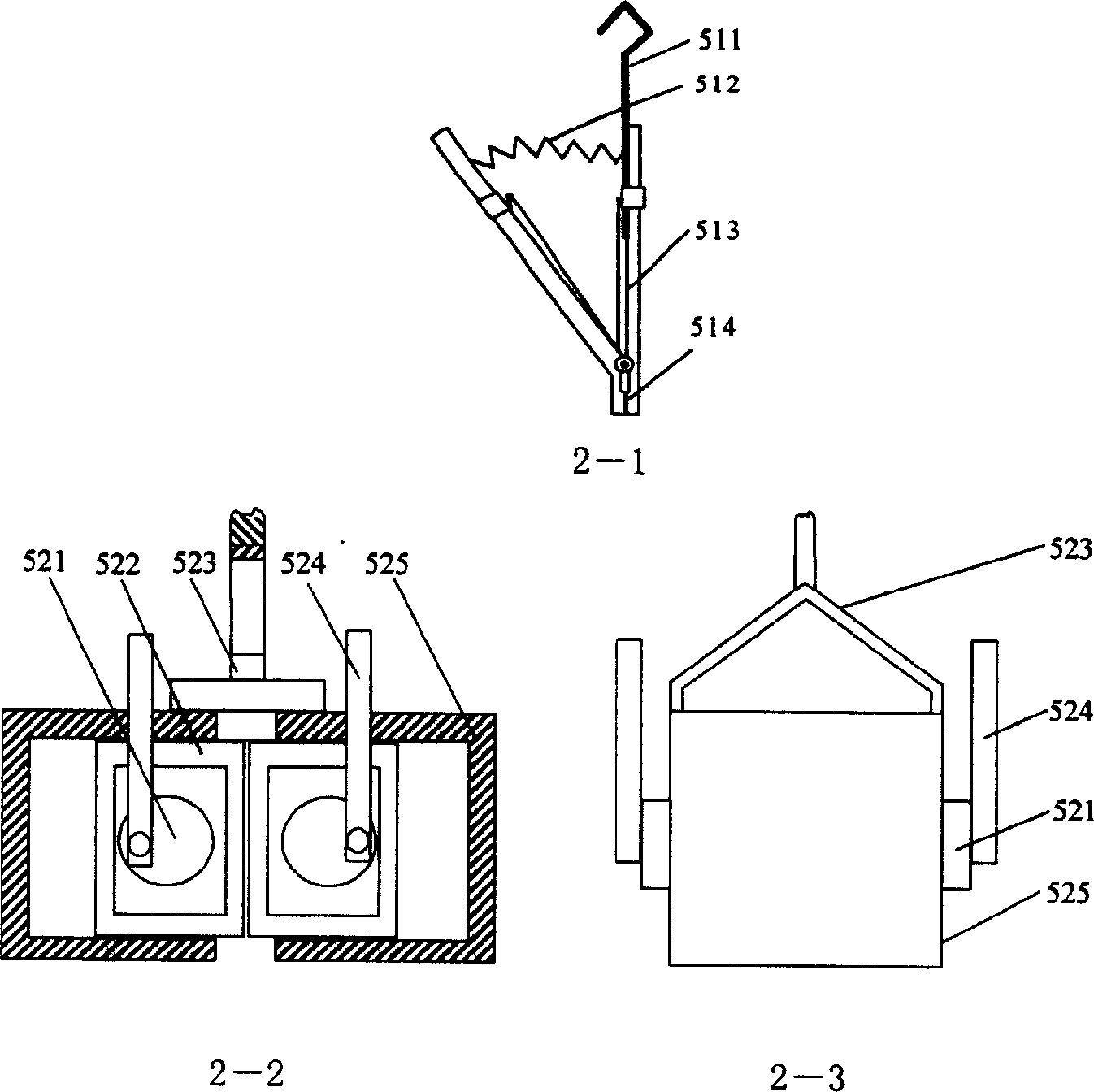

[0051] By adopting the device and method of the present invention, force sensors 4 and small load suspension clips 51 are installed on the upper beam 11 and the middle beam 2, and the middle beam 11 is driven to the set displacement position; a carbon fiber sample of a certain length is prepared on the bottom plate 3, The two ends of the sample are respectively clamped by the small load hanging clamps 51 on the middle beam 2 and the upper beam 11; the clamping distance (20mm), the tensile speed (10mm / min) and the one-time breaking mode are selected by computer operation, Start the program software to drive the center beam 2 to move vertically downwards to complete the tensile test. Since the force sensors 4 are installed on the upper beam 11 and the middle beam 2, two force-displacement curves can be obtained correspondingly. After the carbon fiber is stretched and broken, th...

Embodiment 2

[0053] Embodiment 2, the induced force-displacement curve of the double-ended sensor under compression.

[0054] Adopt the device and method of the present invention, install force sensor 4 and heavy-duty hanging clip 52 on the middle beam 2 and the base plate 3, and drive the middle beam 2 to the set displacement position; cut the worsted wool whose length×width is 8cm×4cm Fabric sample; the two ends of the sample are respectively clamped by the heavy-duty hanging clamps 52 on the middle beam 2 and the bottom plate 3; the clamping distance (3mm), compression moving speed (1mm / min) and constant load are selected by computer operation In the reciprocating mode, the program software drives the middle girder 2 to move vertically downward to complete the compression experiment. The structural diagram of the compression device is shown in Figure 5 shown. Since the force sensor 4 is installed on both the center beam 2 and the bottom plate 3, two force-displacement cycle curves can...

Embodiment 3

[0055] Embodiment 3, single-ended sensor induction force-displacement curve under bursting action.

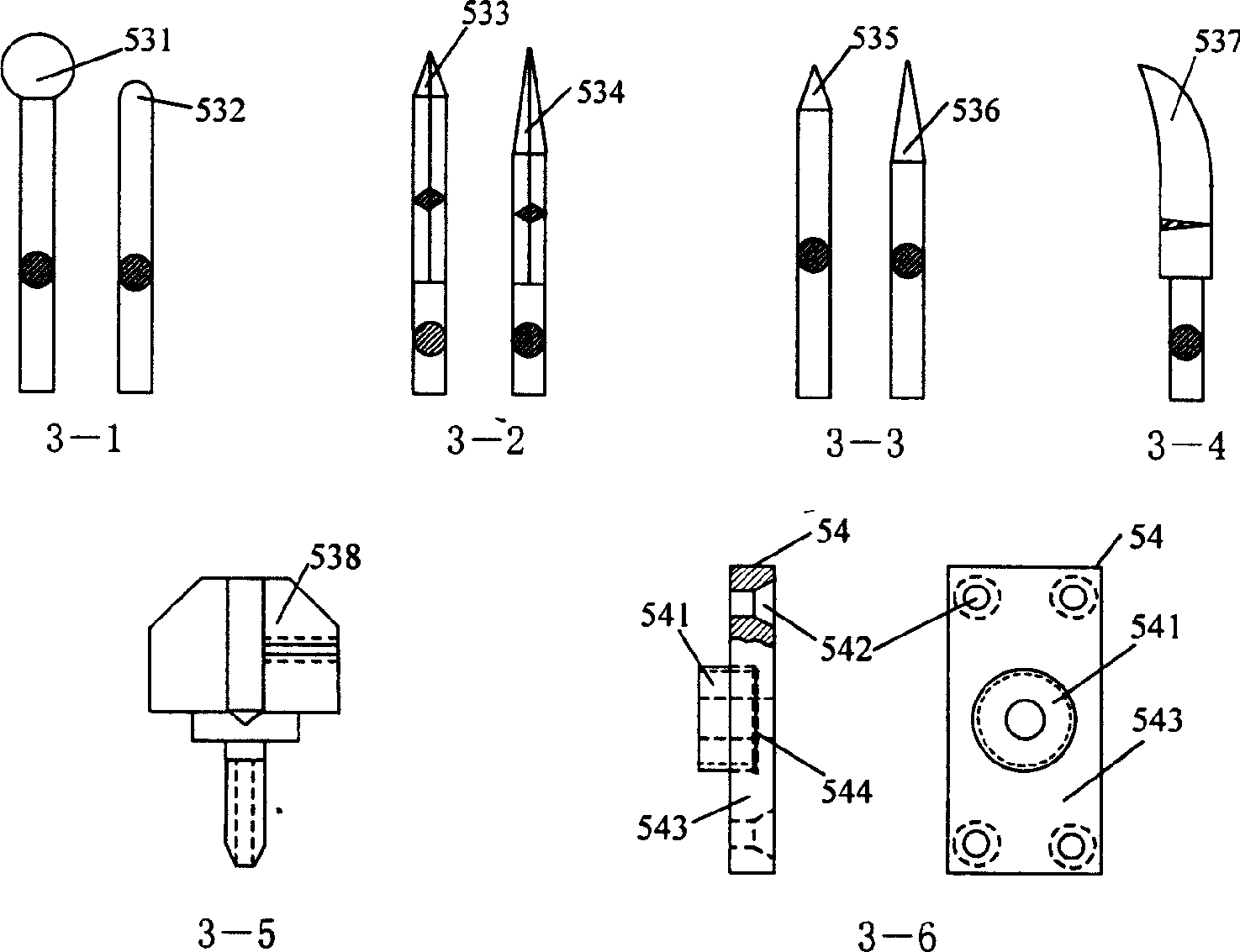

[0056] Adopt the device and method of the present invention, install the force sensor 4 on the center beam 2 and drive the center beam 2 to the set displacement position; insert the round end push rod 531 into the fixed base 538 on the upper beam 11 and fix it; the cutting diameter is 5cm Worsted woolen fabric sample, on the sample preparation table 32 on the bottom plate 3, fix this fabric sample with the top thorn sample holder 54, then the top thorn sample holder 54 is fixed on the middle beam 2; by computer Operate the selected moving speed (10mm / min) and one-time bursting mode, and the program software drives the center beam 2 to move vertically upwards to complete the bursting experiment. After the fabric sample is broken, the micro-motor drives the center beam 2 back to its original position, and the test is completed. The structure diagram of the breaking device is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com