Patents

Literature

31results about How to "Achieve clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

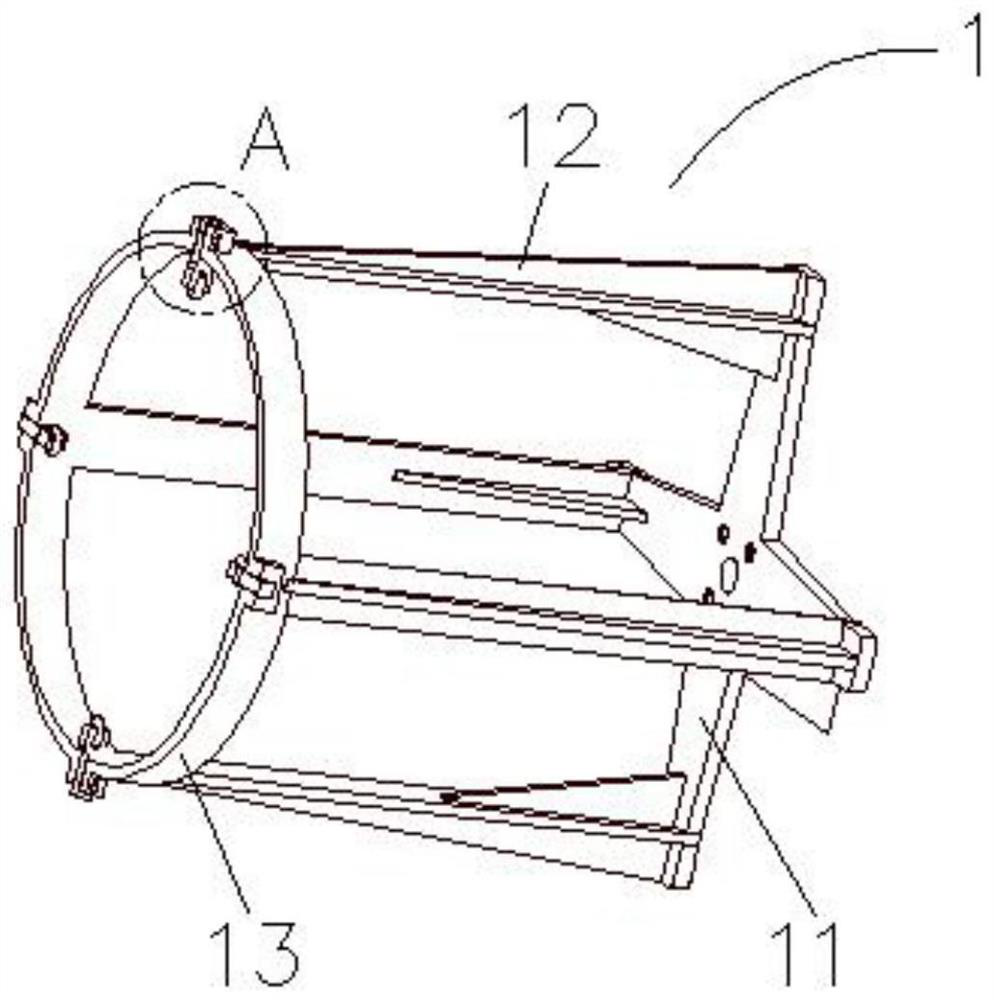

Cleaning device for solar photovoltaic panel

ActiveCN111790647AAchieve cleanAvoid scratchesPhotovoltaicsCleaning using toolsPower apparatusMaterials science

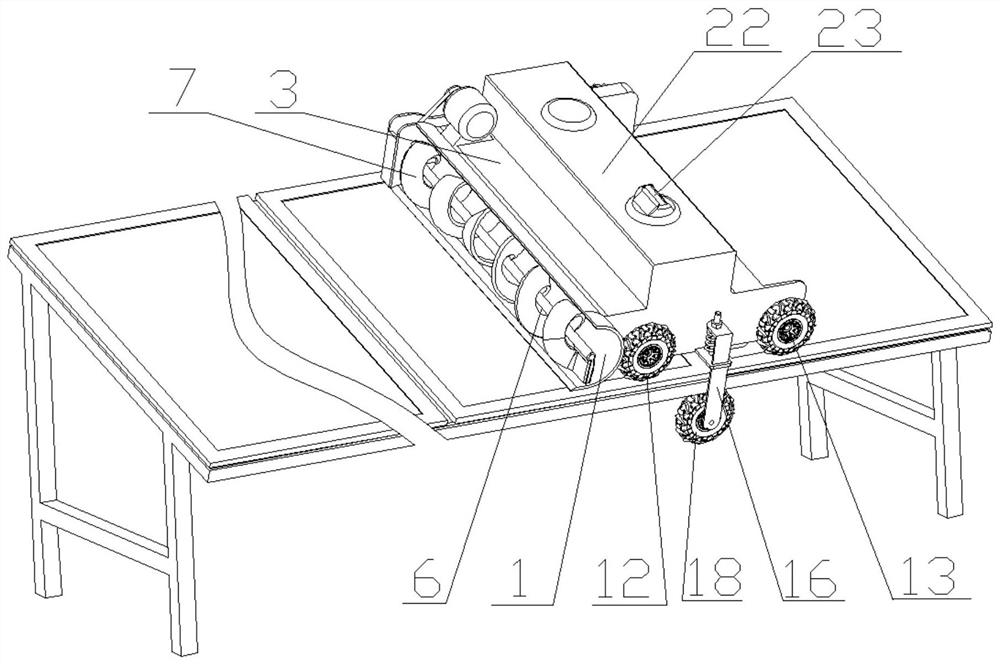

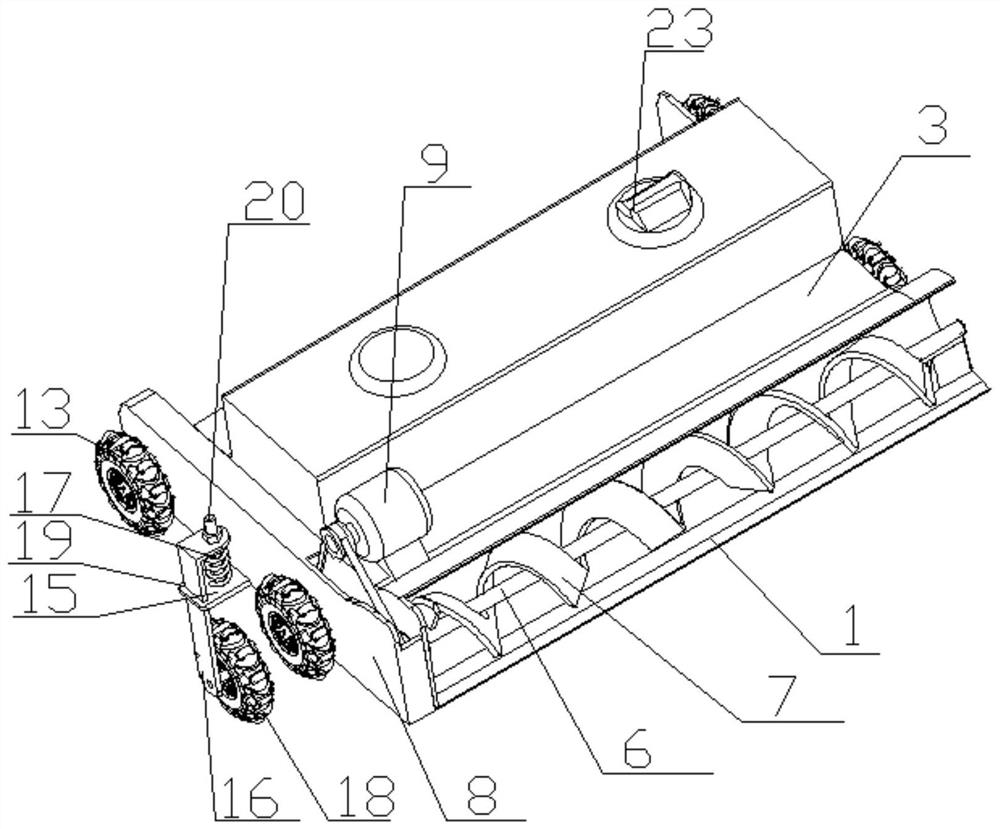

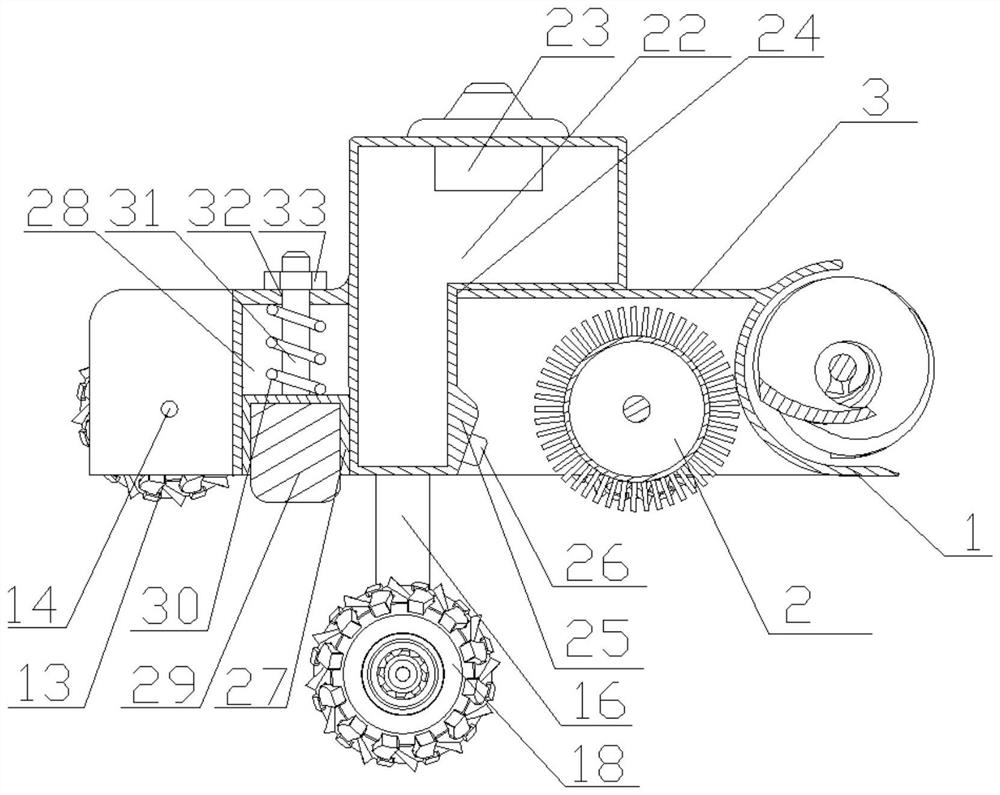

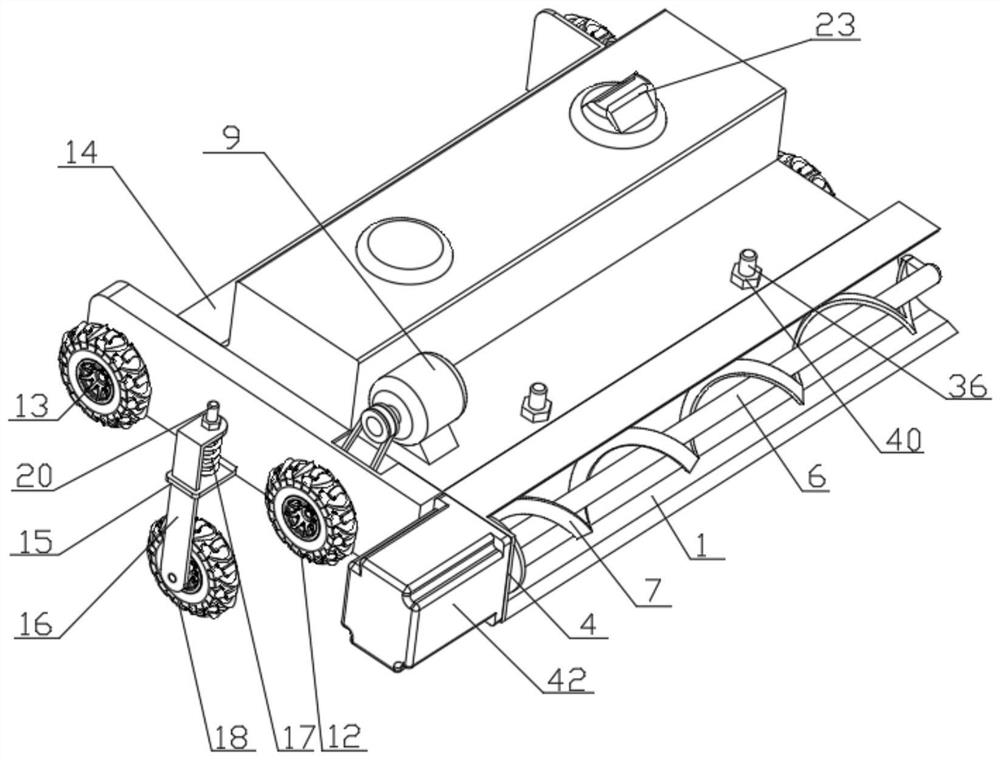

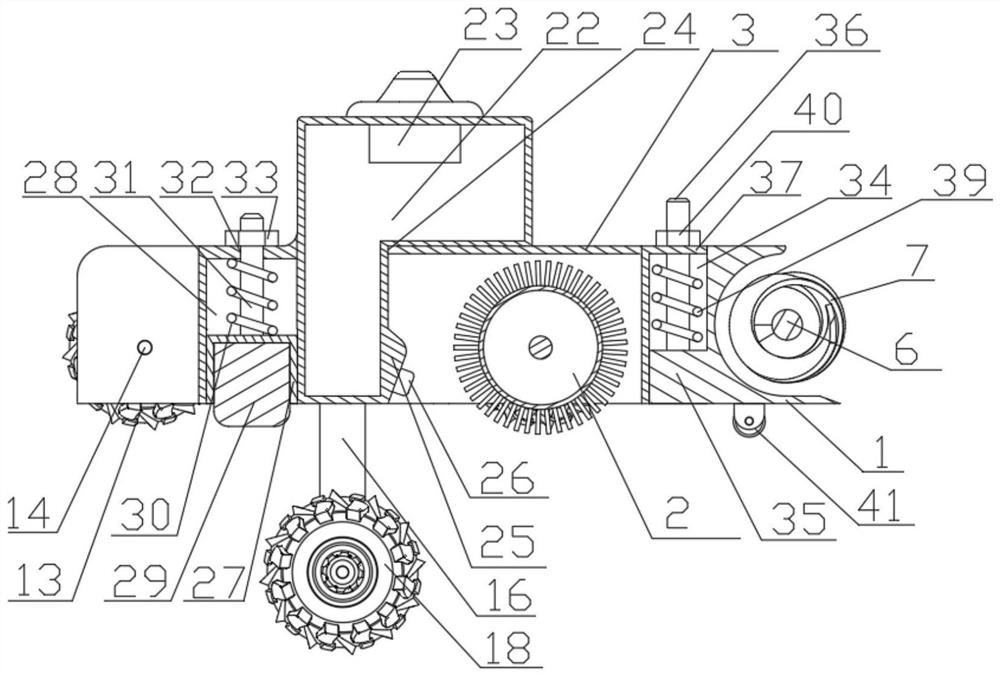

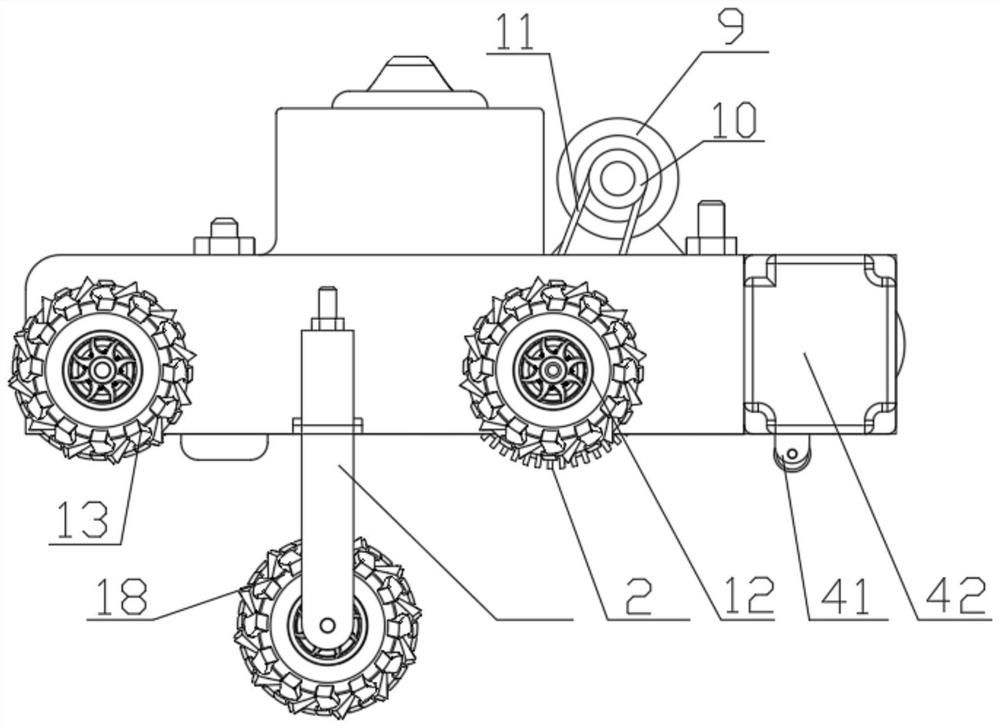

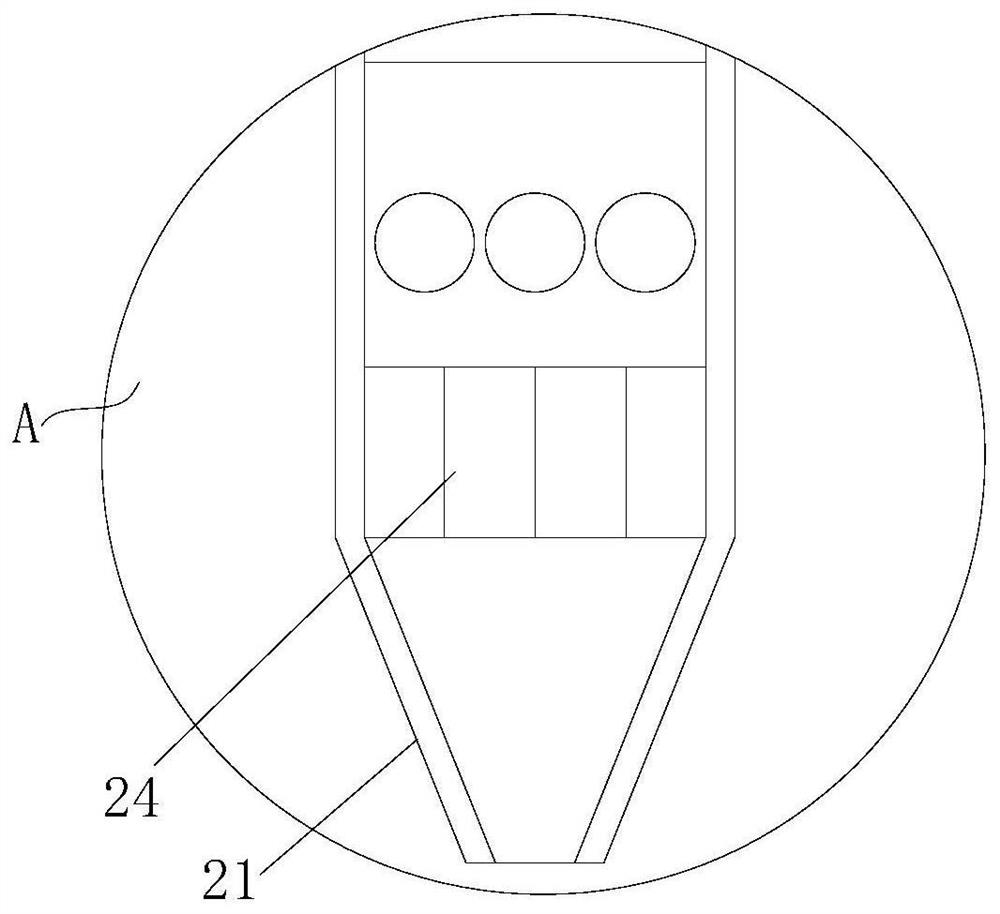

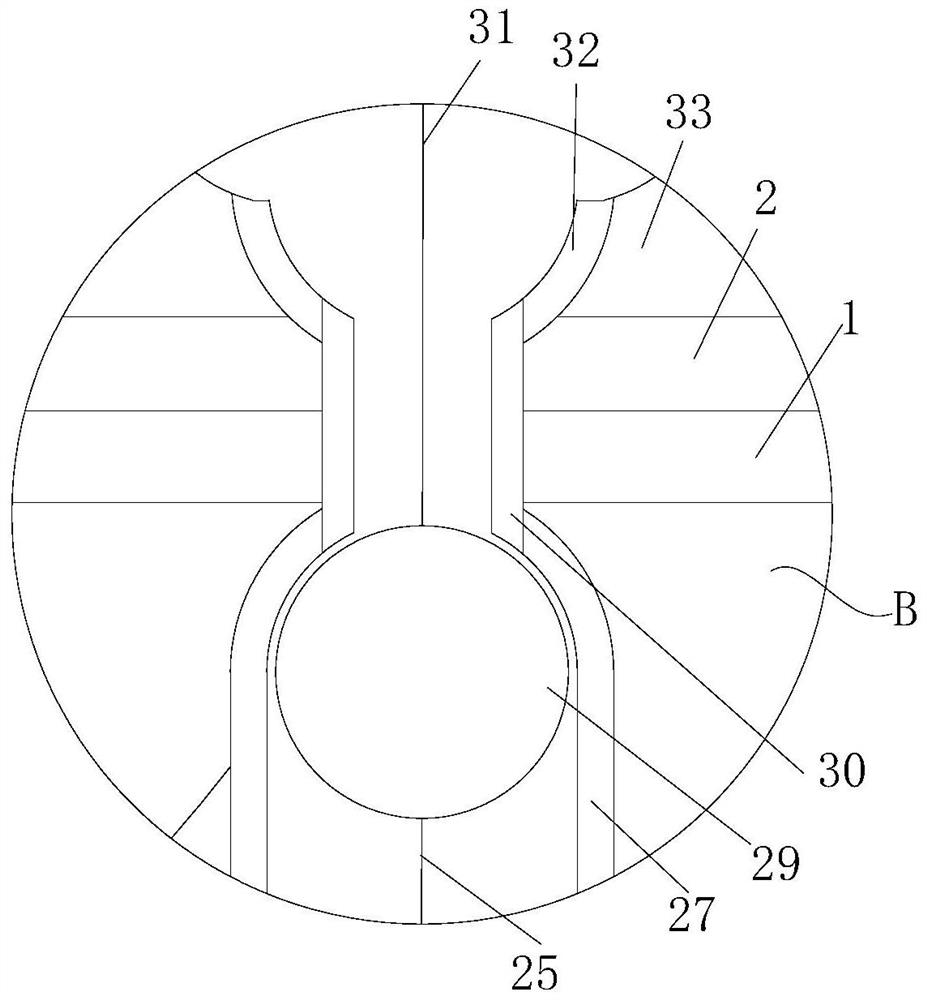

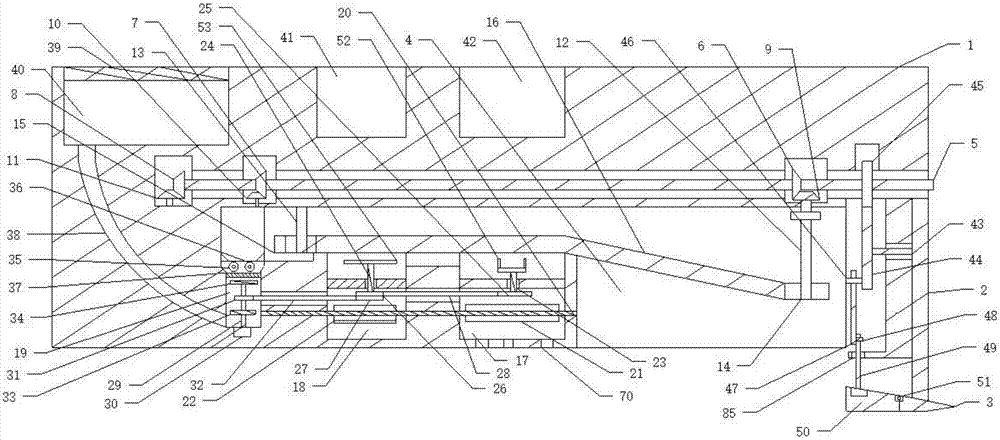

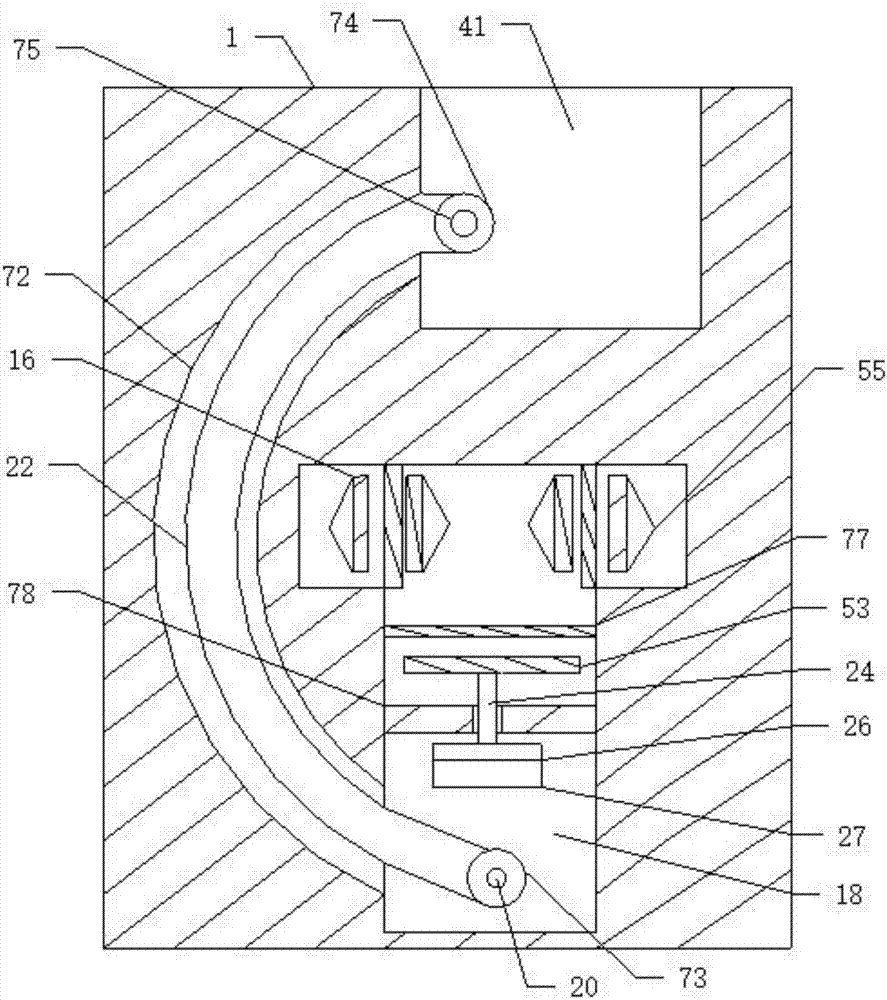

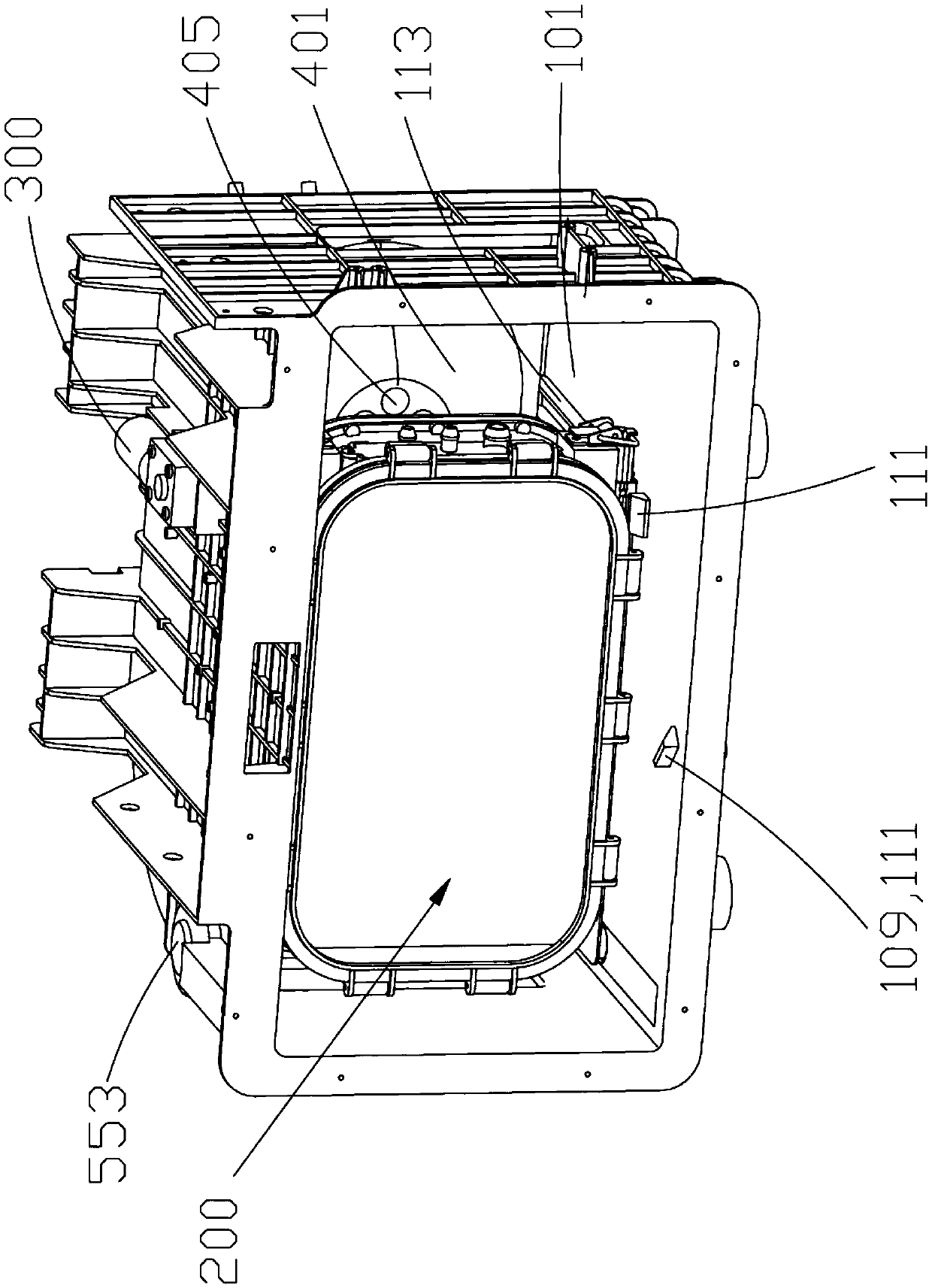

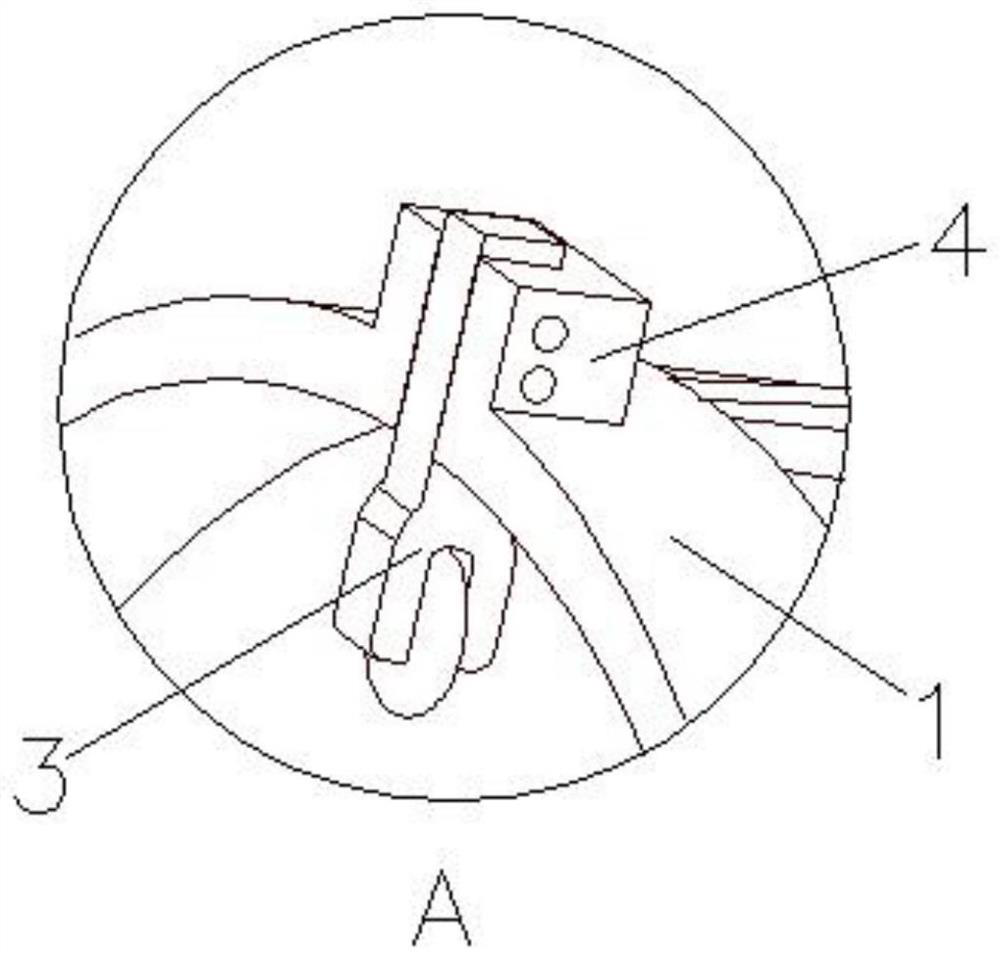

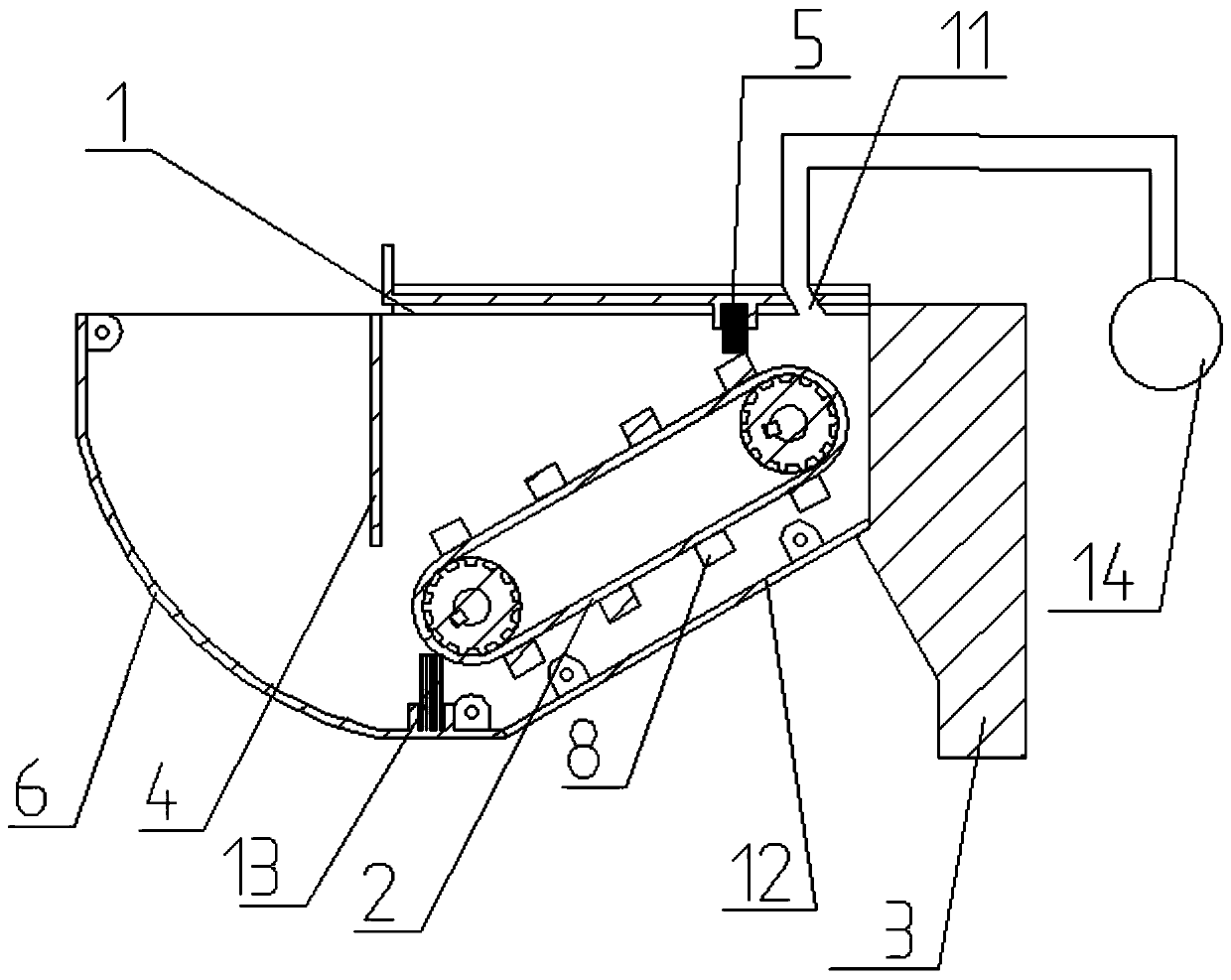

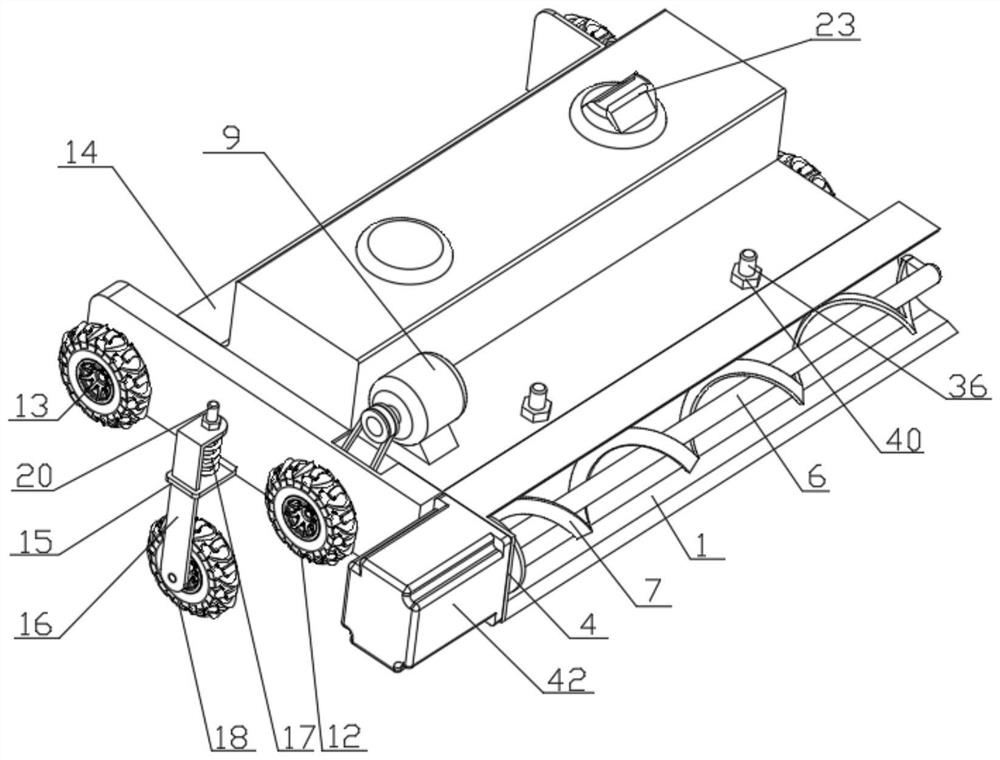

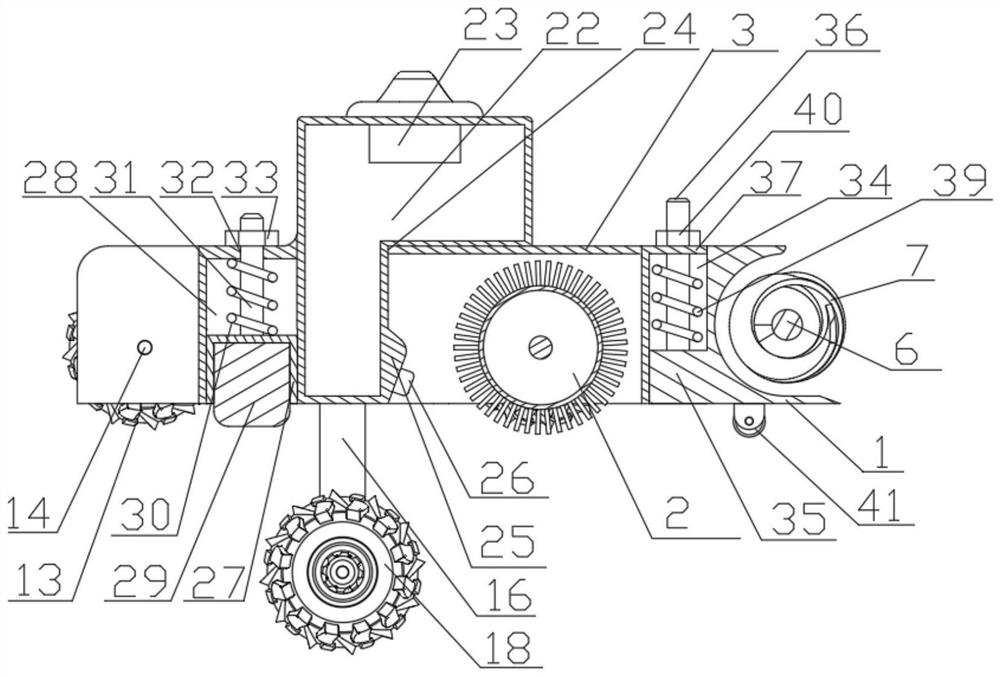

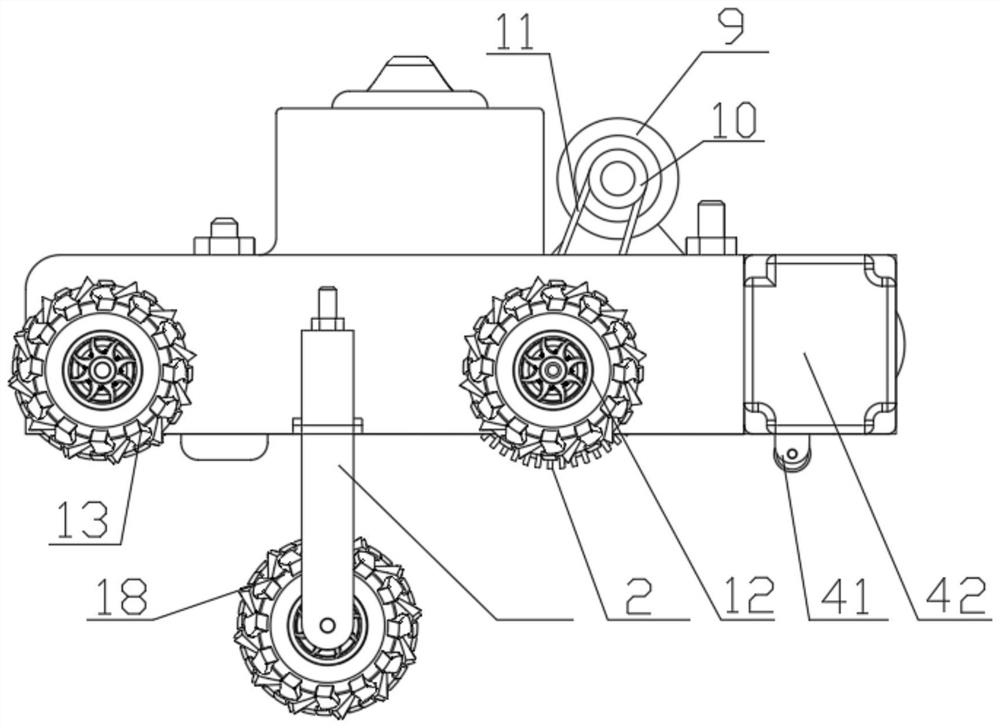

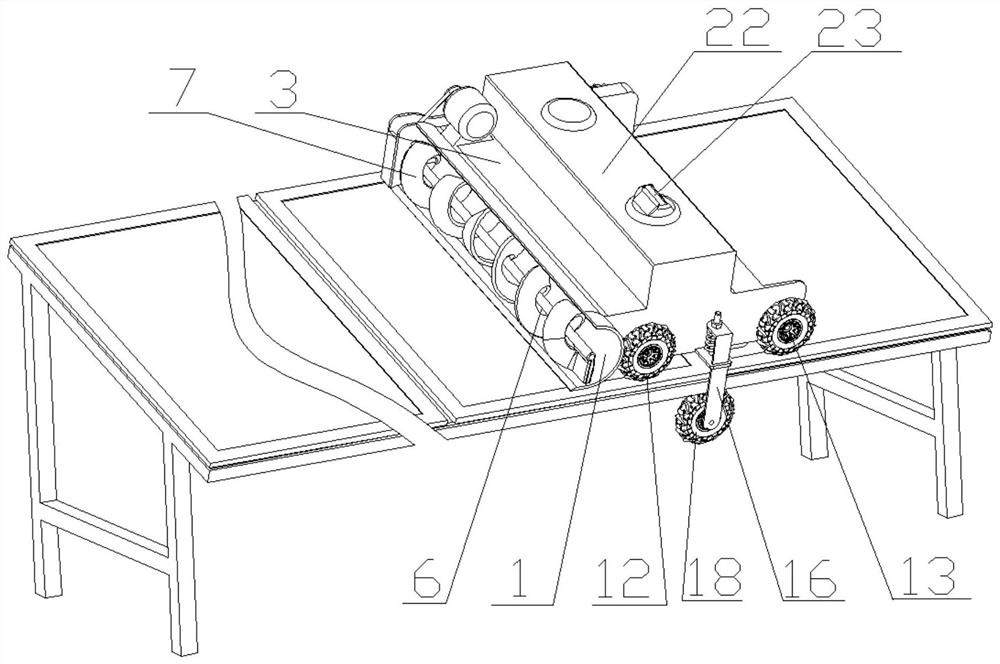

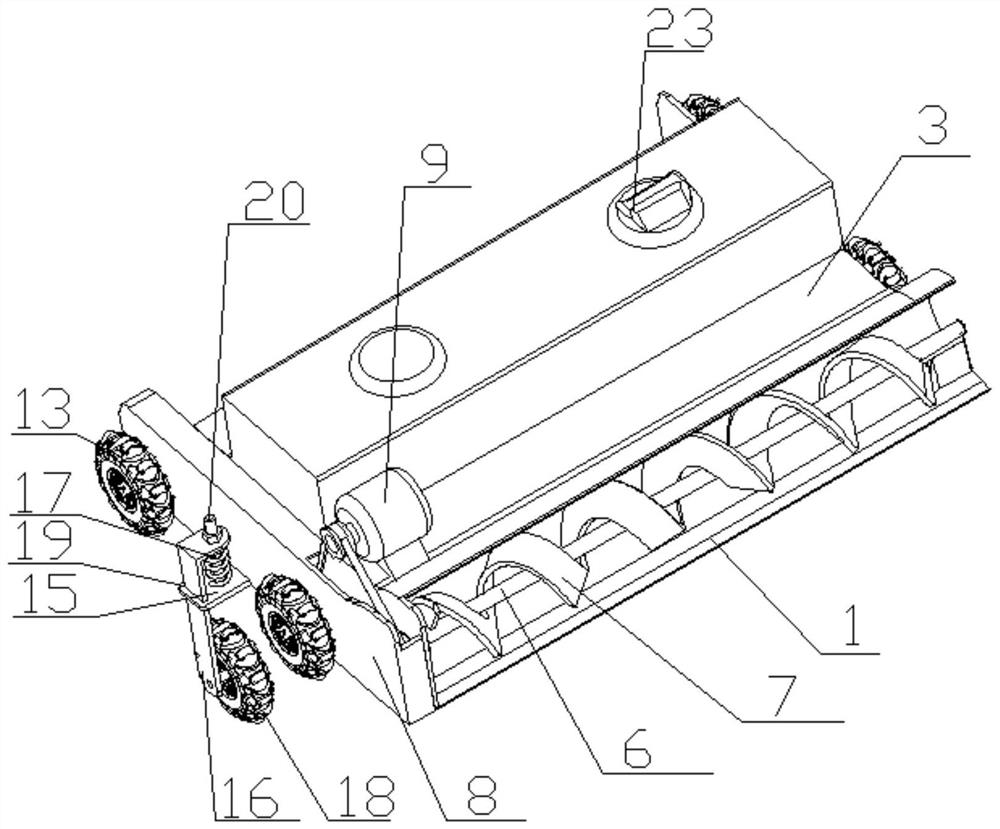

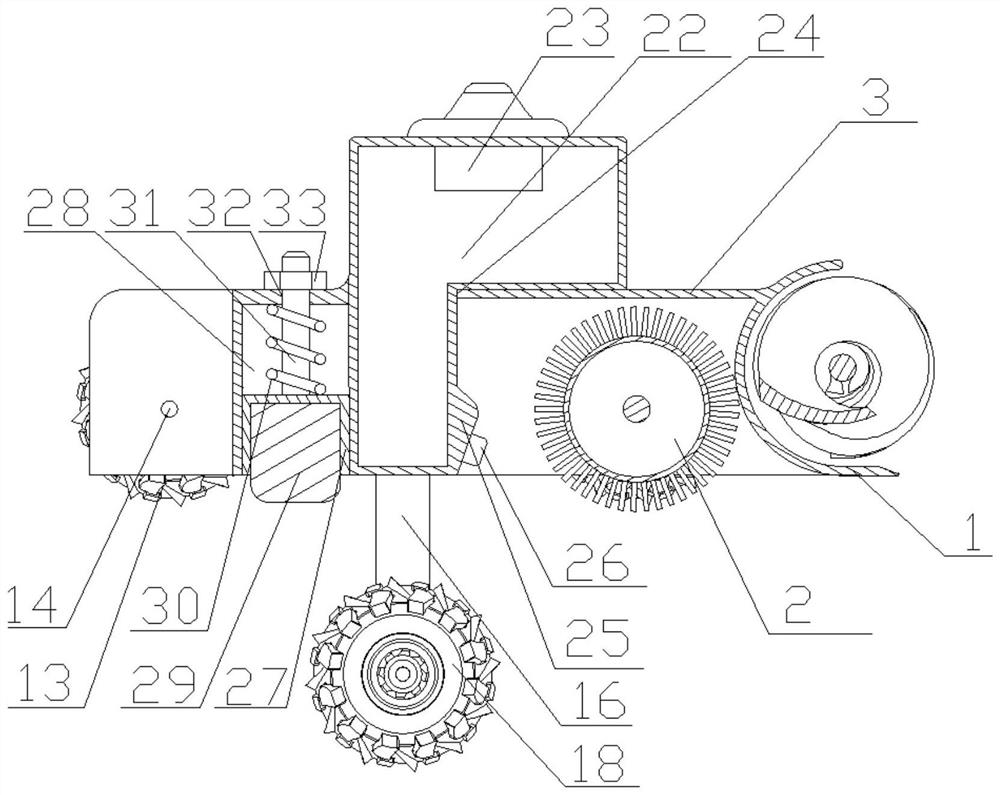

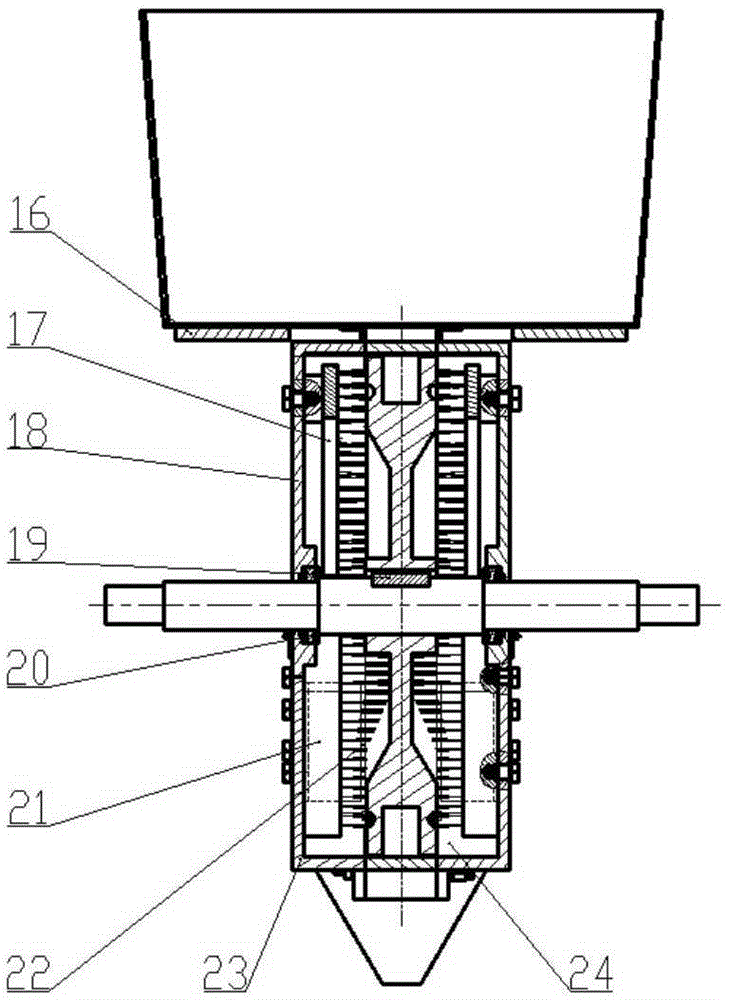

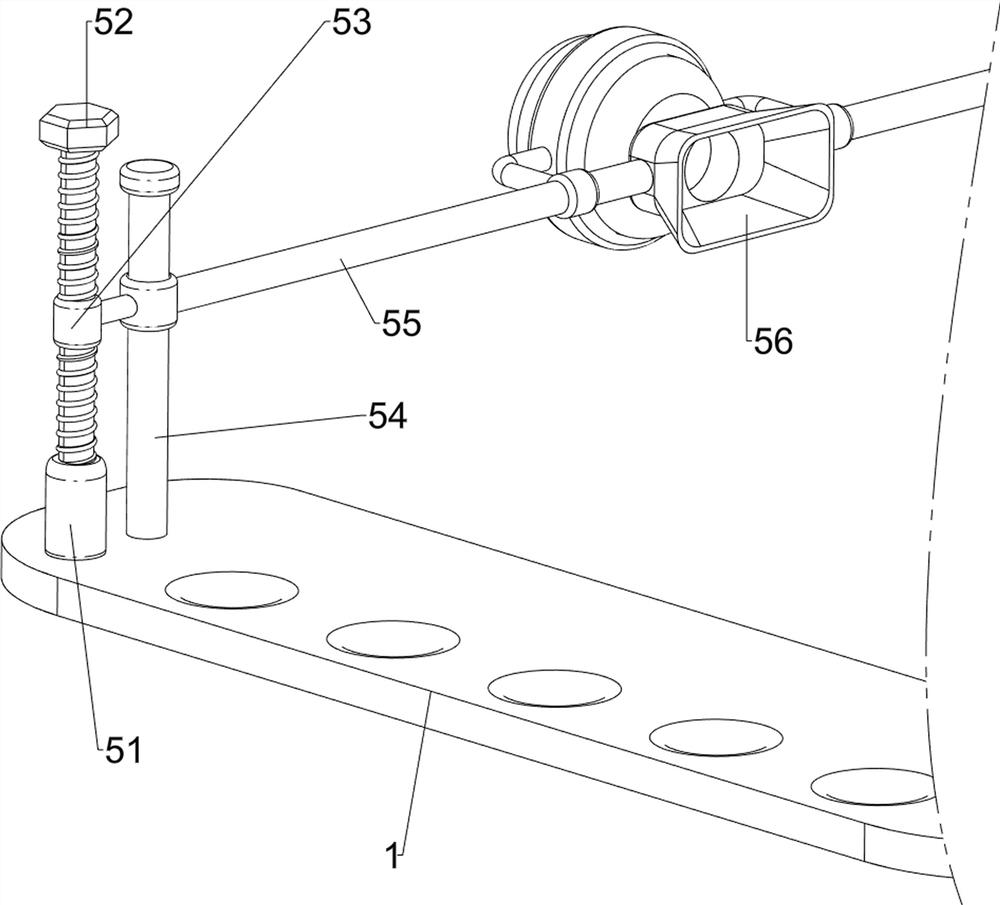

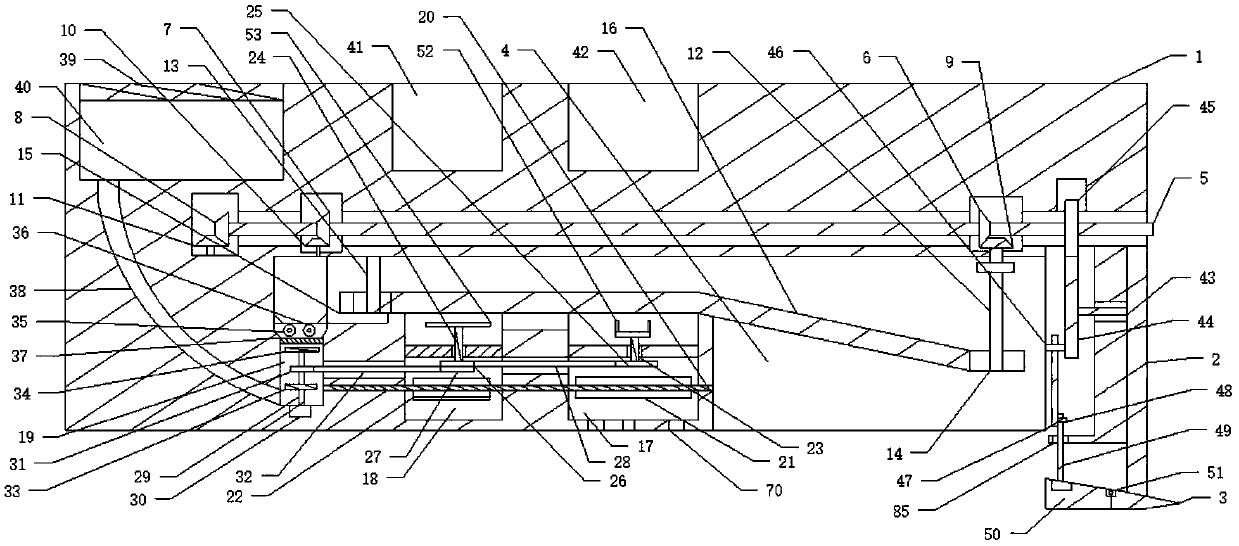

The invention discloses a cleaning device for a solar photovoltaic panel. According to the cleaning device, the cross section of a shovel plate is of an arc-shaped structure, a shell is of a box structure provided with a bottom opening, the shovel plate is fixedly connected with the side wall of the shell, a cleaning roller is mounted in the shell and can partially extend out of the opening of theshell, the cleaning roller can rotate around itself to make contact with the solar photovoltaic panel so as to clean the surface of the solar photovoltaic panel, an end plate is arranged on the end face at one side of the shovel plate, a first through hole is formed in the end plate, one end of a snow guide assembly penetrates through the first through hole so that the snow guide assembly is arranged in the shovel plate, the snow guide assembly also can rotate around the axis of the first through hole, walking devices are mounted at the two sides of the shell, the lowest plane of the shovel plate is higher than the walking surfaces of the walking devices so that the shovel plate can be not in contact with the solar photovoltaic panel, and a power device is mounted at the top of the shelland can drive the cleaning roller and the snow guide assembly to rotate through a transmission assembly. The device can realize rapid cleaning of the solar photovoltaic panel.

Owner:NANJING RUIQI ELECTRONICS TECH CO LTD

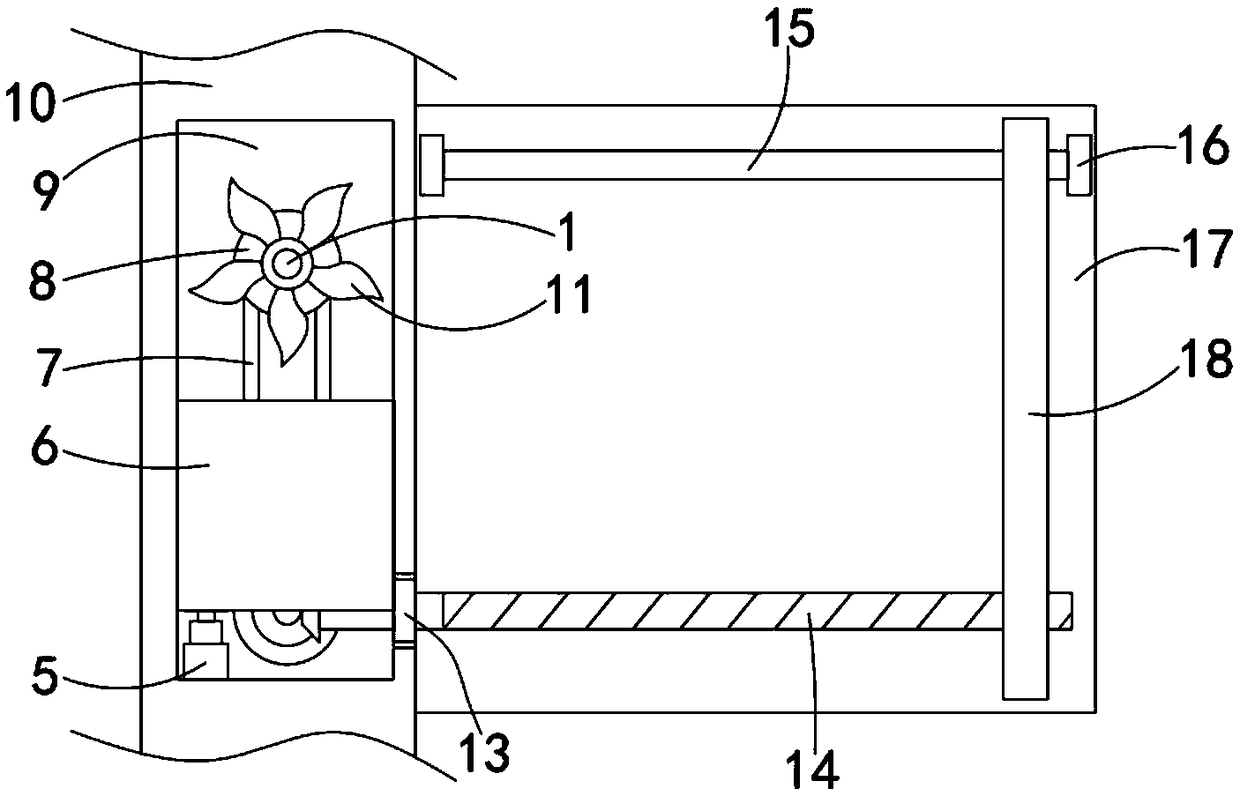

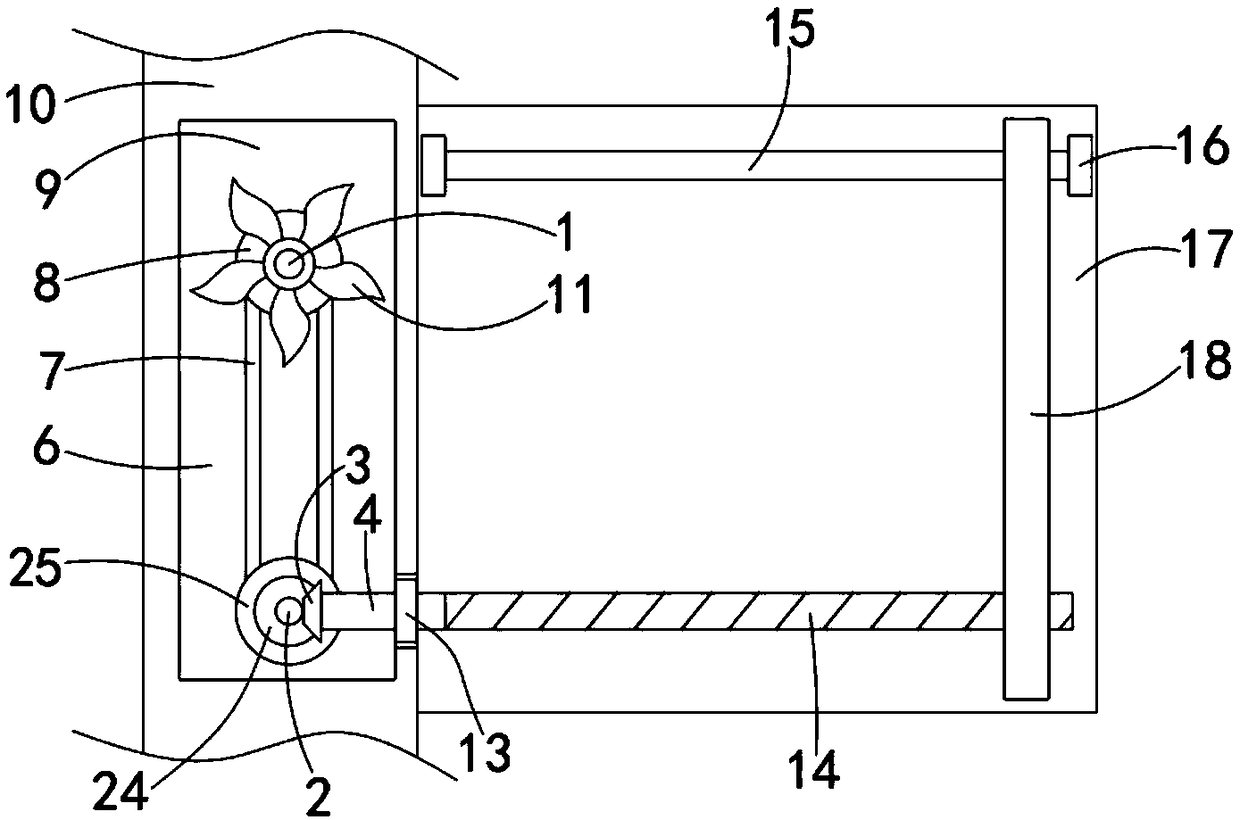

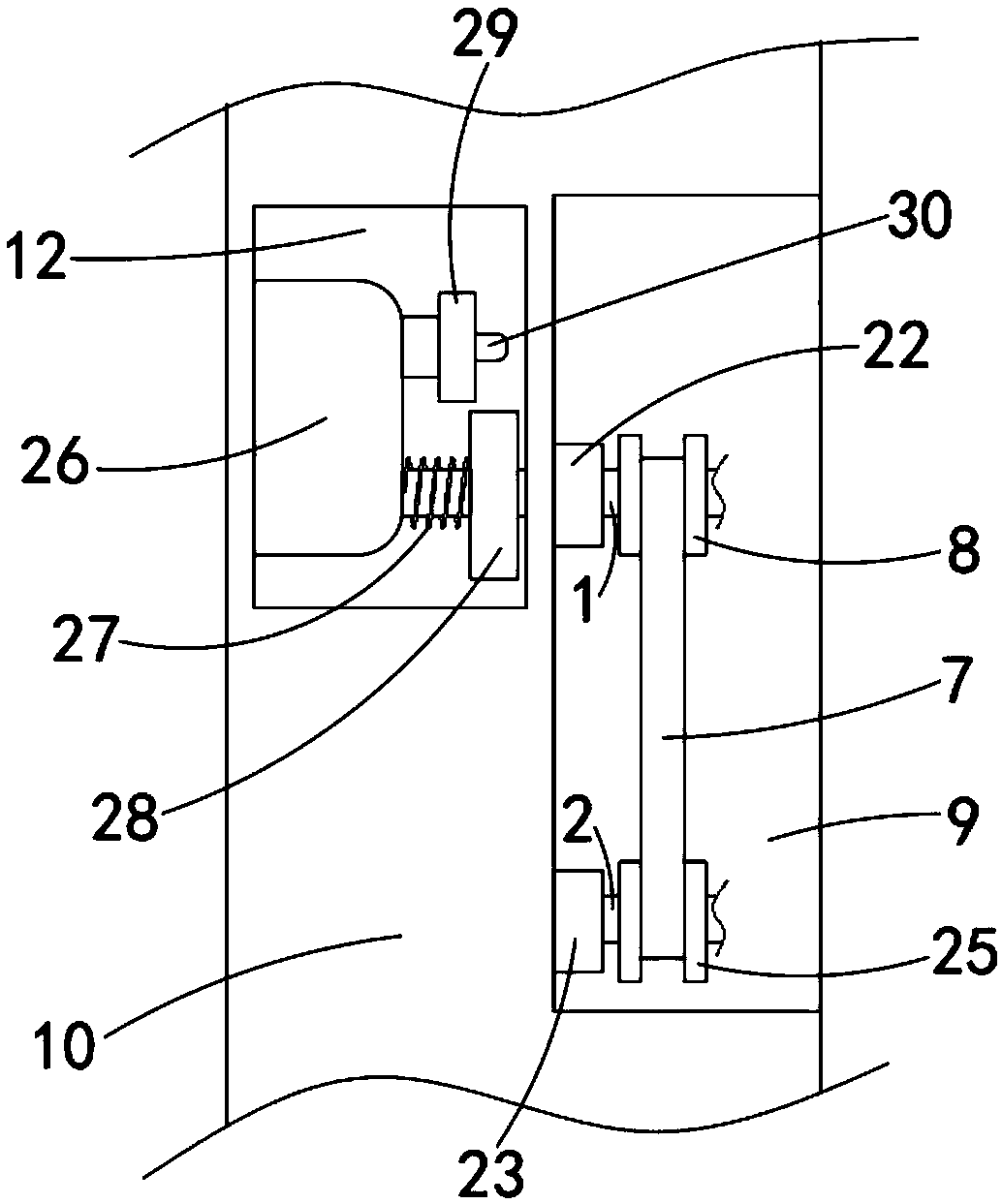

Mansion glass curtain wall with self-cleaning function

ActiveCN108643416AAchieve cleanThe effect of blowing is obviousWallsBuilding repairsSlide plateWind power

The invention discloses a mansion glass curtain wall with a self-cleaning function. The mansion glass curtain wall comprises a vertical column and a glass curtain wall. The glass curtain wall is fixedly connected with the side wall of the vertical column; a mounting groove is formed in the front side surface of the vertical column, an opening of the mounting groove faces forwards, and a first bearing and a second bearing are sequentially and fixedly mounted at the inner bottom of the mounting groove from top to bottom; a first rotating shaft is inserted and rotatably connected in the first bearing, and a second rotating shaft is inserted and rotatably connected in the second bearing; the front end of the first rotating shaft is sequentially sleeved with and fixedly connected with a first transmission wheel and rotating blades from back to front; and a mounting cavity is formed in the vertical column, and a decelerator is fixedly mounted on the inner side wall of the mounting cavity. According to the mansion glass curtain wall with the self-cleaning function, natural wind power at the high floor of a mansion is utilized to drive a sliding plate to slide in a reciprocating mode through a series of transmission so that the glass curtain wall can be wiped cleanly by a smearing and wiping cushion, manpower is saved, and safety and reliability are achieved.

Owner:深圳市腾基建设工程有限公司

Cleaning device for solar photovoltaic panel and cleaning method of solar photovoltaic panel

ActiveCN111790648ALowest point highThe same heightPhotovoltaicsCleaning using toolsEngineeringStructural engineering

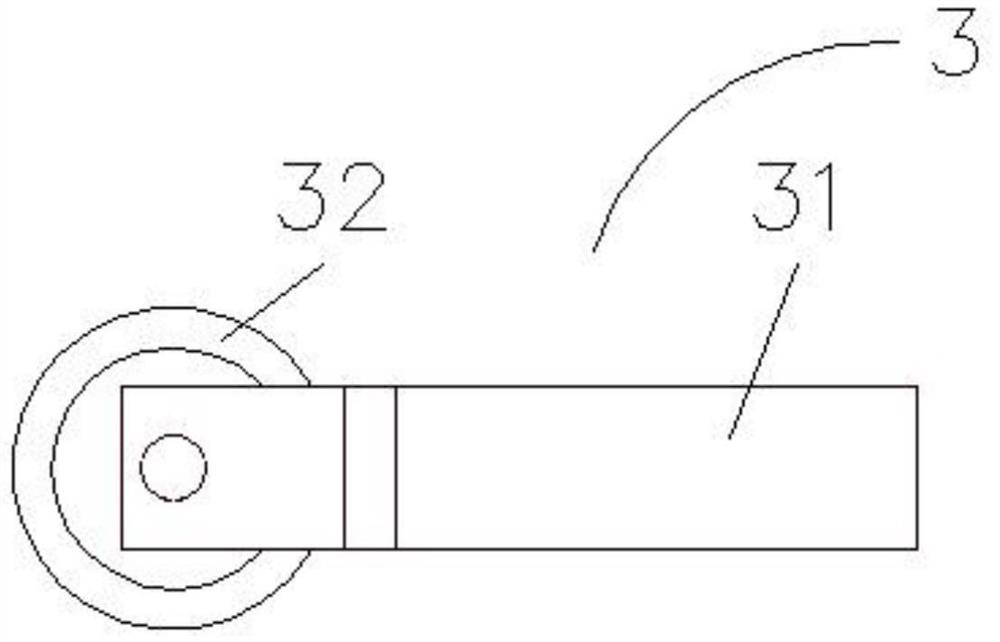

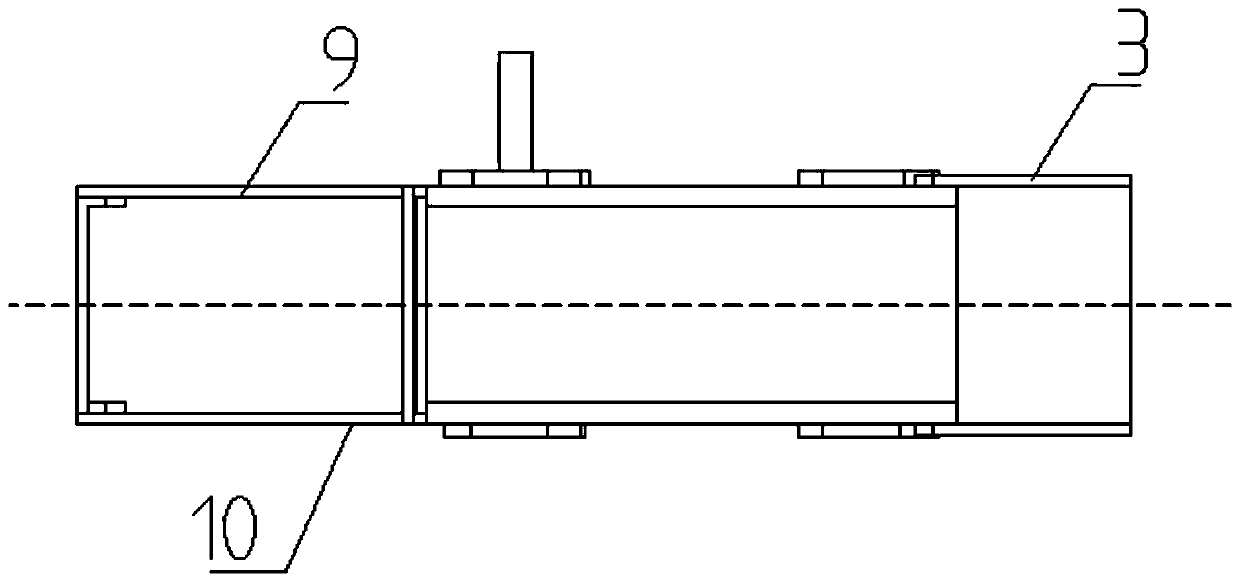

The invention discloses a cleaning device for a solar photovoltaic panel and a cleaning method of the solar photovoltaic panel. A housing is of a box-like structure with a bottom opening, one end of the housing is provided with a guide groove, one end of a shovel plate is of an arc-shaped structure, the other end of the shovel plate is provided with a sliding block, a second connecting rod is arranged at the top of the sliding block, the top of the guide groove is provided with a top plate, the top plate is provided with a fourth through hole, the end portion of the second connecting rod passes through the fourth through-hole to mount the shovel plate in the guide groove, the shovel plate can move in the axial direction of the guide groove, the second connecting rod is sleeved with a thirdspring, the third spring is located between the sliding block and the top plate, a second limiting block is arranged at one end, away from the sliding block, of the second connecting rod, a bottom plate of the shovel plate is provided with a supporting walking wheel, a cleaning roller is installed in the shell, the end face of one side of the shovel plate is provided with an end plate, the end plate is provided with a first through hole, one end of a snow guiding assembly penetrates through the first through hole to arrange the snow guiding assembly in the shovel plate, a walking device is mounted on the two sides of the housing, and a power device can drive the cleaning roller and the snow guiding assembly to rotate.

Owner:徐州顺泰新能源发电有限公司

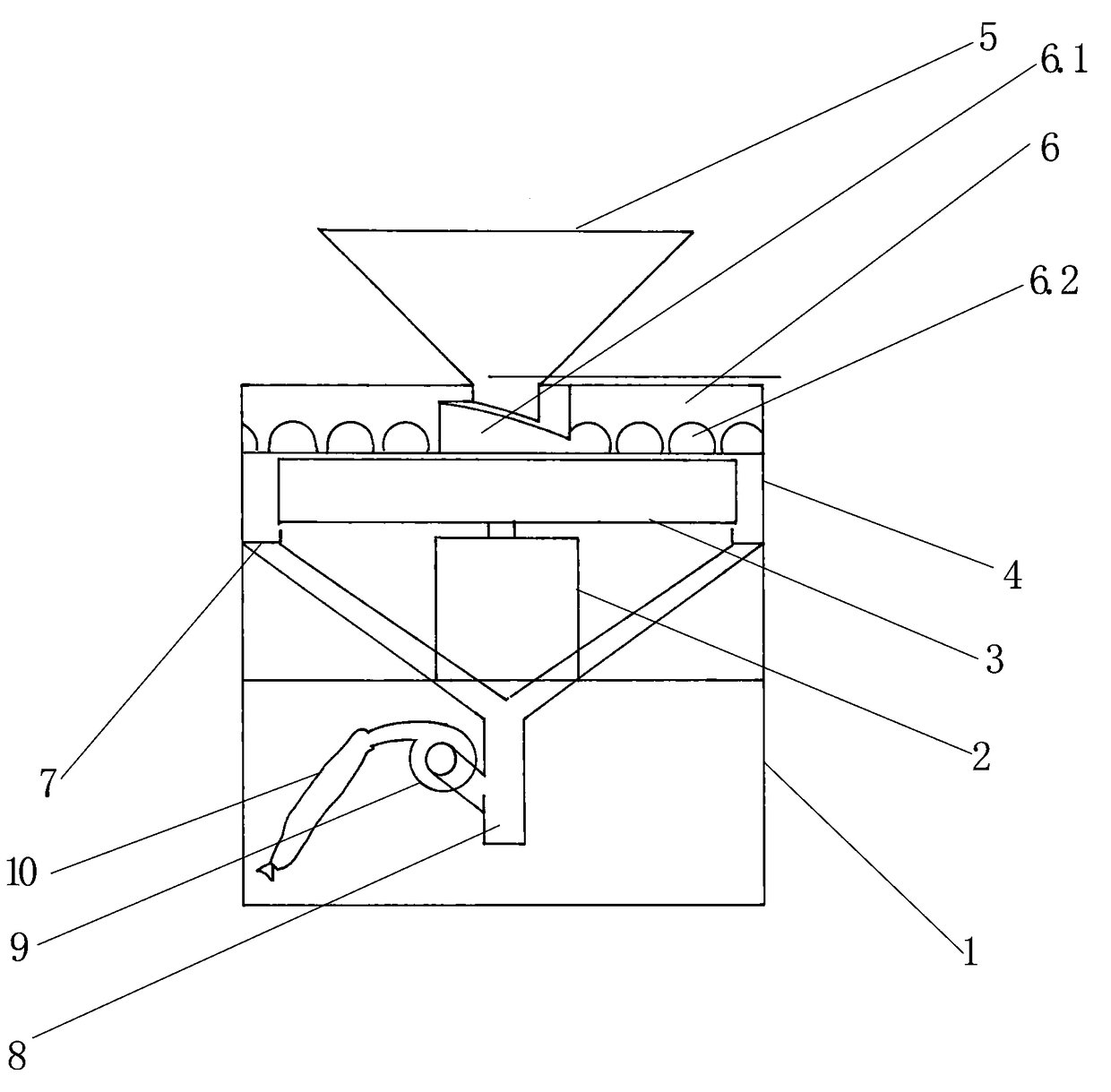

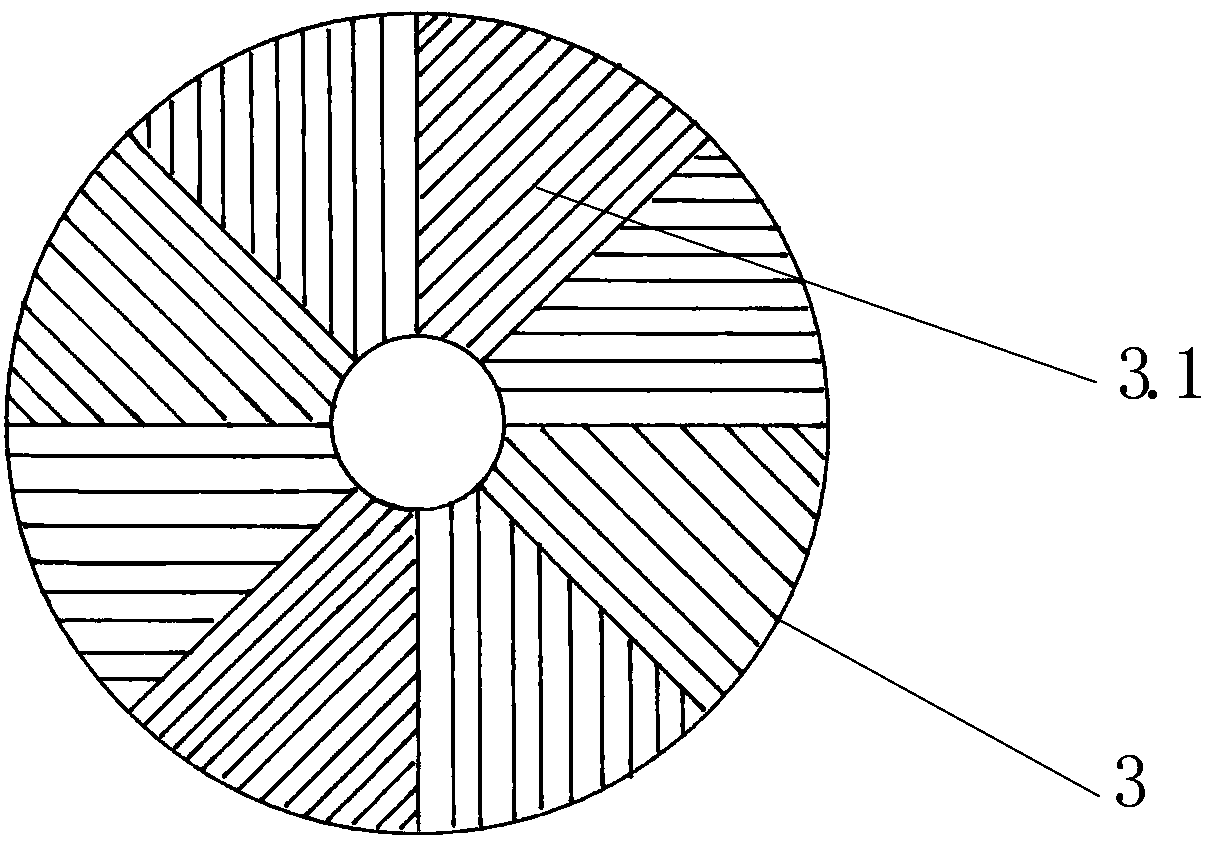

Garlic mill capable of performing peel rubbing

The invention relates to garlic processing machinery, in particular to a garlic mill capable of performing peel rubbing. The garlic mill comprises a milling frame, a motor, an upper rubber milling disk, a lower rubber milling disk, a hopper, a mill housing and an exhaust fan. Through adoption of the technical scheme of the garlic mill capable of performing peel rubbing disclosed by the invention,when the garlic mill is used, a feeding control inserting plate is arranged on the hopper, so that discharging can be uniformly performed; and a centrifuging parabola-shaped garlic splitting groove ofwhich the upper concave depth is gradually transited from 8cm to 3cm is formed in one side of the tail end of a feeding hole of the rubber upper milling disk, so that whole garlics can be gradually pressed downwards and divided into garlic cloves of which the thickness is not greater than 3cm.

Owner:马同金

Urine taking device used for urology department

PendingCN111973232APrevent splashTo achieve the effect of quantitative urine collectionHollow article cleaningSurgeryEngineeringUrology department

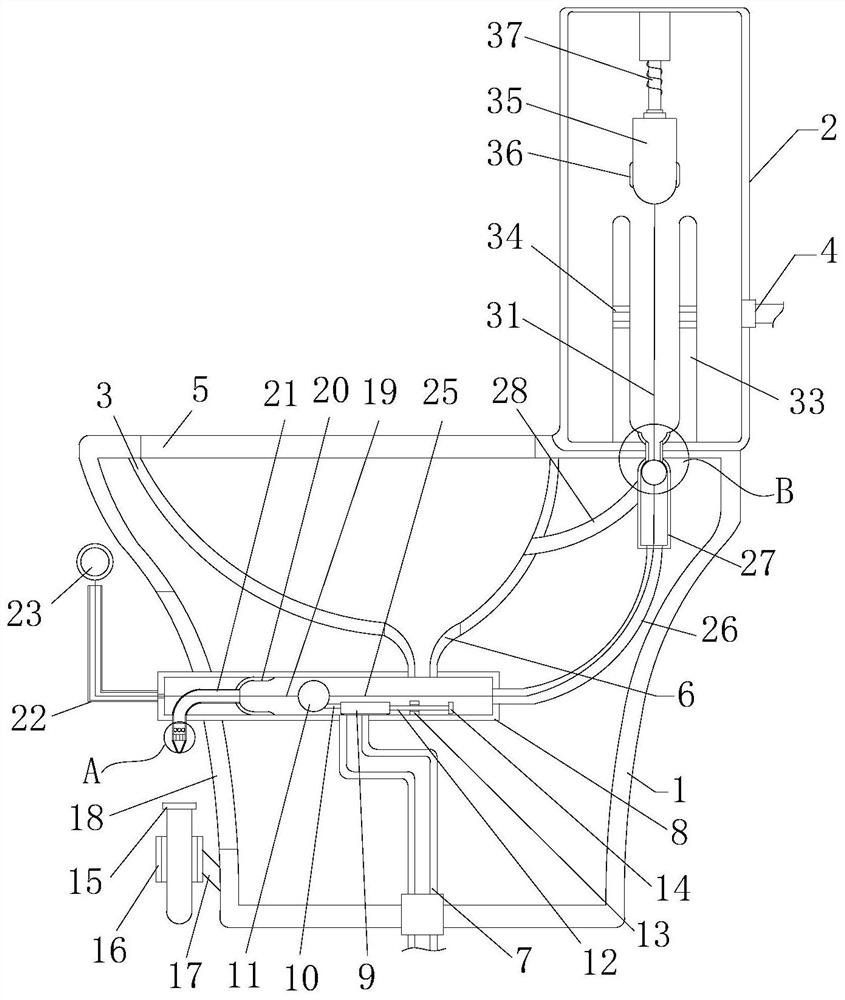

The invention relates to a urine taking device used for urology department. According to the invention, a water inlet pipe is arranged on the side wall of a water box; a basin cavity opening is arranged on the upper plate of a supporting seat box; a liquid collecting basin is arranged at the lower end of the basin cavity opening and fixedly arranged on the inner top wall of the supporting seat box; a first splayed pipe is fixedly inserted into the lower end of the liquid collecting basin; a supporting reset assembly comprises a supporting reset cylinder, a supporting reset rod and a supportingreset spring; the supporting reset rod is movably inserted into the supporting reset cylinder; the supporting reset spring is connected with and arranged on the supporting reset rod in a wound mode;and two ends of the supporting reset spring are correspondingly connected with and arranged on the outer side wall of the supporting reset cylinder and the side wall of the supporting reset rod. According to the invention, when urine is received and taken, a conventional mode that a disposable urine cup is held by hand to take the urine can be avoided, so urine sampling is standard; meanwhile, theurine can be prevented from being splashed to the hand; and through improved equipment provided by the invention, the effect of quantitatively taking the urine can be achieved when the urine is taken.

Owner:重庆知遨科技有限公司

Pipeline cleaning agent

InactiveCN104140898AQuick washWash thoroughlySurface-active detergent compositionsDetergent compounding agentsAcyl groupEngineering

A pipeline cleaning agent is prepared by raw materials of, by weight, 10 to 20 parts of 2-hydroxyphosphonocarboxylic acid, 3 to 8 parts of zinc sulfate, 1.5 to 6 parts of dimethyl formamide, 1.2 to 3.5 parts of benzyl alcohol, 2 to 4 parts of trichloromethane, 6 to 10 parts of simethicone, 1.3 to 3 parts of a hydrotropy agent, 0.6 to 1.3 parts of alkyl ether magnesium sulfonate, 0.5 to 1.1 parts of stannic oxide, 2.3 to 4.8 parts of ethylene glycol monobutyl ether and 1.4 to 2.6 parts of ammonium citrate. The pipeline cleaning agent has the advantages that pollutants in a pipeline can be rapidly cleaned out, so that the pipeline is clean and smooth and is thoroughly cleaned, and the pipeline cleaning agent is convenient to use.

Owner:QINGDAO QIYUAN ZHENDONG ELECTRIC

Agricultural peanut harvester with function of peanut vine separation

InactiveCN106993423AReduce processing costsImprove cleanlinessDigger harvestersThreshersAgricultural engineeringAgriculture

The invention discloses an agricultural peanut harvester with a function of peanut vine separation. The harvester comprises a body with a reaping tank at the bottom, two first chains in corresponding clamped rotation are arranged in the reaping tank, a peanut harvesting tank in corresponding communication with the reaping tank is arranged at the bottom of the body, and a rotary soil discharge support is arranged in the peanut harvesting tank. A peanut vine cutting tank in corresponding communication with the reaping tank is arranged at the bottom of the body, and a rotary second cutting disk is arranged in the peanut vine cutting tank. By rotation of the first chain, peanut vines can be further conveyed; by rotation of the first cutting disk and the soil discharge support, peanuts can be further harvested, and roots of the peanut vines can be cut off, so that smashing of plastic films into the peanut vines is prevented, cleanness of peanut vine feed is further guaranteed, and pork quality is guaranteed.

Owner:盐城市顺天铸造有限公司

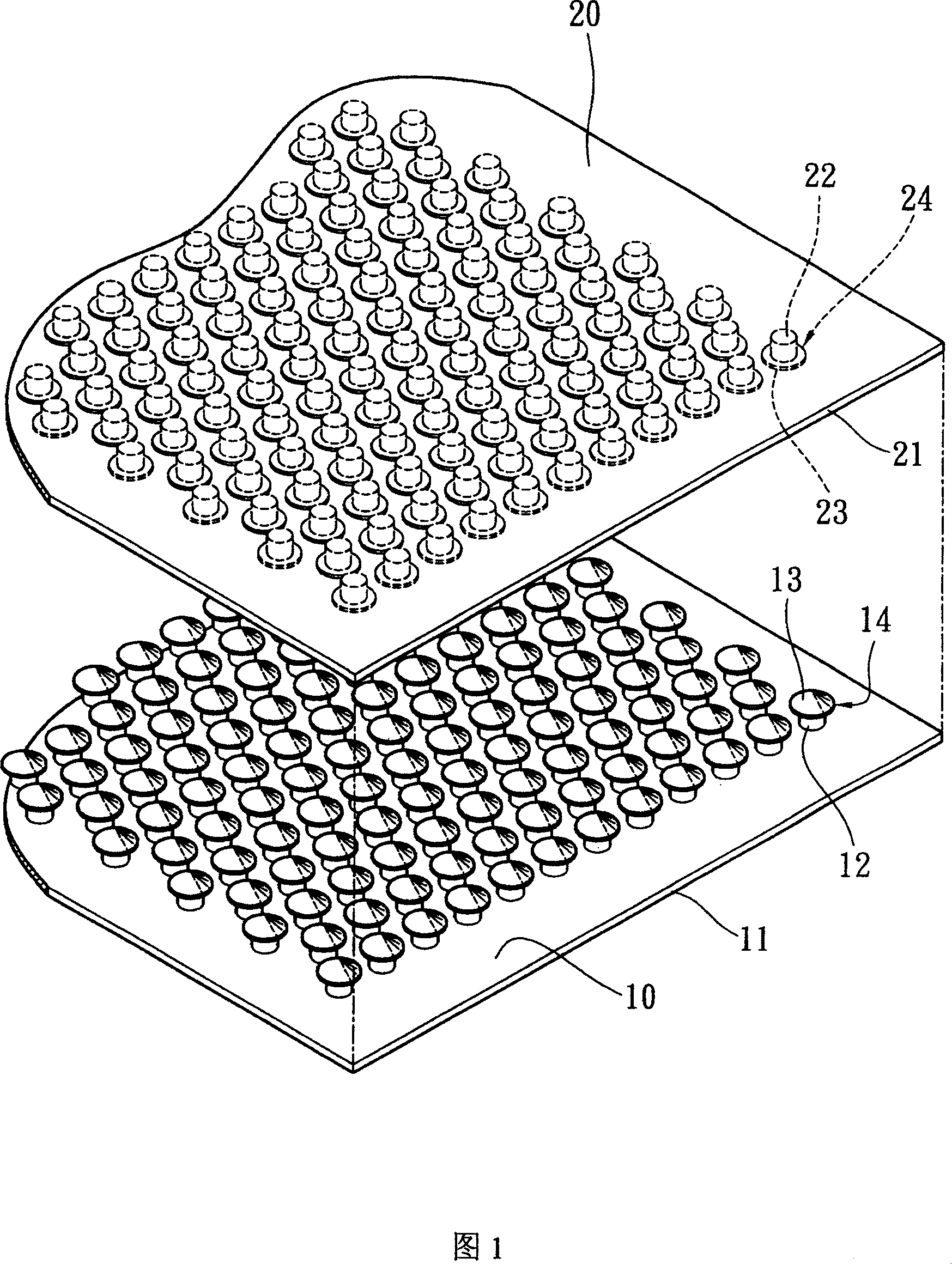

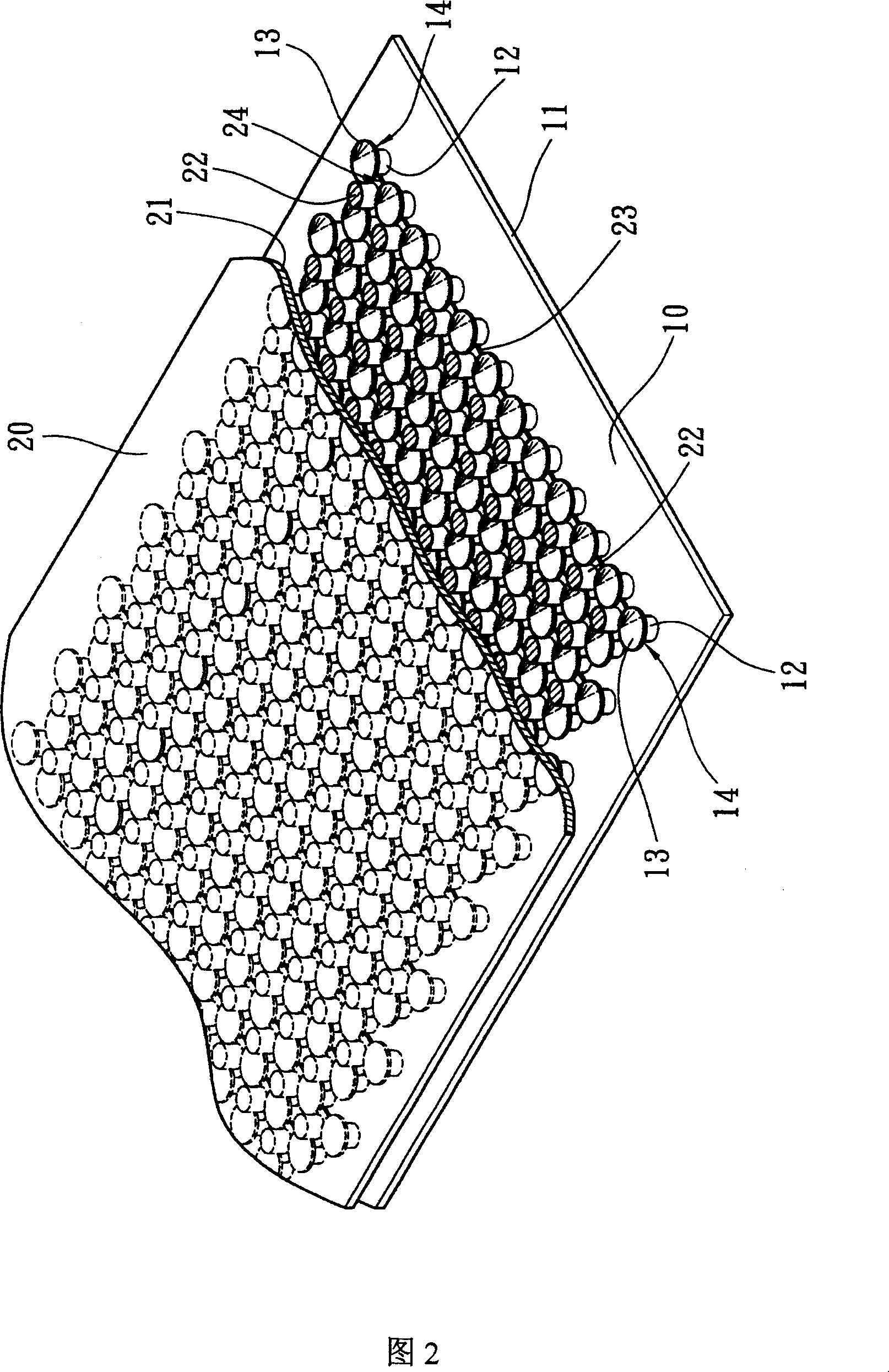

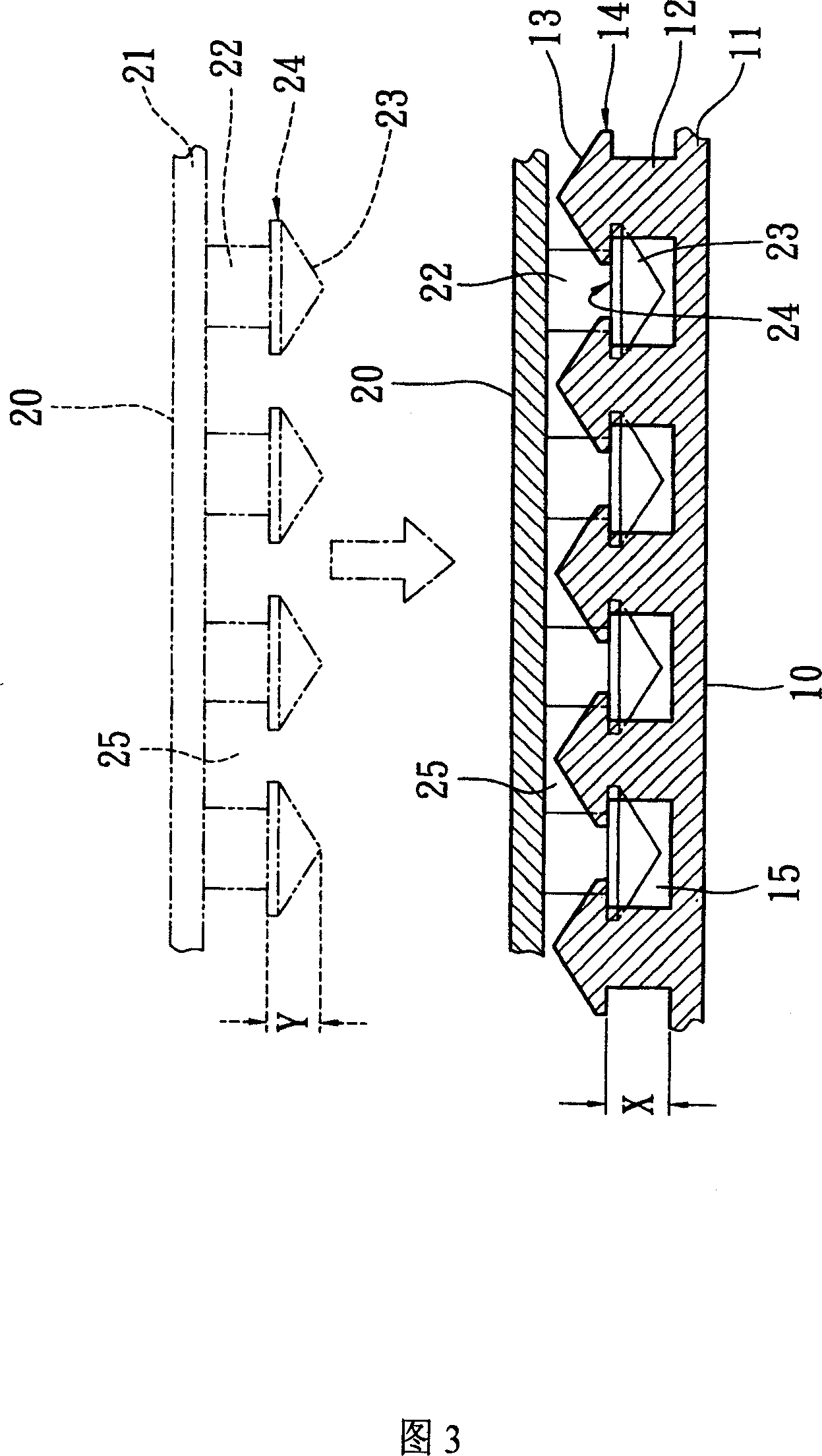

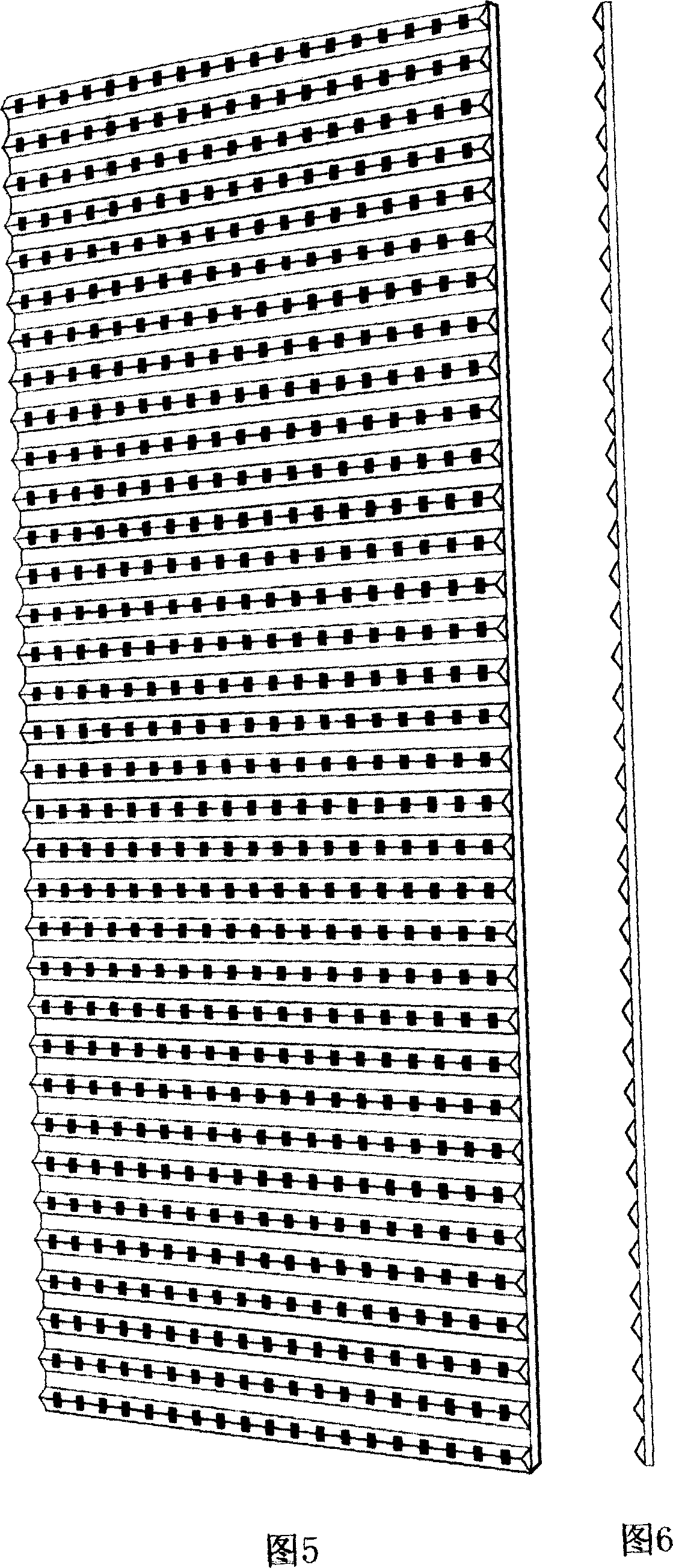

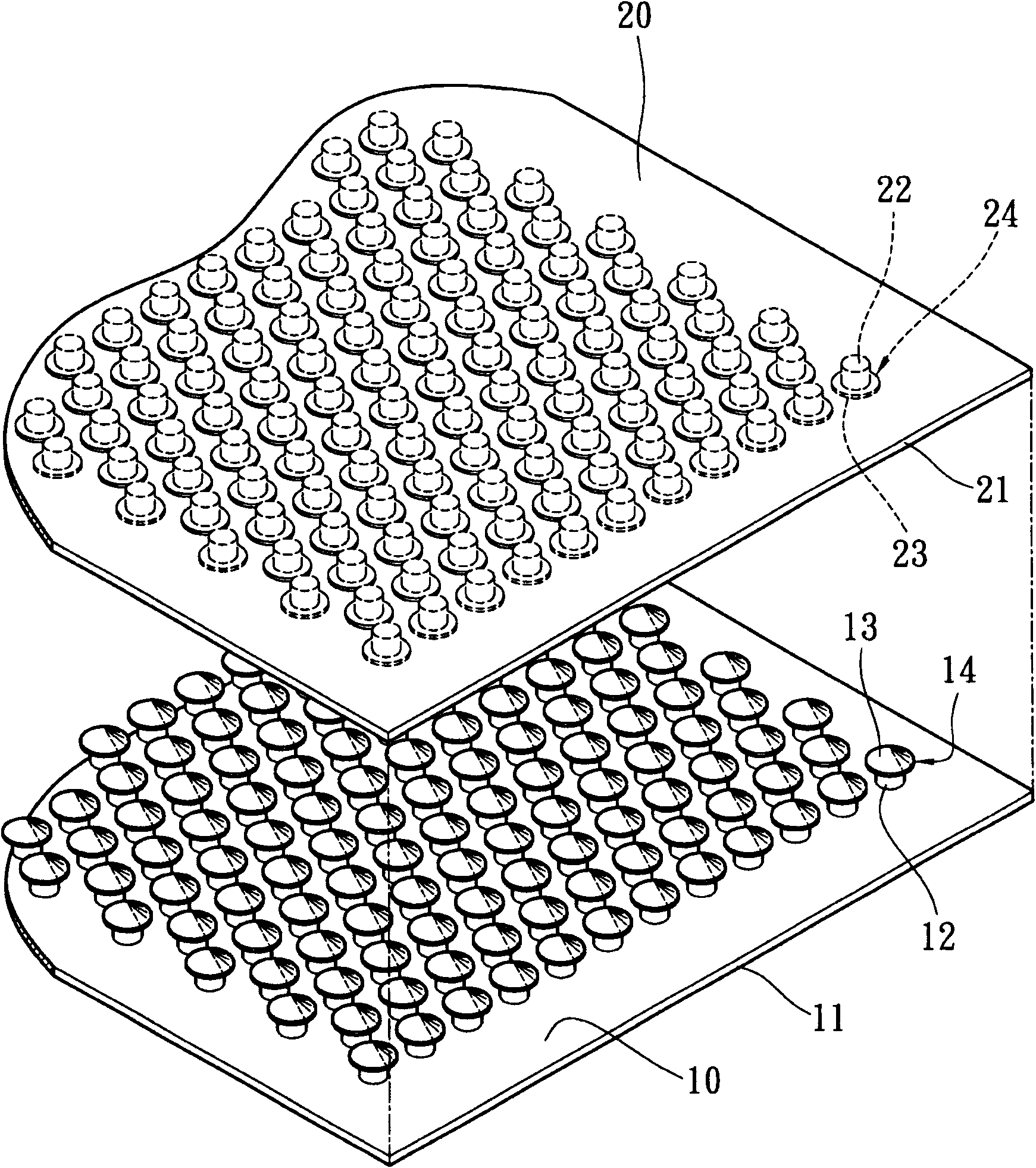

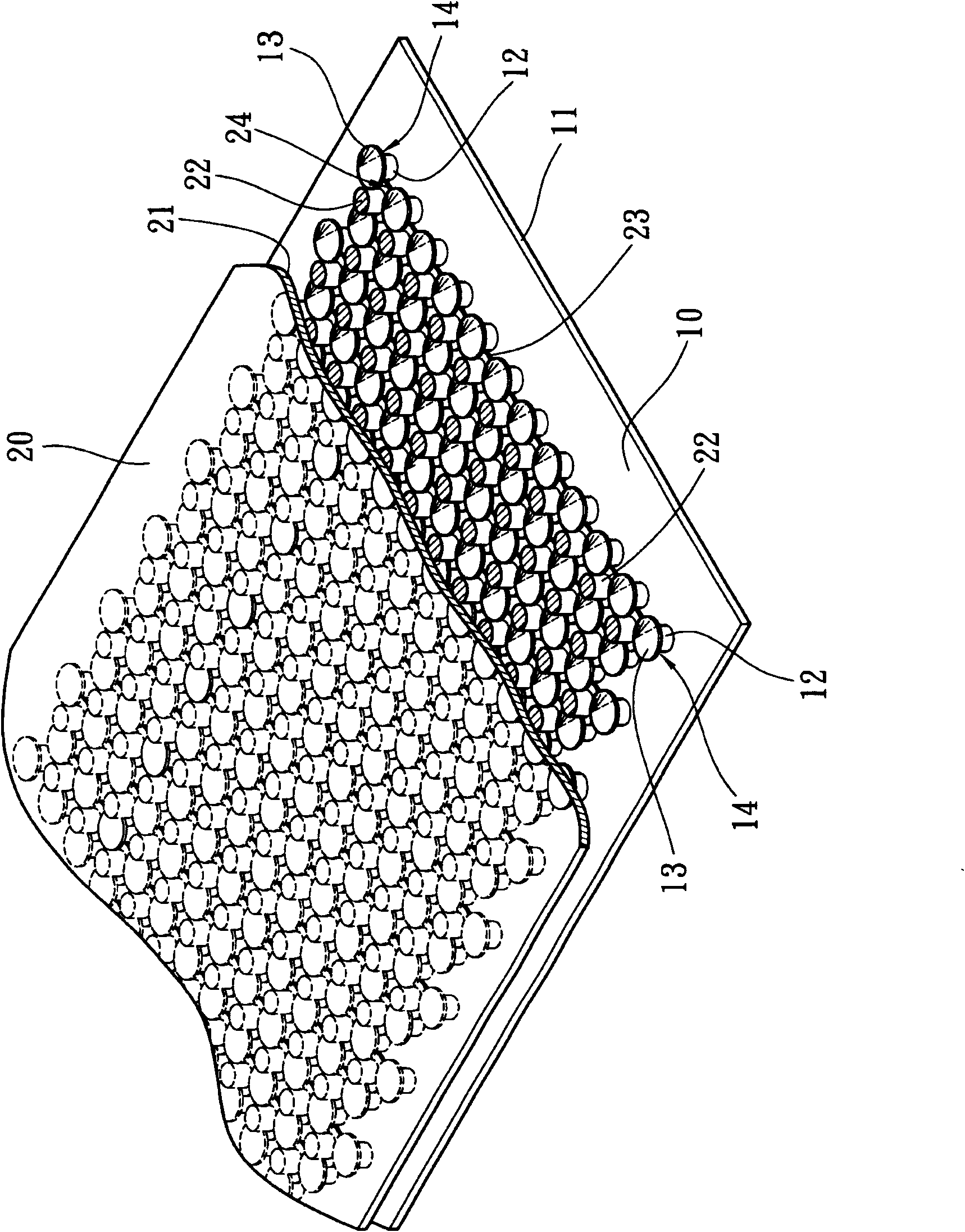

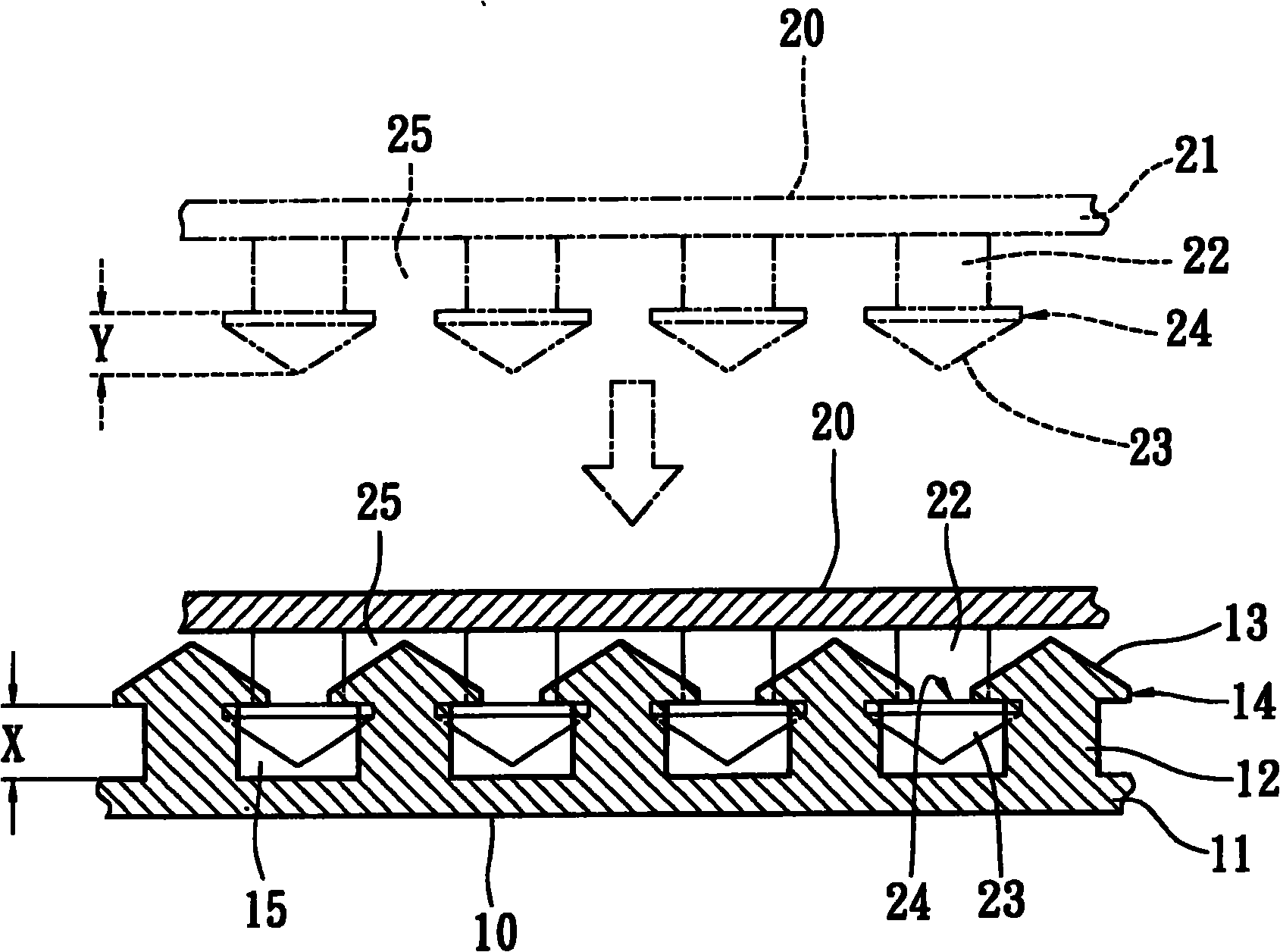

Process for manufacturing linking tape

The sticky cingulum has a top and bottom mold blocks with the up one having grooves with a horizontal passing slide rail which has contained a compression block and several slide mold plates that have up mold cavity at the bottom, and there being bottom mold blocks at the top of the lower mold block. When the top and bottom mold blocks match, it can make each slide mold plate match tightly and form into same grooves with blunt head and nail type. When the mold closes, elastic plastic is injected into the mold cavity to form the sticky cingulum body with posts and cones.

Owner:UNIVERSAL TRIM SUPPLY CO LTD

Method for preventing crazing of outer wall decorative coatings of building

The invention discloses a method for avoiding crack the decorate coat on the building, wherein, the invention first fixes base support at the wall, to be coated with decorate and paint, to eliminate the crack of oil metal paint.

Owner:巢启

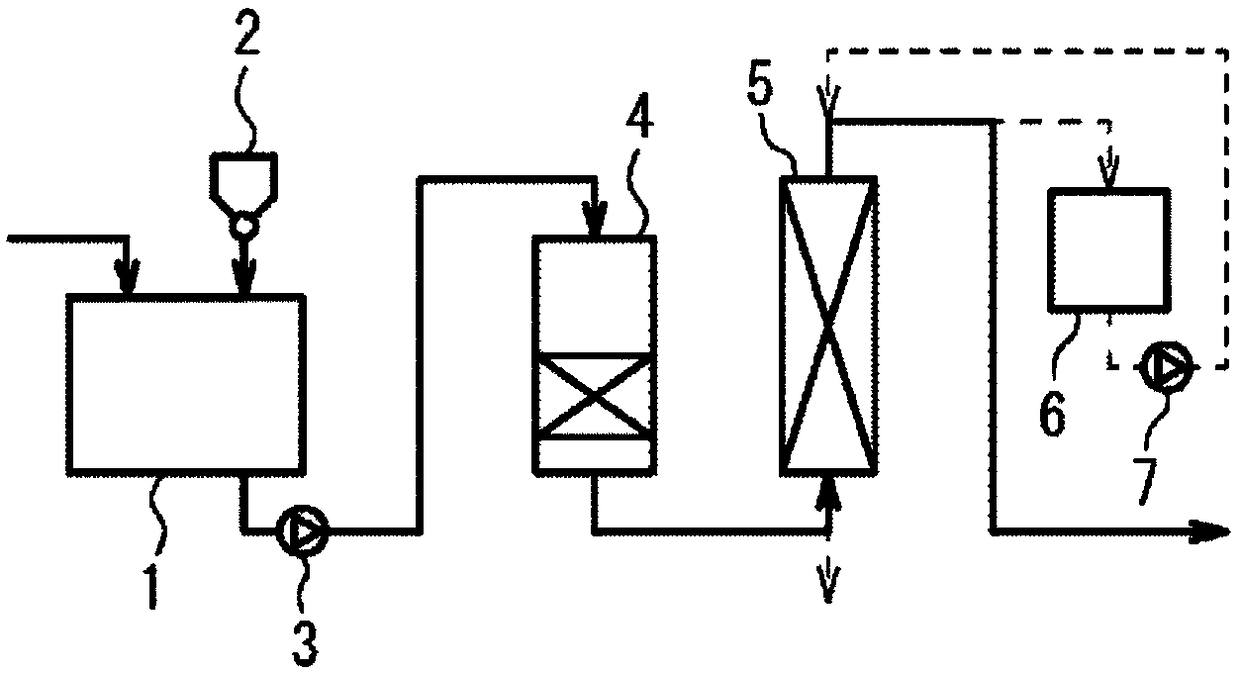

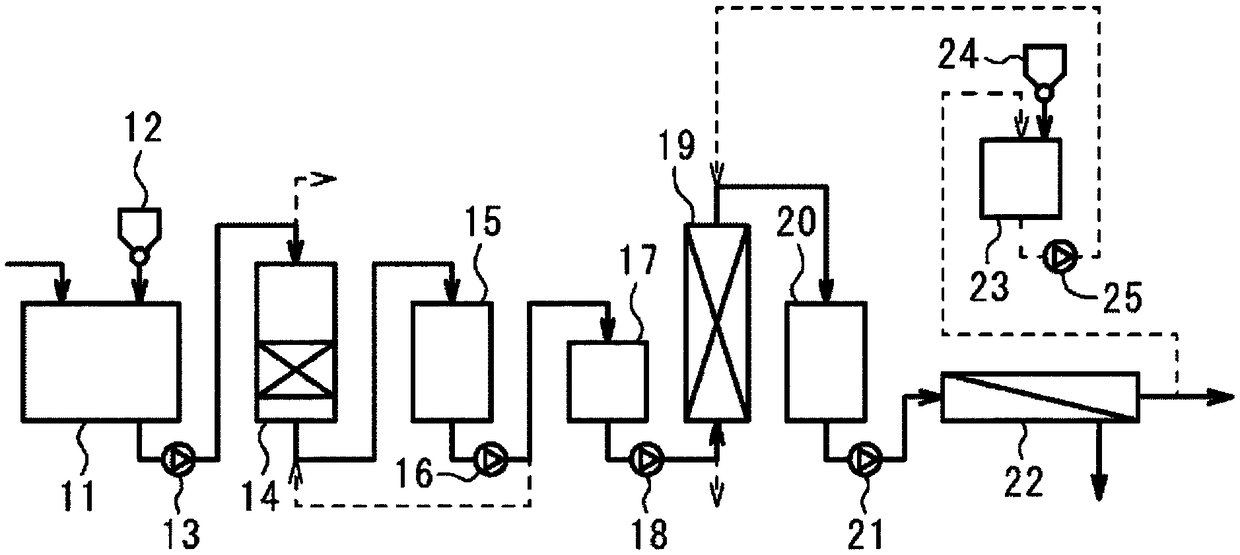

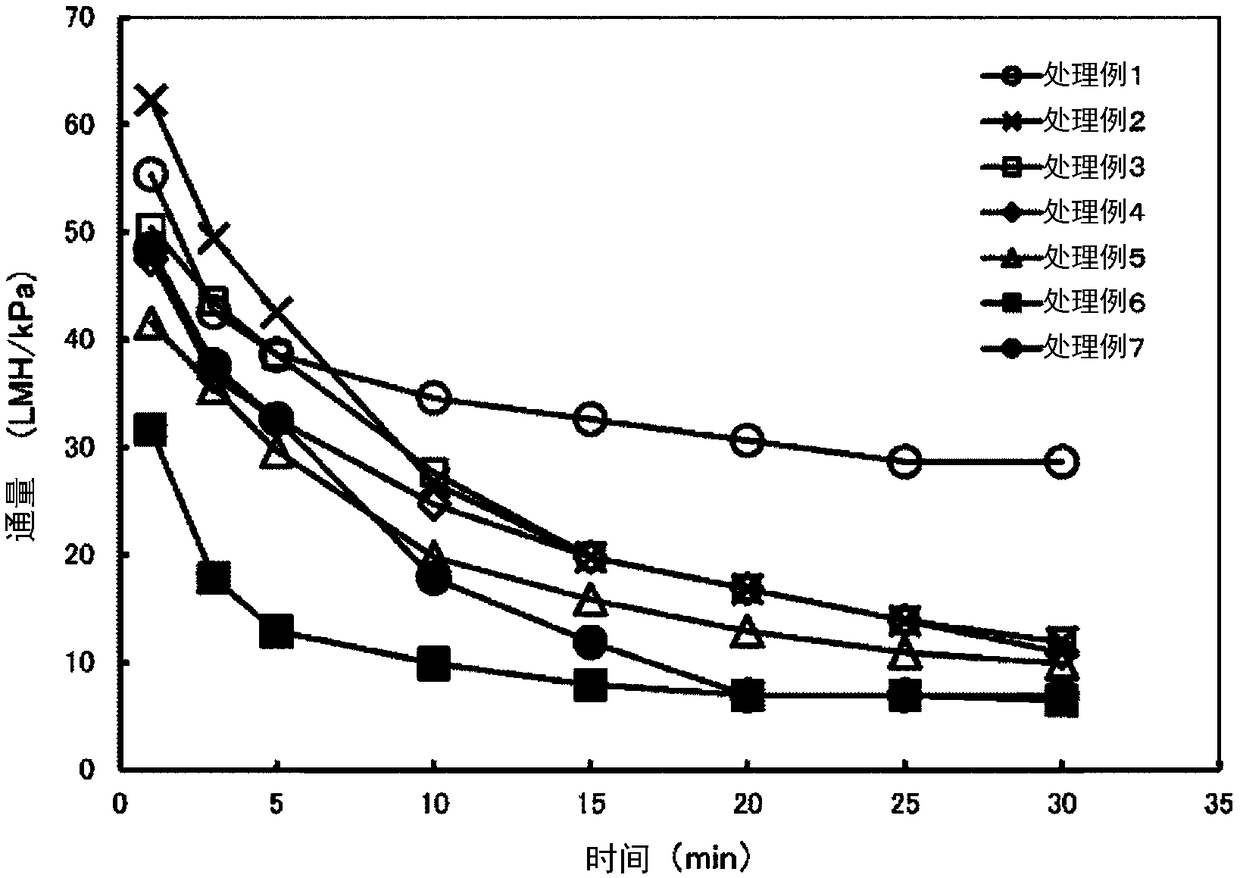

Method for treating waste water having high hardness

InactiveCN108698860AAchieve cleanUltrafiltrationSedimentation separationAluminium chlorohydrateFiltration

A method for treating waste water having high hardness according to one embodiment of the present invention is a method for treating waste water having high hardness, specifically a calcium hardness of 100 or more, and this method comprises: a step for adding a flocculant into the waste water having high hardness; a step for roughly filtering the waste water having high hardness after the flocculant addition step by means of a filter; a step for subjecting the waste water having high hardness after the rough filtration step to membrane filtration with use of a microfiltration membrane or an ultrafiltration membrane; and a step for backwashing the microfiltration membrane or the ultrafiltration membrane with an acidic water. It is preferable that the flocculant is a polyaluminum chloride. It is preferable that the acidic water contains hydrochloric acid or citric acid. It is preferable that this method additionally comprises a step for subjecting the waste water having high hardness after the membrane filtration step to membrane filtration with use of a reverse osmosis membrane. It is preferable that the filter is composed of anthracite. It is preferable that the waste water havinghigh hardness is biologically treated sewage water.

Owner:SUMITOMO ELECTRIC IND LTD

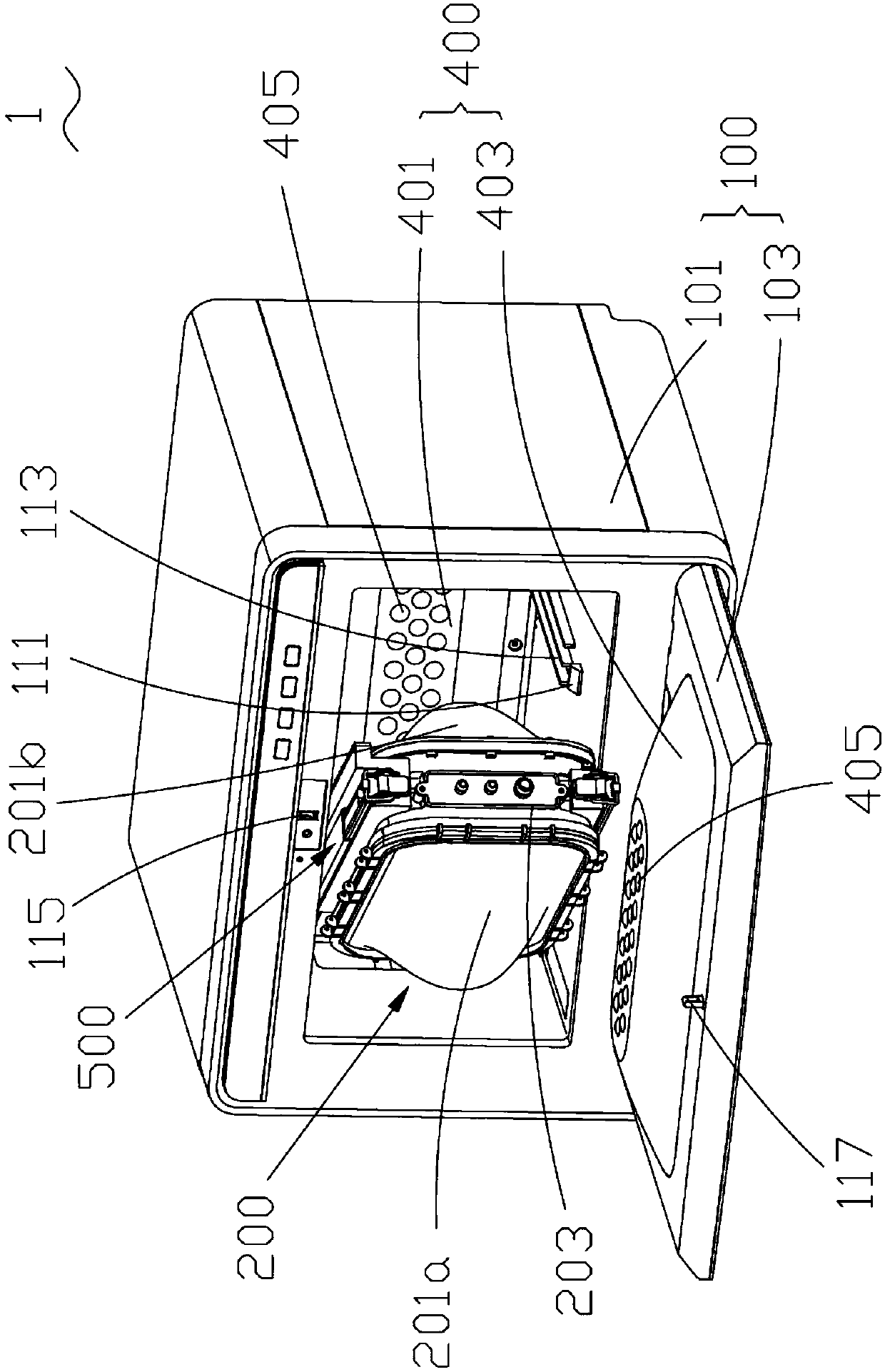

Clothes treatment equipment

ActiveCN110863316AAvoid dependenceAchieve cleanOther washing machinesTextiles and paperProcess engineeringMechanical engineering

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

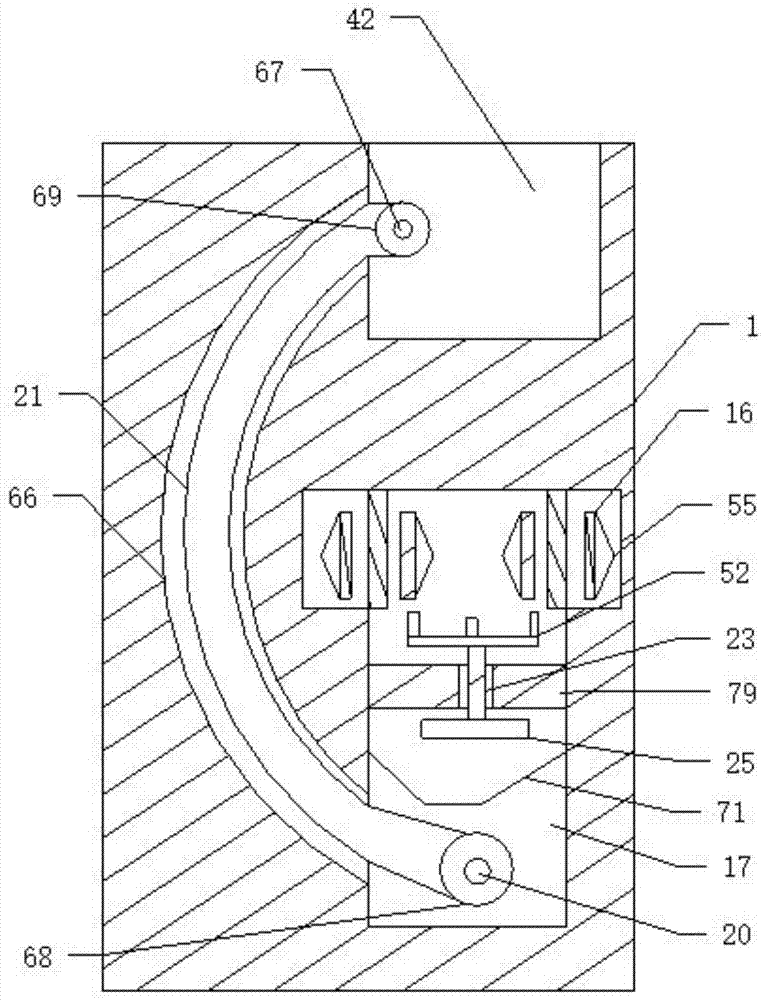

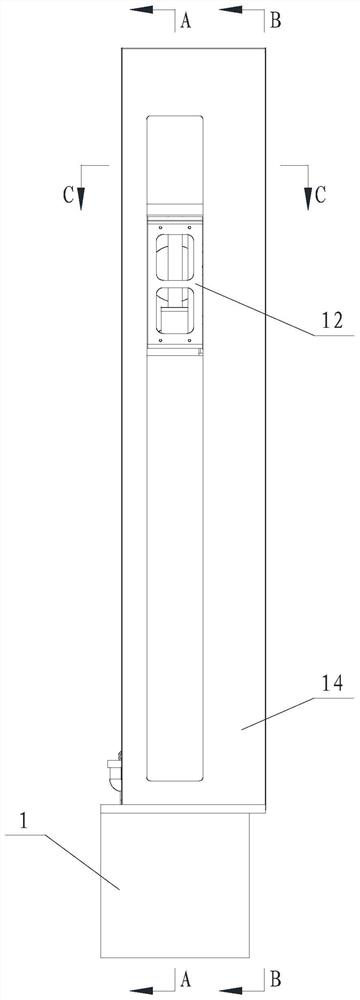

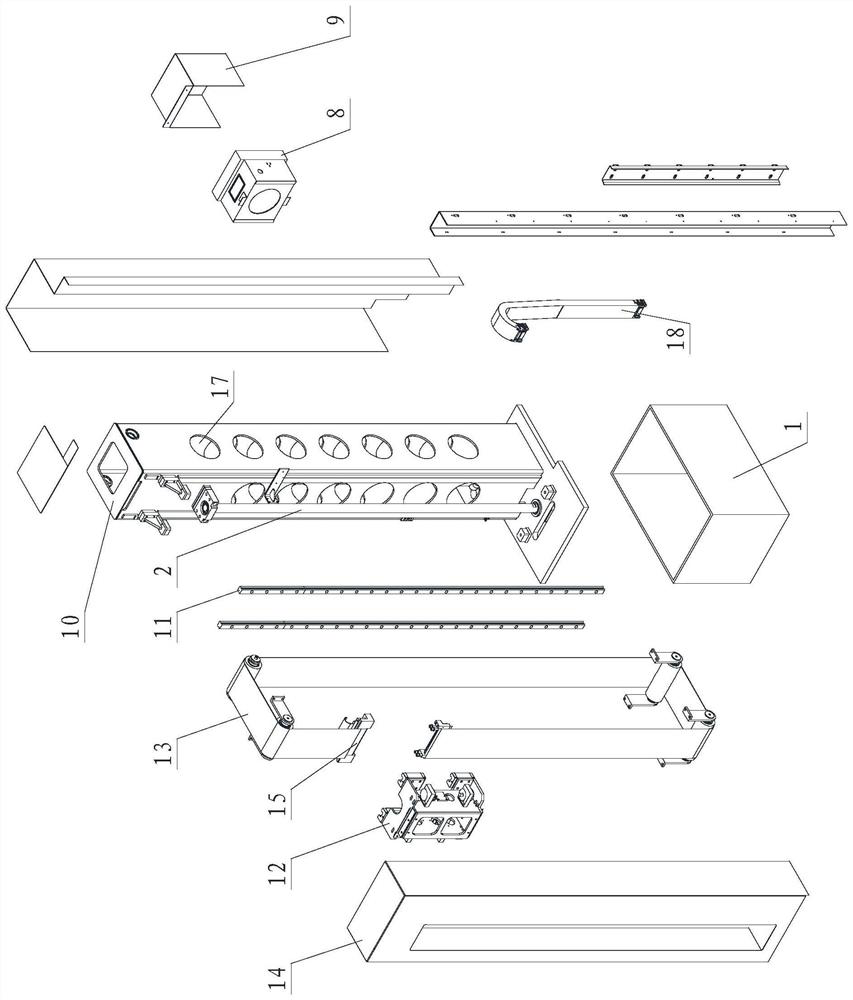

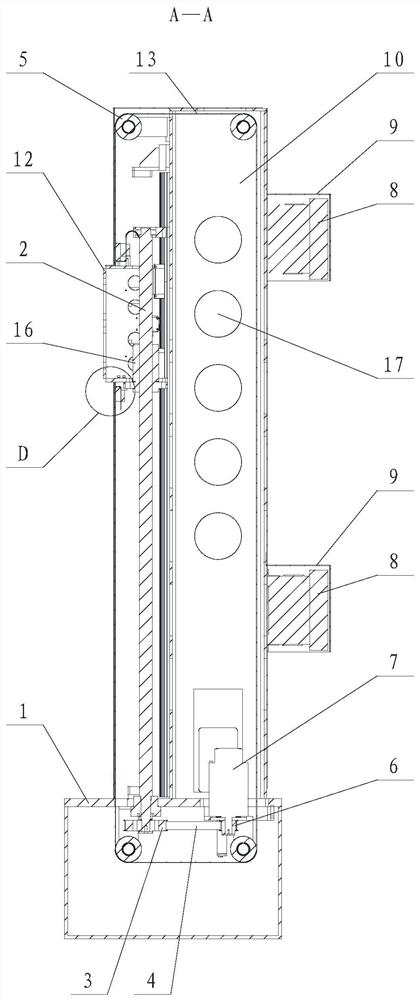

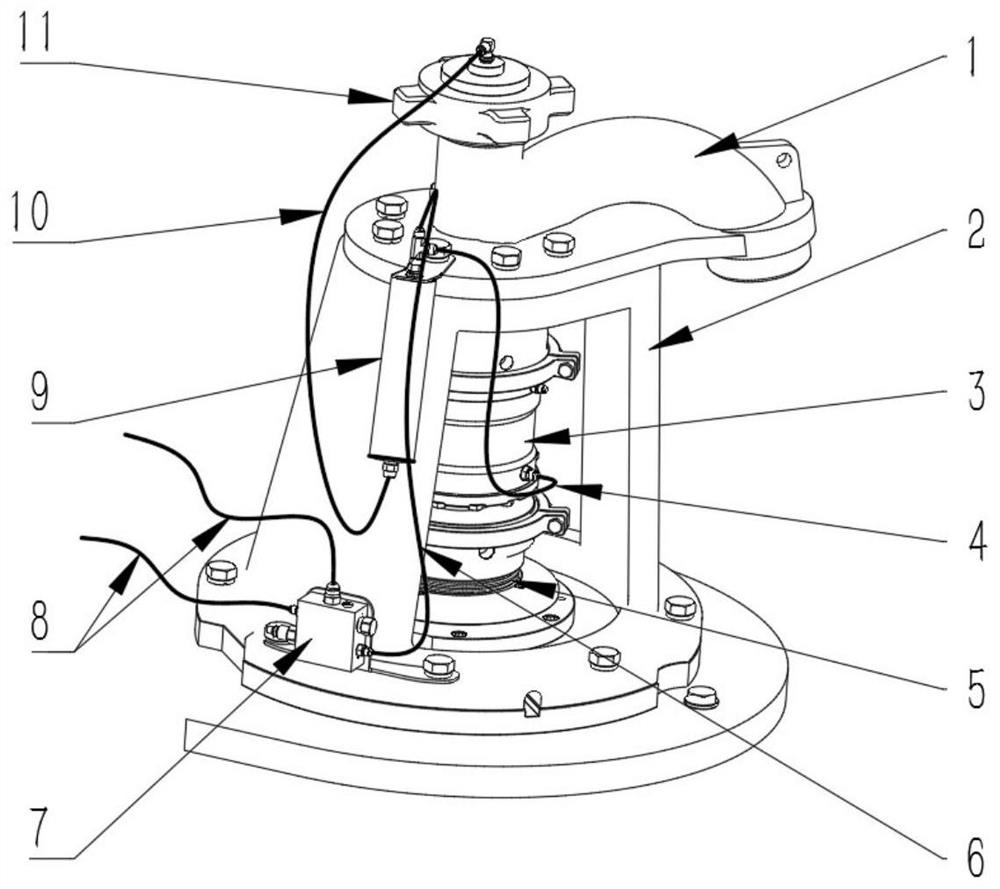

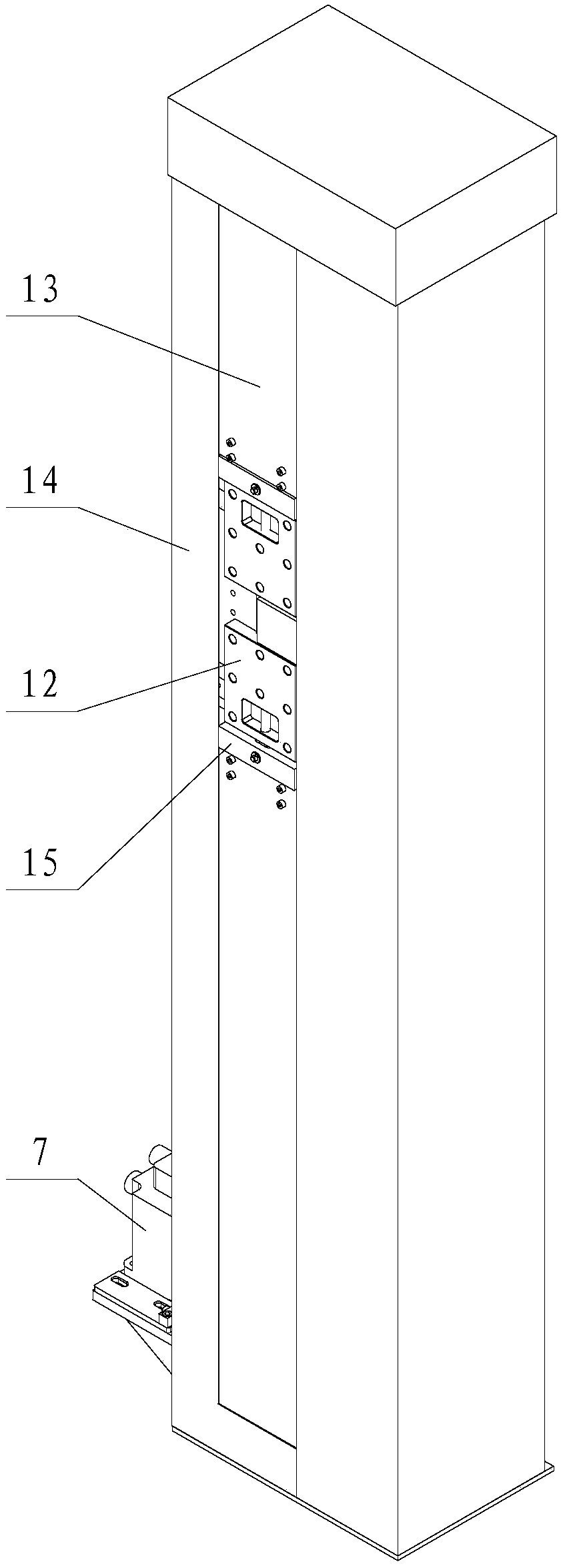

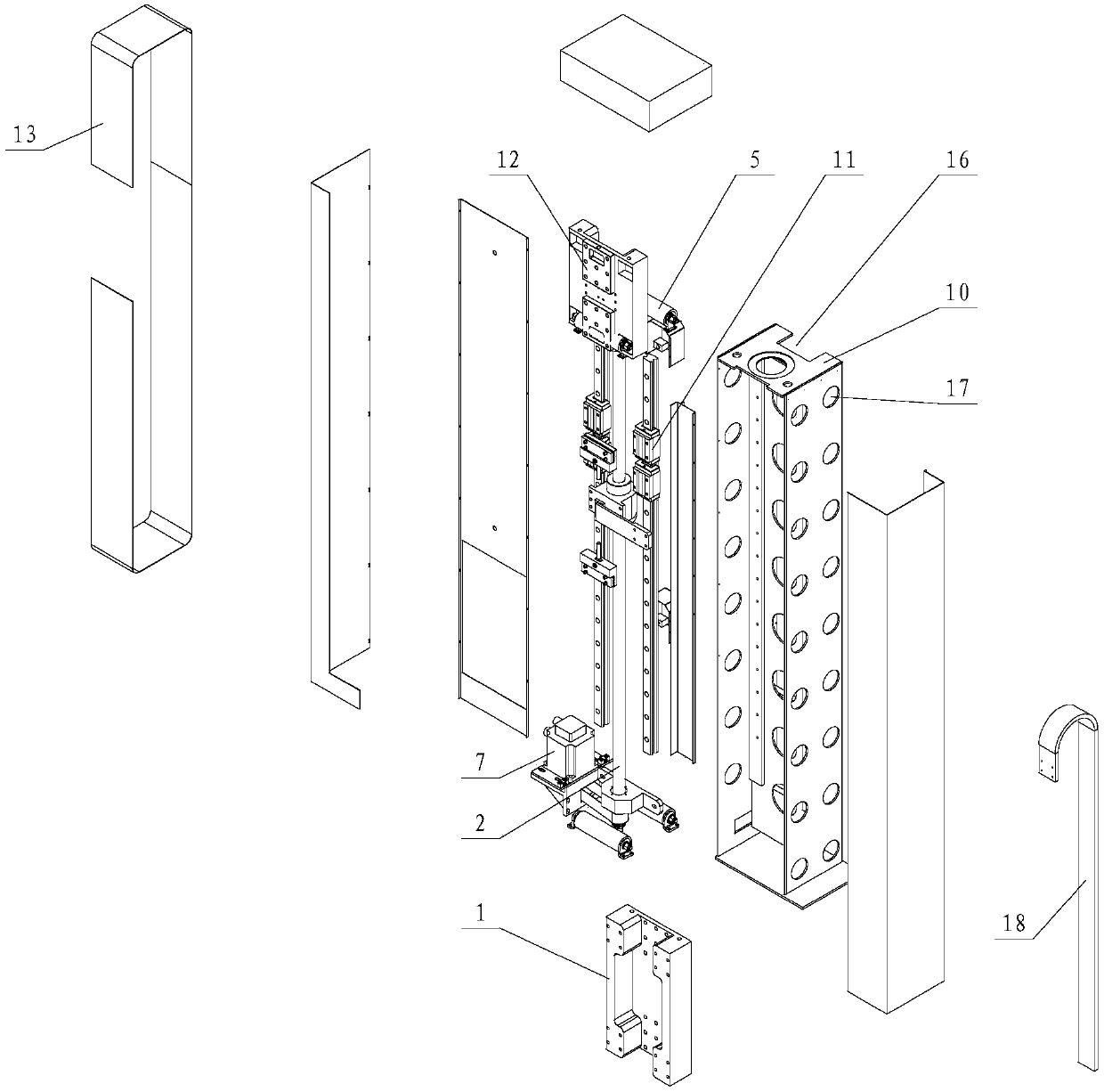

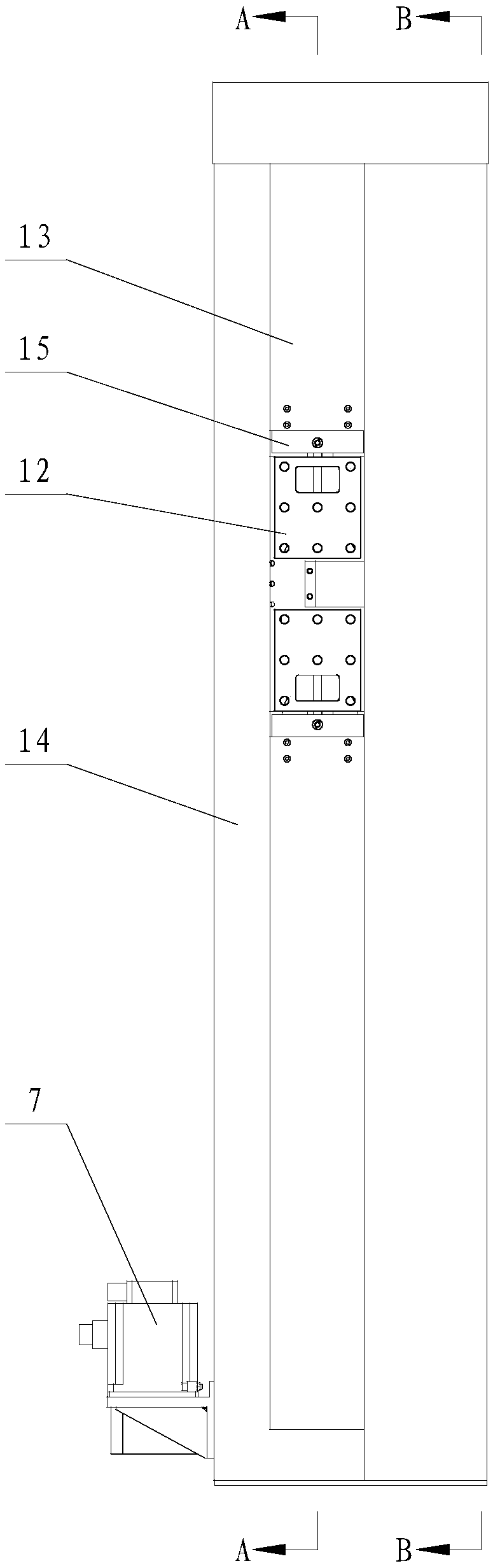

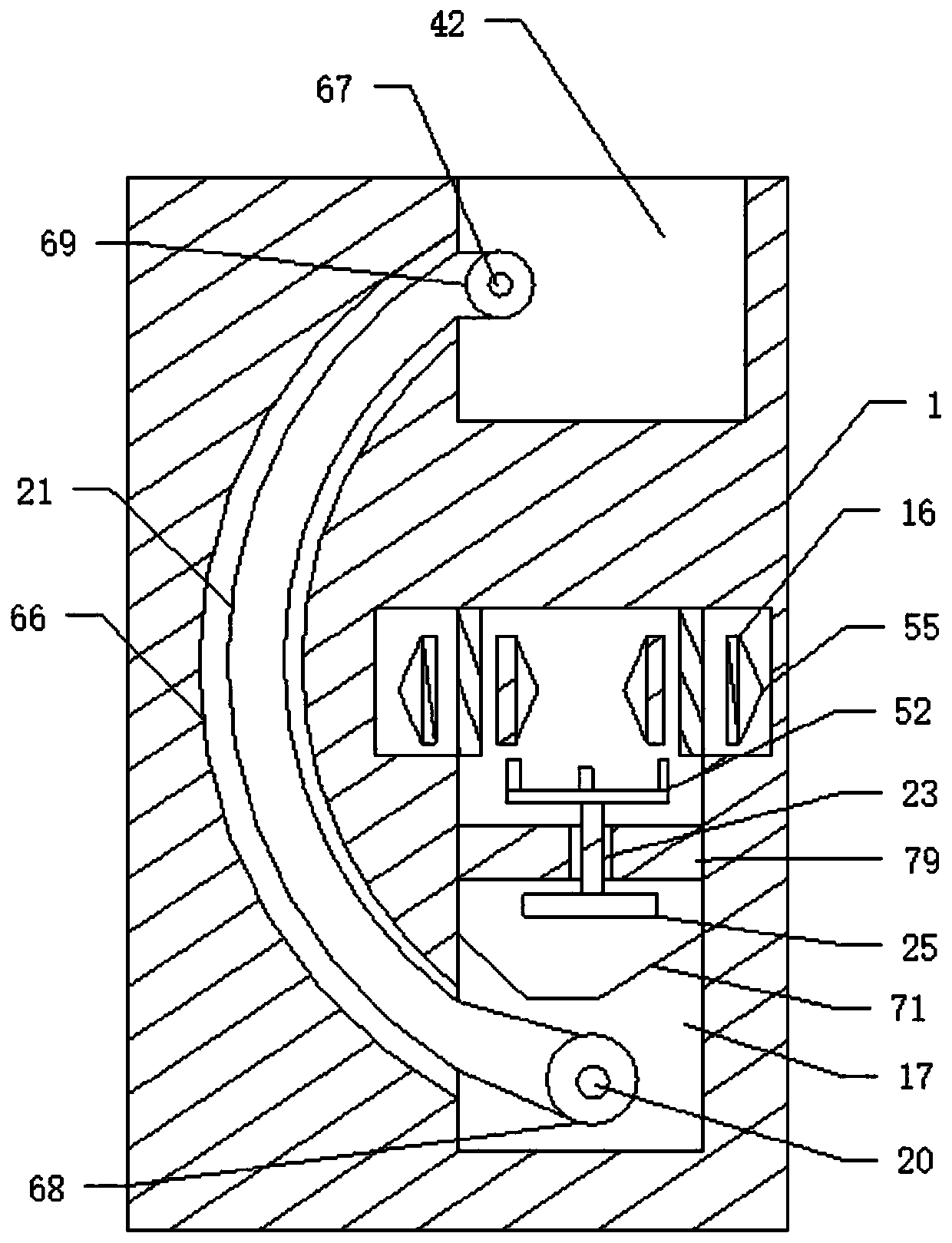

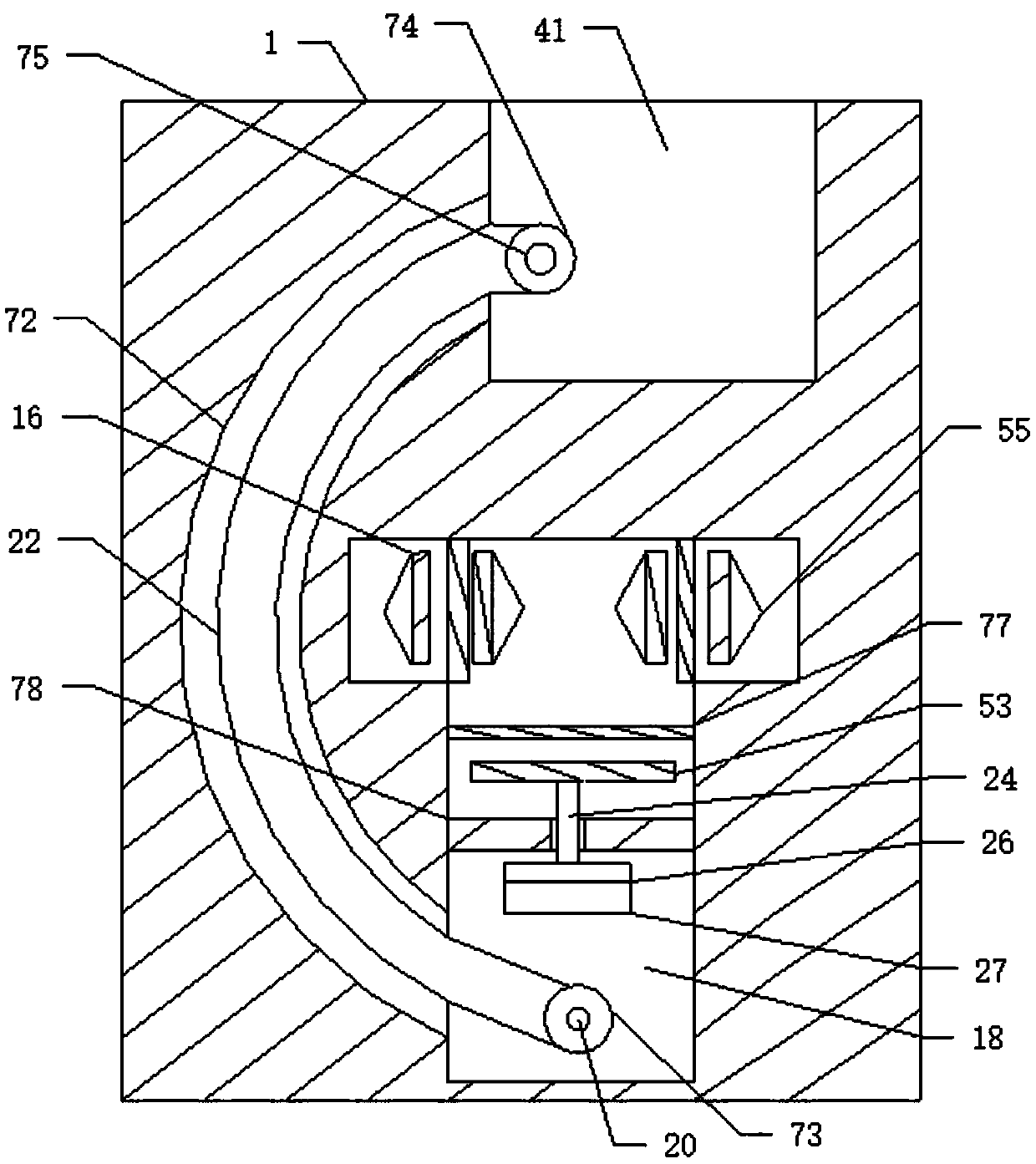

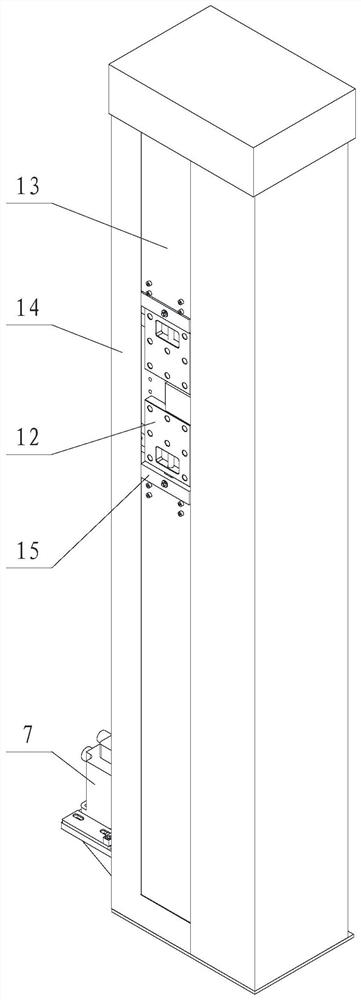

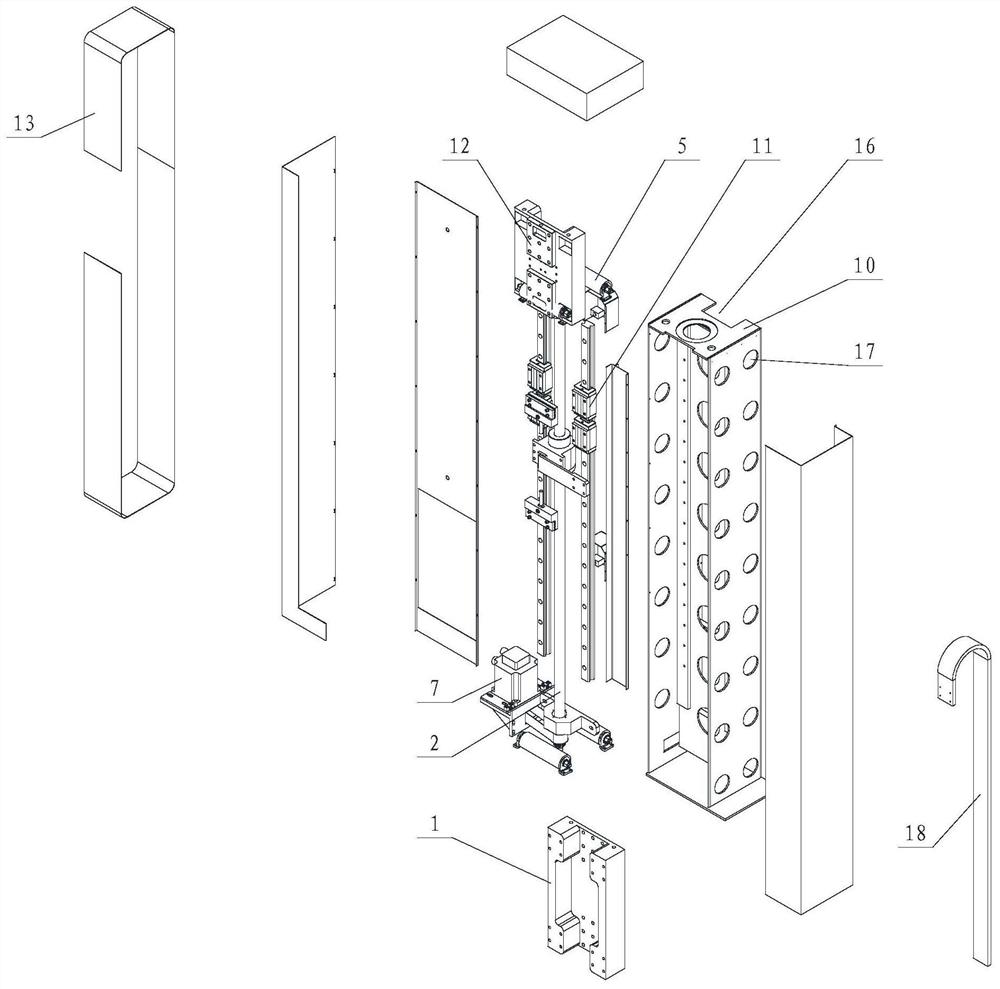

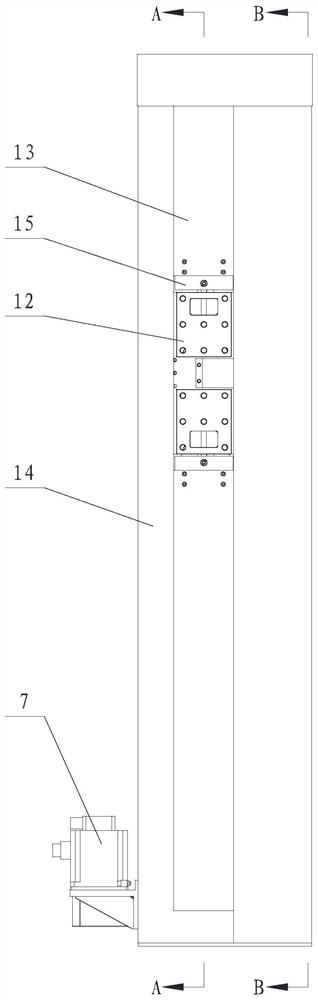

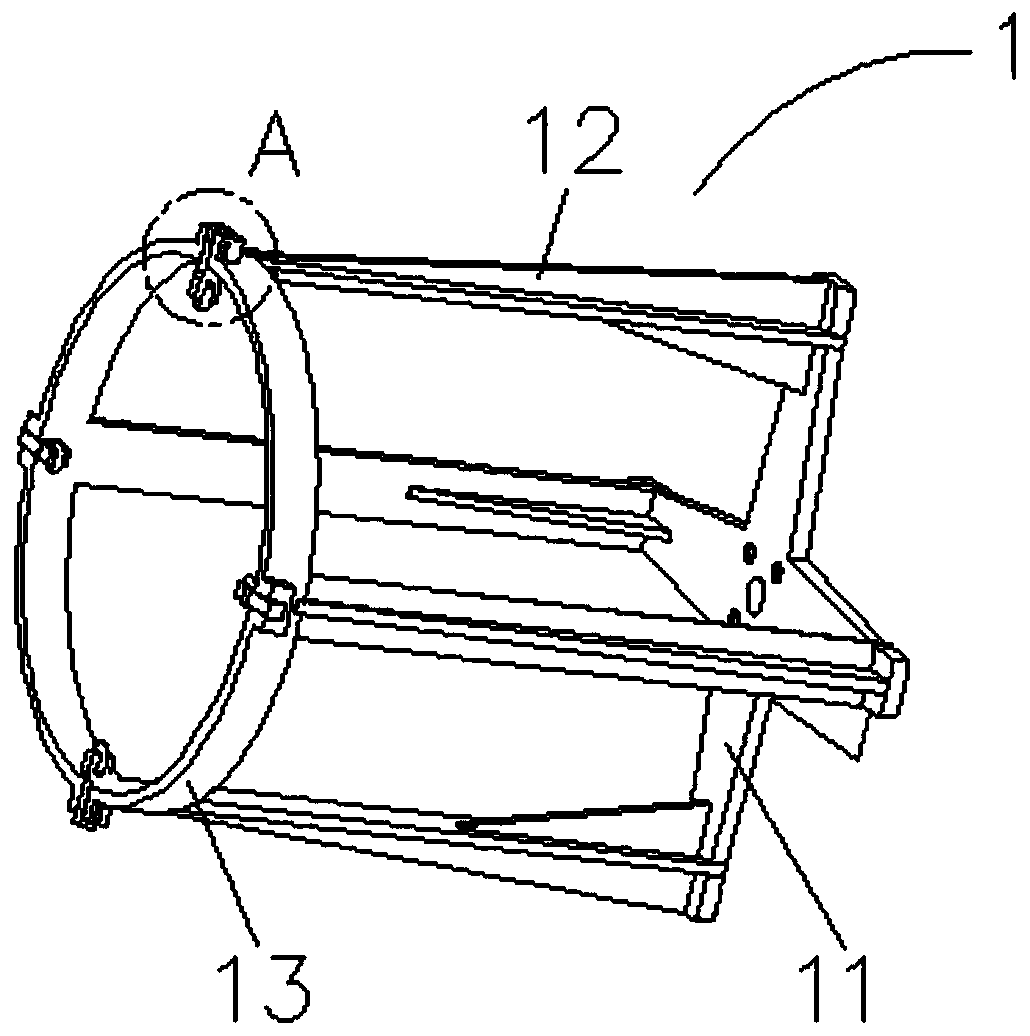

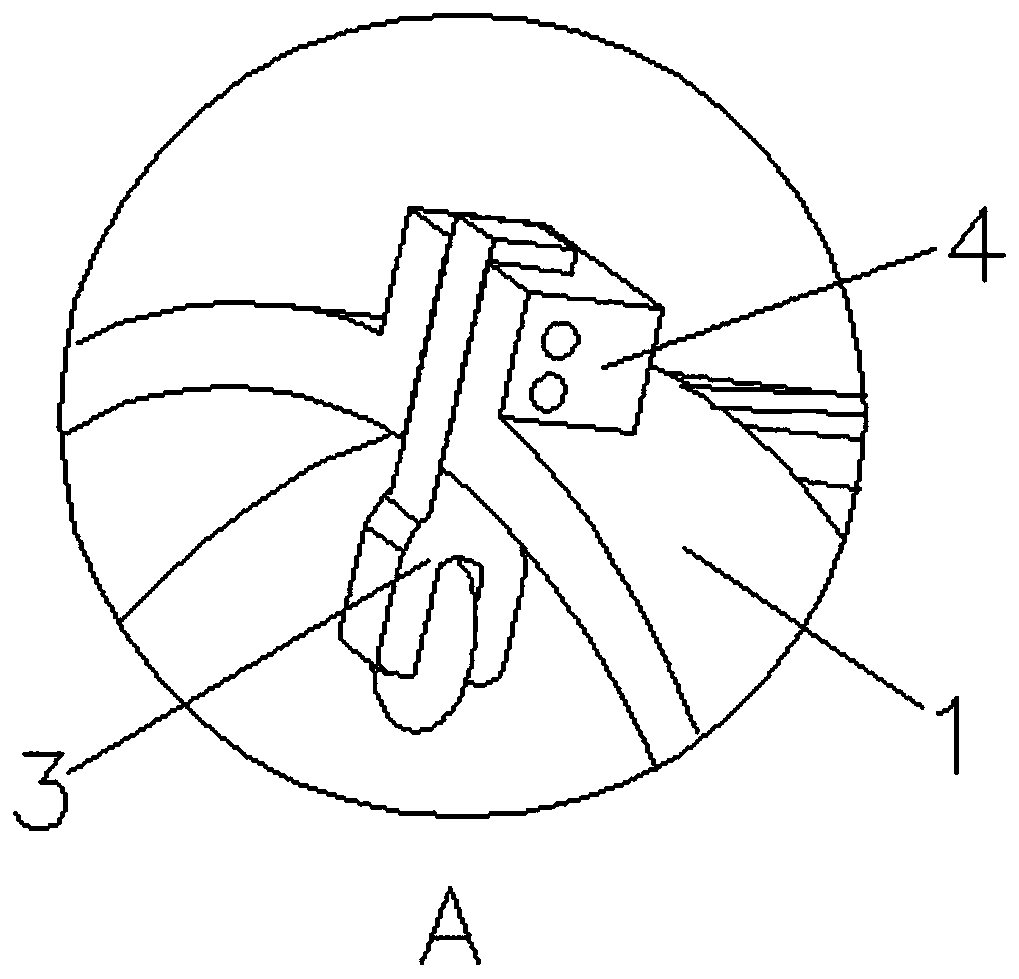

A robotic sealing column

ActiveCN110553022BMeet basic functionsAchieve a joint sealGearingGearing detailsBall screwElectric machinery

The invention relates to a robot sealing column, the column frame is installed in the outer cover, the ball screw is rotatably installed on the column frame, and is connected with the driving motor installed outside the outer cover, the ball screw is screwed with a screw nut, and the screw nut is connected There is a skateboard carriage; the upper and lower ends of the outer cover are equipped with sealing intermediate wheels, the end face of the column skeleton is in the shape of a "mouth", which is an internal hollow structure, and one end of the sealing belt is bypassed by the inner side of the "mouth" end face of the upper end. After the sealing intermediate wheel is wound to the outside of the "口"-shaped end face, it is connected with the upper end of the skateboard frame, and the other end of the sealing tape is wrapped around the lower sealing intermediate wheel from the inner side of the "口"-shaped end face to the "口"-shaped After the outer side of the end face, it is connected with the lower end of the skateboard frame. The drive motor drives the ball screw to rotate through the transmission mechanism, and the screw nut drives the skateboard frame to rise and fall relative to the column frame. The invention satisfies the basic functions of the robot, and at the same time achieves the purposes of sealing the joints of the robot, being dust-free and improving the dynamic performance of the robot.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

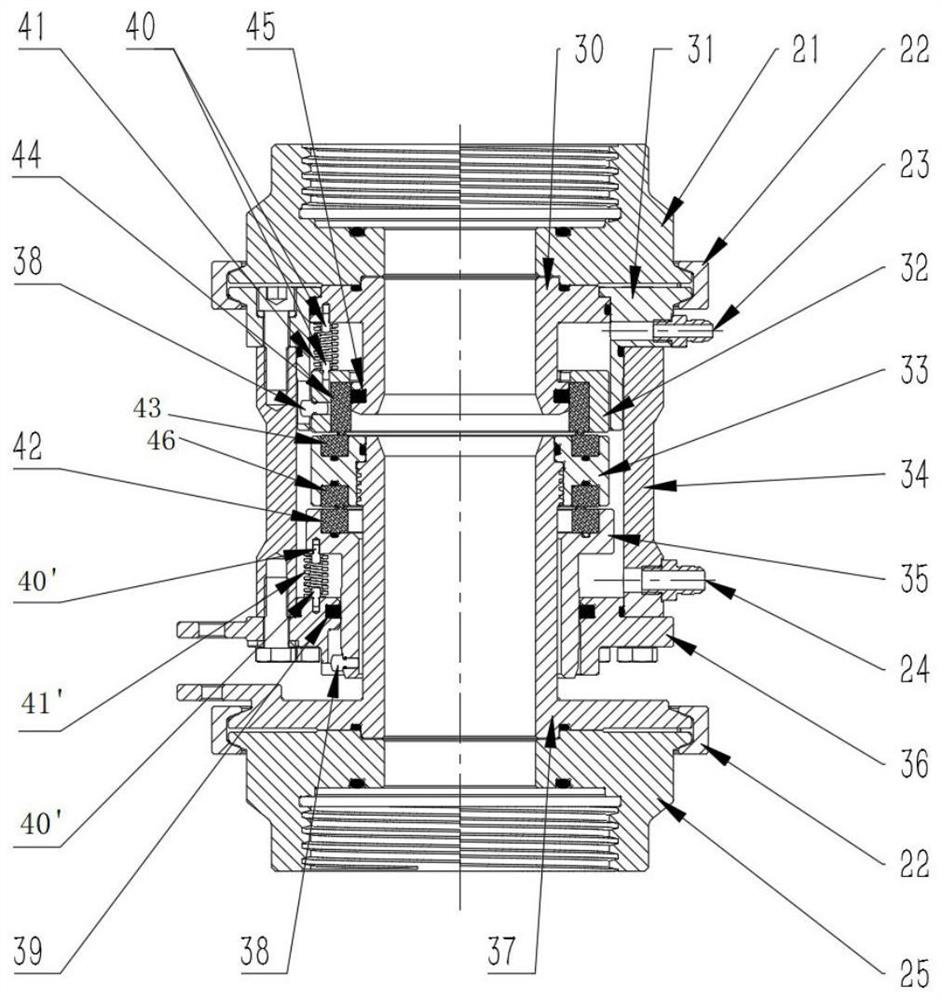

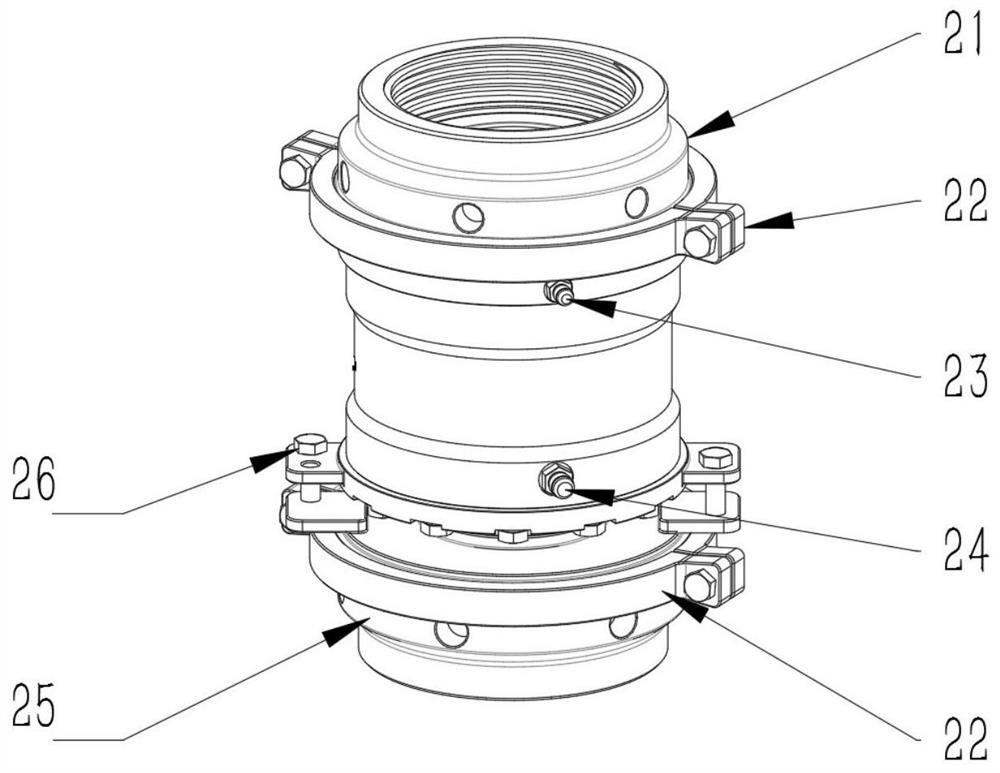

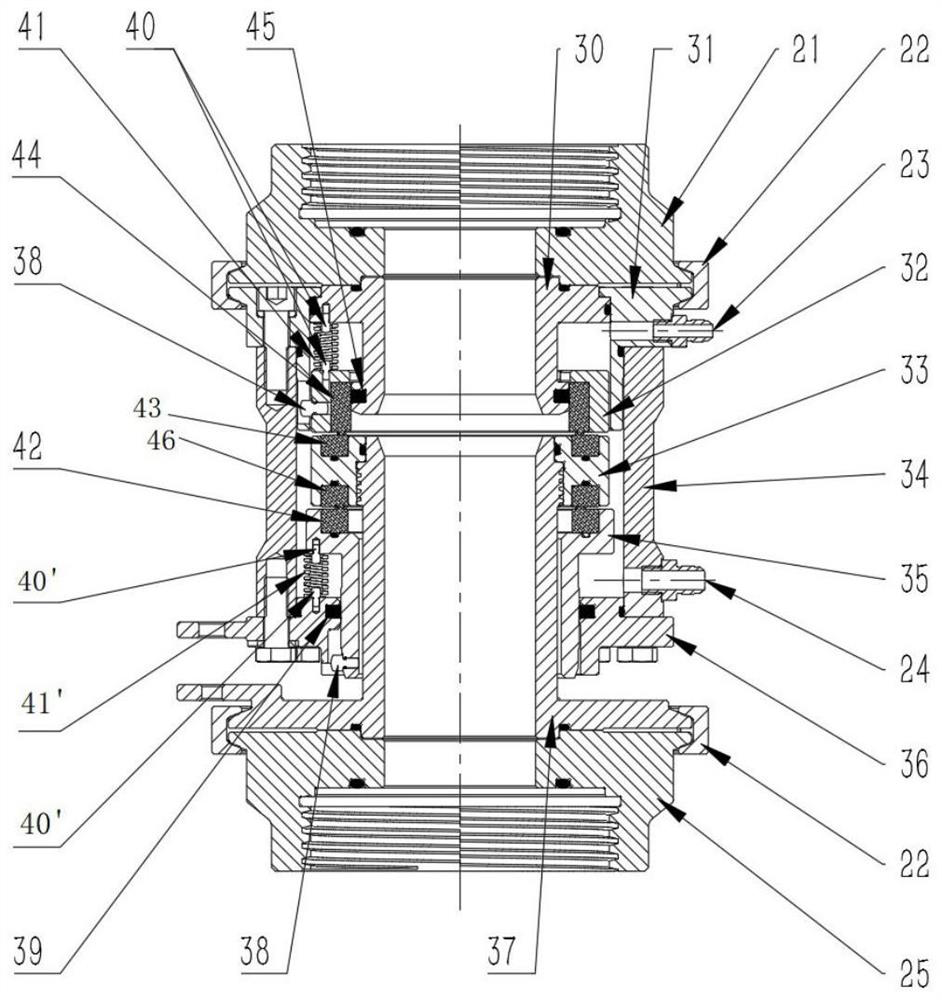

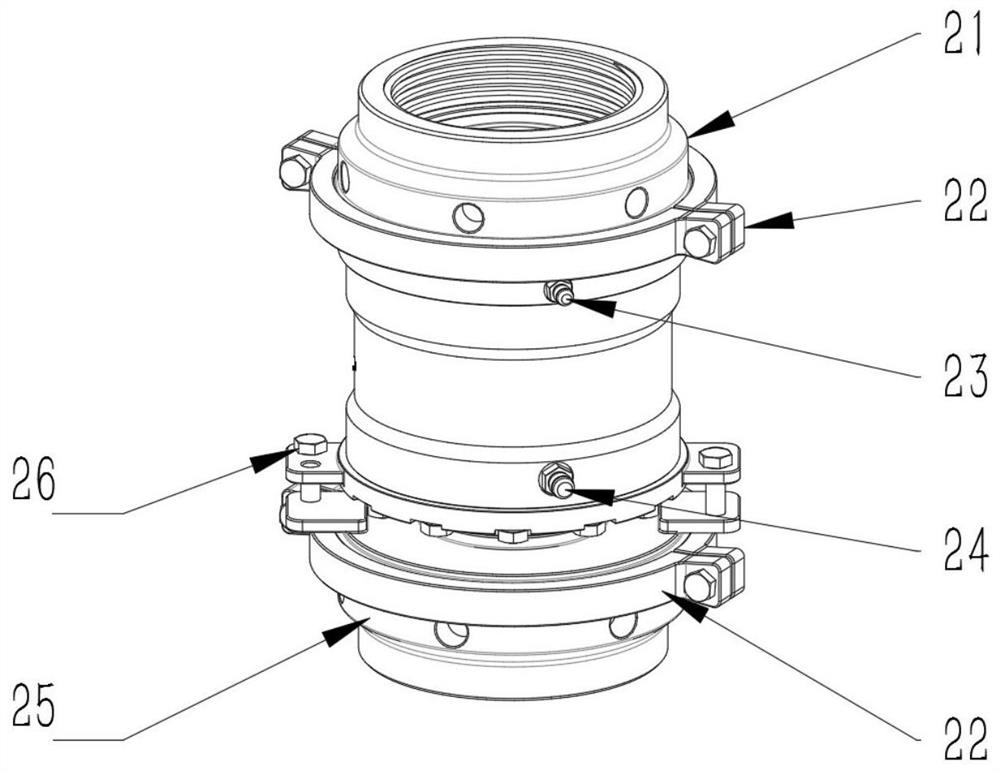

Wash pipe assembly with double-seal structure, wash pipe device, lubricating system and lubricating process

ActiveCN112177551AReduce processing difficultyReduce leakageEngine sealsFlushingSlurryMechanical engineering

The invention relates to a wash pipe assembly with a double-seal structure, a wash pipe device, a lubricating system and a lubricating process. The wash pipe assembly is characterized in that an upperwash pipe and a lower wash pipe are hermetically connected through a sealing component to form a slurry passage inside the upper wash pipe and the lower wash pipe; a fixing component sleeves the peripheries of the sealing component and the upper wash pipe, the upper end of the fixing component is hermetically connected with the upper wash pipe, and the lower end of the fixing component is hermetically connected with the sealing component so as to form a lubricating oil cavity among the upper wash pipe, the sealing component, the lower wash pipe and the fixing component; a first sealing face and a second sealing face are arranged on the sealing component, the first sealing face is used for isolating the slurry channel from the lubricating oil cavity, and the second sealing face is used forisolating the lubricating oil cavity from ambient air; and the lubricating oil cavity is used for being filled with an oil liquid. On one hand, the oil liquid provides lubrication for a rotating partinside the wash pipe assembly; on the other hand, the pressure in the lubricating oil cavity is larger than or equal to the slurry pressure in the slurry channel, so that slurry is prevented from leaking outwards; and the problem that the slurry leakage amount is large, a wash pipe device cannot idle for a long time, and maintenance is inconvenient due to a single-seal mode is solved.

Owner:BEIJING JJC PETROLEUM EQUIP

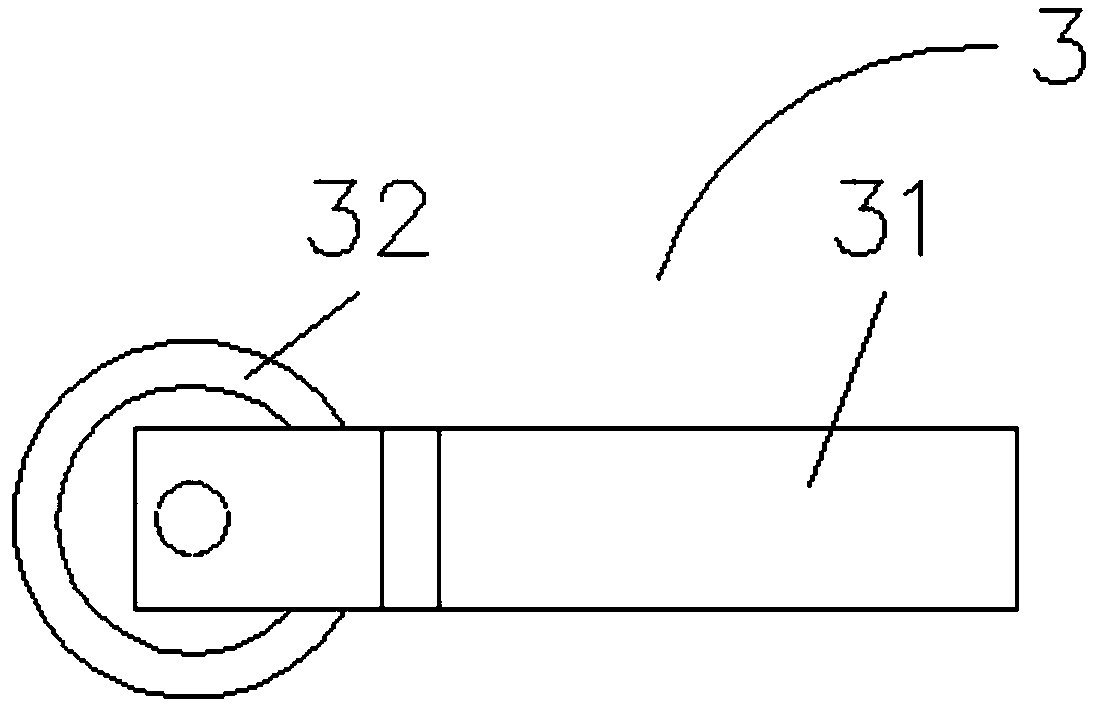

A sleeve rolling tool

The invention relates to a sleeve-shaped rolling processing tool, which includes a sleeve boring body and several rolling cutter heads; the sleeve boring body includes a base, several bars and rings, and one end of the bars is evenly arranged vertically on the base Along the periphery, the other ends of several ribs are connected to one side of the ring; the other side of the ring is equally spaced with tool holder grooves corresponding to the number of rolling cutter heads, and the opening direction of the tool holder grooves points to the center of the ring. The rolling cutter head is fixed on the inner ring of the ring through the cutter holder groove. The sleeve-shaped rolling processing tool provided by the invention is installed on the main shaft of the machine tool through the base, and the tool rotating cutting is used instead of the machine tool rotating cutting processing method, and the roller squeezes the surface of the workpiece to achieve a smooth surface of the workpiece.

Owner:KOCEL EQUIP

Spoon belt pneumatic type seed sowing device

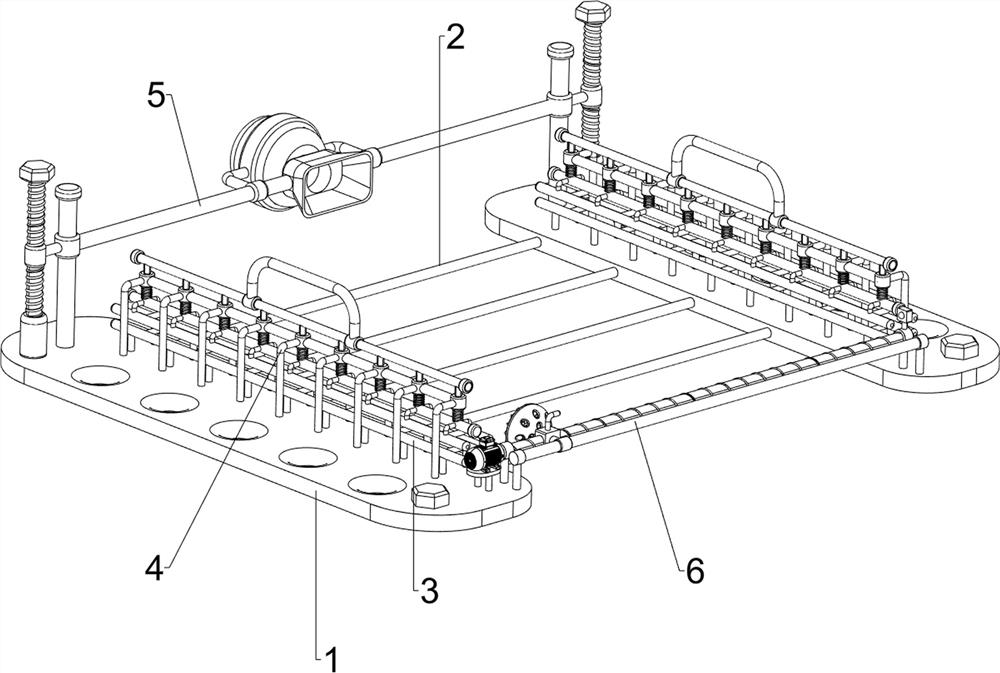

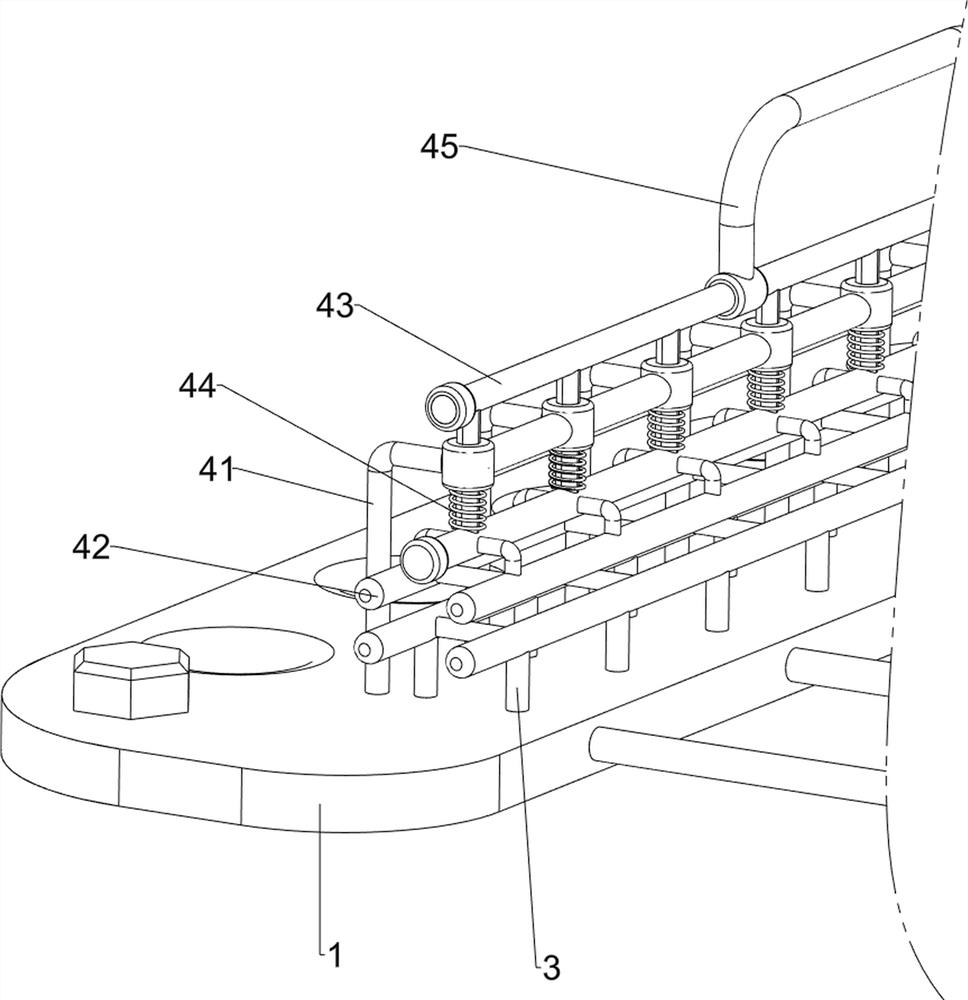

PendingCN110192459AAdjust seedingAdjust broadcast volumeSeed depositing seeder partsRegular seed deposition machinesEngineeringMechanical engineering

The invention relates to a spoon belt pneumatic type seed sowing device which comprises a shell, a conveying mechanism and a seed sowing pipeline. The conveying mechanism is arranged in the shell, theseed sowing pipeline is arranged on the outer side of a seed dropping port at the right end of the shell, a baffle is vertically arranged on the upper surface of the inner side of the shell, the baffle can move up and down along the shell, the inner areas, below the baffle, of the shell are communicated with each other, the space of the shell on the left side of the baffle is a seed box area, andthe conveying mechanism is arranged below the inside of the shell on the right side of the baffle. The conveying mechanism is obliquely arranged, the right end of the conveying mechanism is higher than the left end of the conveying mechanism, the conveying mechanism is used for conveying seeds from the seed box area to the seed sowing pipeline through seed spoons, and a plurality of seed spoons are detachably arranged on the conveying mechanism. The mechanical seed sowing device integrates the advantages of a mechanical seed sowing device and a pneumatic seed sowing device, and is novel and compact in structure and low in manufacturing cost. By adopting the spoon belt pneumatic type seed sowing device, seeding of different species such as rice, wheat and corn and adjustment of seeding amount can be realized by replacing the seed spoons with different sizes and shapes, adjusting the rotating speed of a synchronous belt wheel and the like.

Owner:HUAZHONG AGRI UNIV

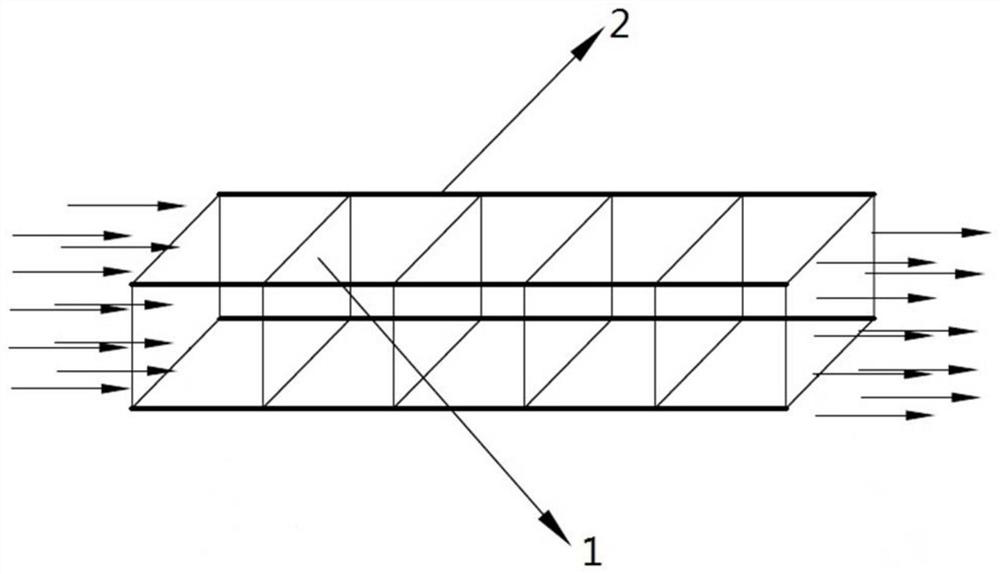

Disinfecting air conditioner

PendingCN111706925AClean thoroughlyAchieve cleanLighting and heating apparatusAir conditioning systemsUltraviolet lightsEngineering

The embodiment of the invention discloses a disinfecting air conditioner. The disinfecting air conditioner comprises an air conditioner main body, one or more ultraviolet light-emitting diode arrays,an inductive switch and a driving circuit, wherein a filtering net is arranged in the air conditioner main body; one or more ultraviolet light-emitting diode arrays are arranged on the surface or at the periphery of the filtering net; the ultraviolet light-emitting diode is used for emitting ultraviolet rays to disinfect air conditioner air passing through the filtering net; the inductive switch is used for generating a disinfecting start signal when sensing that the air conditioning air is blown out; the driving circuit is connected to the ultraviolet light-emitting diode arrays and the inductive switch; and the driving circuit generates a driving voltage according to the disinfecting start signal to drive the ultraviolet light-emitting diode array to emit the ultraviolet rays. Accordingto the technical solution of the embodiment of the invention, the ultraviolet light-emitting diode array is arranged on the filtering net in the air conditioner and emits the ultraviolet rays to irradiate at the periphery of the filtering net to sterilize and disinfect the blown air conditioning air, so that clean and healthy air conditioning air is realized.

Owner:SHENZHEN SITAN TECH CO LTD

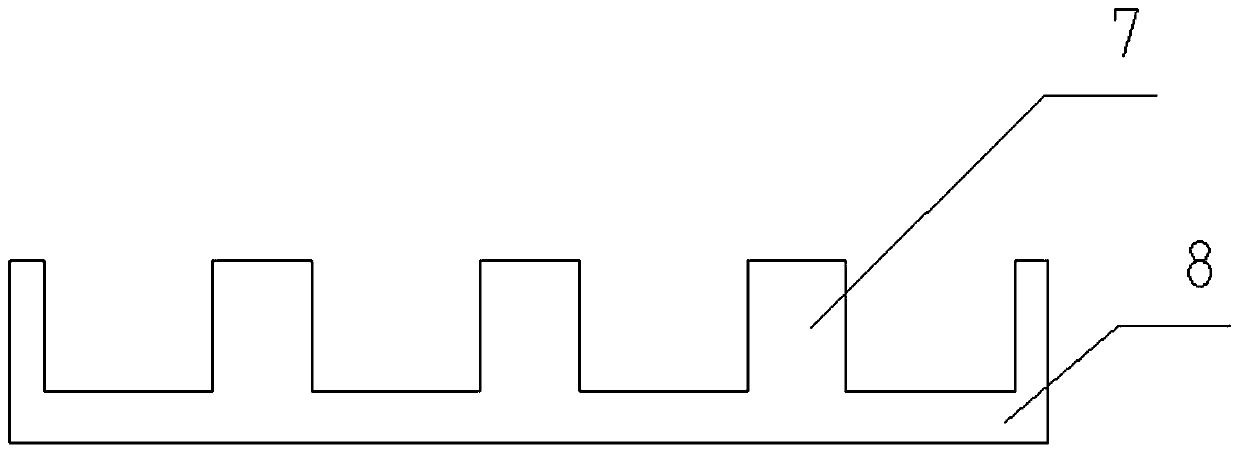

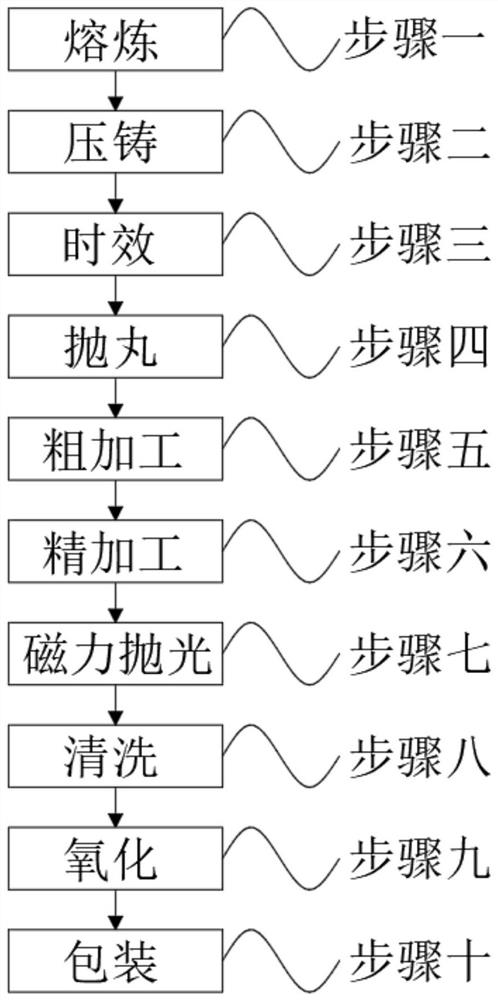

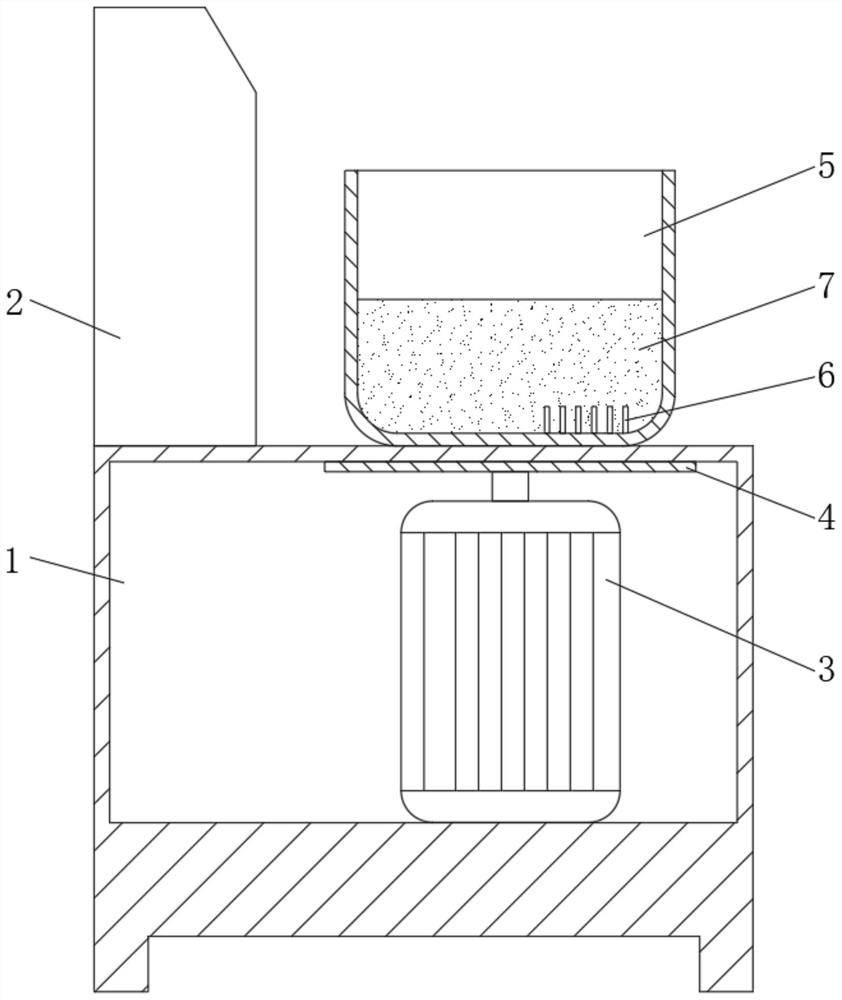

Ultra-precision machining process for aluminum alloy die-casting gearbox valve sleeve

PendingCN114227521ARealize chamferAchieve polishEdge grinding machinesPolishing machinesPolishingDie casting

The invention discloses an ultra-precision machining technology for an aluminum alloy die-casting gearbox valve sleeve. The ultra-precision machining technology comprises the following steps that firstly, smelting is conducted; step 2, die casting; step 3, aging; step 4, shot blasting; 5, rough machining; step 6, finish machining; seventhly, magnetic polishing is conducted; step 8, cleaning; step 9, oxidation; and step 10, packaging. The polishing machine has the beneficial effects that multiple effects of deburring, chamfering, polishing, cleaning, environmental protection and the like can be achieved; the grinding and polishing device is suitable for grinding and polishing nonmetal workpieces such as metal workpieces, hard plastic workpieces, ceramic workpieces and silicon wafers; irregular parts, hole-shaped parts, pipe-shaped parts, cracks and the like can be polished, polishing is free of dead angles, the ground workpieces are never deformed, the surfaces are never damaged, and the precision is never affected; customization time is short, processing speed is high, and operation is easy and convenient; variable frequency adjustment is achieved, various polishing requirements are met, and voltage, current, frequency and time can be monitored.

Owner:德阳上川科技有限公司

A cleaning device for solar photovoltaic panels

ActiveCN111790648BLowest point highThe same heightPhotovoltaicsCleaning using toolsMaterials scienceShovel

The invention discloses a cleaning device and a cleaning method for solar photovoltaic panels. There is a slider, the top of the slider is provided with a second connecting rod, the top of the guide groove is provided with a top plate, and the top plate is provided with a fourth through hole, and the end of the second connecting rod passes through the fourth through hole to install the shovel plate in the guide groove , and the shovel plate can move along the vertical direction of the guide groove, the second connecting rod is sleeved with a third spring, and the third spring is located between the slider and the top plate, and the end of the second connecting rod away from the slider is provided with a first Two limit blocks, the bottom plate of the shovel plate is provided with supporting walking wheels, the cleaning roller is installed in the housing, an end plate is provided on one side of the shovel plate, and a first through hole is provided on the end plate, and one end of the snow guide assembly passes through the first through hole. The snow guide assembly is arranged in the shovel plate through the through hole, the traveling device is installed on both sides of the housing, and the power device can drive the cleaning roller and the snow guide assembly to rotate.

Owner:徐州顺泰新能源发电有限公司

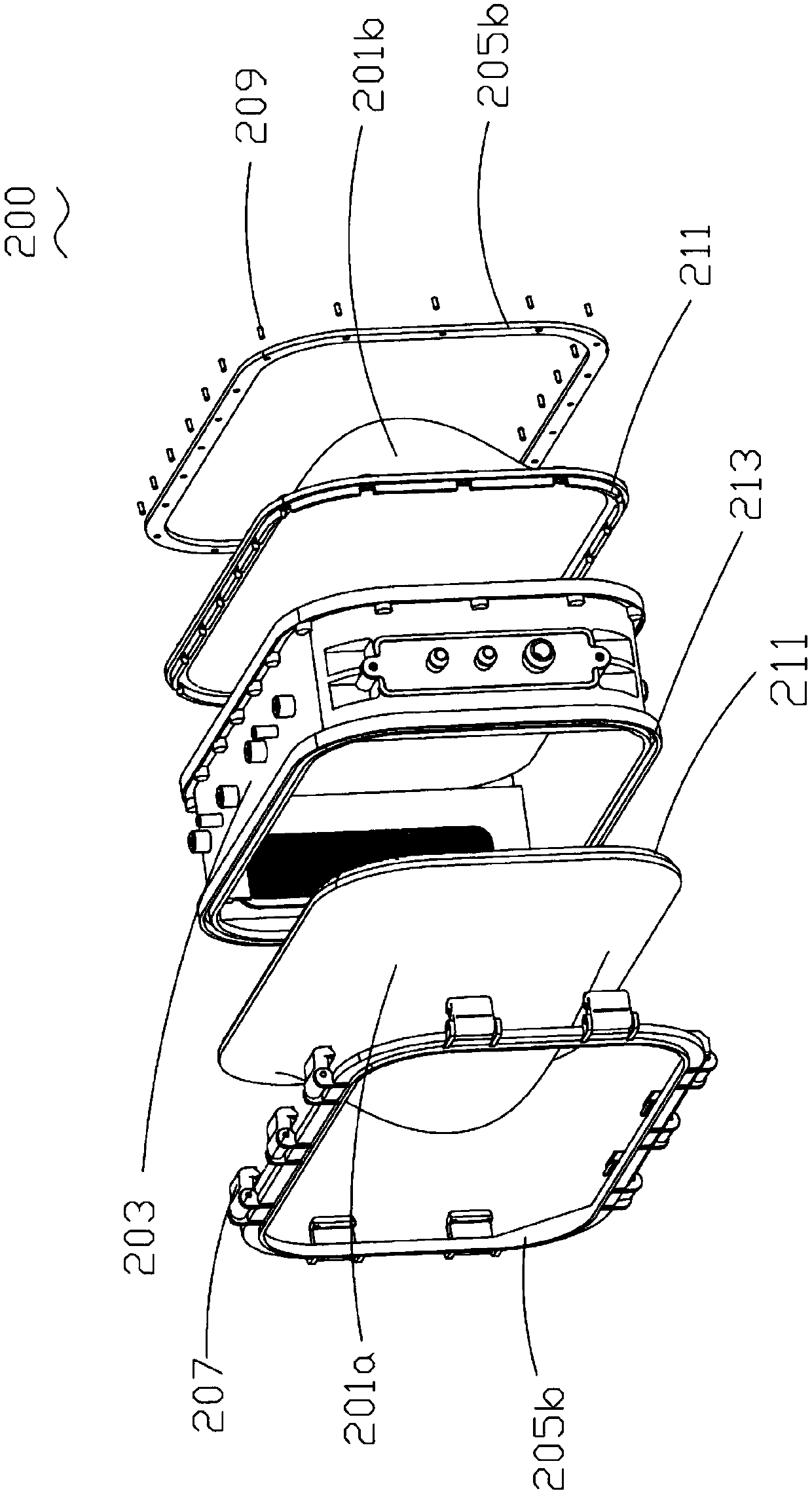

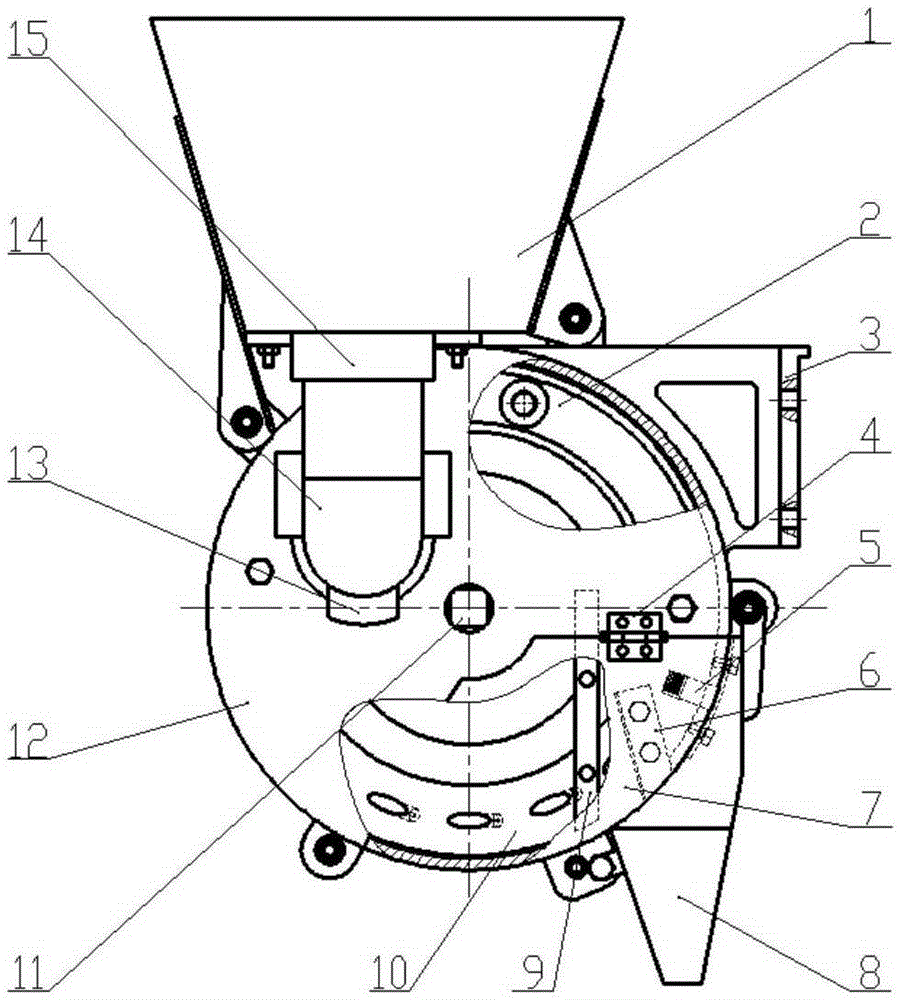

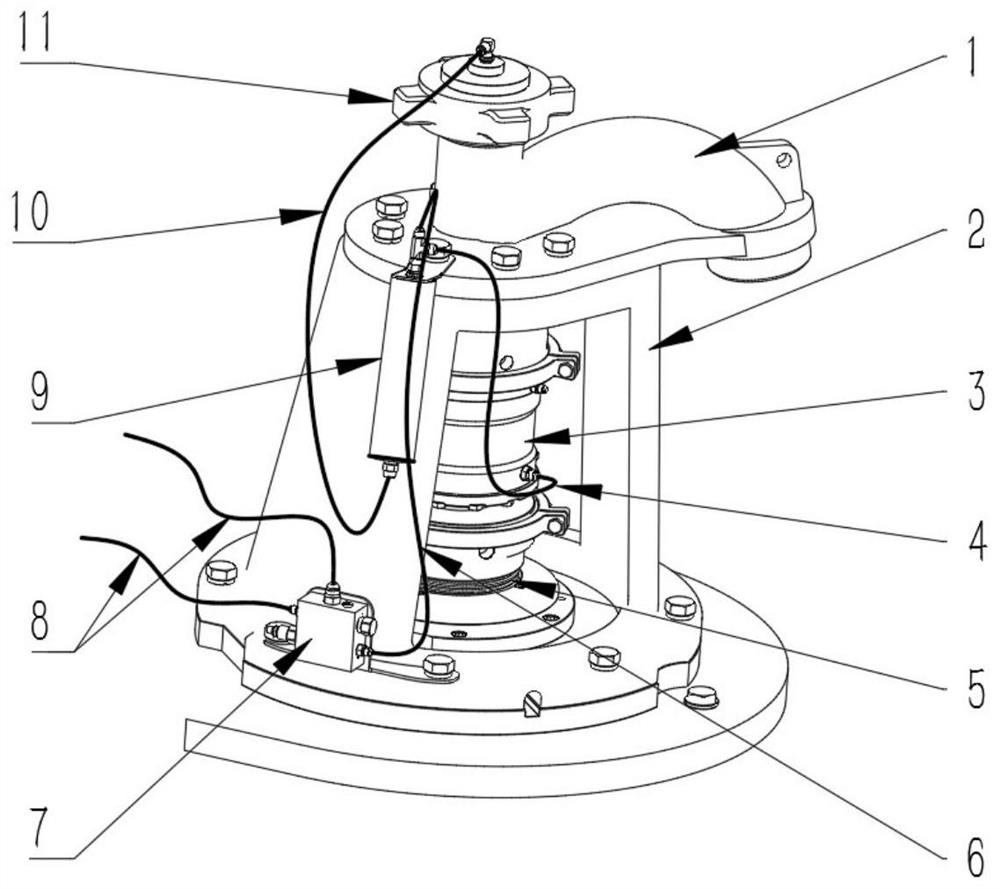

Robot pillar structure

ActiveCN110549323AEasy to installOptimize layoutProgramme-controlled manipulatorBall screwSlide plate

The invention relates to a robot pillar structure, a pillar skeleton is installed in an outer cover, a ball screw is rotationally installed on the pillar skeleton, and is connected with a drive motorinstalled outside the outer cover, the ball screw is in threaded connection with a nut, the nut is connected with a sliding plate skeleton; the upper and lower ends in the outer cover are provided with sealing medium wheels, the cross section of the pillar skeleton is H-shaped, one end of a sealing belt is connected with the upper end of the sliding plate skeleton after one side of a H-shaped beampasses through the sealing medium wheel at the upper end and surrounds to the other side of the H-shaped beam; the other end of the sealing belt is connected with the lower end of the sliding plate skeleton after one side of the H-shaped beam passes through the sealing medium wheel at the lower end and surrounds to the other side of the H-shaped beam; and the drive motor drives the sliding plateskeleton to lift relatively to the pillar skeleton through the ball screw and the nut. The robot pillar structure allows the environment inside and outside the robot's joints to be physically isolated, while meeting the basic functions of the robot, the purposes of sealing the joints of the robot, dust-free and improving the dynamic performance of the robot can be achieved.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

A cleaning device for solar photovoltaic panels

ActiveCN111790647BAchieve cleanAvoid scratchesPhotovoltaicsCleaning using toolsPower apparatusMaterials science

Owner:NANJING RUIQI ELECTRONICS TECH CO LTD

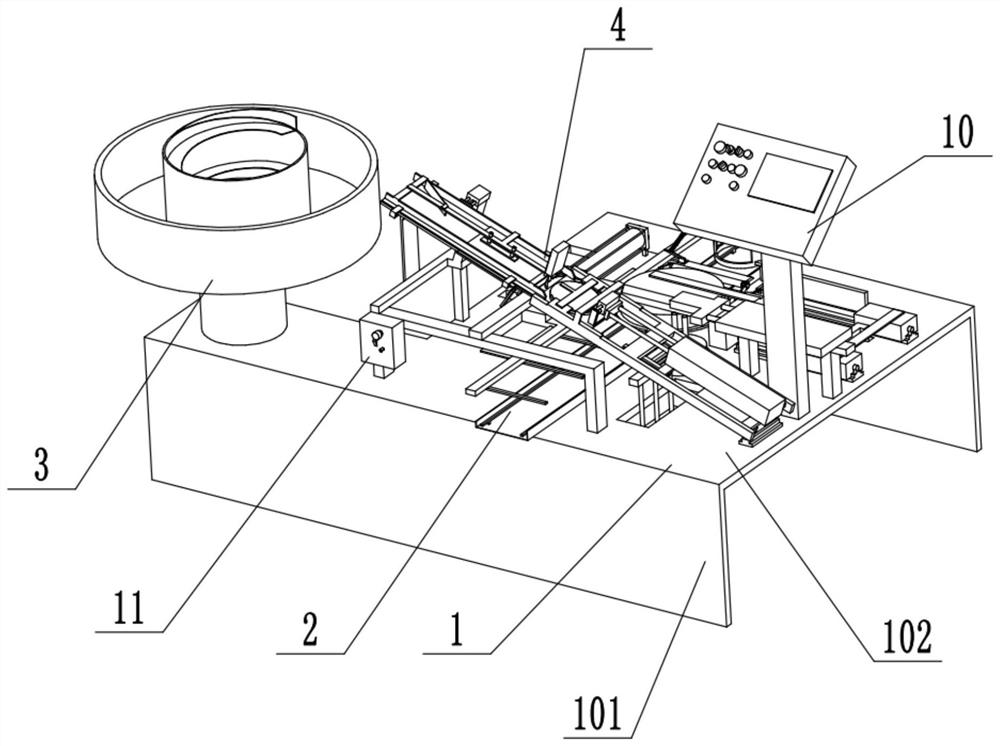

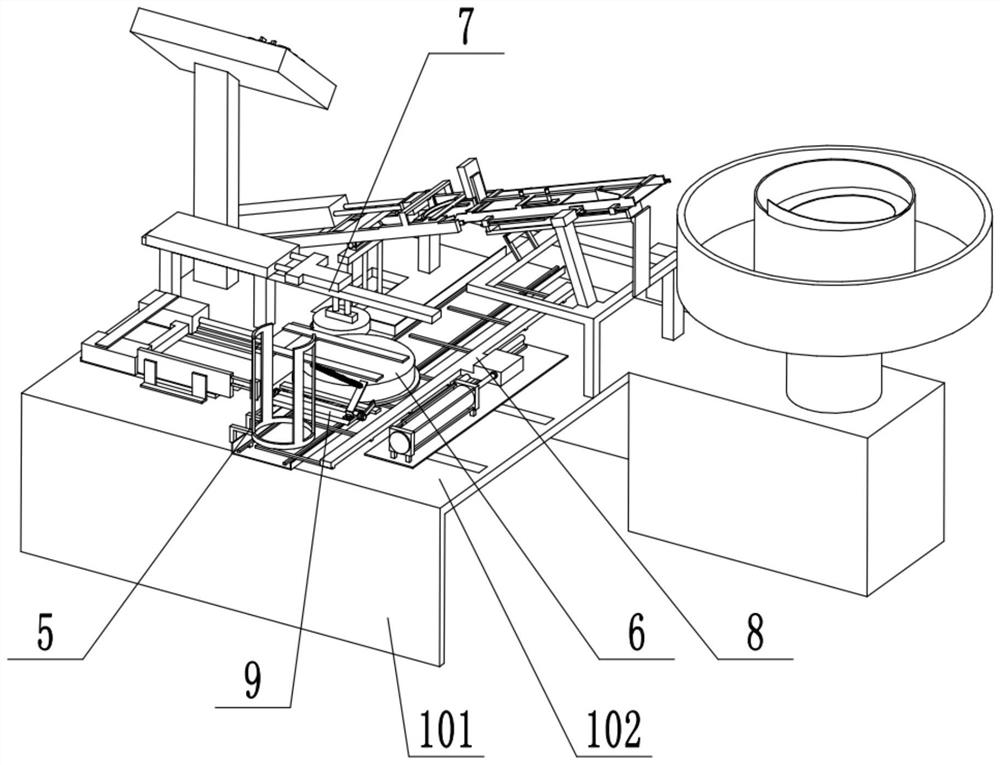

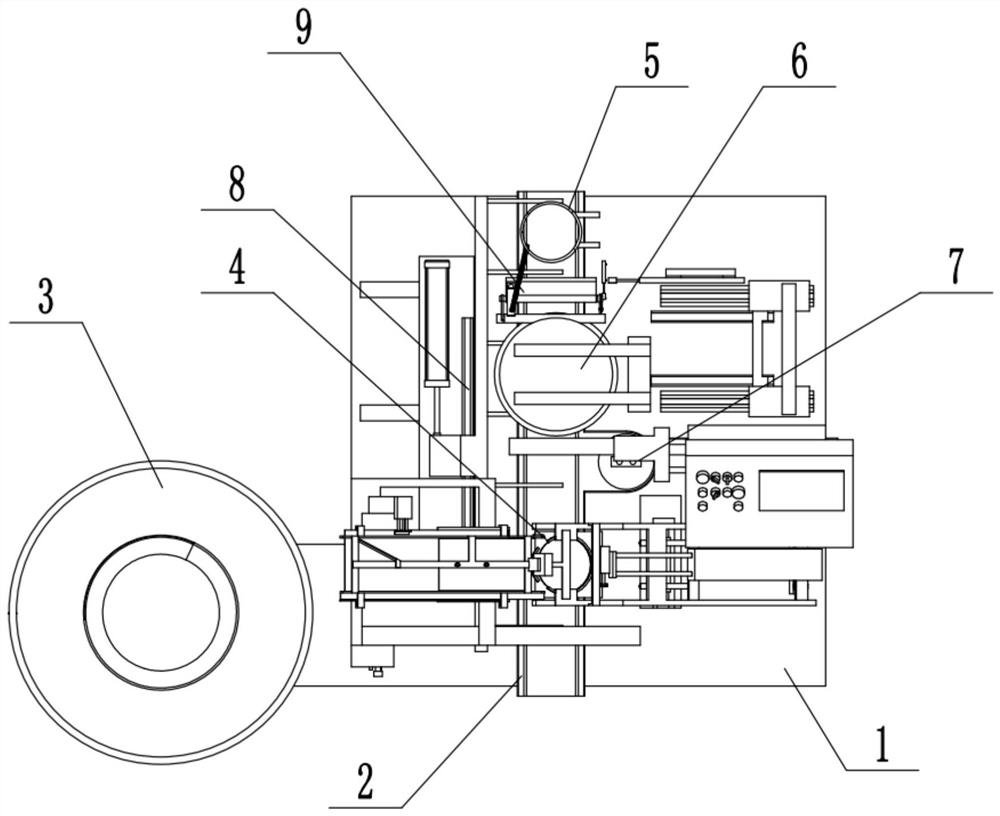

Automatic placement machine

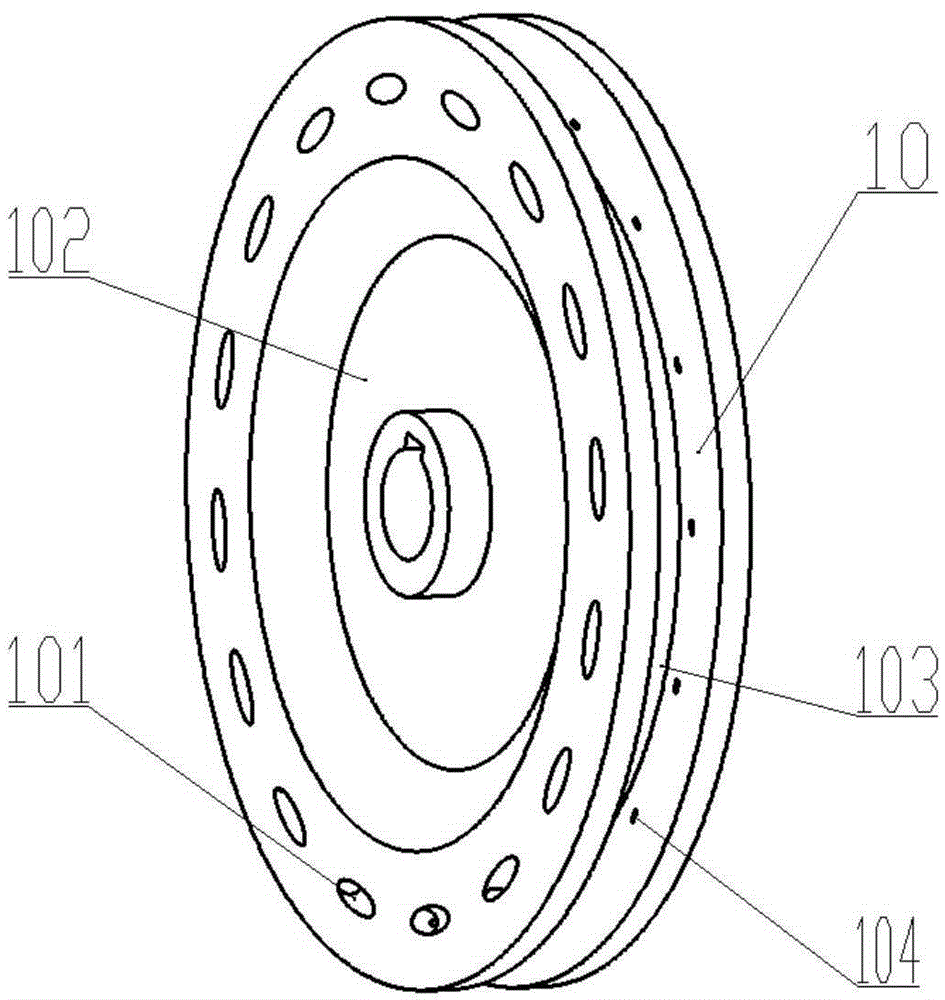

ActiveCN106996408BHigh speedImprove efficiencyMaterial gluingConveyor partsParaffin waxCircular disc

The invention relates to an automatic placement machine, which replaces the traditional manual placement, and mainly comprises: a frame, on which an iron plate conveying guide rail is arranged; posture conveying; shaking arrangement device, installed on the frame, connected with the output end of the vibration conveying device, used to arrange the valve plate into a disc shape, so as to centrally place the valve plate on the iron plate; iron plate storage device, Used for stacking and storing iron plates; iron plate heating device, covering the top of the iron plate conveying rail and set close to the iron plate storage device; paraffin melting and coating device, used to coat the molten paraffin on the surface of the iron plate; iron plate conveying The device is used to push the iron plate from the iron plate storage device to the iron plate heating device, the paraffin melting coating device and the shaking finishing device. The invention replaces the traditional manual patch operation, reduces labor intensity, improves patch speed and efficiency, and improves patch quality.

Owner:贵州群华九九特种陶瓷科技有限公司

Process for manufacturing linking tape

The sticky cingulum has a top and bottom mold blocks with the up one having grooves with a horizontal passing slide rail which has contained a compression block and several slide mold plates that have up mold cavity at the bottom, and there being bottom mold blocks at the top of the lower mold block. When the top and bottom mold blocks match, it can make each slide mold plate match tightly and form into same grooves with blunt head and nail type. When the mold closes, elastic plastic is injected into the mold cavity to form the sticky cingulum body with posts and cones.

Owner:UNIVERSAL TRIM SUPPLY CO LTD

A kind of double cavity mechanical seed metering device

ActiveCN104255142BSmall sizeReduce weightSeed depositing seeder partsCircular discAgricultural engineering

Owner:HUAZHONG AGRI UNIV

Flexible circuit board processing and fixing device capable of preventing static electricity and collecting dust

ActiveCN112543553AEasy clampingStable vacuumInsulating layers/substrates workingFlexible circuitsEngineering

The invention relates to a circuit board processing and fixing device, and particularly relates to a flexible circuit board processing and fixing device capable of preventing static electricity and collecting dust. The flexible circuit board processing and fixing device capable of preventing static electricity and collecting dust prevents static electricity and efficiently collects dust. The flexible circuit board processing and fixing device capable of preventing static electricity and collecting dust comprises bases, connecting rods, rubber supporting columns, clamping mechanisms, dust collection mechanisms and the like, wherein five connecting rods are arranged between the bases, the rubber supporting columns are arranged on the upper portions of the bases, the clamping mechanisms are arranged outside the rubber supporting columns, and the dust collection mechanisms are arranged at the two ends of the rear sides of the bases. By arranging the clamping mechanisms, the circuit board is grounded, static electricity generated during dust collection is reduced, and the rubber columns press the circuit board on the rubber supporting columns, so that the circuit board is better clamped, and the circuit board is more stable and firmer during dust collection.

Owner:东莞市溢信高电子科技有限公司

An agricultural peanut harvesting machine for separating and harvesting peanut seedlings

InactiveCN106993423BReduce processing costsImprove cleanlinessDigger harvestersThreshersAgricultural engineeringPeanut meal

The invention discloses an agricultural peanut harvester with a function of peanut vine separation. The harvester comprises a body with a reaping tank at the bottom, two first chains in corresponding clamped rotation are arranged in the reaping tank, a peanut harvesting tank in corresponding communication with the reaping tank is arranged at the bottom of the body, and a rotary soil discharge support is arranged in the peanut harvesting tank. A peanut vine cutting tank in corresponding communication with the reaping tank is arranged at the bottom of the body, and a rotary second cutting disk is arranged in the peanut vine cutting tank. By rotation of the first chain, peanut vines can be further conveyed; by rotation of the first cutting disk and the soil discharge support, peanuts can be further harvested, and roots of the peanut vines can be cut off, so that smashing of plastic films into the peanut vines is prevented, cleanness of peanut vine feed is further guaranteed, and pork quality is guaranteed.

Owner:盐城市顺天铸造有限公司

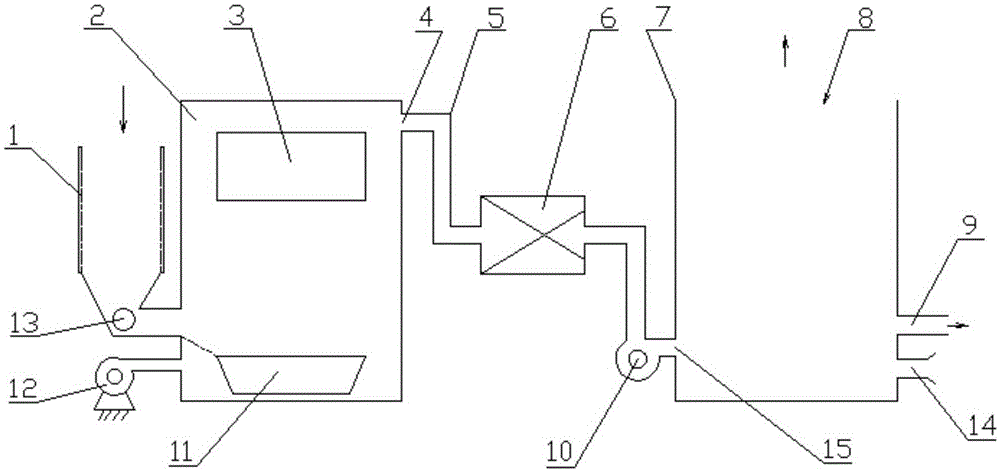

Biomass source combustion system

InactiveCN105423330AImprove combustion efficiencyTo achieve the effect of cooling and dust removalNon-combustible gases/liquids supplyHeating arrangementCombustion systemCombustion chamber

The invention discloses a biomass source combustion system which comprises a combustion chamber and a drying kiln, wherein a combustor for combusting a material is arranged at the bottom of an inner cavity of the combustion chamber; a heat exchanger is arranged at the upper part of the inner cavity of the combustion chamber; a smoke vent is formed in one side of the upper part of the combustion chamber; one side of the combustion chamber is connected with a hopper; a feeding machine for feeding the combustor is arranged in the hopper; an energy saver is arranged between the drying kiln and the combustion chamber; an air inlet and a dust and impurity outlet are formed in the two sides of the bottom of the drying kiln correspondingly; a biomass raw material discharge hole is formed in the middle lower part of the drying kiln; and a conveying device is arranged between the discharge hole and the feeding hole of the hopper. With the biomass source combustion system, the combustion efficiency can be greatly improved, and the effect of dust-free and low-temperature discharge is reached.

Owner:林强

Pipe flushing assembly with double seal structure, pipe flushing device, lubrication system and lubrication process

ActiveCN112177551BPrevent leakageReduce processing difficultyEngine sealsFlushingMechanical engineeringLubrication

The invention relates to a flushing pipe assembly with a double-seal structure, a flushing device, a lubricating system and a process thereof. The upper flushing pipe and the lower flushing pipe are sealed and connected by a sealing member to form a mud passage inside the flushing pipe. The fixing member is sleeved on the outer periphery of the sealing member and the upper punching tube, the upper end is sealed to the upper punching tube, and the lower end is sealed to the sealing member to form a lubricating oil chamber between the upper punching tube, the sealing member, the lower punching tube and the fixing member. The sealing member is provided with a first sealing surface and a second sealing surface, the first sealing surface is used for isolating the mud channel and the lubricating oil chamber, and the second sealing surface is used for isolating the lubricating oil chamber and ambient air. The lubricating oil chamber is used for filling oil. On the one hand, the oil provides lubrication for the rotating parts in the flush tube assembly. On the other hand, the pressure in the lubricating oil chamber is greater than or equal to the mud pressure in the mud passage, so as to avoid the mud from leaking outwards. It solves the problems that the large amount of mud leakage caused by the single-sealing form, the flushing device cannot be idling for a long time, and it is not easy to maintain.

Owner:BEIJING JJC PETROLEUM EQUIP

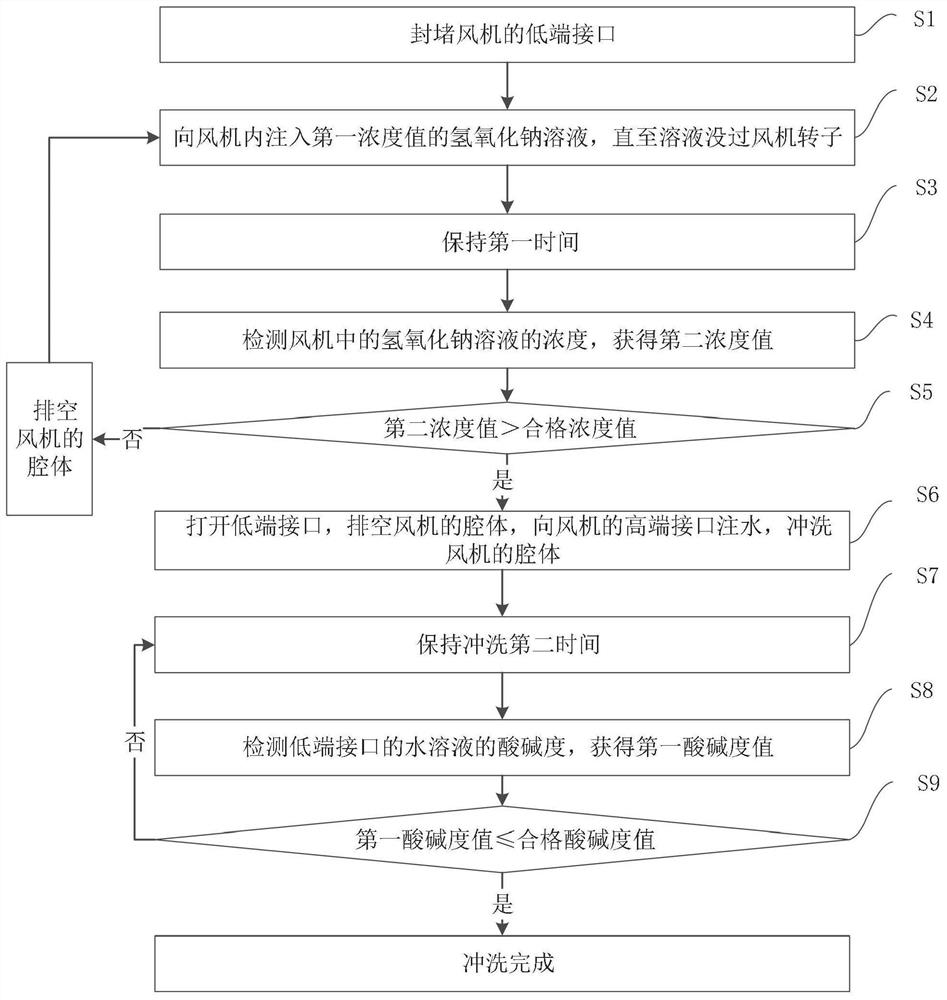

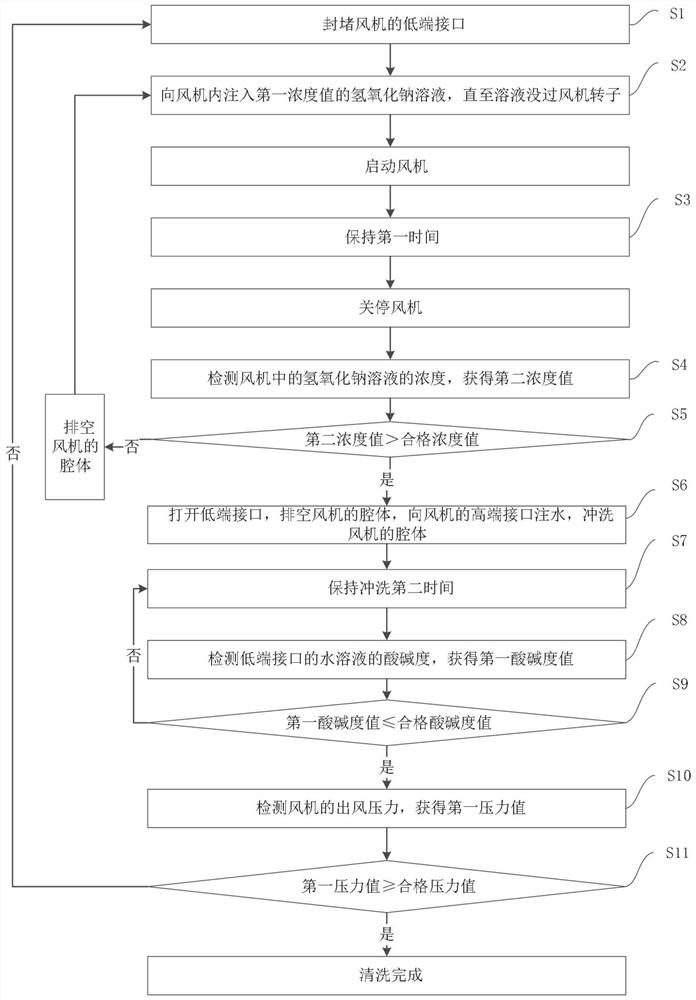

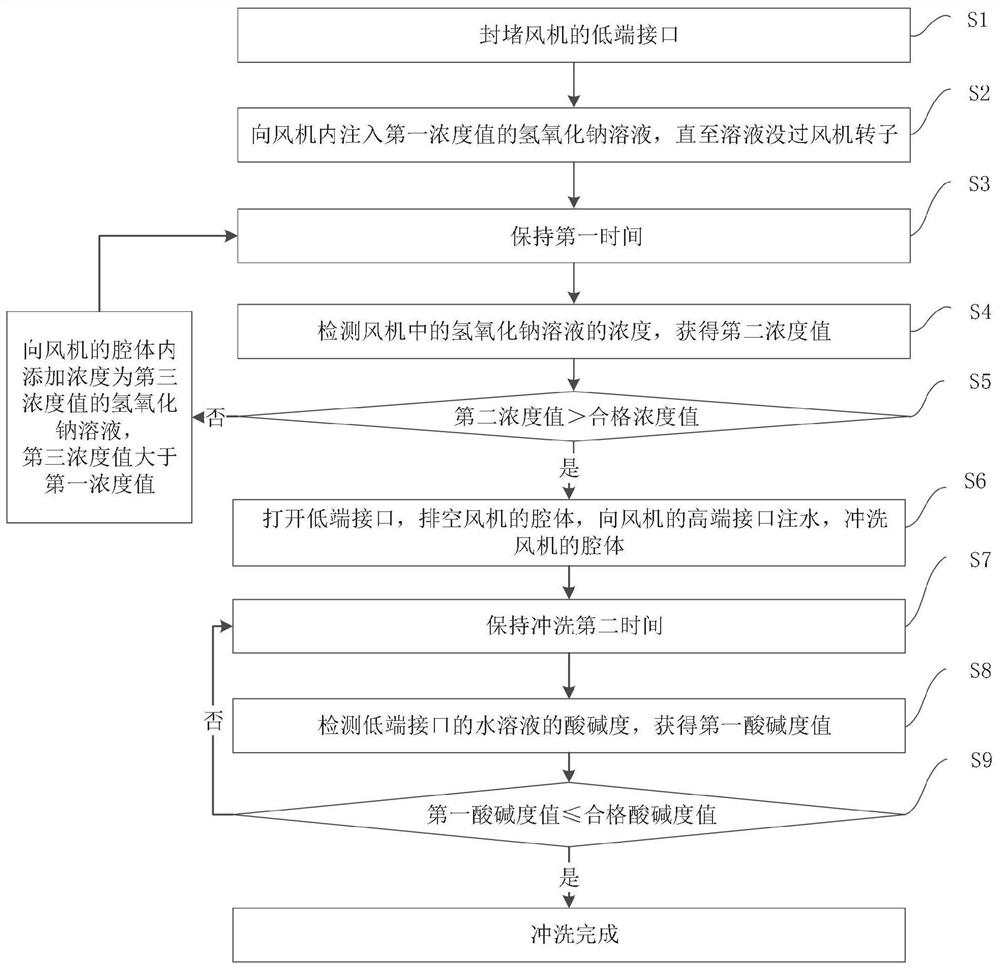

Dirt cleaning method for fan

PendingCN114433551AFast and cleanAchieve cleanCleaning using liquidsEnvironmental engineeringCleaning methods

The invention belongs to the technical field of equipment cleaning, and discloses a cleaning method for a fan, which comprises the following steps: S1, blocking a low-end interface of the fan; s2, injecting a sodium hydroxide solution with a first concentration value into the fan until the solution submerges a rotor of the fan; s3, keeping for a first time; s4, detecting the concentration of the cleaned mixed solution; s5, if the concentration value is not greater than the qualified concentration value, emptying the fan cavity, and then repeating the steps S2-S4, otherwise, carrying out the next step; s6, a cavity of the fan is emptied, and the fan is washed with water; s7, washing is kept for the second time; s8, detecting the pH value of the low-end interface solution; s9, if the pH value is greater than the qualified pH value, repeating the steps S7-S8; otherwise, fan flushing is completed. According to the dirt removing method for the fan, impurities such as tar and dust on the rotor of the fan can be removed, operation is easy and convenient, the removing efficiency is high, and the effect is good.

Owner:SGIS SONGSHAN CO LTD

A robot column structure

ActiveCN110549323BMeet basic functionsAchieve a joint sealProgramme-controlled manipulatorShaped beamBall screw

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Sleeve-shaped rolling processing cutter

The invention relates to a sleeve-shaped rolling processing cutter. The sleeve-shaped rolling processing cutter comprises a sleeve boring body and a plurality of rolling cutter heads; the sleeve boring body comprises a base, a plurality of strip-shaped ribs and a circular ring, one ends of the plurality of strip-shaped ribs are uniformly and vertically arranged on the periphery of the base, and the other ends of the plurality of strip-shaped ribs are connected with one side of the circular ring; and a cutter holder groove corresponding to the number of the rolling cutter heads is arranged on the other side of the circular ring at equal intervals, the opening directions of the cutter holder grooves point to the center of the circular ring, and the plurality of rolling cutter heads are fixedon the inner ring of the circular ring through the cutter holder grooves. According to the sleeve-shaped rolling processing cutter provided by the invention, the base is arranged on a main shaft of amachine tool, a processing mode of rotary cutting of a machine tool is replaced by rotary cutting of the cutter, and a roller extrudes the surface of a workpiece, so that the surface of the workpieceis smooth and clean.

Owner:KOCEL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com