Process for manufacturing linking tape

A manufacturing method and technology of hook and loop fasteners, applied in the direction of buckles, fasteners, household components, etc., can solve the problem that the hook body is easy to scratch the cloth, break, or the felt surface and thread ends of other miscellaneous thread felt sticky male fasteners. damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

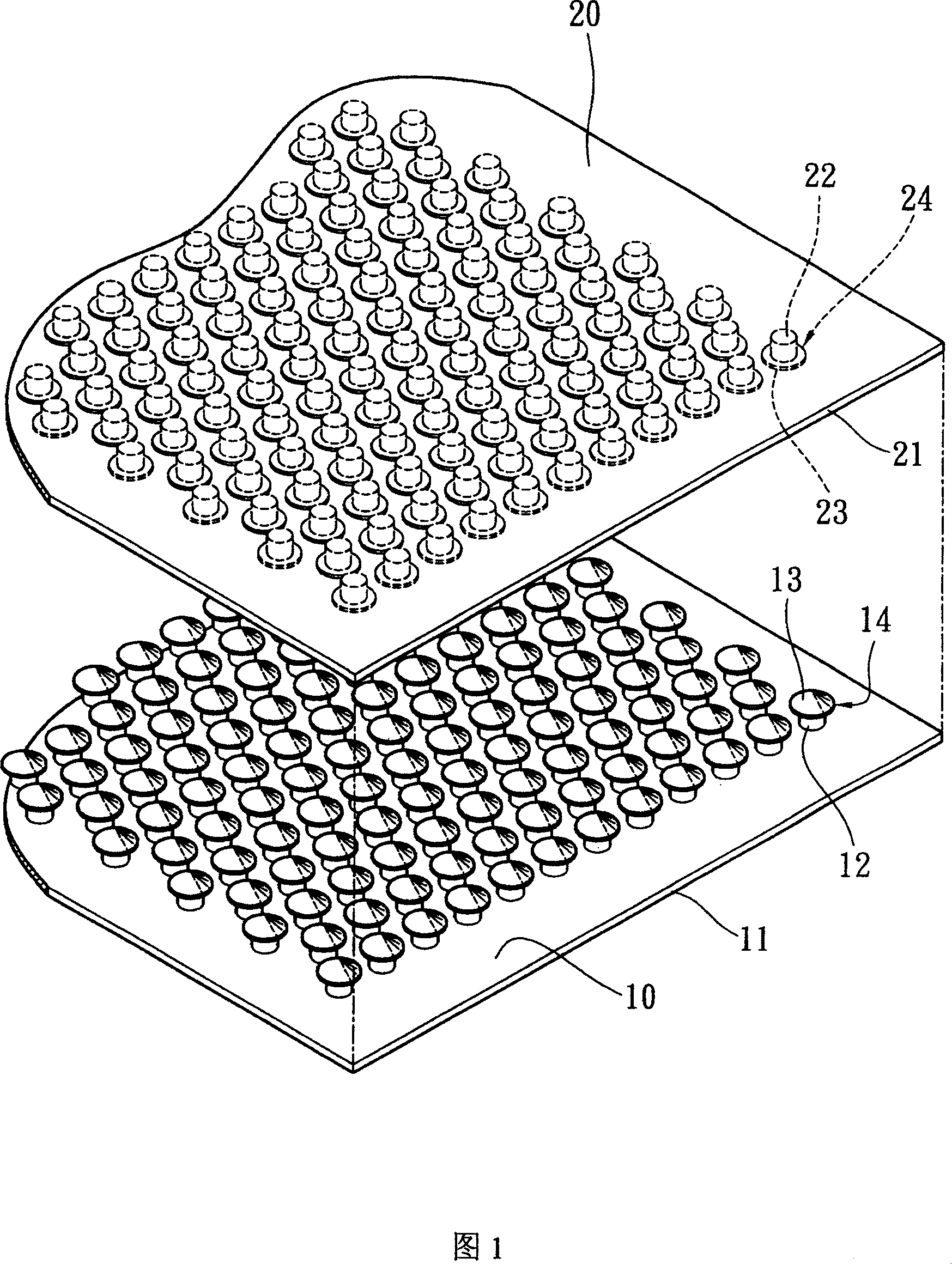

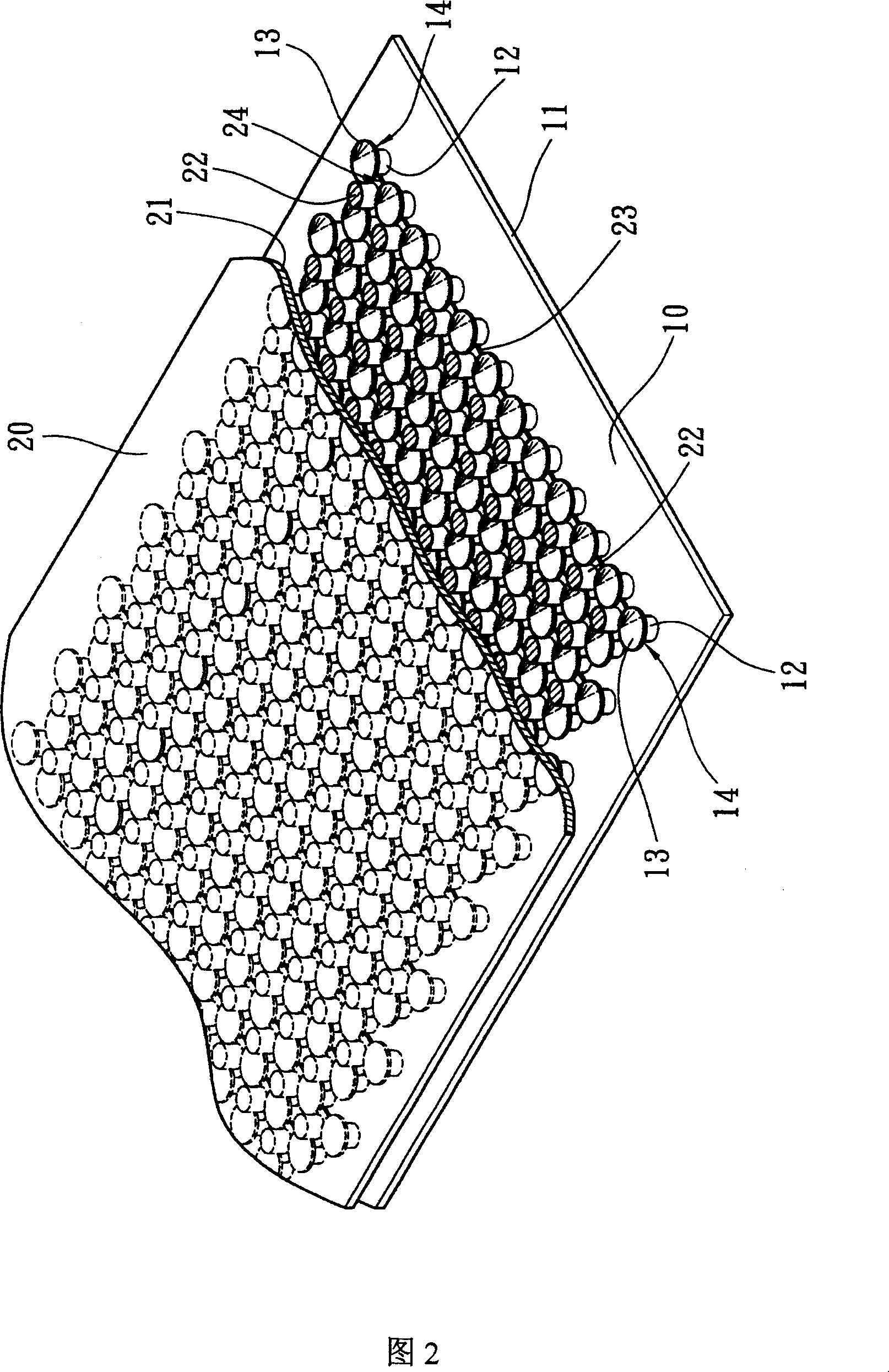

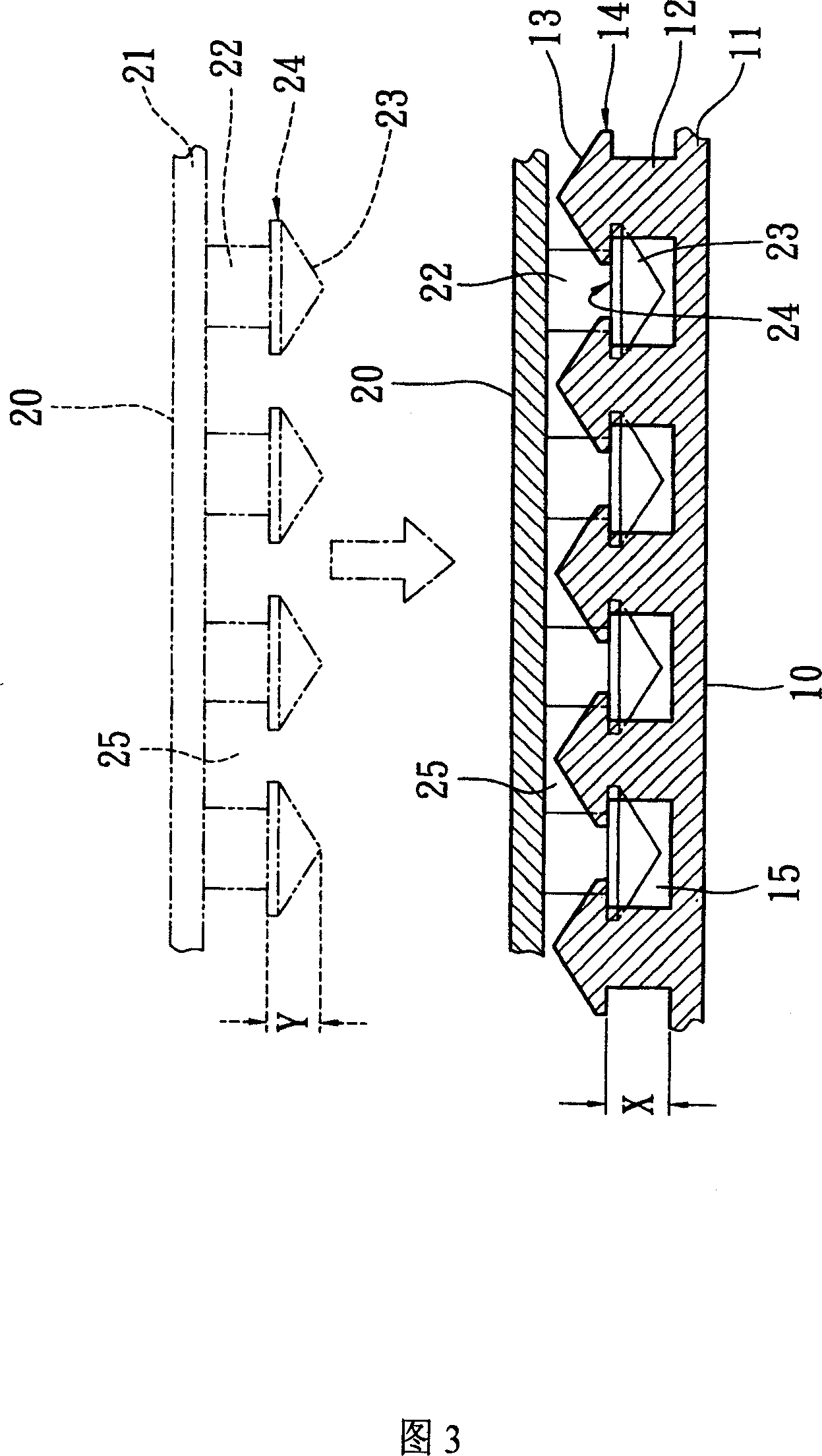

[0031] Please refer to Figures 1 to 3, the hook and loop fastener manufactured by the present invention is mainly made of elastic material, and is composed of a male buckle 10 and a female buckle 20 that are integrally formed and correspond to each other. The structure 10 is that a plurality of cylinders 12 are uniformly arranged on the plane of a plate 11 , and a cone 13 with a larger diameter is arranged on the end surface of the cylinders 12 to form a hook-shaped body 14 .

[0032] The female buckle 20 is configured to be the same as the male buckle 10, so that the female buckle 20 and the male buckle 10 face each other when combined, so that the hooks 14 of the male buckle 10 are staggered in the female. Between the hook-shaped body 24 of the buckle 20, the female buckle 20 is provided with evenly distributed cylinders 22 on the surface of the plate body 21, and the end surface of the cylinder 22 is provided with a cone 23 with a larger diameter and a blunt head shape. , m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com