Pipe flushing assembly with double seal structure, pipe flushing device, lubrication system and lubrication process

A pipe flushing and assembly technology, which is applied in wellbore flushing, engine sealing, wellbore/well components, etc., to increase service life, avoid mud leakage, and reduce leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Detailed ways

[0058] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

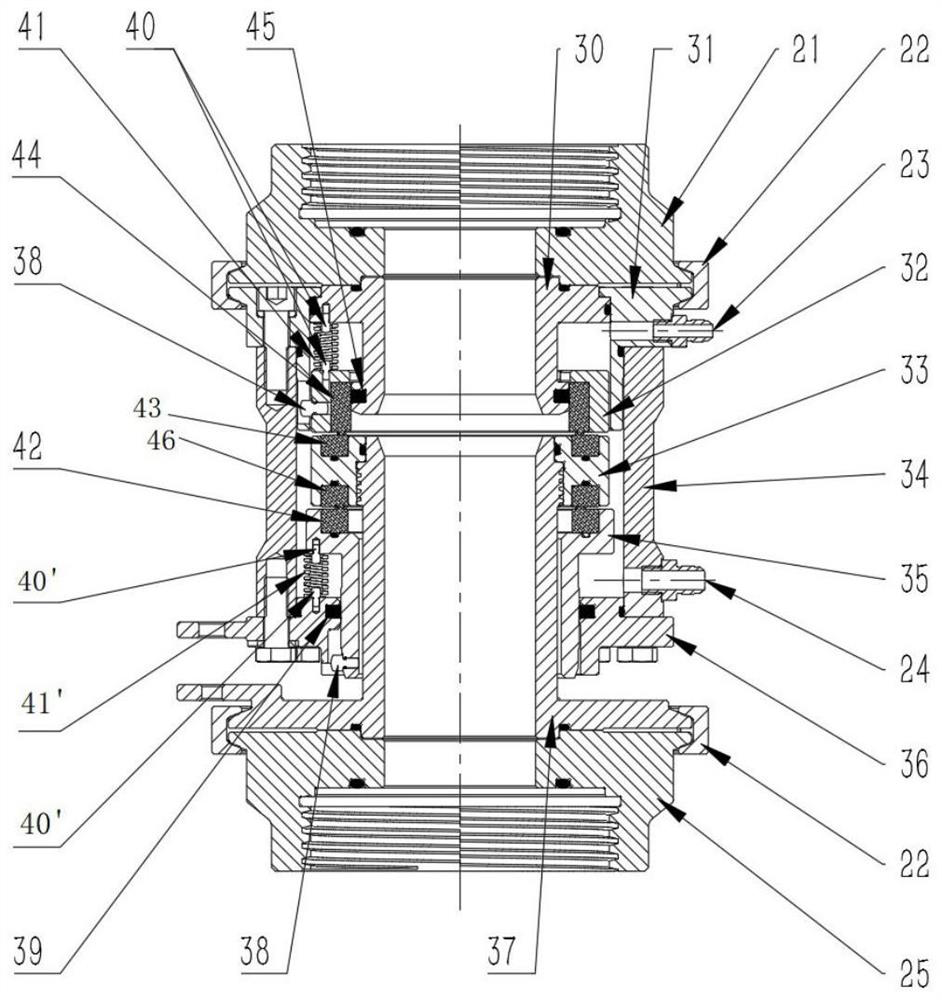

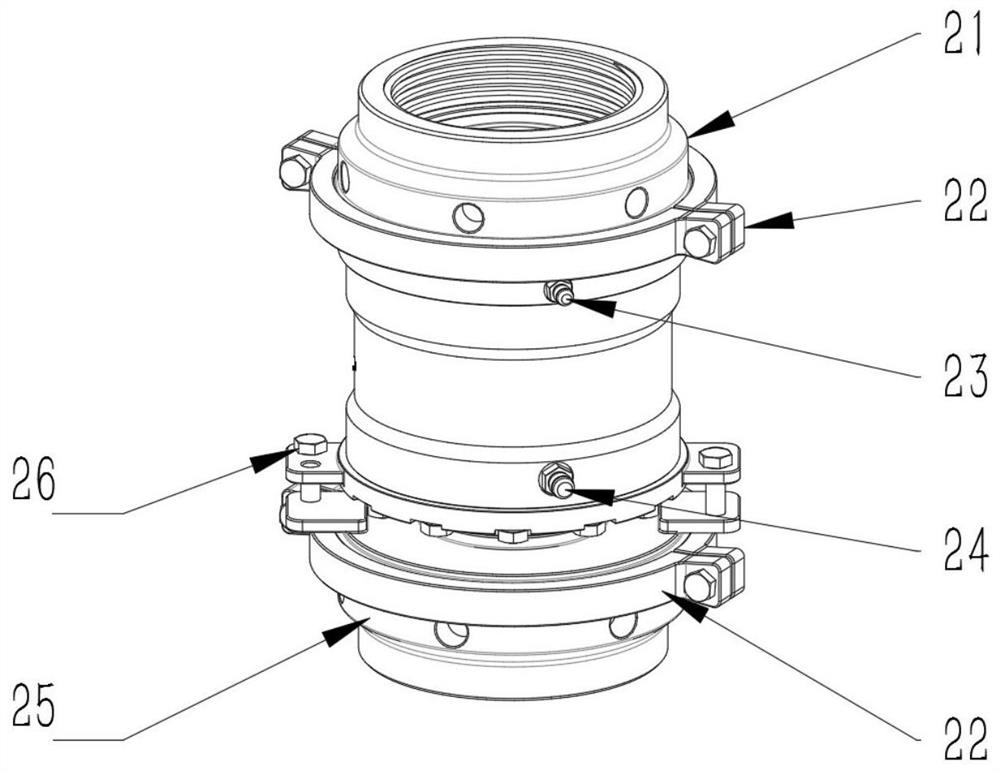

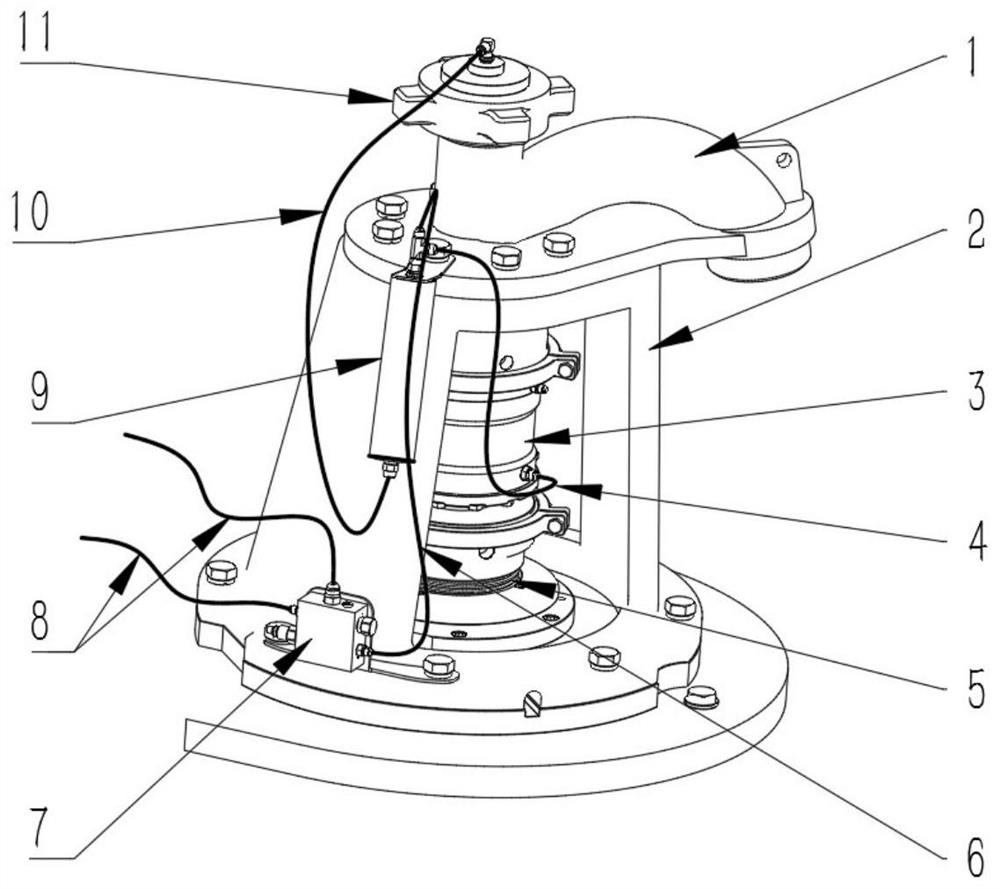

[0059] see figure 1 , this embodiment provides a flushing tube assembly 3 with a double-sealed structure, including an upper flushing tube 30, a lower flushing tube 37, a sealing member A and a fixing member B.

[0060] Specifically, the upper flushing pipe 30 and the lower flushing pipe 37 are hermetically connected through the sealing member A to form a mud channel 104 inside. The fixing member B is sleeved on the outer circumference of the sealing member A and the upper flushing pipe 30, the upper end is sealed and connected with the upper flushing pipe 30, and the lower end is sealed and connected with the sealing member A to form a ring between the upper flushing pipe 30, the sealing member A and the fixing member B lubricating oil chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com