Method for preventing crazing of outer wall decorative coatings of building

A technology for building exterior walls and coatings, applied in construction, building structure, covering/lining, etc., can solve problems such as unsolved problems, and achieve the effect of eliminating cracks, eliminating small structural cracks, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] As shown in accompanying drawing 1 and accompanying drawing 2, the base supporting plate 1 used in the present invention is a flat structure, and it is mainly formed by pressing plastic material, or by cement, gypsum, kaolin or magnesite as filler, supplemented with Fiber webs are prepared. The surface of the base supporting plate 1 is flat and smooth, so that when the wall decoration is required, the base supporting plate 1 of the present invention is fixed on the wall by bonding or anchoring, or a combination of the two, and then Paint is applied on the surface of the base pallet 1 .

[0020] When the anchoring method is used alone to fix the base pallet, a 2 to 8 mm thick elastic material gasket, such as a rubber gasket or a polyurethane elastomer gasket and a polystyrene foam gasket, can be placed between the pallet and the mortar.

[0021] The bonding mortar can be polymer elastic mortar, and this polymer refers to acrylic acid or vinyl acetate·ethylene (VAE for s...

Embodiment 2

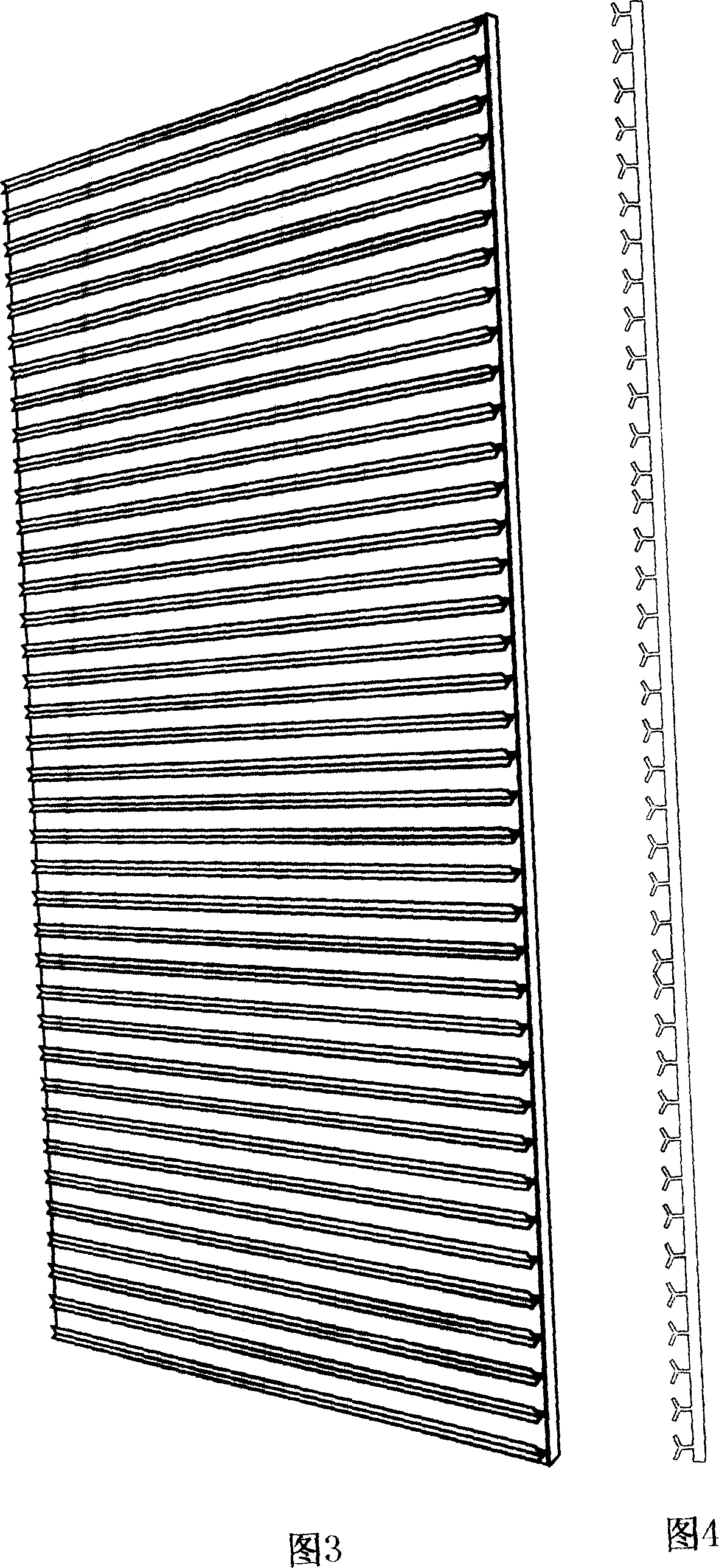

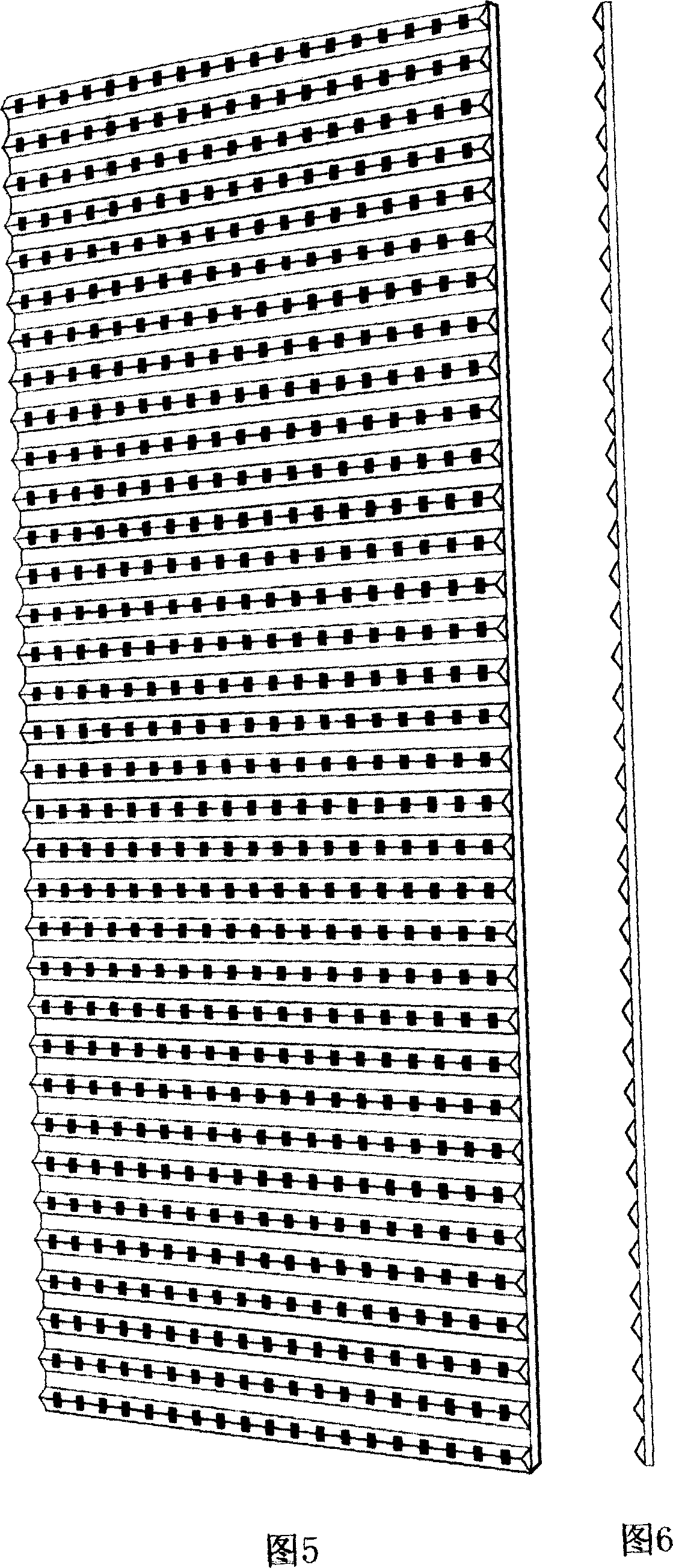

[0023] As shown in accompanying drawing 3, accompanying drawing 4, accompanying drawing 5 accompanying drawing 6, the base pallet 1 used in the present invention is the form that has anchor, and the cross-sectional shape of anchor 2 shown in accompanying drawing 3, accompanying drawing 4 It is in the shape of "Y". The anchors 2 shown in accompanying drawings 5 and 6 are triangular, and these anchors 2 are all on the facing surface. Bonding or anchoring, or a combination of the two, is fixed on the wall, and then various decorative materials and insulation boards are pasted on the facing surface of the base supporting plate 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com