Pressure core-filling continuous casting equipment and process for double-metal-bag long carbon fiber composite material

A long carbon fiber, core-filled continuous casting technology, applied in the field of metal materials, can solve the problems of affecting the metallurgical bonding of copper and inner metal, unable to prepare bimetallic clad long carbon fibers, unable to obtain bimetallic composite materials, etc. The effect of strength, reduction of copper plating process, and improvement of composite quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

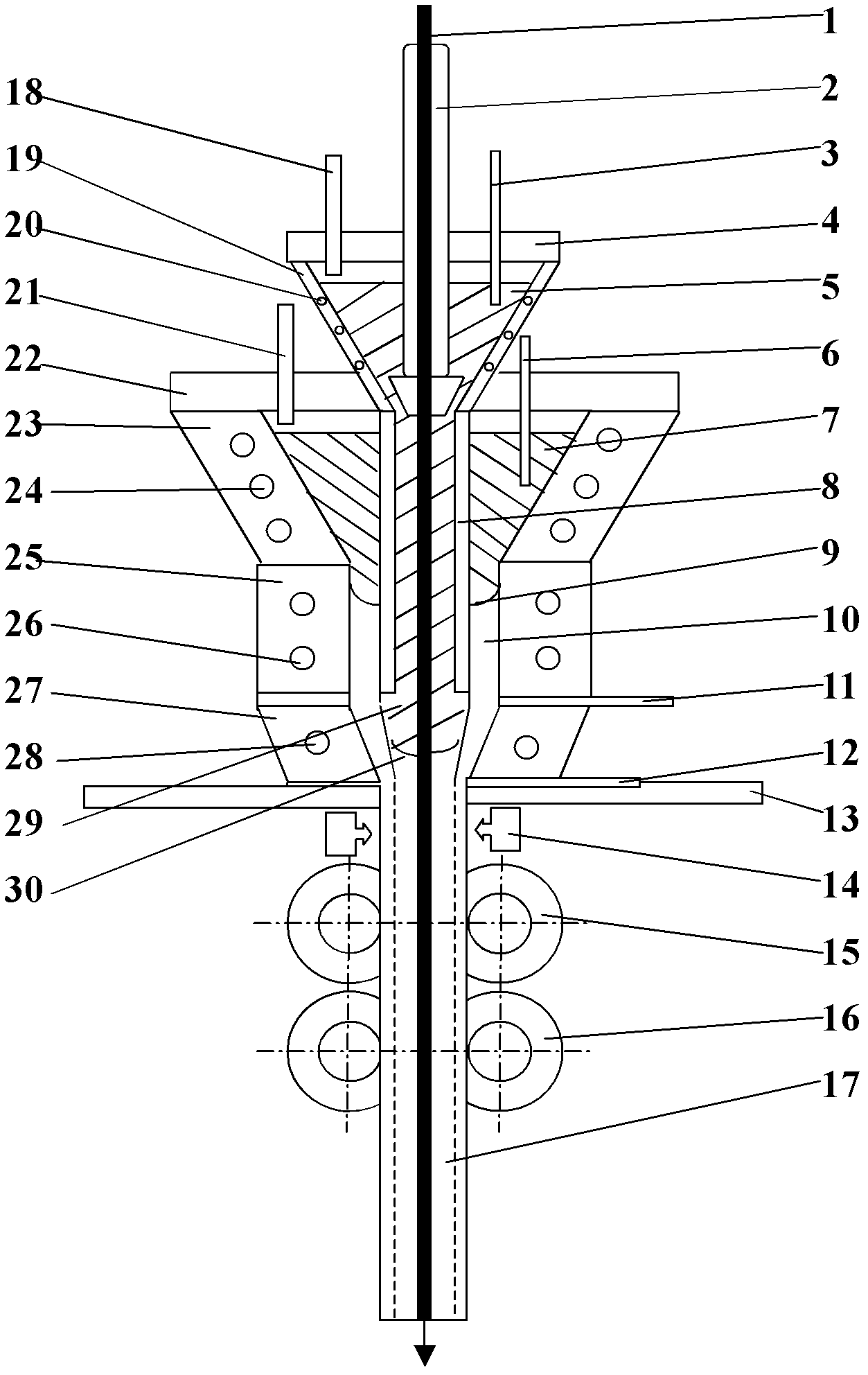

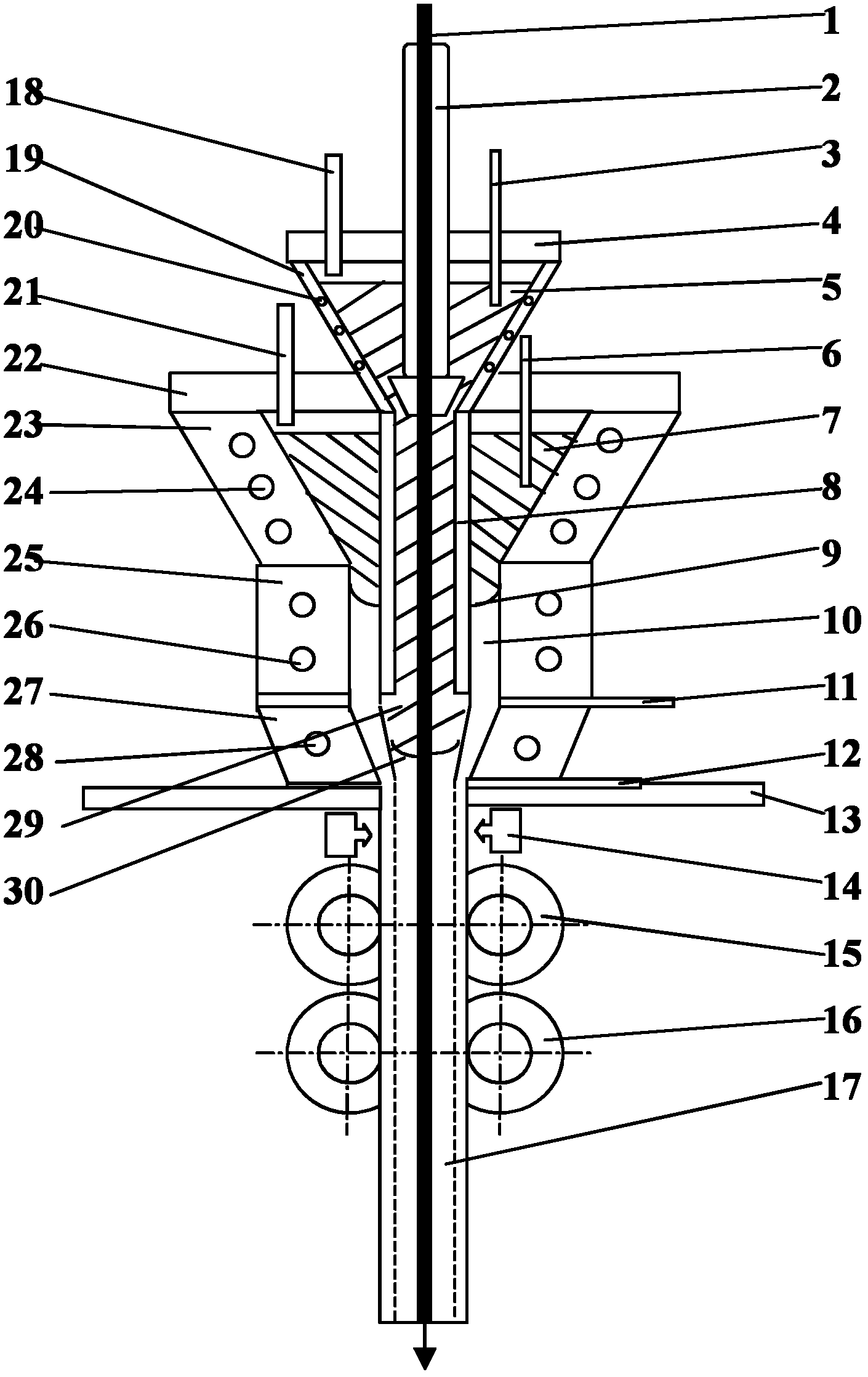

[0019] Pressure-filled core continuous casting of lead-clad tin and long carbon fiber layered composites

[0020] Lead-clad tin and long carbon fiber composite materials have an outer metal diameter of 20mm, an outer lead metal thickness of 4mm, and a core long carbon fiber bundle with a diameter of 2mm, and the rest is filled with tin metal. The inner metal stopper rod and carbon fiber guide tube (2) are made of 45 The upper and lower thermometers (3, 6) use thermocouples to measure the temperature; the heating methods of the inner metal temperature control furnace (19) and the outer metal temperature control furnace (23) adopt resistance heating, and the inner layer metal temperature control furnace (23) adopts resistance heating. The layer metal temperature control furnace (19), the outer layer metal temperature control furnace (23) and the core tube (8) are all made of No. 45 steel; the inner layer metal liquid pressure tube (18), the outer layer metal liquid pressure The ...

Embodiment approach 2

[0022] Copper-clad aluminum and long carbon fiber layered composites by pressure-filled core continuous casting

[0023] The outer metal diameter of copper-clad aluminum and long carbon fiber composite material is 12mm, the thickness of the outer copper metal is 3mm, the diameter of the long carbon fiber bundle in the core is 2mm, and the rest is filled with aluminum metal. The inner metal stopper rod and carbon fiber guide tube (2) adopt Made of No. 45 steel, the upper and lower thermometers (3, 6) use thermocouples for temperature measurement; the heating method of the inner metal temperature control furnace (19) adopts resistance heating, and the heating of the outer metal temperature control furnace (23) The method adopts electromagnetic induction heating; the inner metal temperature control furnace (19), the outer metal temperature control furnace (23) and the core filling tube (8) are all made of graphite; the outer metal temperature control crystallizer (25) is water-coo...

Embodiment approach 3

[0025] Silver-clad aluminum and long carbon fiber composite material pressure-filled core continuous casting

[0026] The outer metal diameter of silver-clad aluminum and long carbon fiber composite material is 12mm, the outer silver metal thickness is 2mm, the core long carbon fiber bundle diameter is 3mm, the rest is filled with aluminum metal, the inner metal stopper rod and carbon fiber guide tube (8) adopt 45 Made of high-grade steel, the upper and lower thermometers (3, 6) use thermocouples for temperature measurement; the heating method of the inner metal temperature control furnace (19) adopts resistance heating, and the heating method of the outer metal temperature control furnace (23) Electromagnetic induction heating is adopted; the inner metal temperature control furnace (19), the outer metal temperature control furnace (23) and the core filling tube (8) are all made of graphite; the outer metal temperature control crystallizer (25) is made of water-cooled metal Ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com