Garlic mill capable of performing peel rubbing

A garlic and skin grinding technology, which is applied in application, food processing, food science, etc., can solve the problems of high garlic clove damage rate, inability to work continuously, low efficiency, difficulty in turning over, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

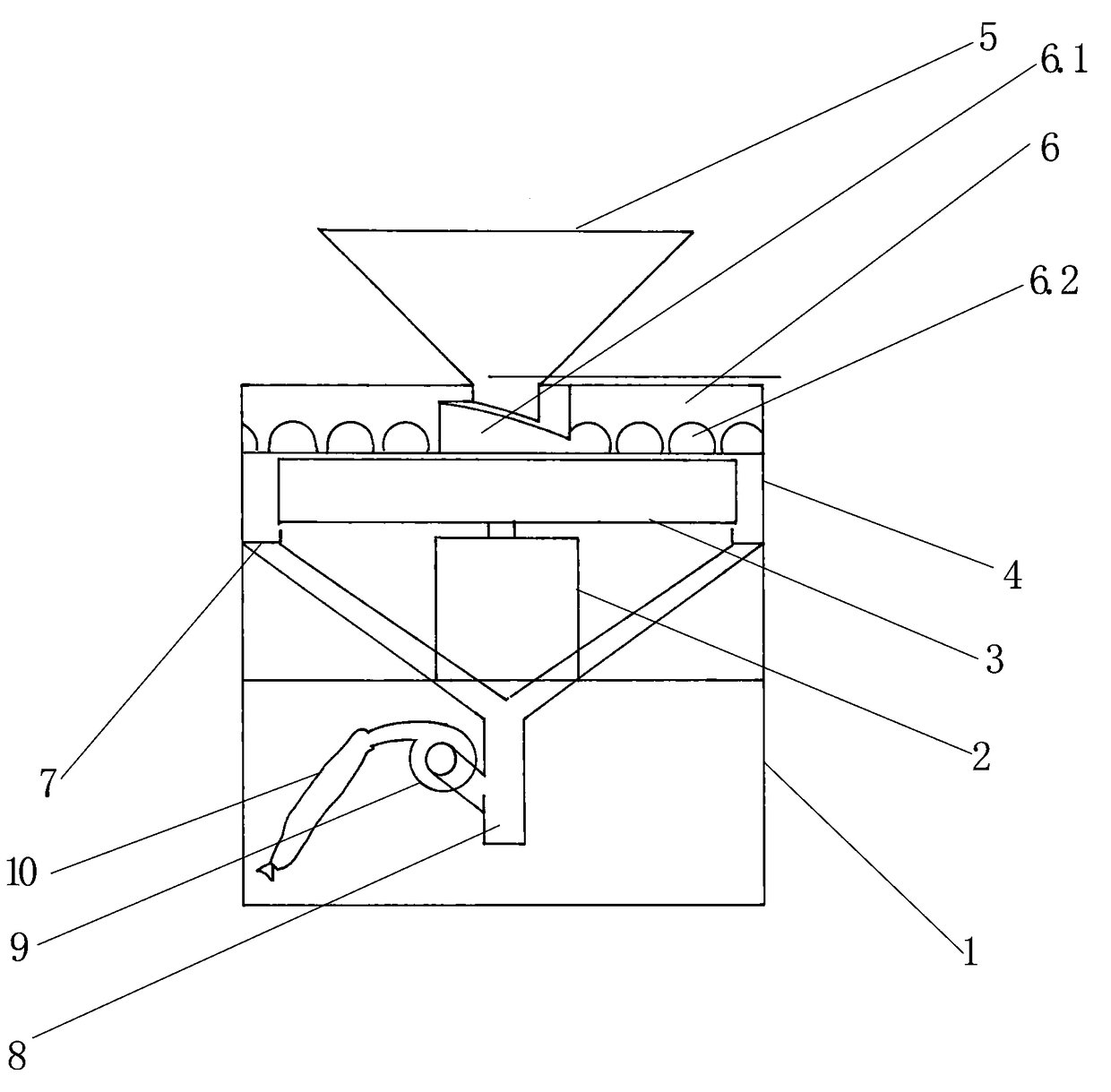

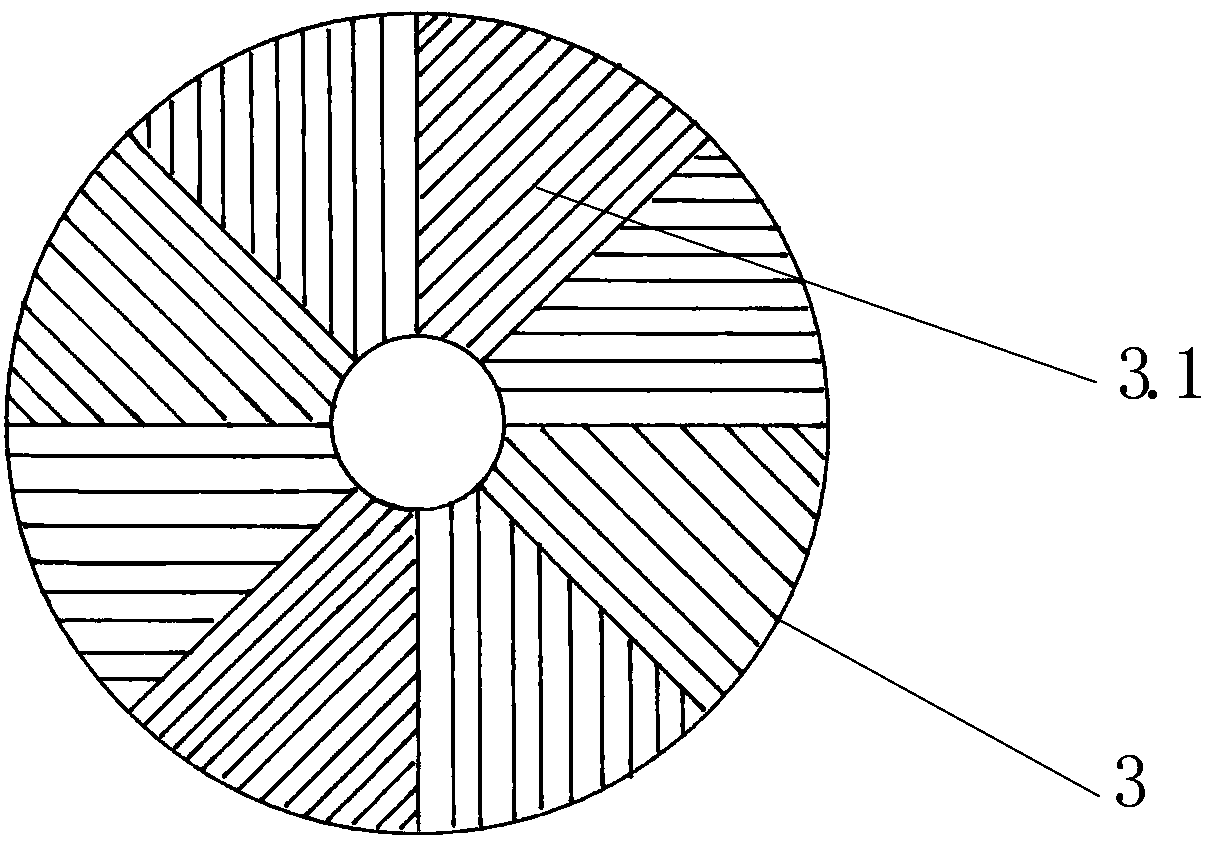

[0009] exist figure 1 Among them, a garlic rubbing mill provided by the present invention includes a grinding frame, a motor, upper and lower rubber grinding discs, a hopper, a grinding shell and an exhaust fan, and is characterized in that a motor (2) is fixed inside the grinding frame (1), A rubber grinding disc is fixed on the motor shaft. There are multiple groups of radial grinding teeth on the upper surface of the rubber grinding disc. Each group of radial grinding teeth is composed of a plurality of parallel small grinding teeth with a tooth depth of 2mm. 1) There is also a cylindrical grinding shell (4) fixed on the top, and a hopper (5) with a feed control plate is located on the top of the grinding shell (4); a rubber upper grinding disc (6) is fixed inside the upper end of the grinding shell (4), The diameter of the rubber upper grinding disc (6) is 10 cm larger than the diameter of the rubber lower grinding disc (3); the center of the rubber upper grinding disc (6)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com