Overturning mechanism for mattress processing

A turning mechanism and mattress technology, applied in the direction of the workbench, manufacturing tools, workpiece clamping device, etc., can solve the problems of mattress slipping, time-consuming and labor-intensive, affecting the mattress turning work, etc., to achieve convenient turning, simple and convenient operation, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

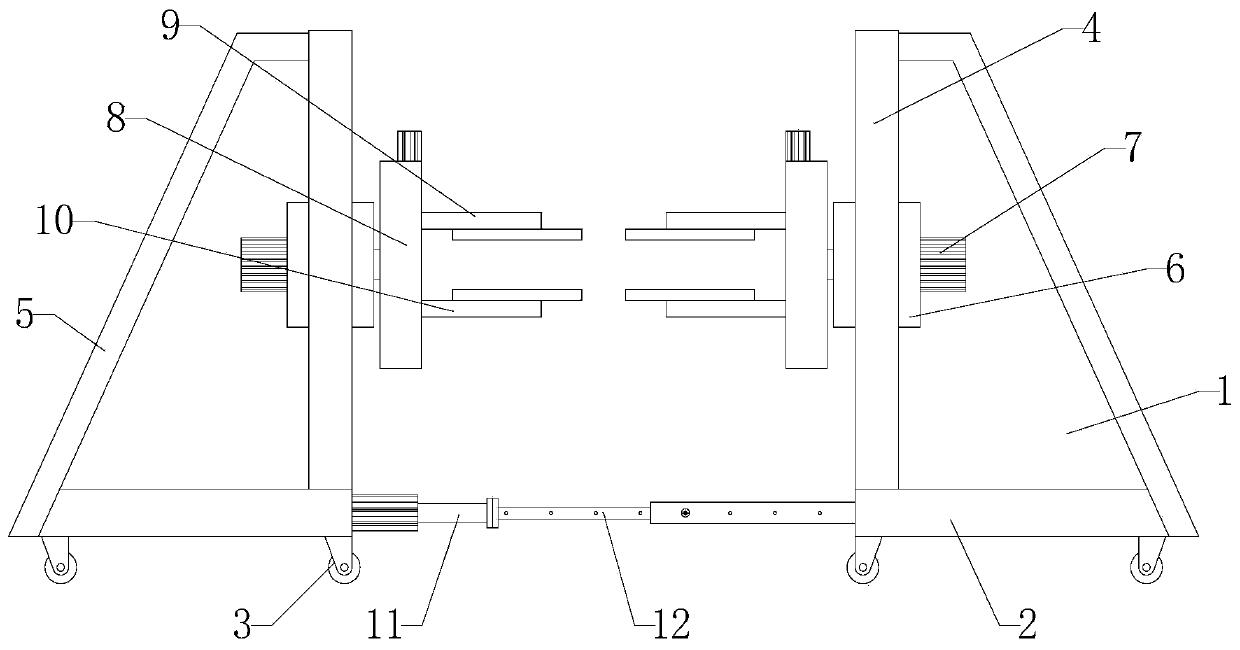

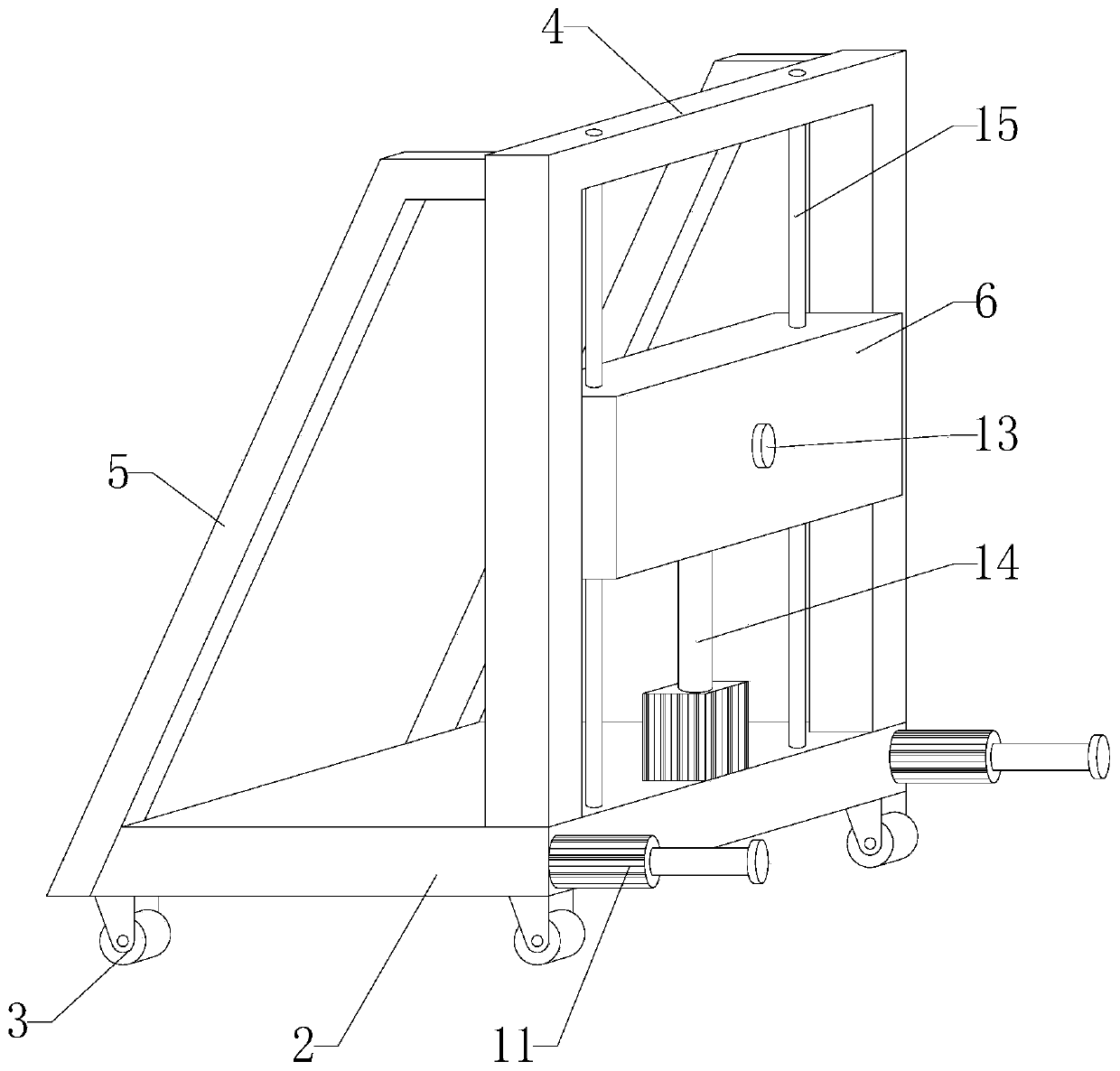

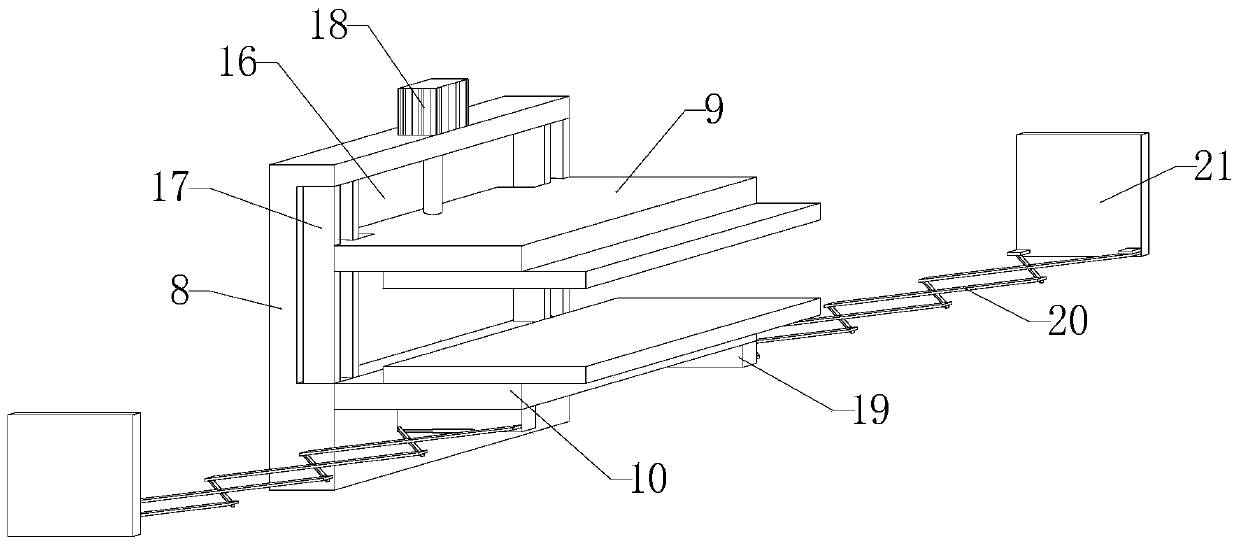

[0025] Such as Figure 1-2 As shown, an overturning mechanism for mattress processing includes two overturning main bodies 1, each overturning main body 1 includes a base 2, universal wheels 3, portal frame 4 and rotating frame 8, universal wheels are installed at the bottom of the base 2 3. A gantry 4 is vertically welded on the top of one side of the base 2. A movable block 6 is arranged inside the gantry 4. A rotating shaft 13 is installed on the movable block 6 through a bearing. One end of the rotating shaft 13 is fixed with a bolt or welded to the rotating The frame 8 is fixedly connected, the other end of the rotating shaft 13 is fixedly connected with the rotary motor 7 through a coupling, a hydraulic cylinder 14 is arranged between the movable block 6 and the top of the base 2, and the hydraulic cylinder 14 is fixed on the base 2 by bolts. The output shaft is fixed on the movable block 6 bottom by bolting or welding.

[0026] Such as Figure 1-2 As shown, a support ...

Embodiment 2

[0029] Such as figure 1 As shown, an electric push rod 11 and a telescopic rod 12 are fixedly connected between the two overturning bodies 1. The electric push rod 11 is horizontally fixed on the side of the base 2 of one of the overturning main bodies 1 through bolts, and the end of the electric push rod 11 is connected to the The end of the telescopic rod 12 is fixedly connected, the telescopic rod 12 is provided with several threaded holes, the telescopic rod 12 is provided with locking bolts for adjusting the length of the telescopic rod 12, and the end of the telescopic rod 12 away from the electric push rod 11 is fixed or welded by bolts It is fixed on the side of the base 2 of the other turning body 1 in the same way.

[0030] By adopting the above-mentioned technical scheme, two overturning main bodies 1 are used to overturn the mattress at the same time, which greatly improves the stability of the mattress overturning, and the width between the two overturning main bo...

Embodiment 3

[0032] Such as figure 2 As shown, the left and right ends of the movable block 6 are sleeved on the guide rod 15, and the left and right ends of the movable block 6 are provided with guide holes suitable for the guide rod 15, and the upper and lower ends of the guide rod 15 are respectively fixed on the top of the portal frame 4. and base 2 top.

[0033] By adopting the above technical solution, the up and down movement of the movable block 6 is guided by the guide rod 15, which is beneficial to increase the stability of the movable block 6 driving the rotating frame 8 to move up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com