Precise indexing clamp special for turning

A special fixture and fixture technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor indexing accuracy, limited force between the fixture and workpiece, and low indexing effect of special tooling for indexing. Achieve the effect of improving clamping effect, improving clamping efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the drawings:

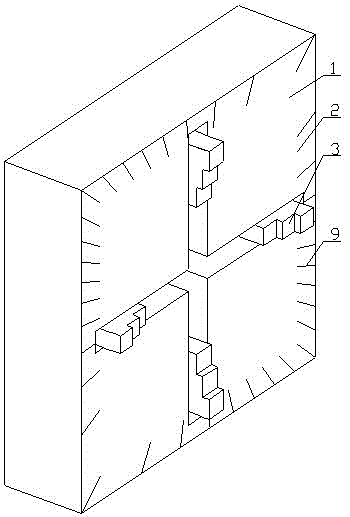

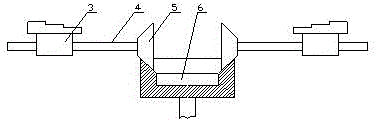

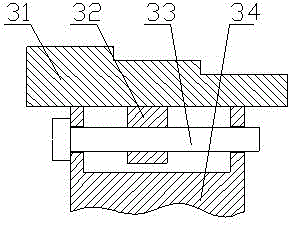

[0020] A precise indexing special fixture for turning processing. The special fixture is used for clamping workpieces during turning on a lathe. The special clamp includes a clamp body 1, and the clamp body 1 may have a square structure or a cylindrical structure. In this embodiment, the clamp body 1 uses a cube structure. The clamp body 1 is provided with a plurality of inner index lines 9, and the plurality of inner index lines 9 are distributed circumferentially with the center of the clamp body 1 as the center. The inner indexing line 9 is matched with the outer indexing line set on the chuck of the lathe, and the number of lines of the inner indexing line 9 is different from that of the outer indexing line. Due to the difference in the number of lines, the degree indicated between the two inner graduation lines 9 is different from the degree indicated between the two outer gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com